Vacuum valve that closes the flow path with a two-piece disc

A vacuum valve and flow path technology, applied in the valve operation/release device, valve details, valve device, etc., can solve the problems of reduced reliability, weakened sealing effect, etc., to achieve reliable maintenance of sealing effect, simple valve structure, compact And the effect of valve structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

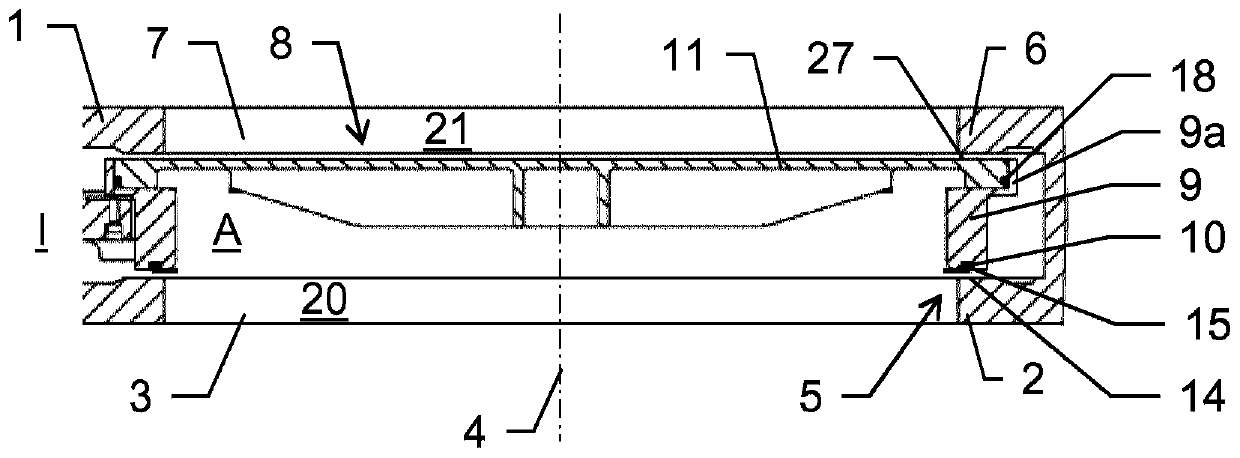

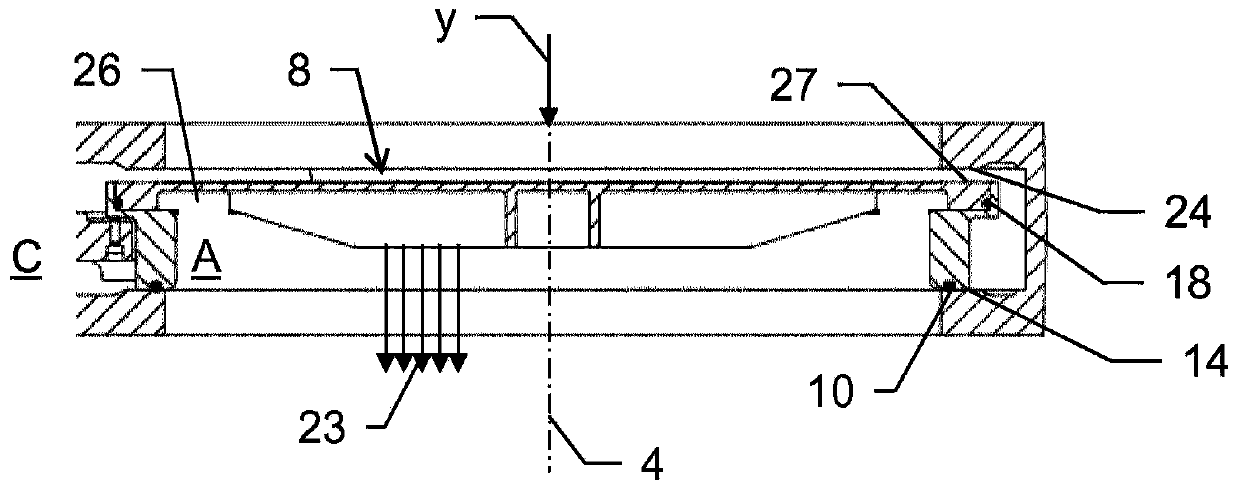

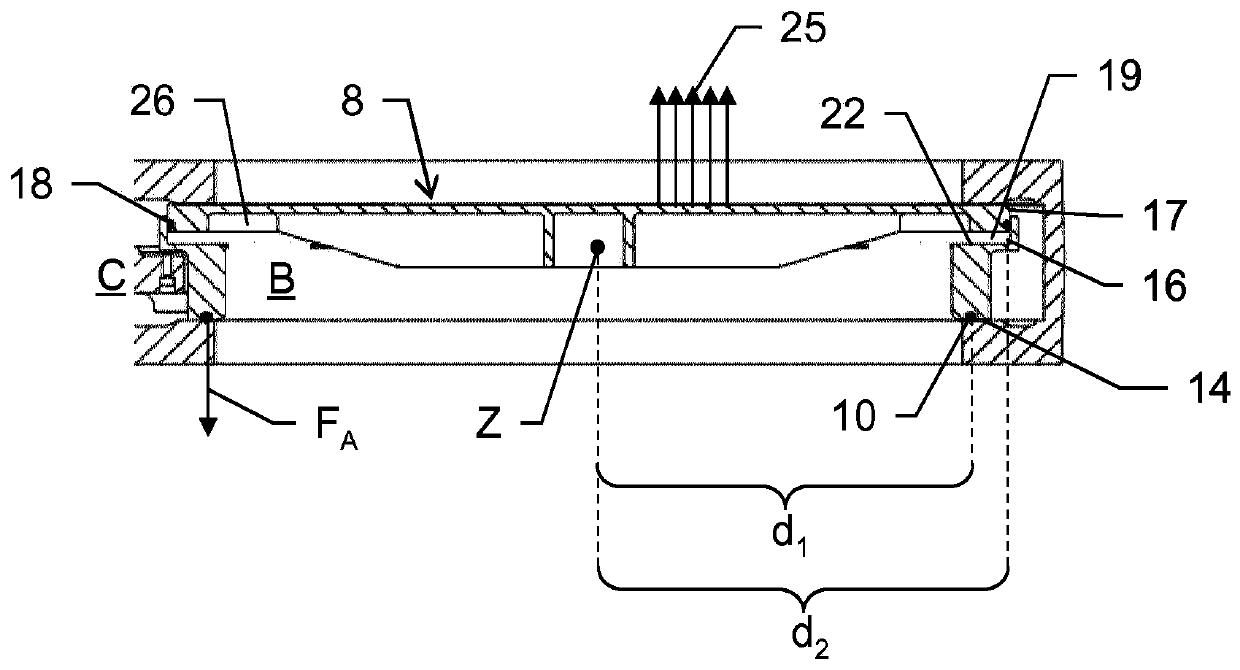

[0074] Figure 1a to Figure 4 The same exemplary embodiment of the valve according to the invention is shown in different states in different views and in different degrees of detail.

[0075] Accordingly, these figures are described together, and reference numerals and features already described in previous figures are sometimes not reintroduced here.

[0076] exist Figure 1a to Figure 4 A possible embodiment of a valve according to the invention in the form of a pendulum valve is shown in . for basic hermetic breaks as in Figure 4 The valve of the flow path F symbolized by an arrow in the middle includes a valve housing 1 having a first opening 3 and an opposing second opening 7 . The two openings 3, 7 have a circular cross-section, but other shapes are also possible. exist Figure 1b , Figure 1c , Figure 2b and Figure 2c In the closed position C of the valve disc 8, the two openings 3, 7 are airtightly separated from each other by the valve disc 8, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com