Patents

Literature

39results about How to "Avoid early wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

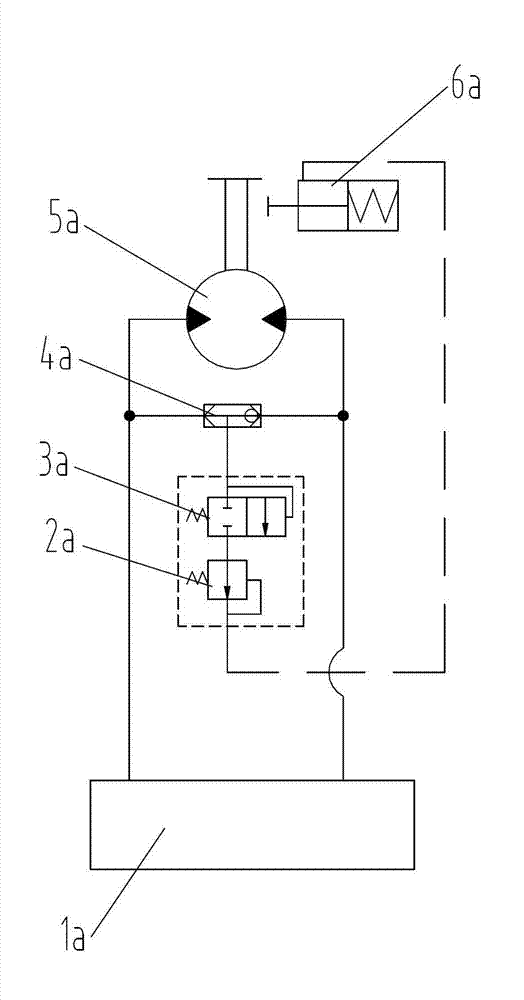

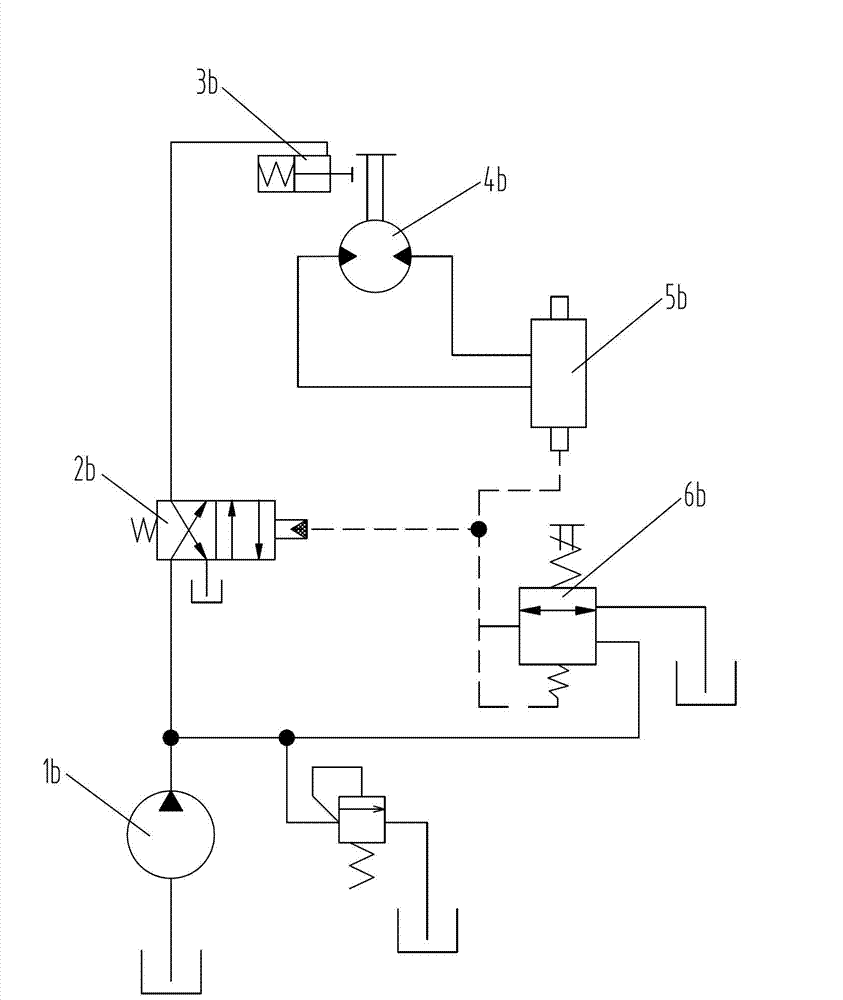

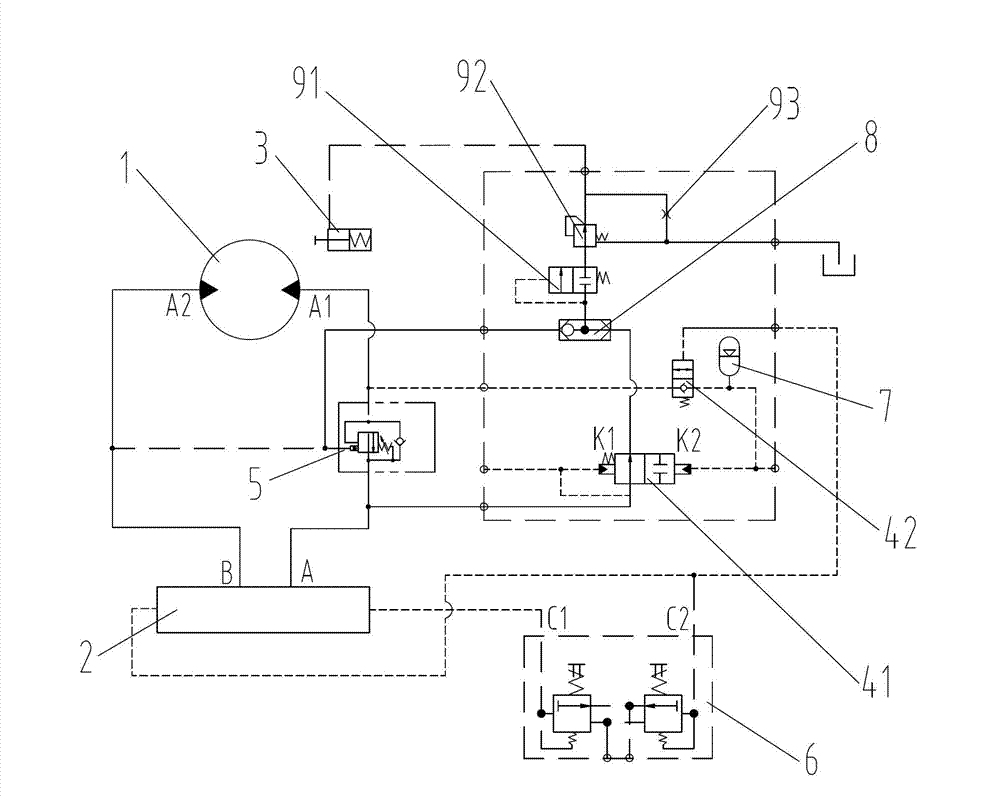

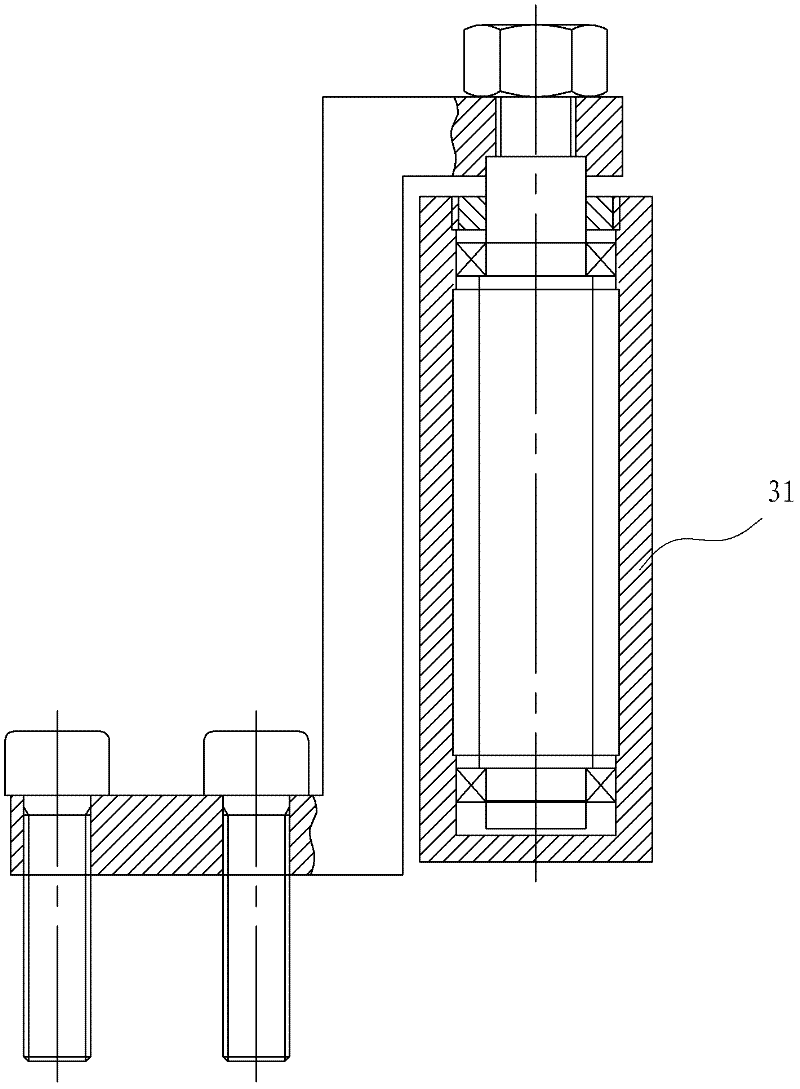

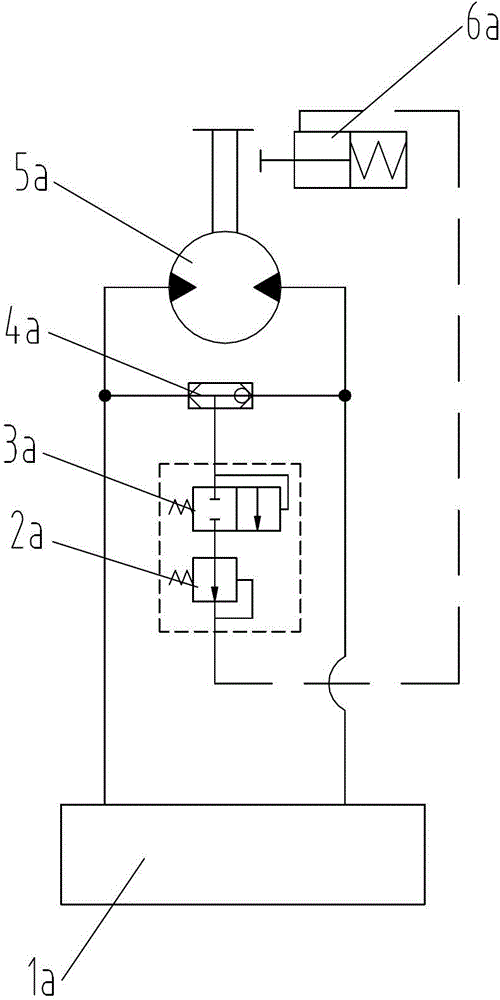

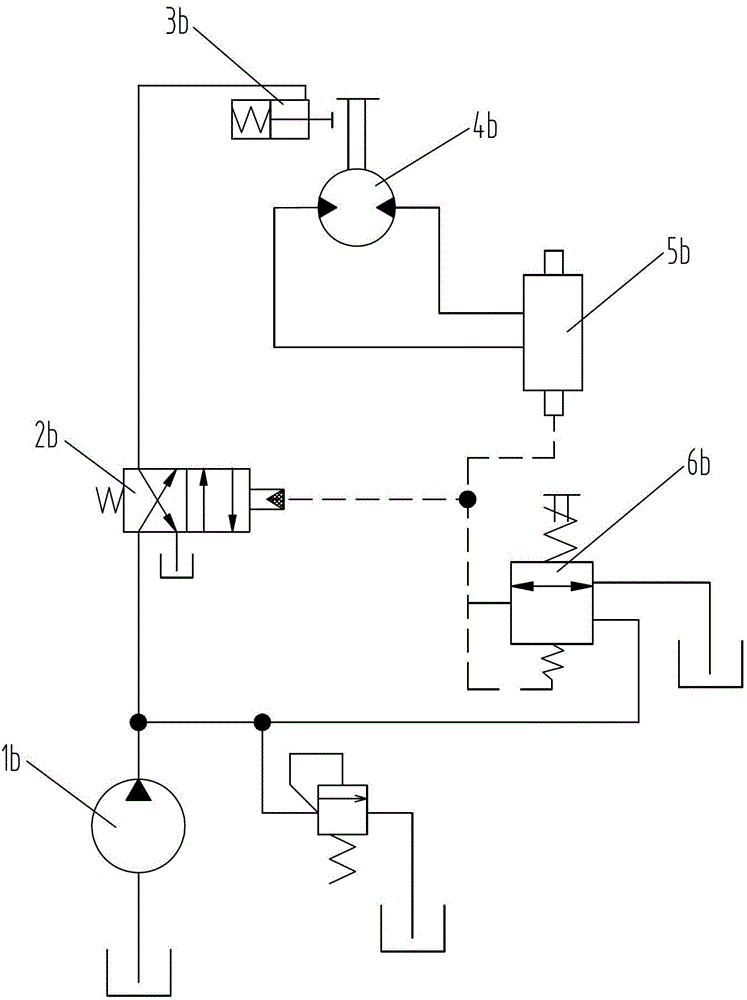

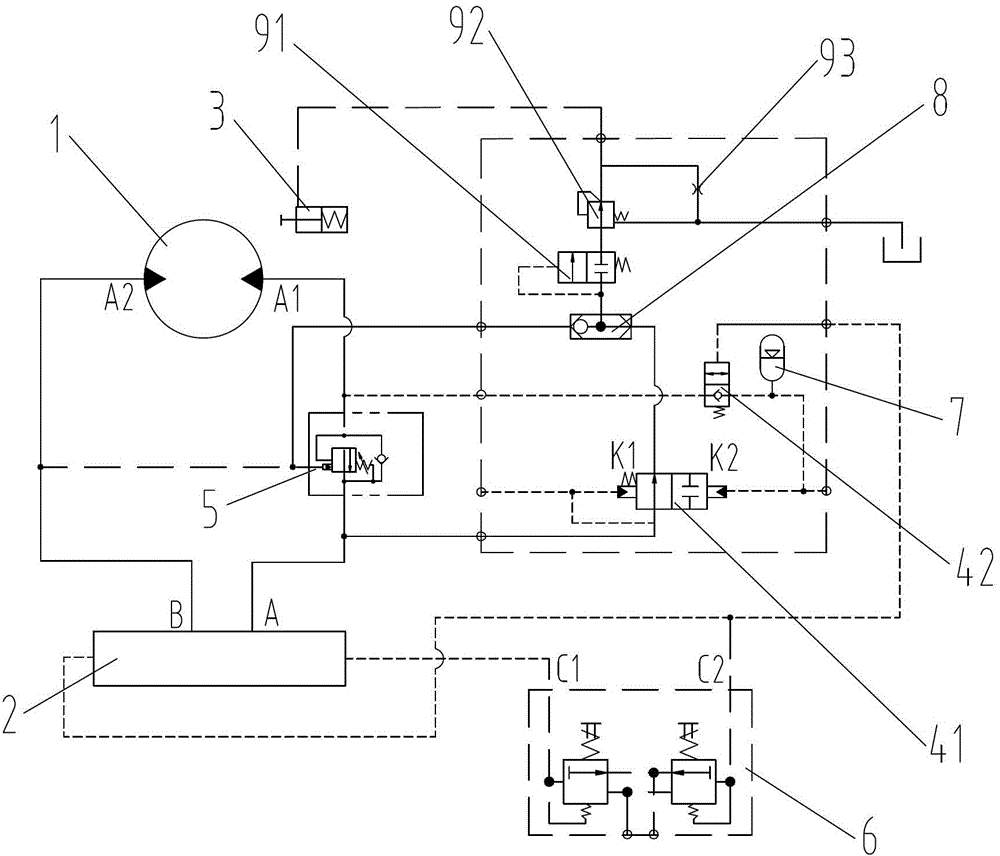

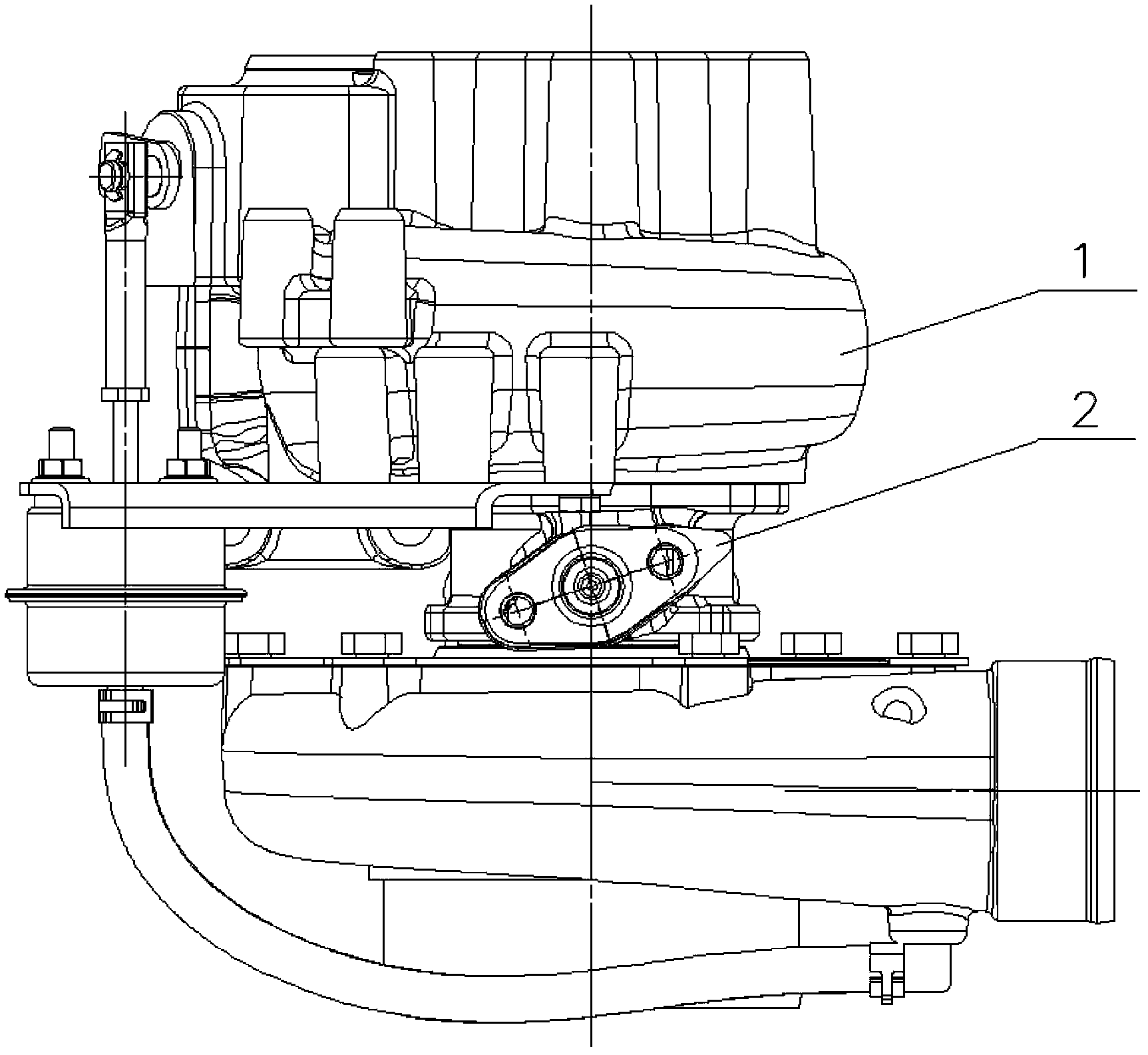

Hydraulic system, hoisting mechanism and engineering machinery

InactiveCN102874704AImprove securityAvoid early wearServomotor componentsServomotorsControl engineering

The invention discloses a hydraulic system, a hoisting mechanism and engineering machinery. The hydraulic system comprises an execution part, a main valve used for reversing of the execution part and a brake used for braking the execution part, wherein the brake is in an open state during oil-taking and in a closed state during oil-returning. The hydraulic system further comprises a brake oil way which is connected between an oil source and the brake, and a first control valve is arranged on the brake oil way, and opens or closes the brake oil way according to load pressure of the execution part and output pressure of the main valve. The hydraulic system can effectively prevent a load from driving the execution part to move, can avoid hook gliding when applied to the hoisting mechanism, and has the advantages of high safety, high reliability, small braking block abrasion and the like.

Owner:SANY HEAVY IND CO LTD (CN)

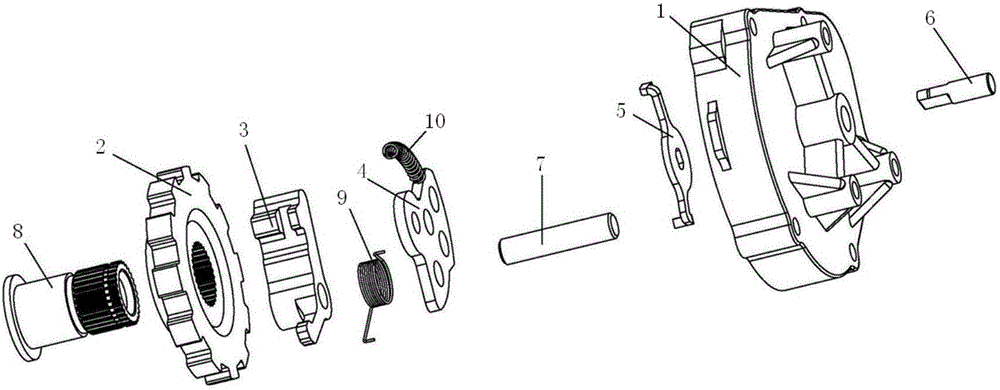

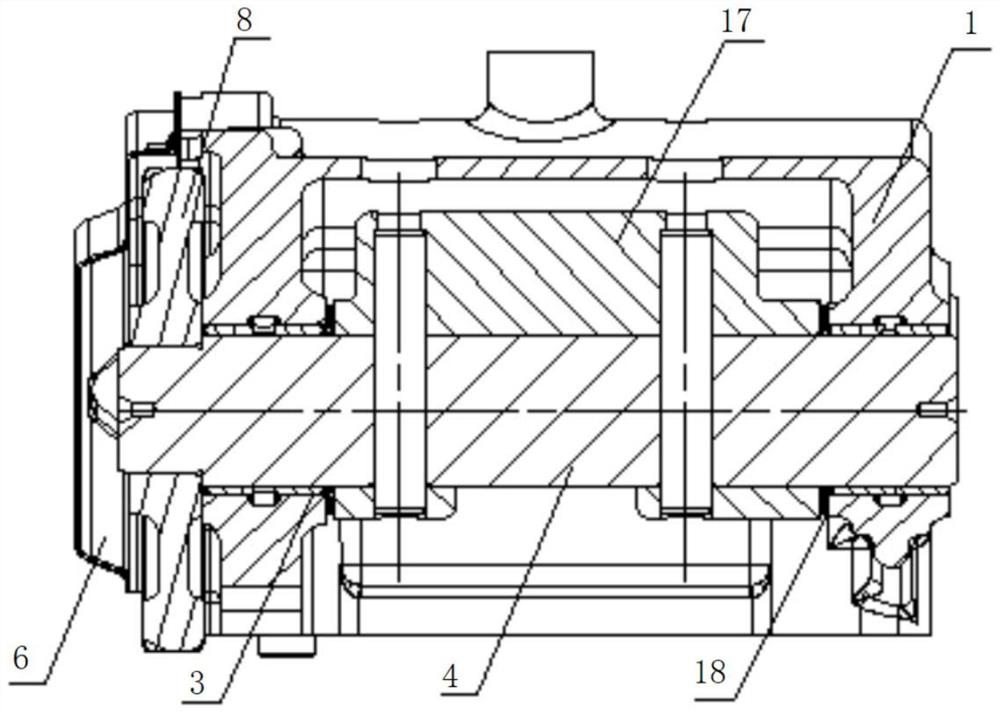

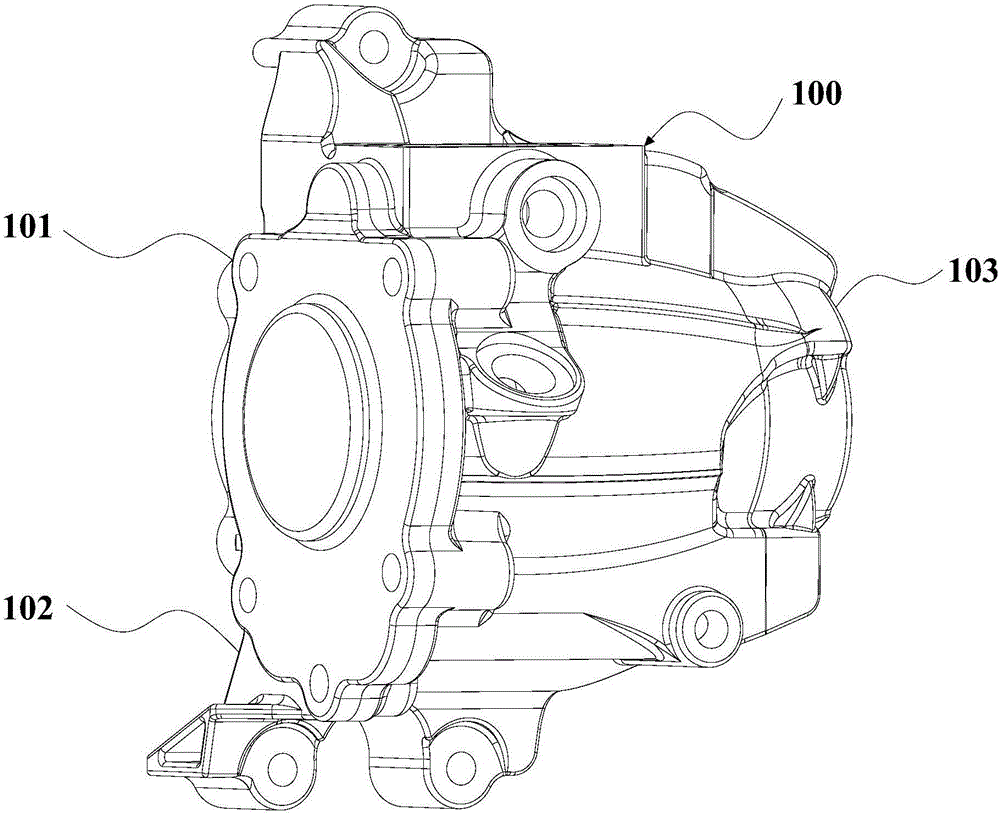

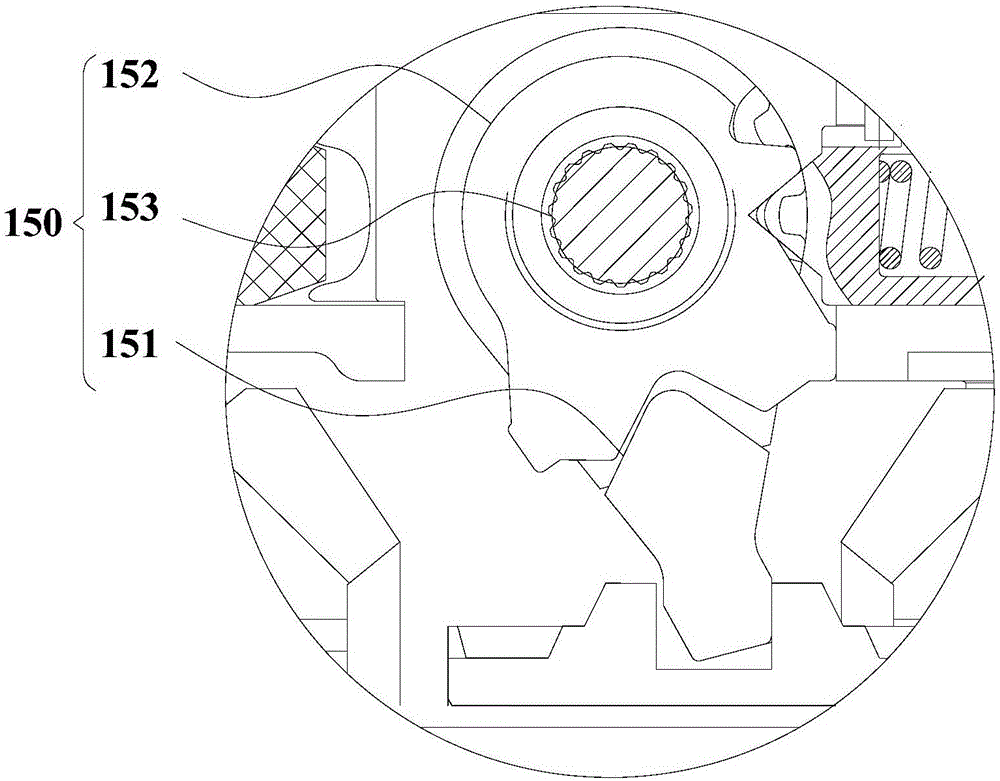

Multi-layer parking system for all-electric vehicle

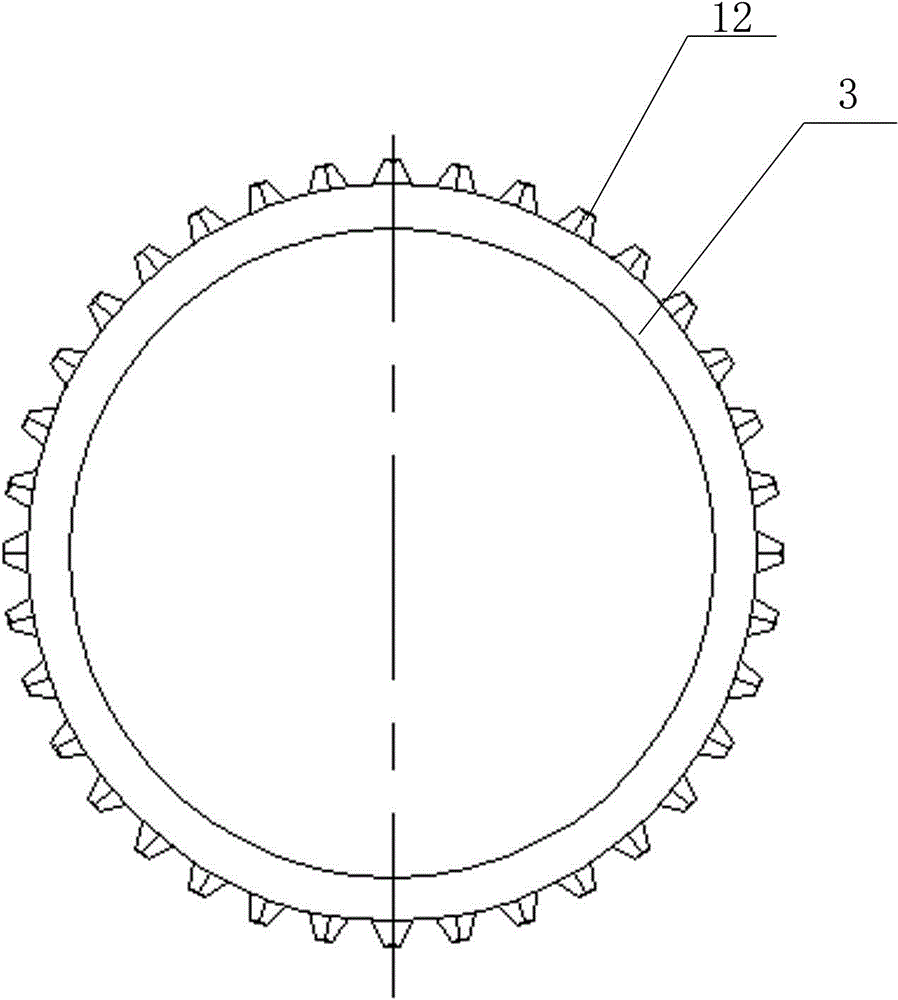

PendingCN106347115AImprove securityReduce radial sizeGearing controlTransmission elementsRotational axisRatchet

The invention discloses a multi-layer parking system for all-electric vehicle. The system comprises a casing, a ratchet wheel, a ratchet, a ratchet shaft, a torsional spring, a cam disc, a driving piece and a driving shaft, wherein the ratchet wheel is fixedly mounted on a rotating shaft enabling a wheel to always keep power transmission in a speed changer; the ratchet shaft and the driving shaft do not share one shaft and are arranged on the casing; the cam disc is rotationally arranged on the driving shaft; the driving piece is fixed on the driving shaft; the ratchet is rotationally arranged on the ratchet shaft; the driving shaft rotates positively and negatively and can drive the driving piece to rotate positively and negatively with the driving shaft; the driving piece further drives the cam disc to rotate positively and negatively around the driving shaft; the cam disc further drives the ratchet to rotate positively and negatively around ratchet shaft, so as to enable the ratchet and the ratchet wheel to be meshed with each other for parking or be separated from each other for unlocking; the torsional spring is pre-tightened and is mounted on the ratchet shaft, and provides an elastic force for pushing the ratchet to rotate to an unlocking direction. All mechanisms of the system adopt multilayer arrangement, so that the radial dimension of the system can be greatly shortened, and the system is convenient to mount and maintain.

Owner:昆山德拉特兰传动科技有限公司

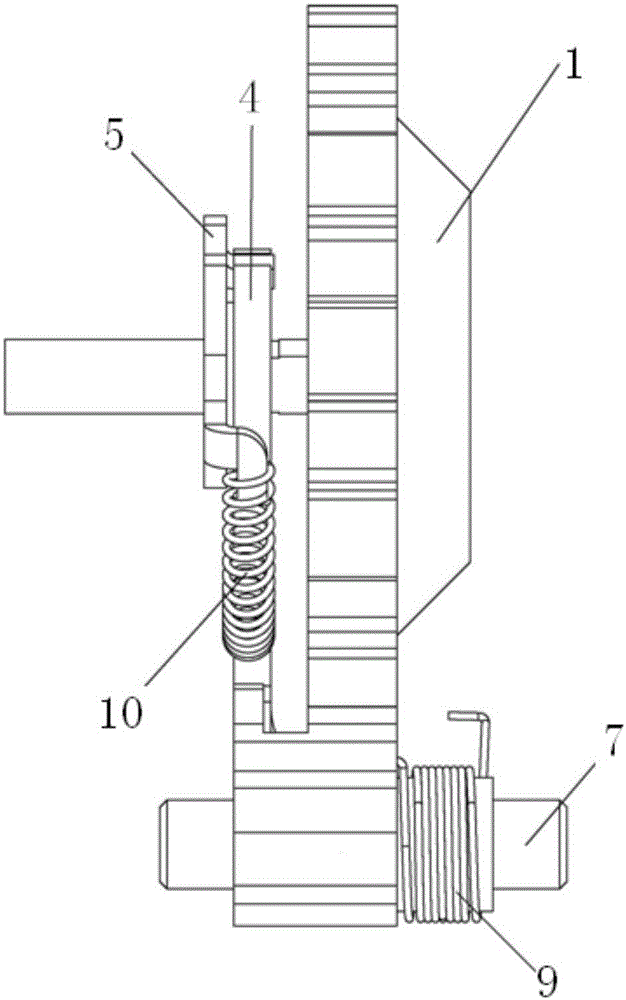

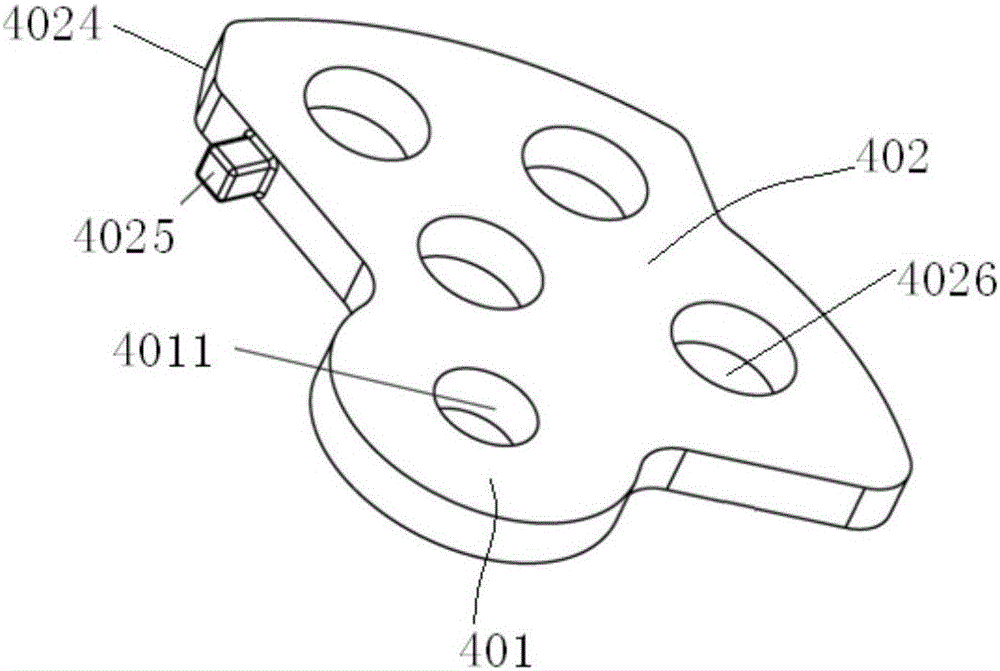

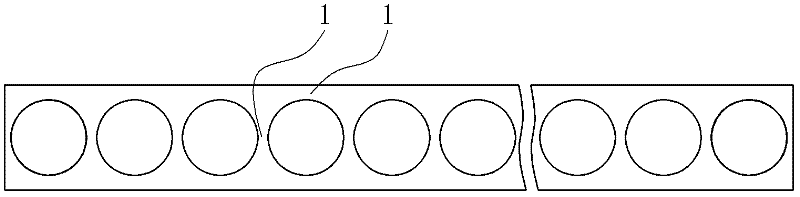

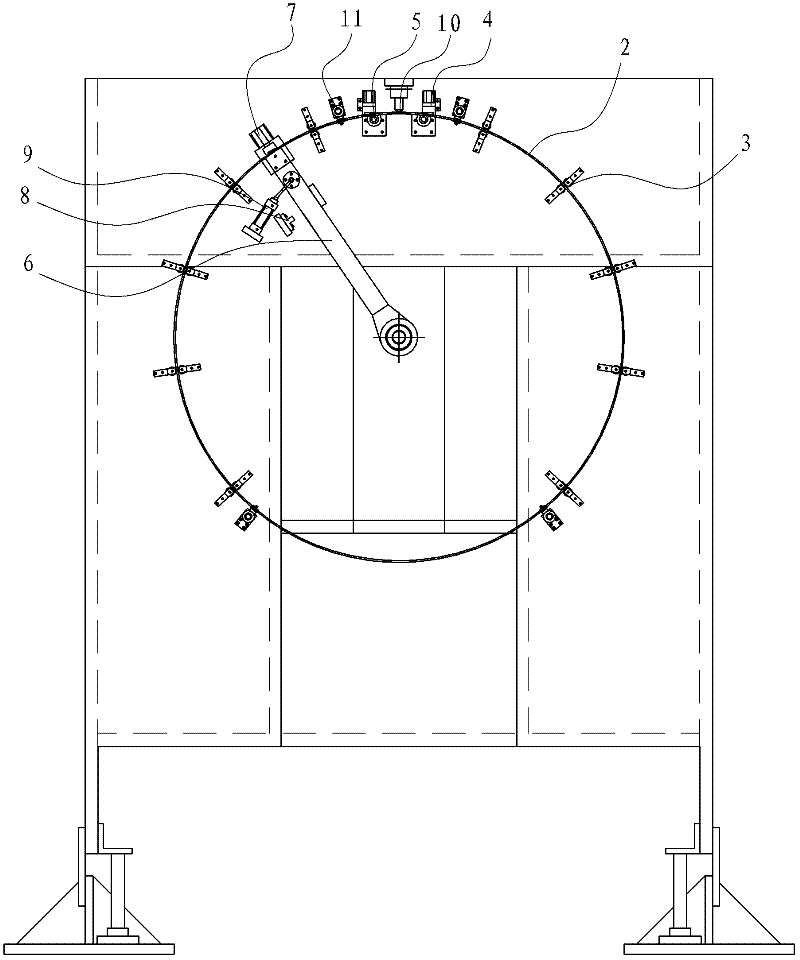

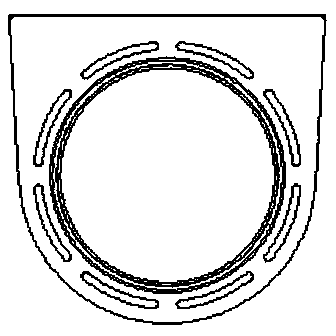

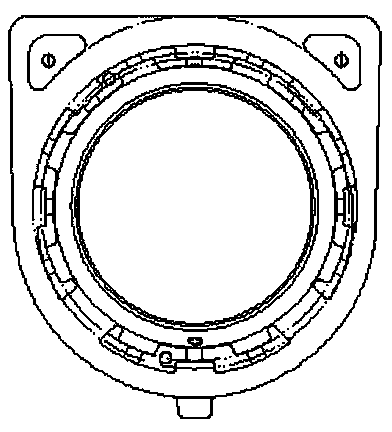

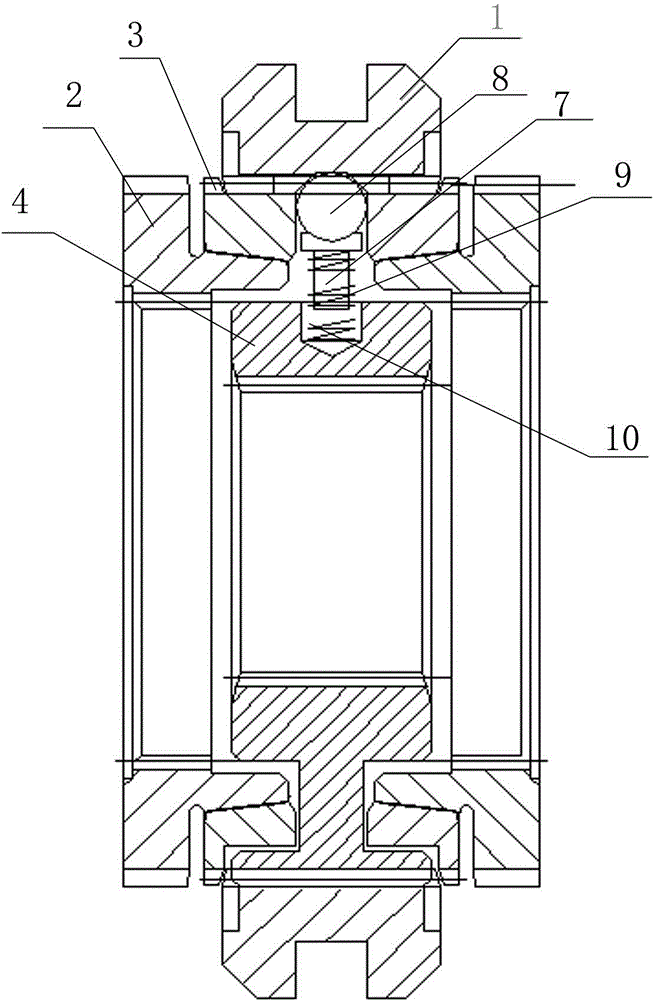

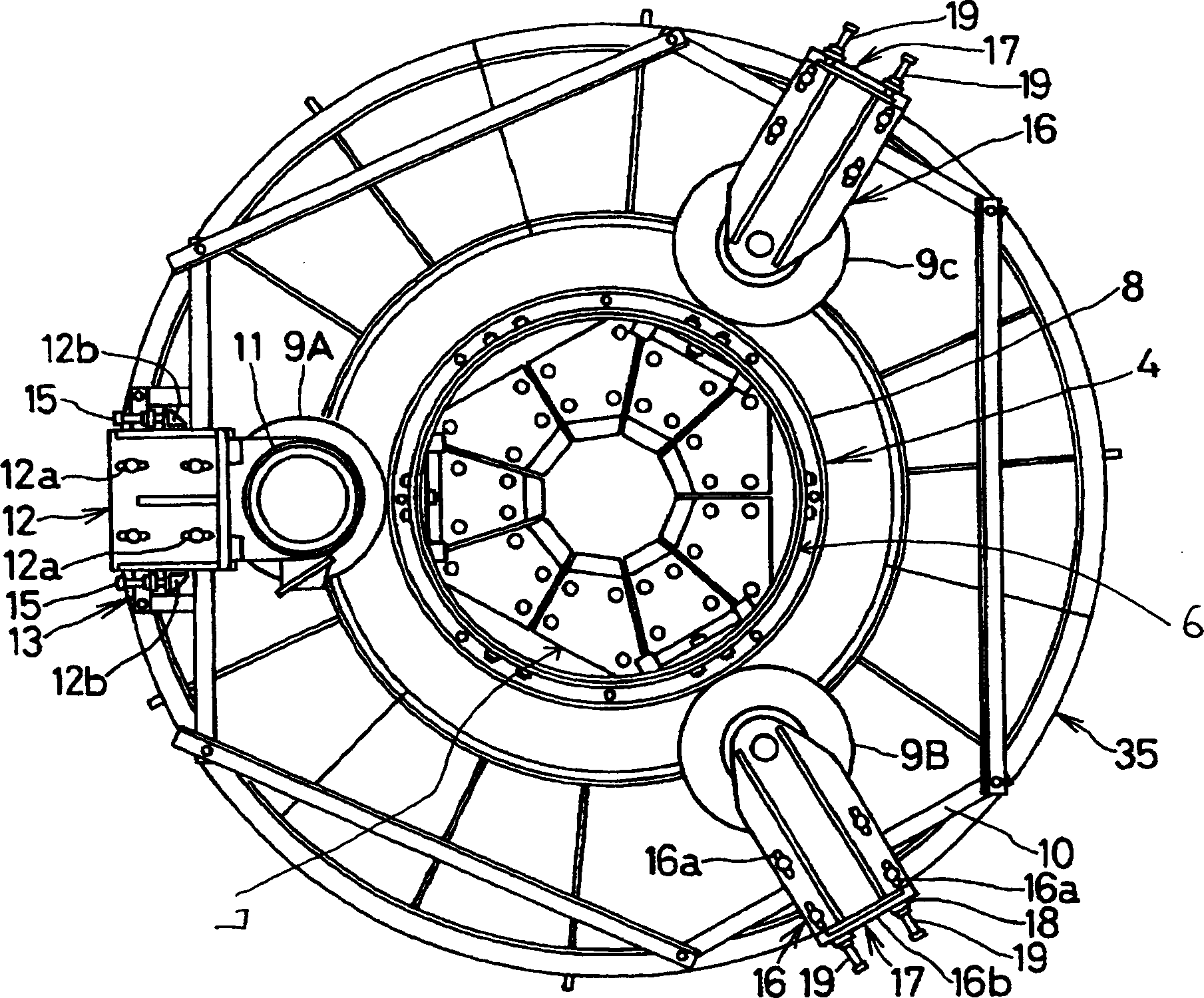

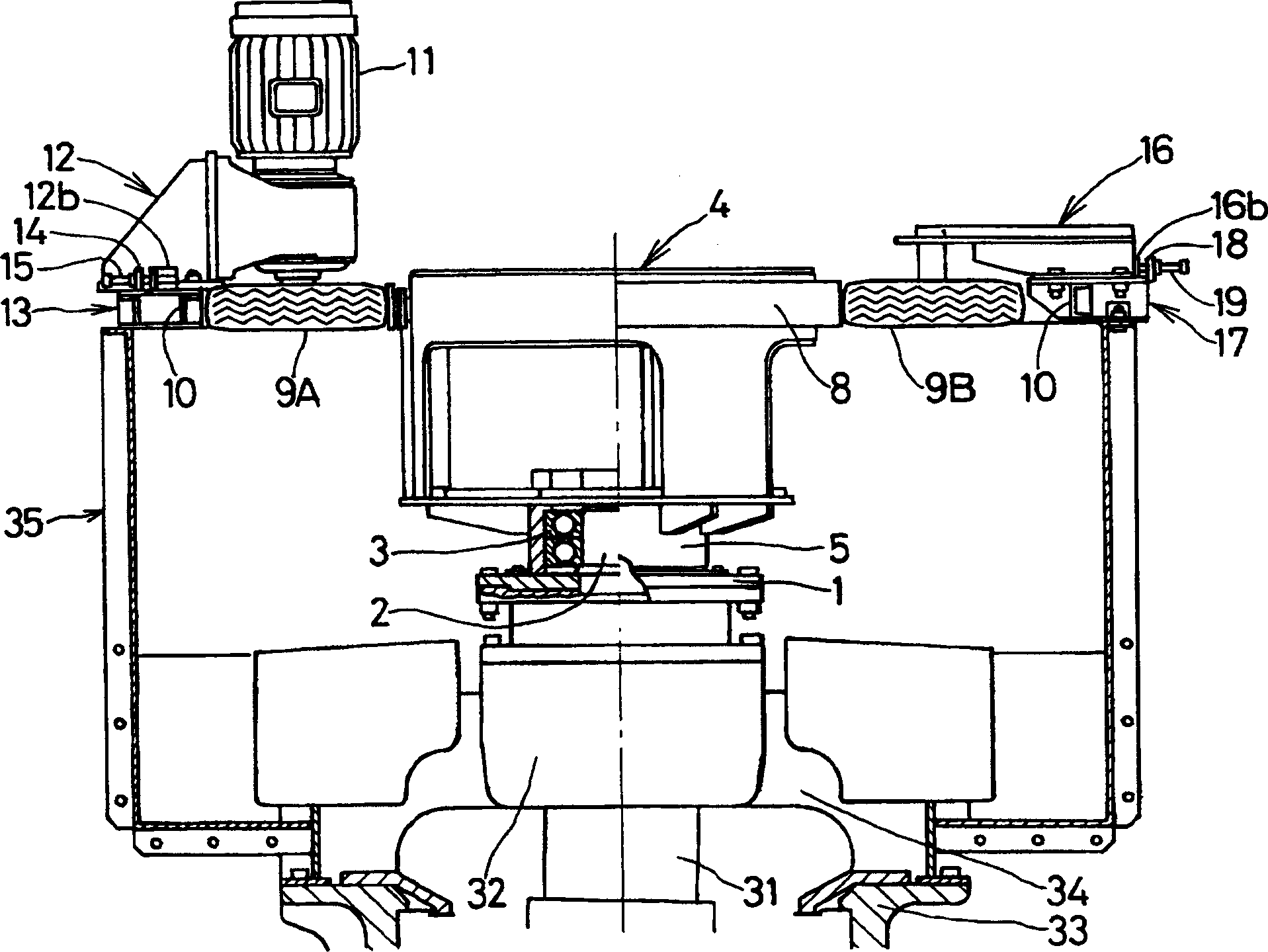

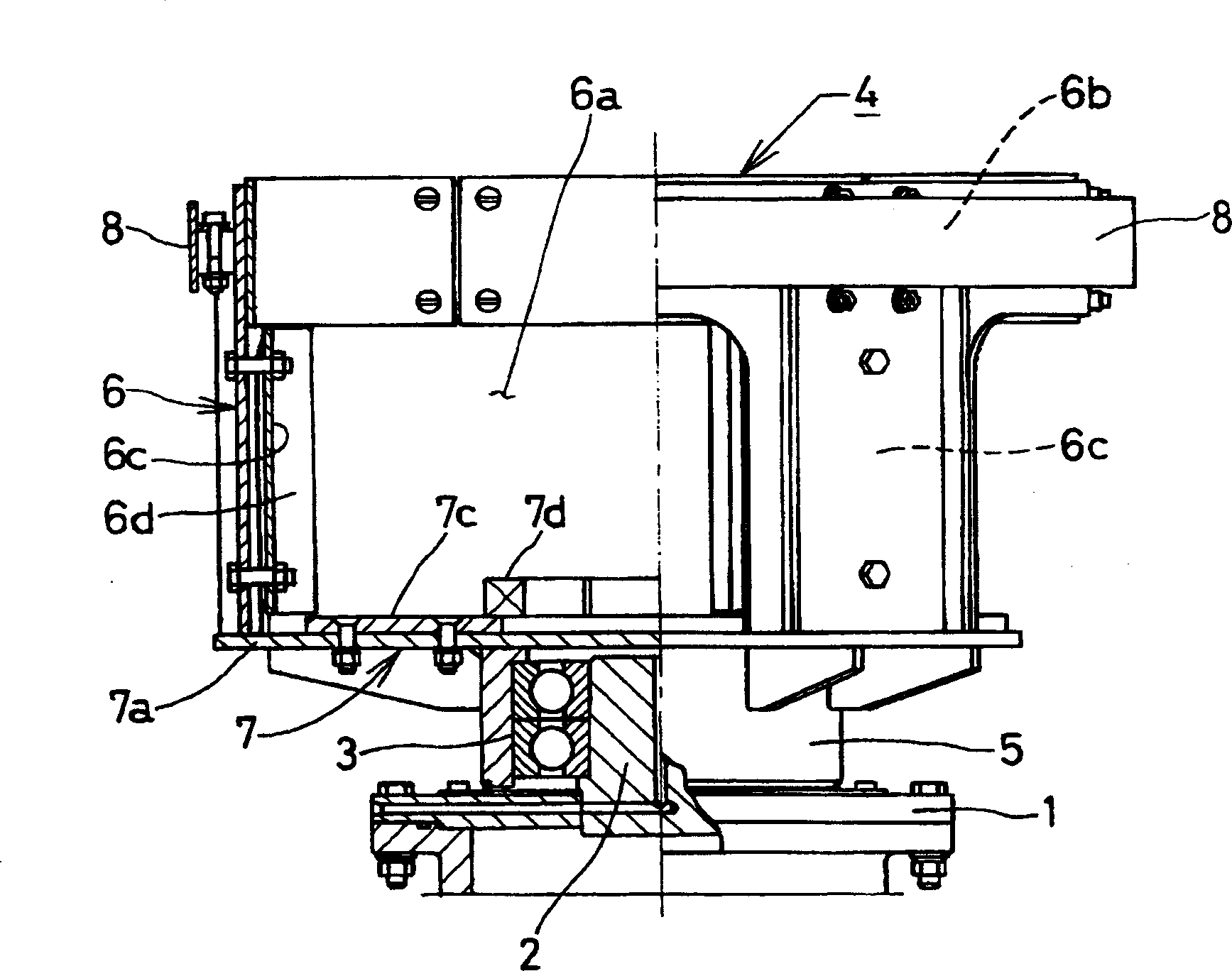

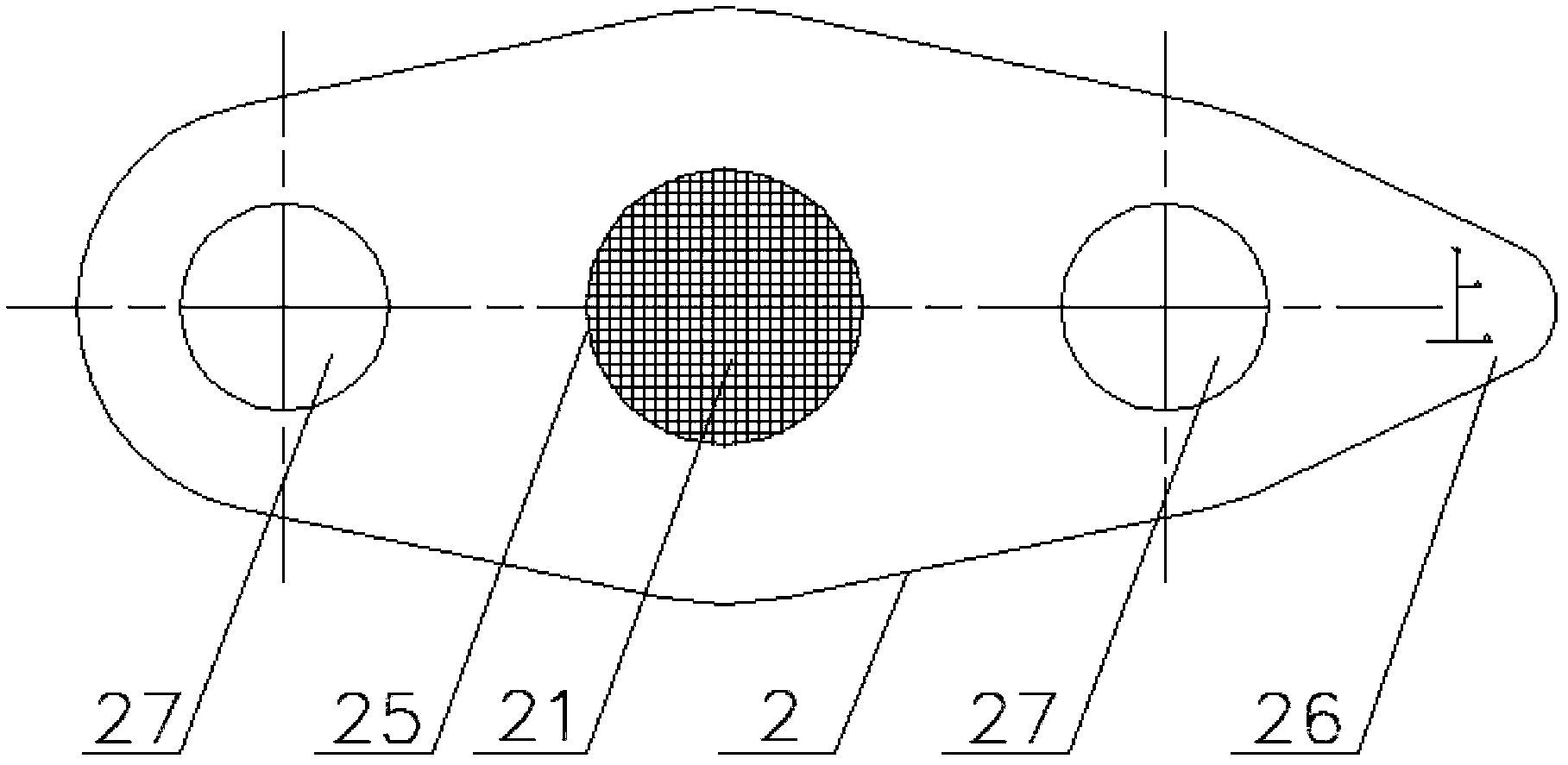

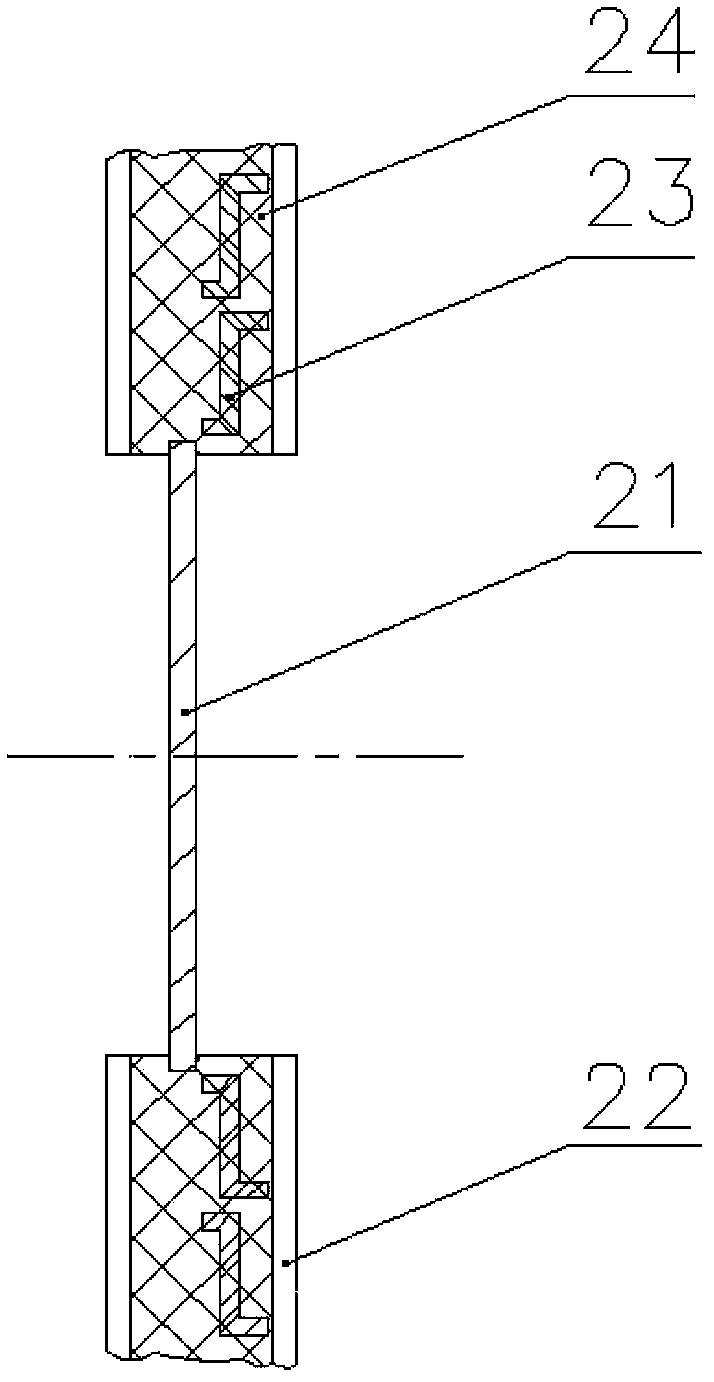

A processing method and a pocket hole processing device for an integral cage of a wind power equipment bearing

InactiveCN102267042AGuaranteed accuracyAvoid early wearPositioning apparatusMetal-working holdersElectricityRounding

The invention relates to a pocket machining device and a method for machining an integral bearing retainer of wind power equipment. The machining method comprises the steps of material feeding, rough rounding, welding, fine rounding and shaping in sequence, as well as pocket machining; the machining method is characterized in that: in the material feeding step, a cold-rolled plate is cut into a straight-strip-shaped pocket-free plate; the pocket machining step is performed after the fine rounding step and before the shaping step; and the roundness of pockets on the retainer can be ensured, the pockets can be prevented from deforming and generating multi-edge round, and the precision of the pockets on the retainer can be guaranteed. The pocket machining device comprises a supporting mechanism, a radial positioning mechanism, an axial positioning mechanism, a retainer driving and moving mechanism and a movable arm limiting mechanism, as well as a hydraulic control system which is used for controlling a first cylinder, a second cylinder, a movable arm cylinder and a third cylinder. The functions of clamping, positioning, equal-distance feeding, compressing and discharging and the like of the retainer after being welded into a whole can be realized during pocket laser cutting and machining.

Owner:田天红

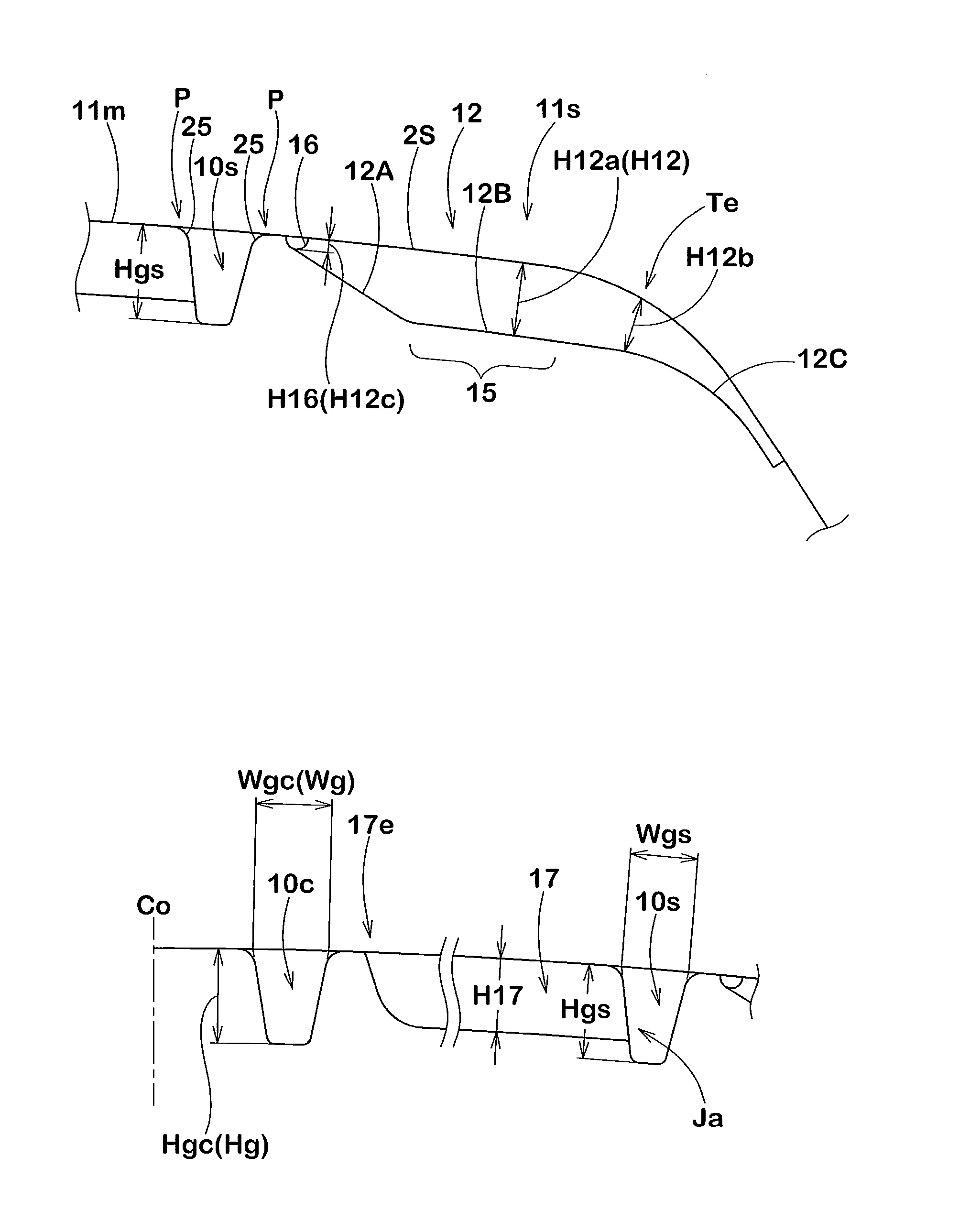

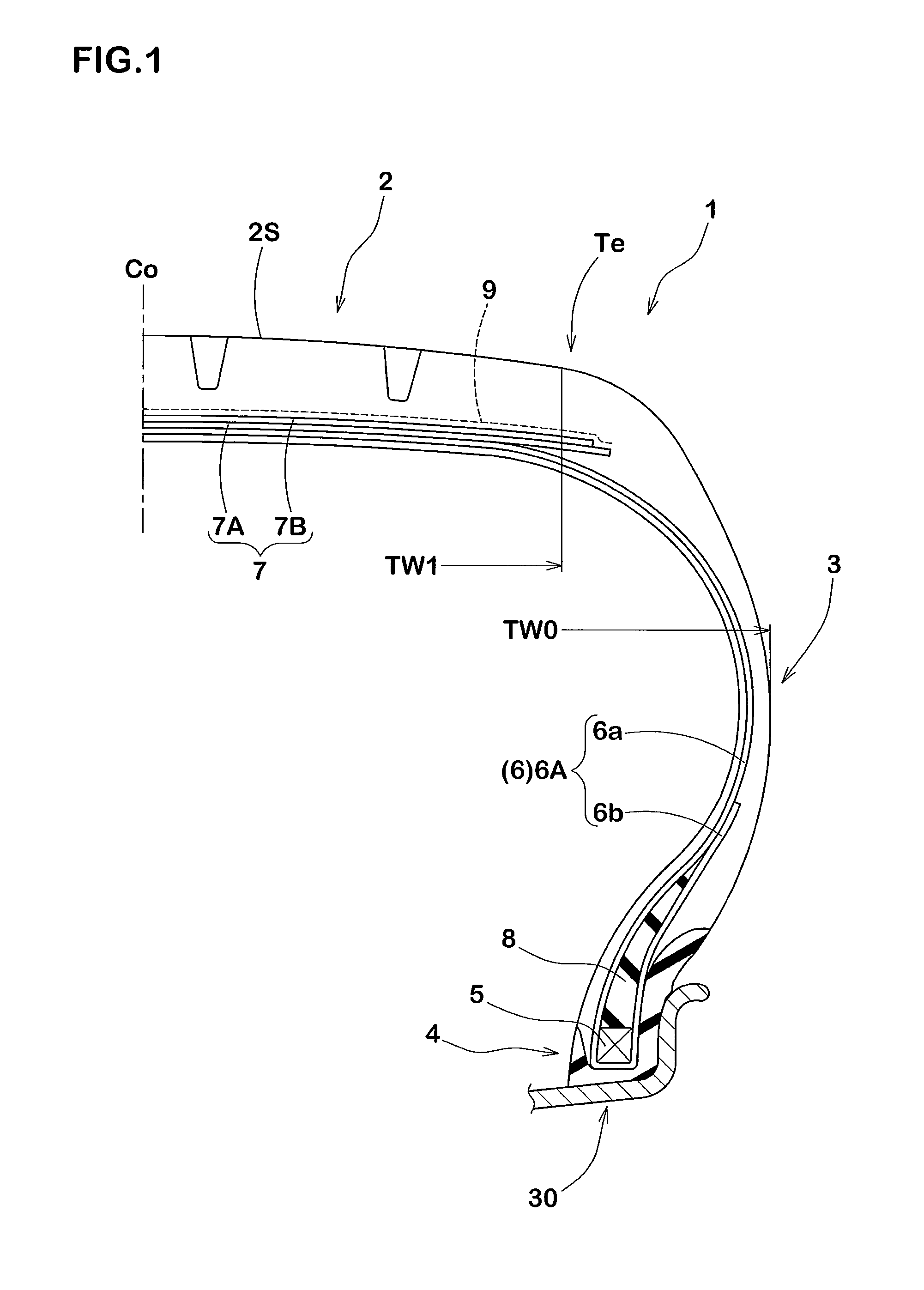

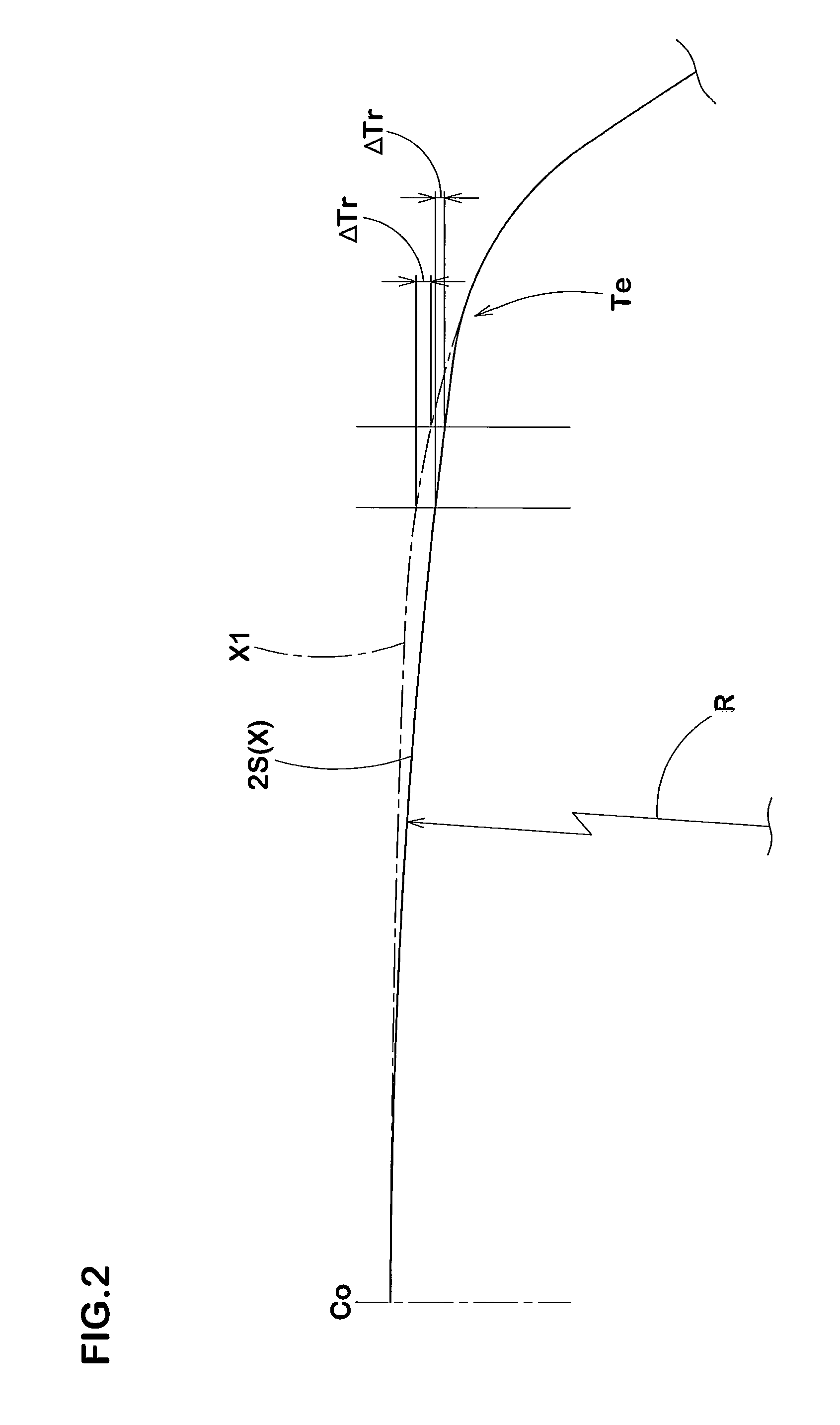

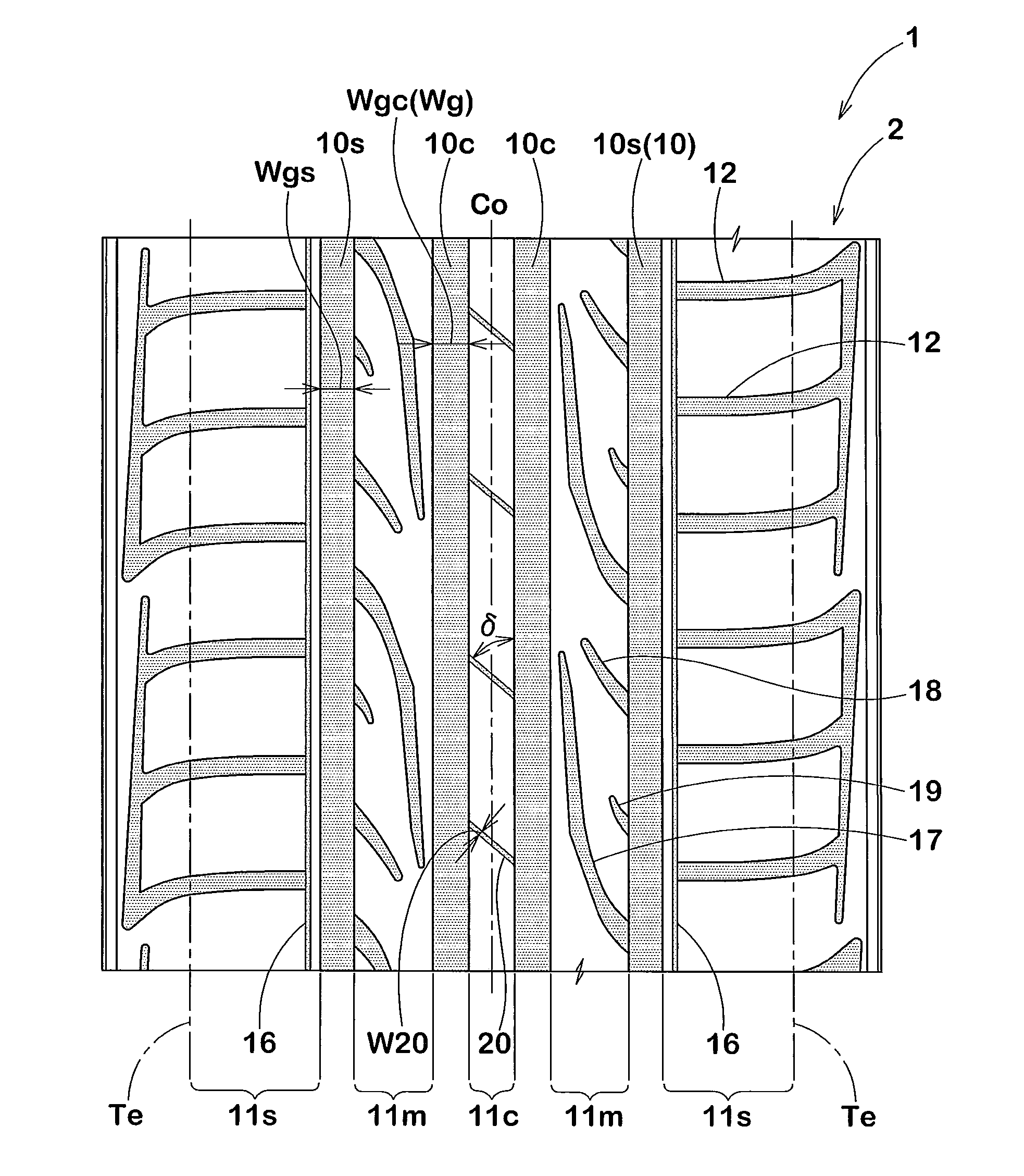

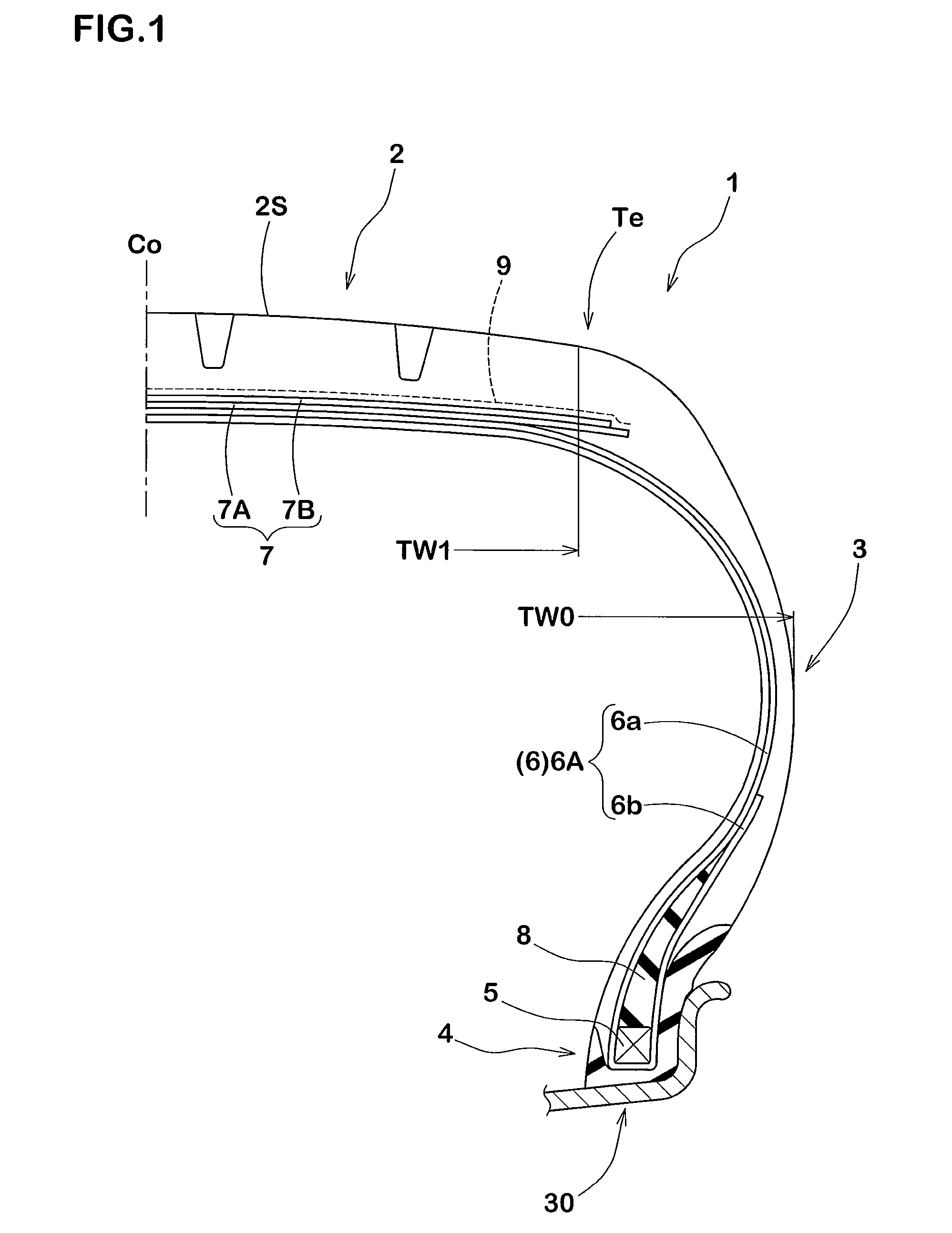

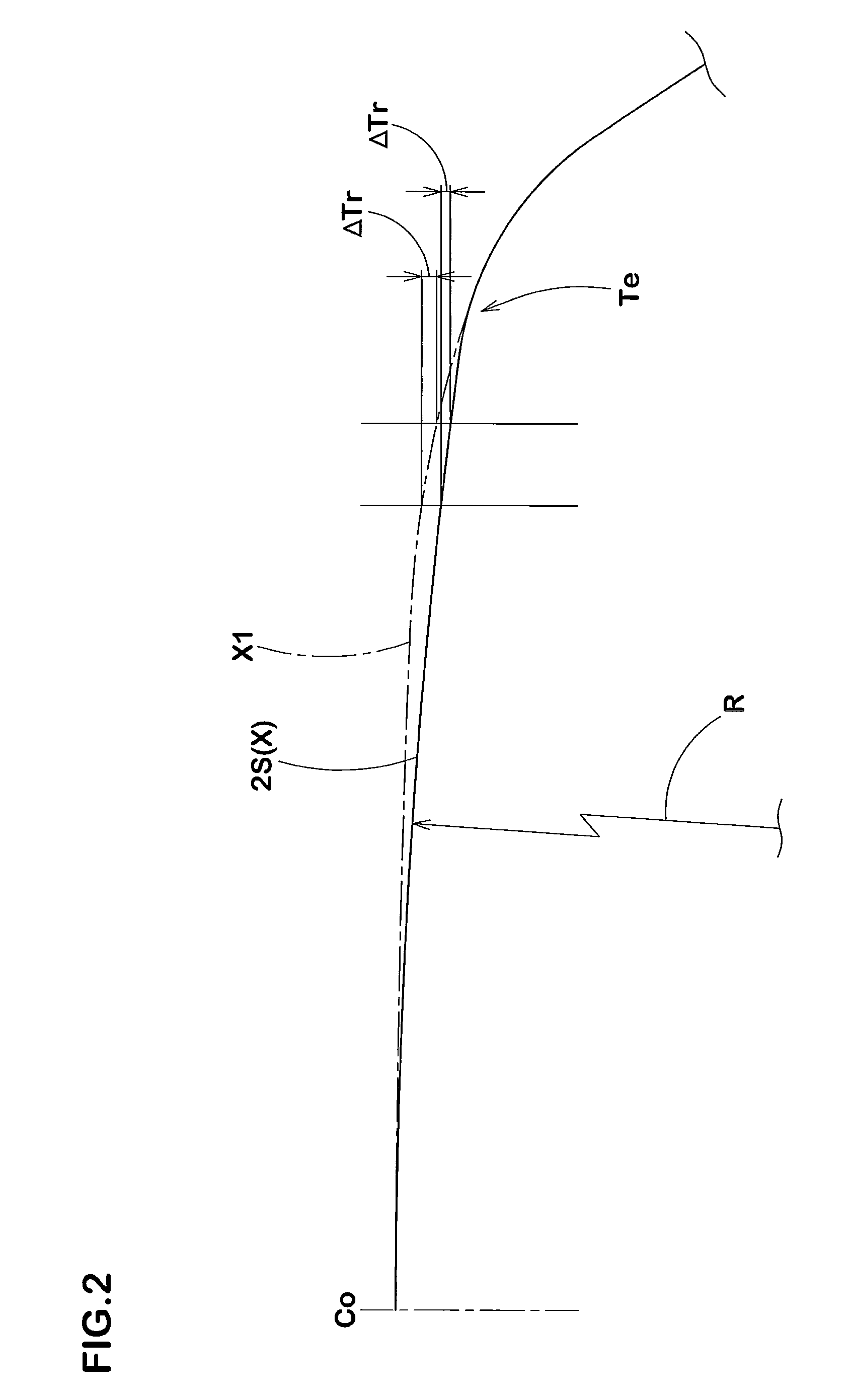

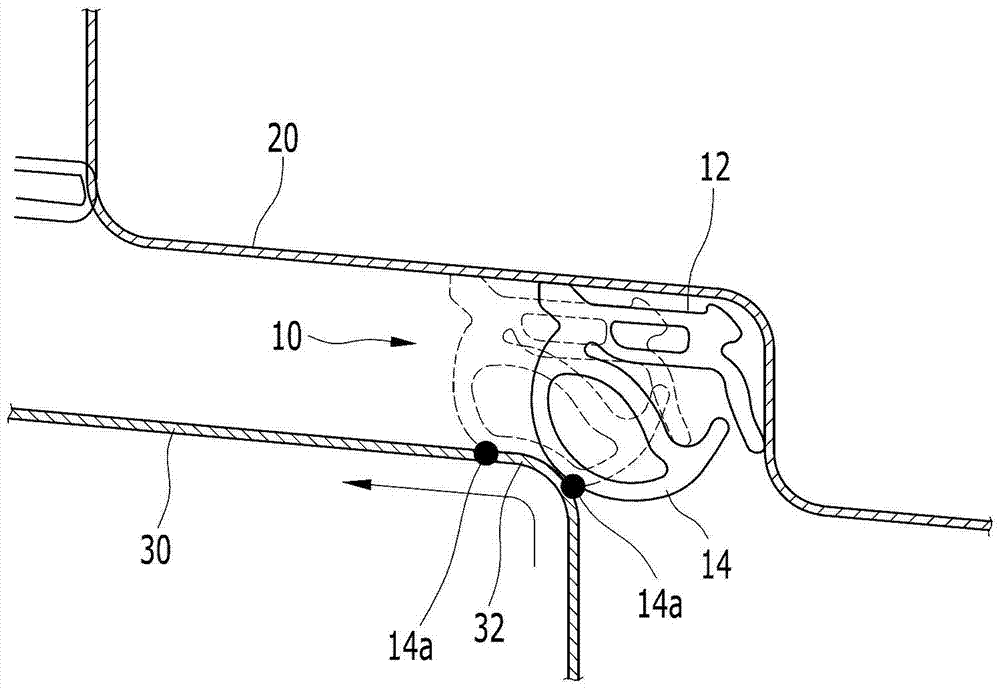

Pneumatic tire

ActiveUS20120168050A1Low in changeSmall differenceSpecial tyresPneumatic tyre reinforcementsGround contactInternal pressure

A tire contour shape is formed by a single arc in a condition in which tire flattening rate is more than 55% and less than 70% and internal pressure is 5%. Shoulder lateral grooves extend at an angle α of 80 to 90° from the axially outer side of the tread ground-contact edge to the axially inner side of the tire, and the tire axially inner ends terminate within the shoulder land portion. A tire axial distance Ds between the tire axially inner end and the shoulder circumferential main groove is in the range of 3.5 to 5.5 mm, the shoulder lateral groove has the deepest part where the groove depth is largest, and the groove depth of the deepest part is 70 to 90% of the groove depth of the shoulder circumferential main grooves.

Owner:SUMITOMO RUBBER IND LTD

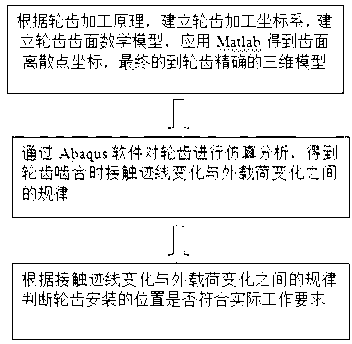

Klingelnberg bevel gear contact regulating method

ActiveCN103268368AAvoid early wearImprove carrying capacitySpecial data processing applicationsPoint equationEngineering

The invention discloses a Klingelnberg bevel gear contact regulating method. A recognition method comprises the following steps that (1) a gear processing coordinate system is built according to the Klingelnberg bevel gear processing theory, a wheel tooth surface equation is deduced according to a tool nose one-point equation, the equation is processed, and a wheel tooth three-dimensional model is obtained; (2) the built wheel tooth three-dimensional model is utilized, and the contact trace change rule of the gear is studied under the external load effect through Abaqus software simulation; and (3) the preloading is implemented after the practical installation according to the wheel tooth contact trace change rule and the variable load obtained in the second step, and the position of the wheel tooth contact region is checked. The contact region is best regulated to the small end, so the stressed contact region is right positioned in the middle position of the gear surface, the condition that the contact region is out of the gear surface when the wheel tooth suffers the heavy load can be avoided, the wheel tooth damage is avoided, the bearing capability of the gear is improved, important theoretical basis is provided for reasonably and economically improving the transmission accuracy of a Klingelnberg bevel gear, and the effective reference is provided for the installation of the Klingelnberg bevel gear.

Owner:BEIJING UNIV OF TECH

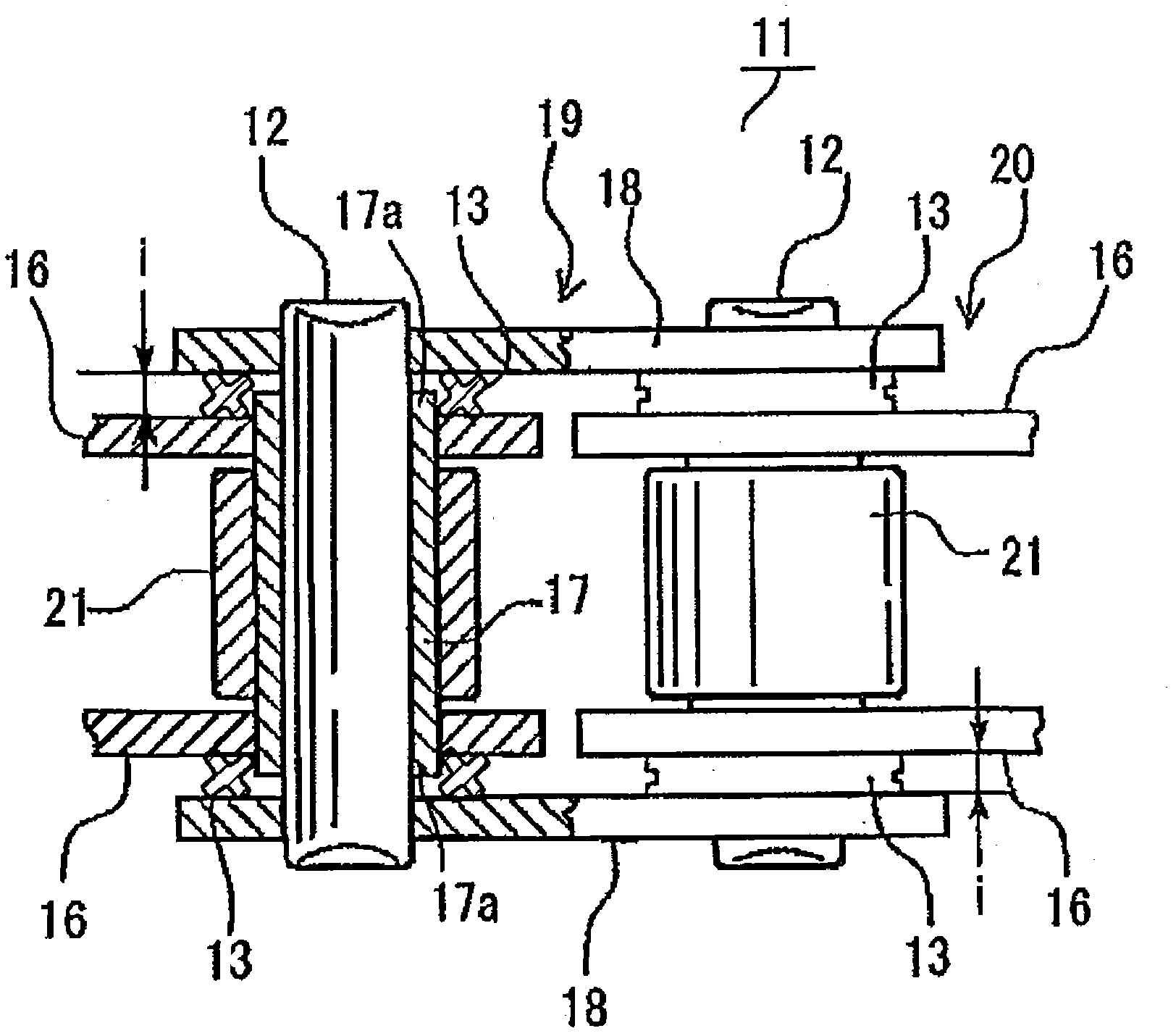

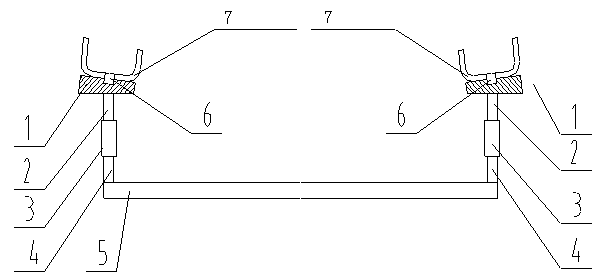

Intermediate support assembly of heavy vehicle drive shaft

InactiveCN103832272ASet strength goodReasonable static and dynamic stiffnessControl devicesDrive shaftEngineering

The invention relates to an intermediate support assembly of a heavy vehicle drive shaft. A bearing is assembled in an inner frame through clamp springs on two sides, sealing rings are arranged on two sides of the bearing, the inner frame is externally vulcanized with an outer cover into a whole through a rubber damping pad, the rubber damping pad is hollowed out internally to form an 'n'-shaped damping groove I which forms a semi-surrounded structure, the rubber damping pad on the upper portion of the inner frame and the inner frame are both covered in an 'n'-shaped empty space, clearances are formed at two side edges of the inner frame, and the lower portion of the rubber damping pad and the inner bottom of the outer cover are connected to form a connecting rib. After the assembly is subjected to complete vehicle trial assembly, the 'n'-shaped semi-surrounded structure of the rubber damping pad can absorb large axial movement of the intermediate support assembly, the angle of the intermediate support assembly is radially adjustable, the radial direction of the intermediate support assembly is ensured to be perpendicular to the axial direction of a center line of the drive shaft, and the intermediate support assembly is simple and feasible and remarkable in benefit, and has promotional value in the automobile industry.

Owner:湖北省丹江口丹传汽车传动轴有限公司

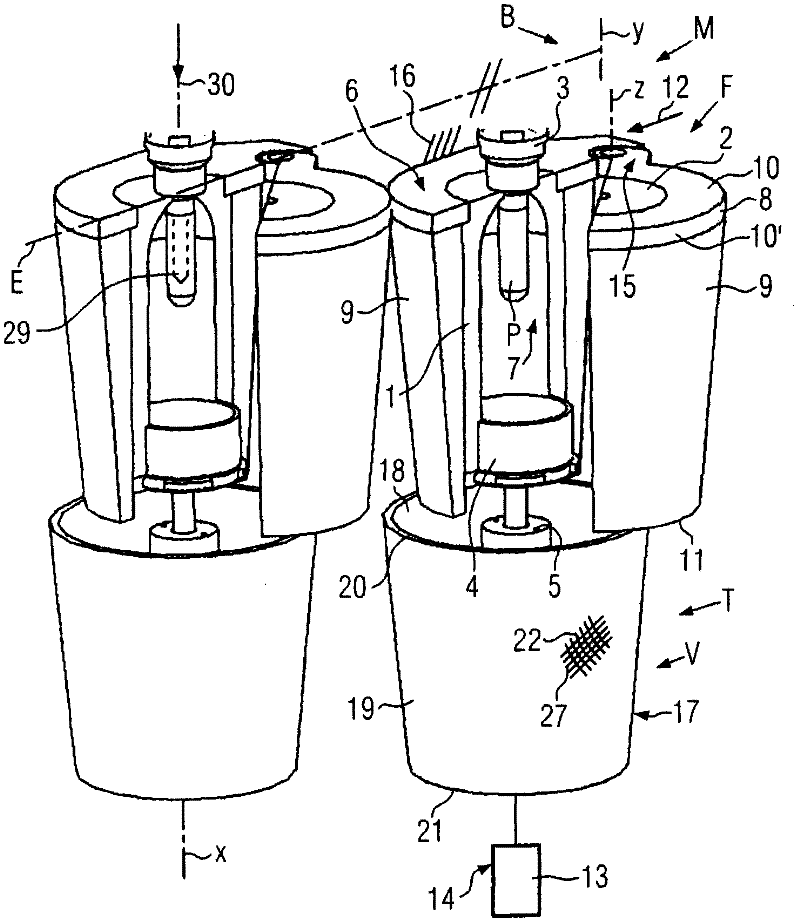

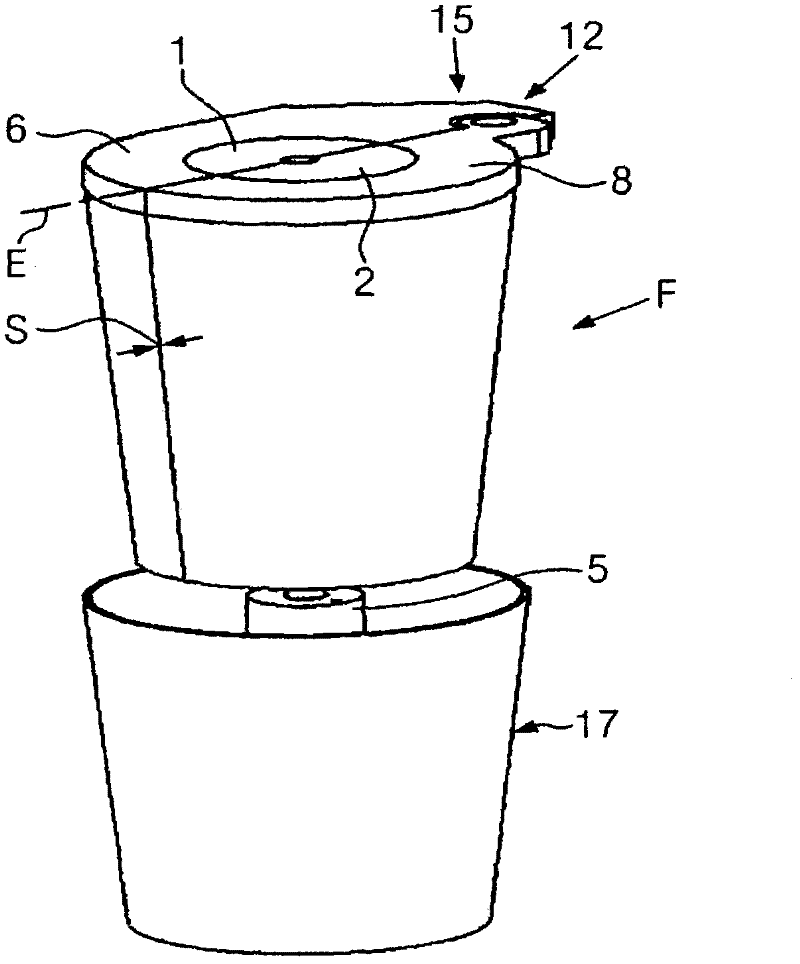

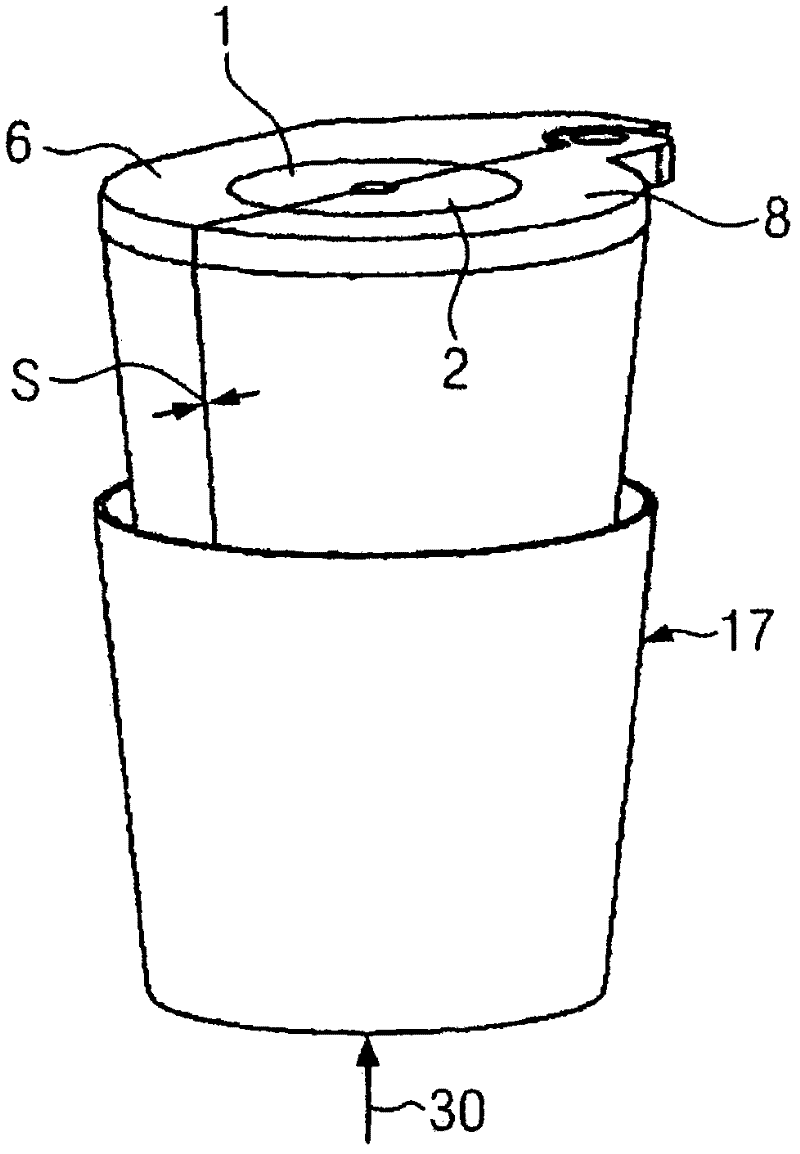

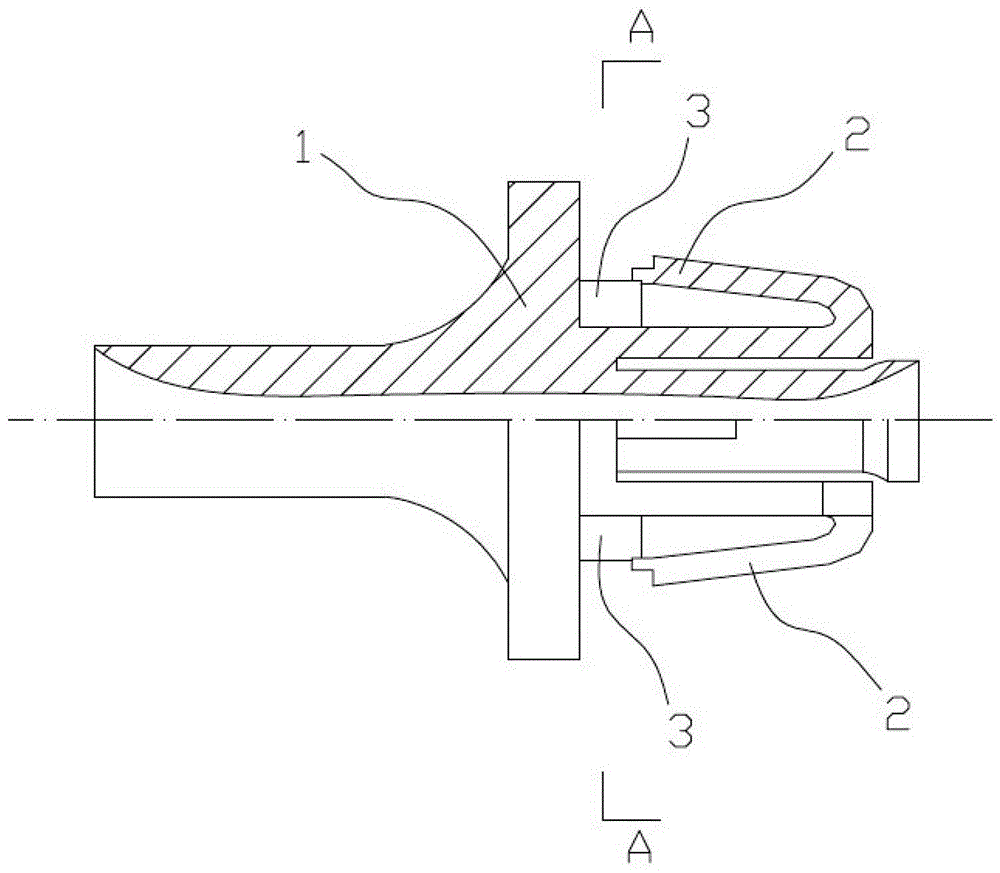

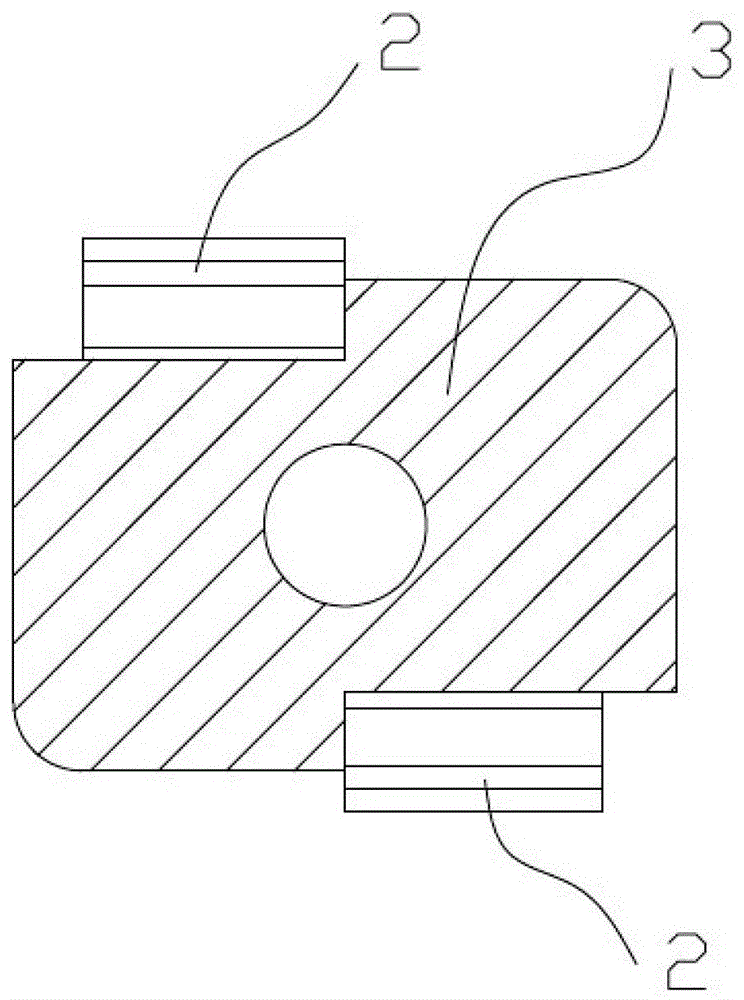

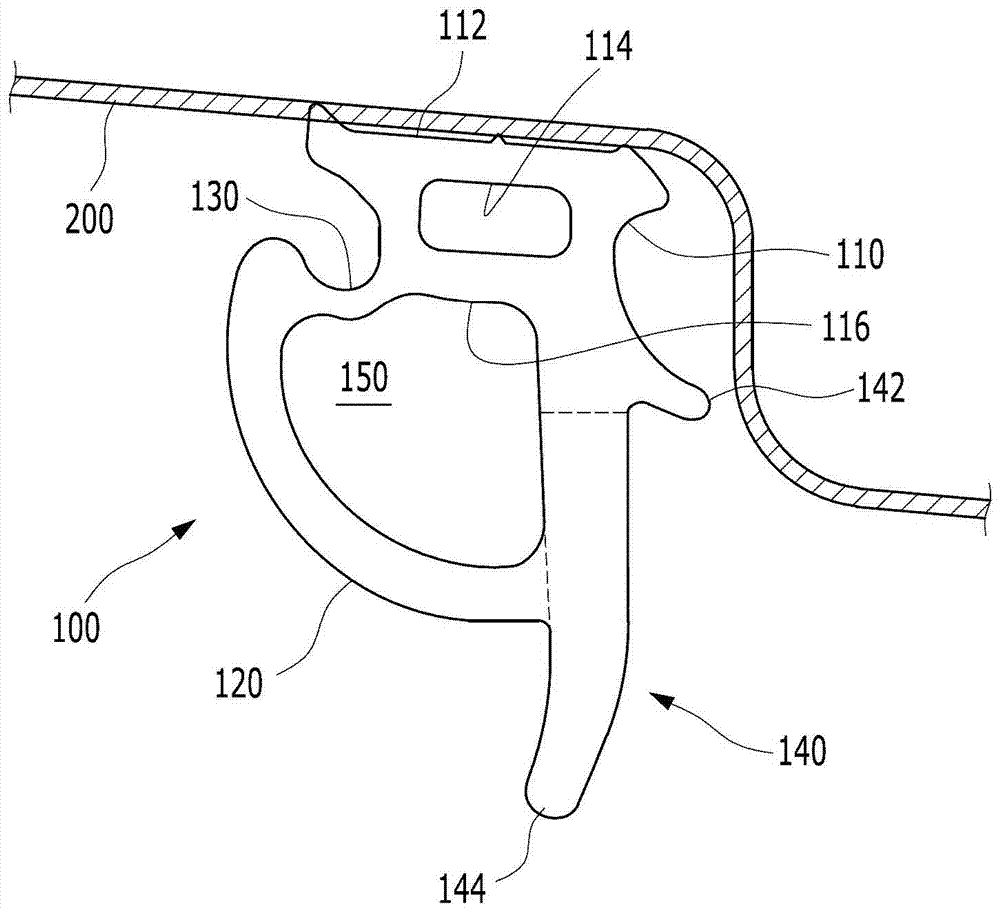

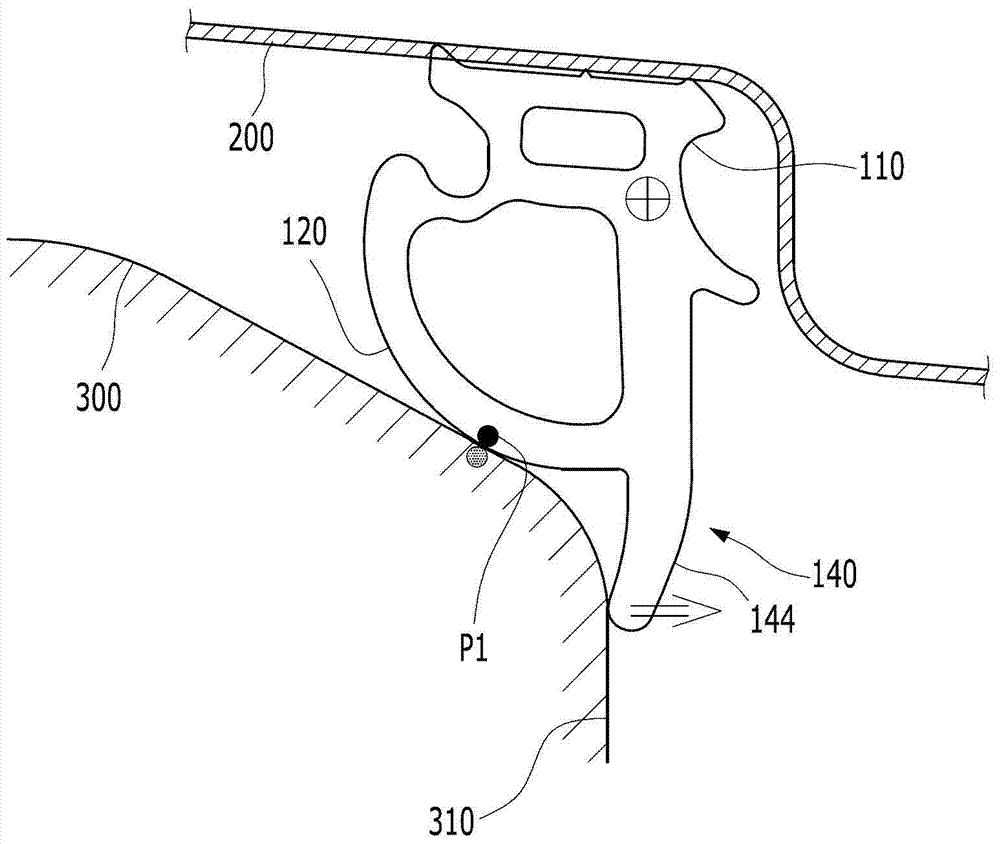

Blow mold

Owner:KRONES AG

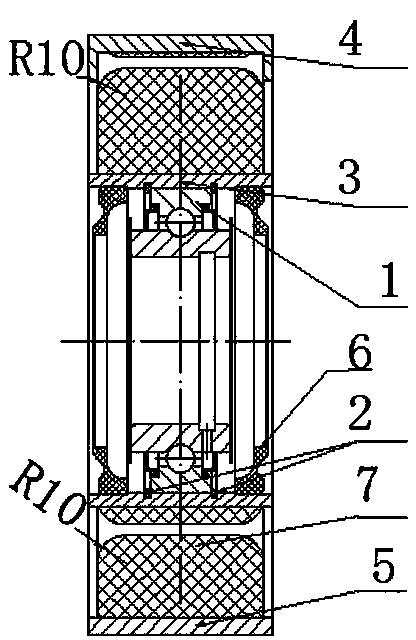

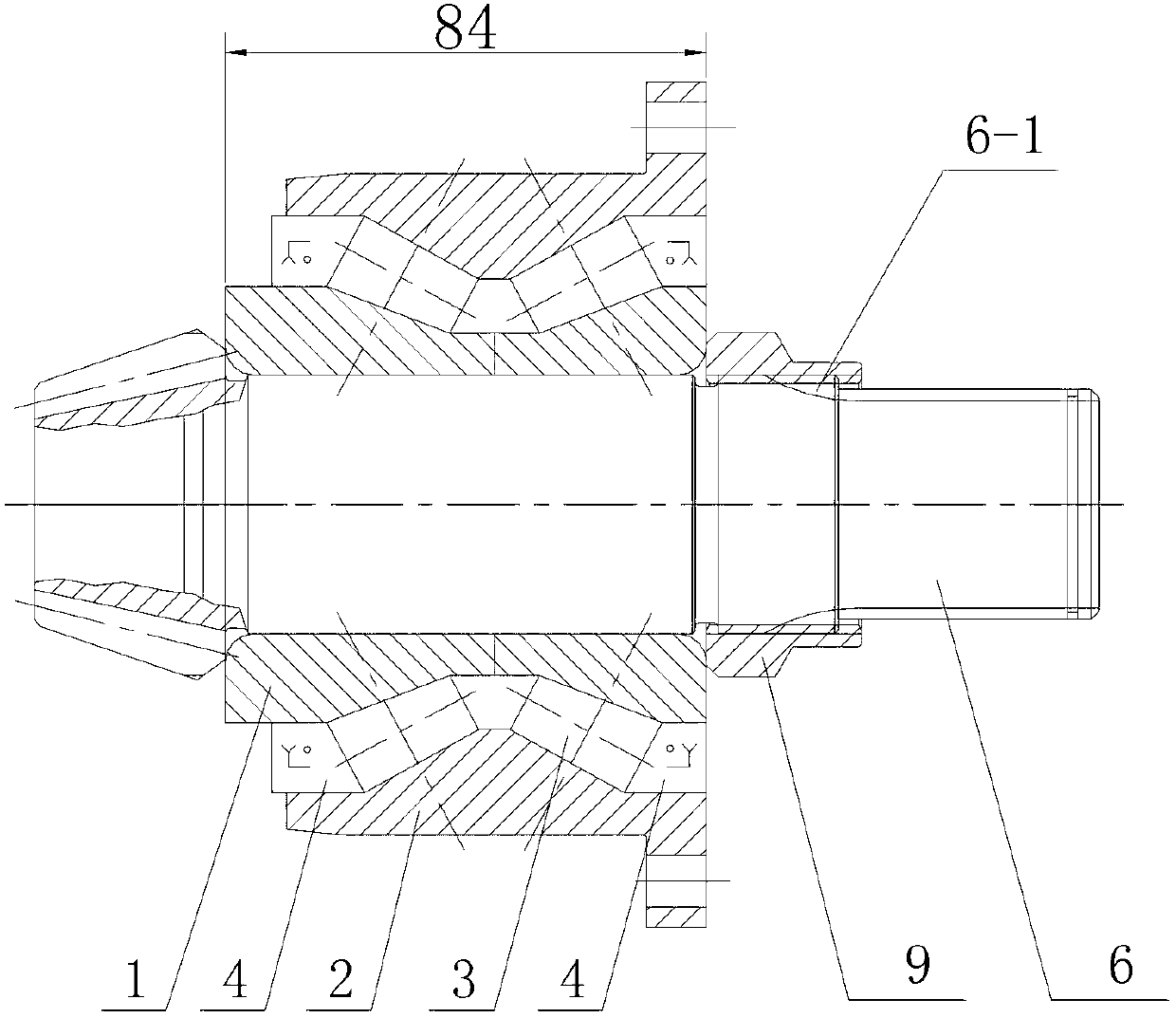

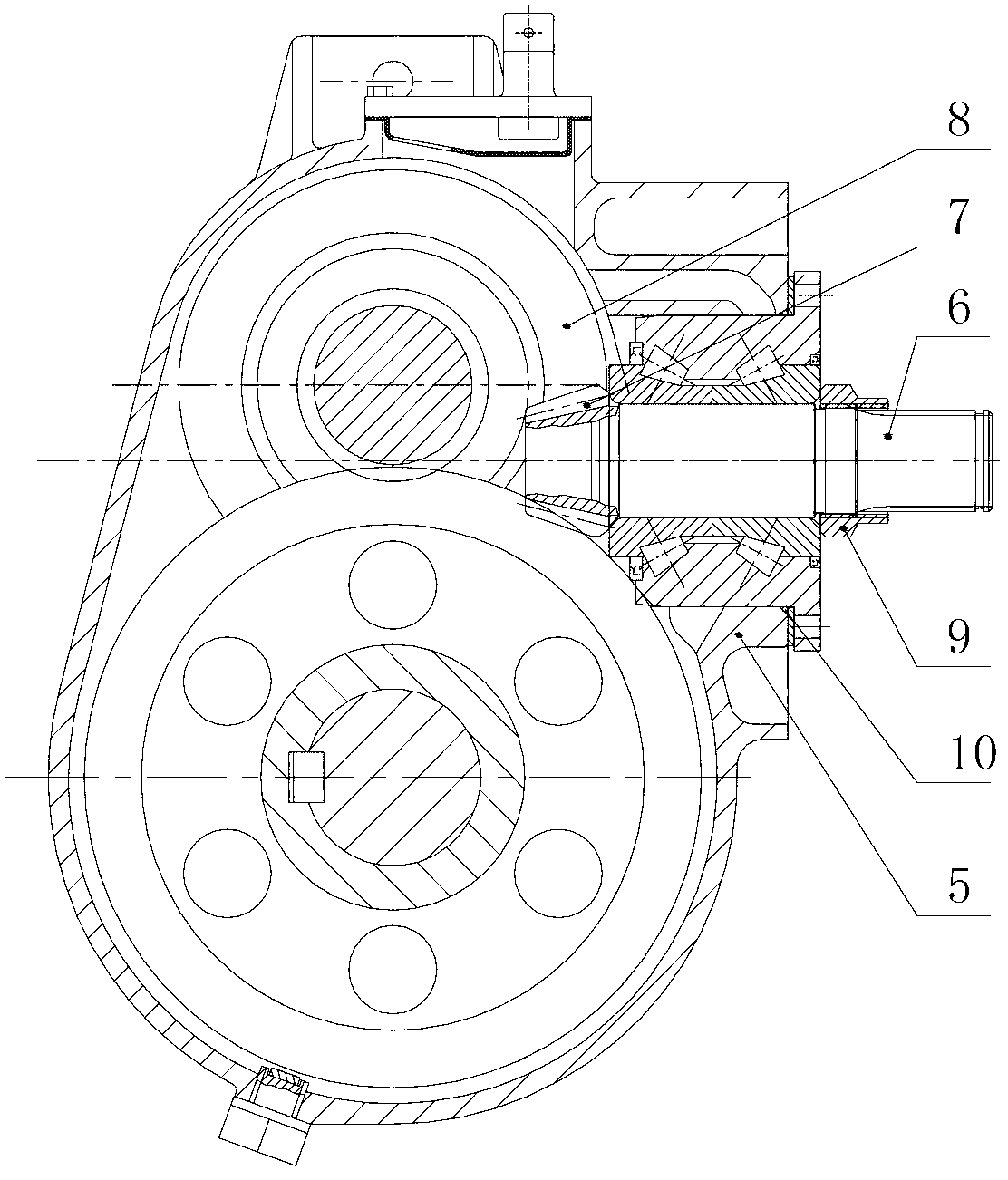

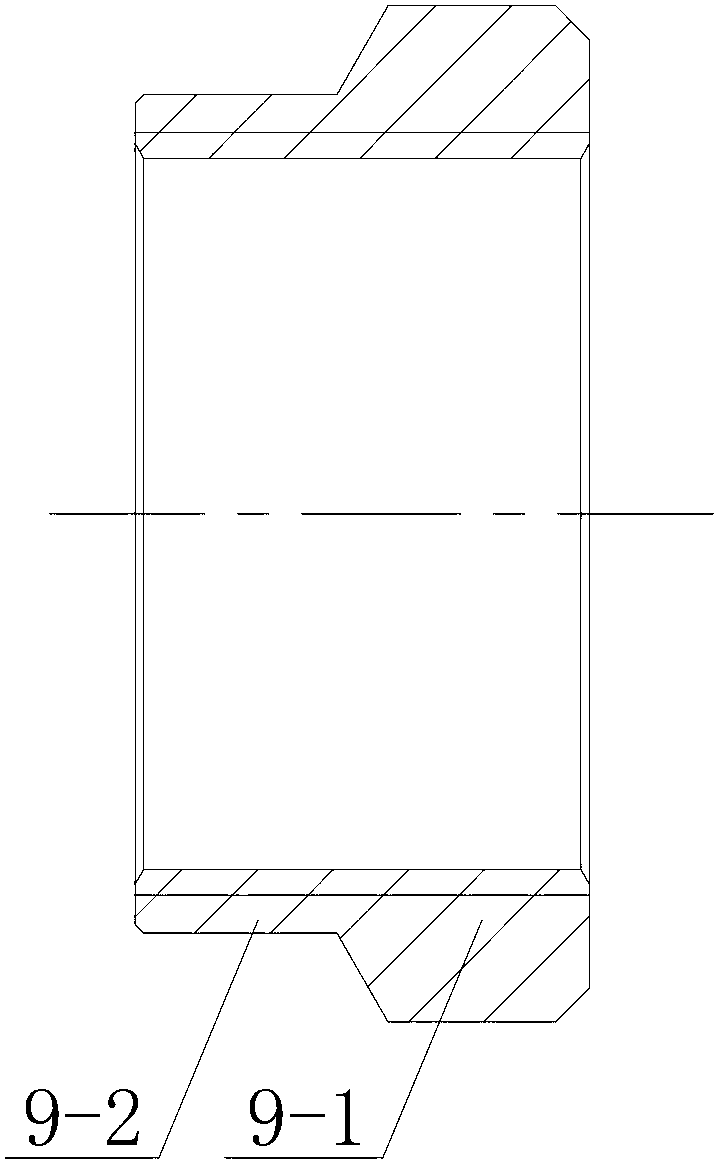

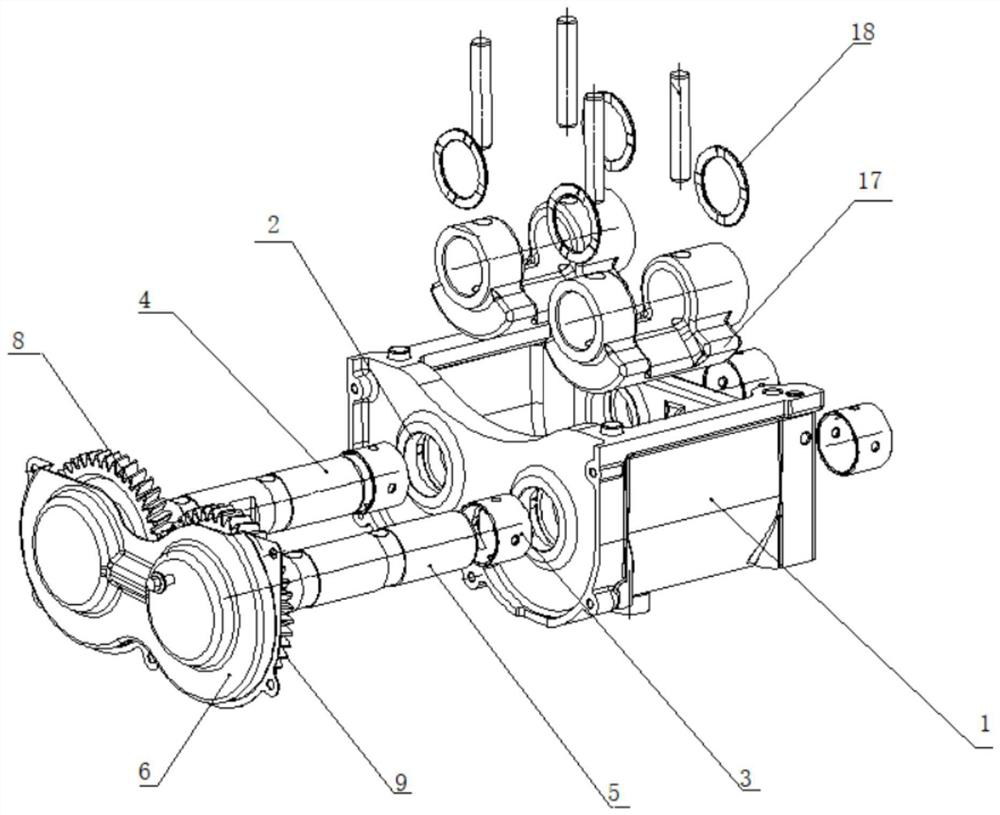

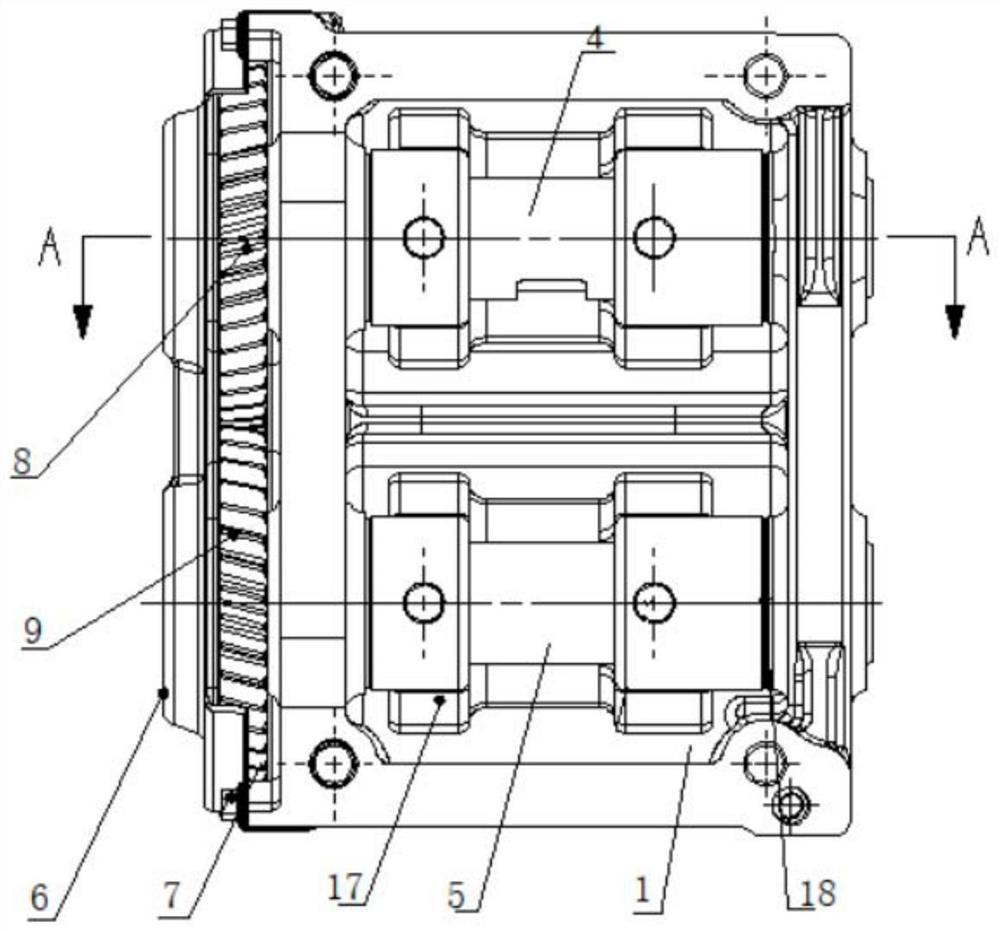

Bearing unit for supporting transmission shaft and gear reducer

InactiveCN102996630AImprove performanceClearance remains stableRoller bearingsBearing componentsDrive shaftGear wheel

The invention relates to a bearing unit for supporting a transmission shaft, which comprises an inner ring, an outer ring, a sealing member, and tapered rollers; two tapered rollers are respectively disposed between the inner ring and the outer ring; the inner ring has a fission structure; the outer ring has an integrated structure; a sealing member is disposed between the outer ring and the inner ring. The invention also relates to a gear reducer which mainly comprises a casing, a transmission shaft, a driving bevel gear, and a driven bevel gear; the transmission shaft is mounted on the casing through the bearing unit; the outer transmission shaft of the bearing unit is equipped with a retaining locking nut. The reducer improves the stability in bevel gear operation, changes traditional assembling methods for obtaining a required bearing clearance by replacing a shim and repeatedly adjusting, omits clearance adjustment, greatly improves the manufacturability and reliability of reducer assembling, reduces complicated process flow for original assembling, and improves production efficiency. In addition, the invention also has the advantages of compact structure, easy mounting and dismounting, and the like.

Owner:TIANJIN HUAYE RONGCHENG PRECISION MACHINERY +1

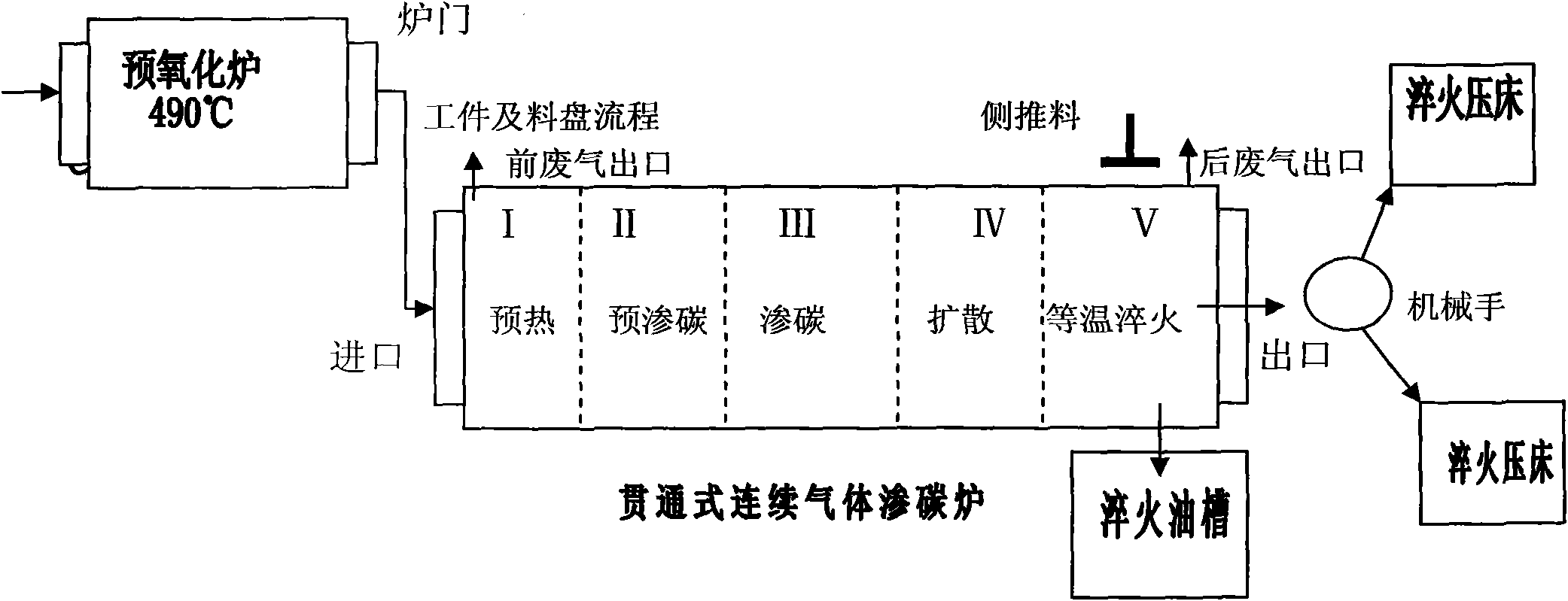

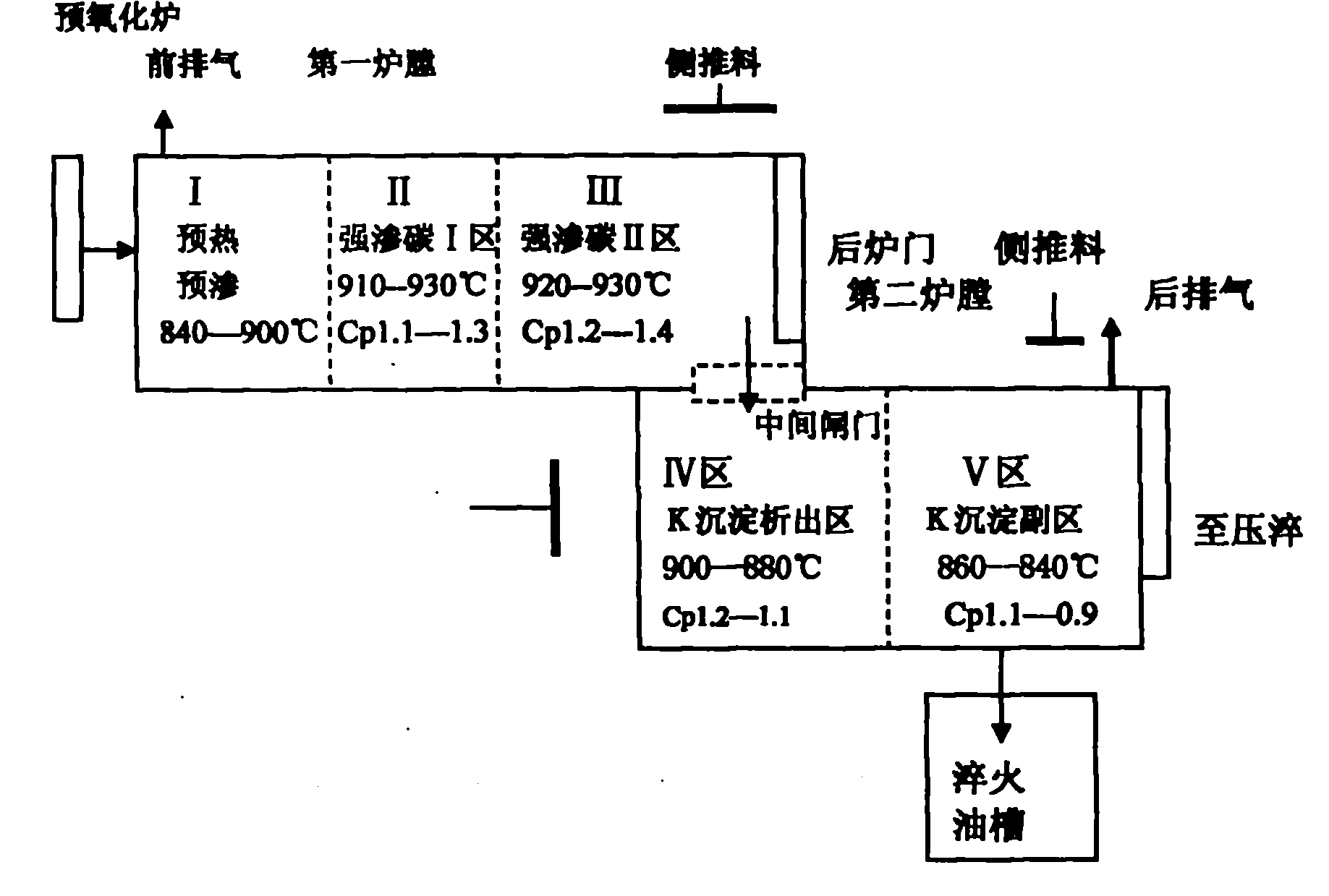

Double-hearth continuous rare earth carburizing equipment and process thereof

InactiveCN102191451AIncrease carburizing speedIncrease the diffusion coefficientSolid state diffusion coatingCarbon potentialRare earth

Owner:哈尔滨意锋稀土材料开发有限公司

Pneumatic tire

ActiveUS9139047B2Improve wear resistanceAvoid early wearSpecial tyresPneumatic tyre reinforcementsInternal pressureGround contact

A tire contour shape is formed by a single arc in a condition in which tire flattening rate is more than 55% and less than 70% and internal pressure is 5%. Shoulder lateral grooves extend at an angle α of 80 to 90° from the axially outer side of the tread ground-contact edge to the axially inner side of the tire, and the tire axially inner ends terminate within the shoulder land portion. A tire axial distance Ds between the tire axially inner end and the shoulder circumferential main groove is in the range of 3.5 to 5.5 mm, the shoulder lateral groove has the deepest part where the groove depth is largest, and the groove depth of the deepest part is 70 to 90% of the groove depth of the shoulder circumferential main grooves.

Owner:SUMITOMO RUBBER IND LTD

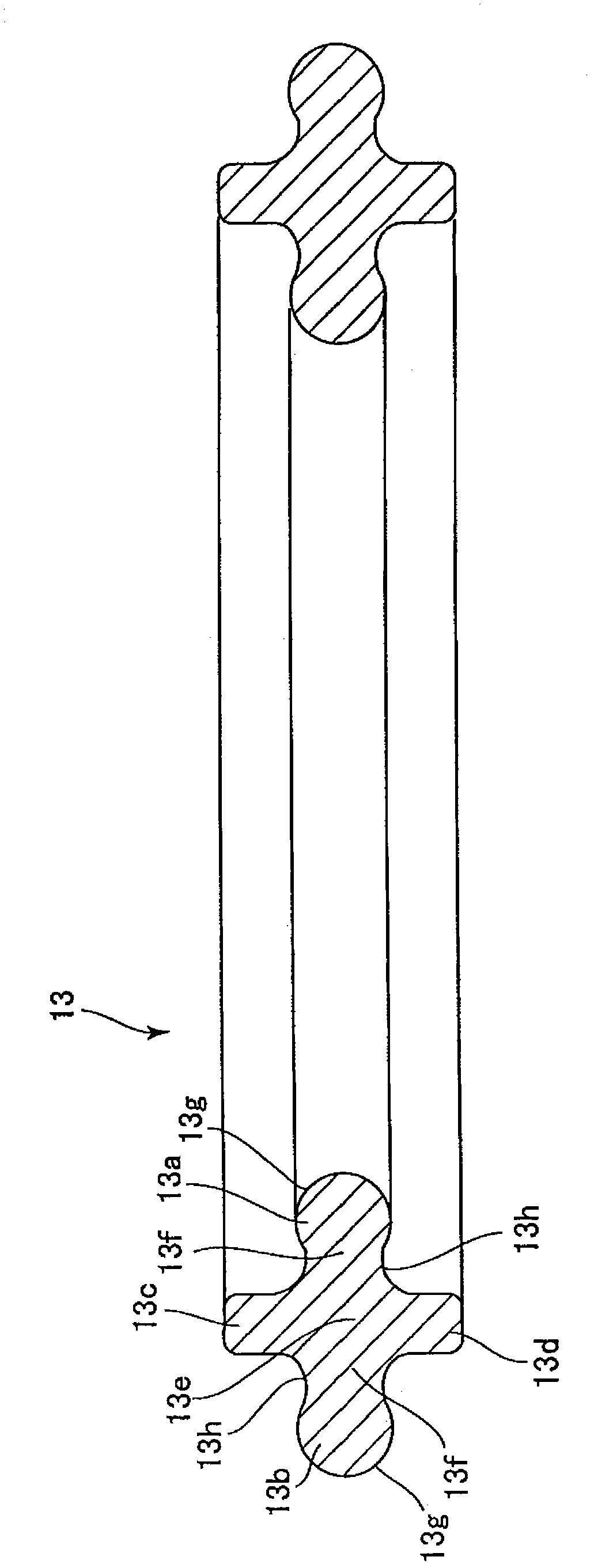

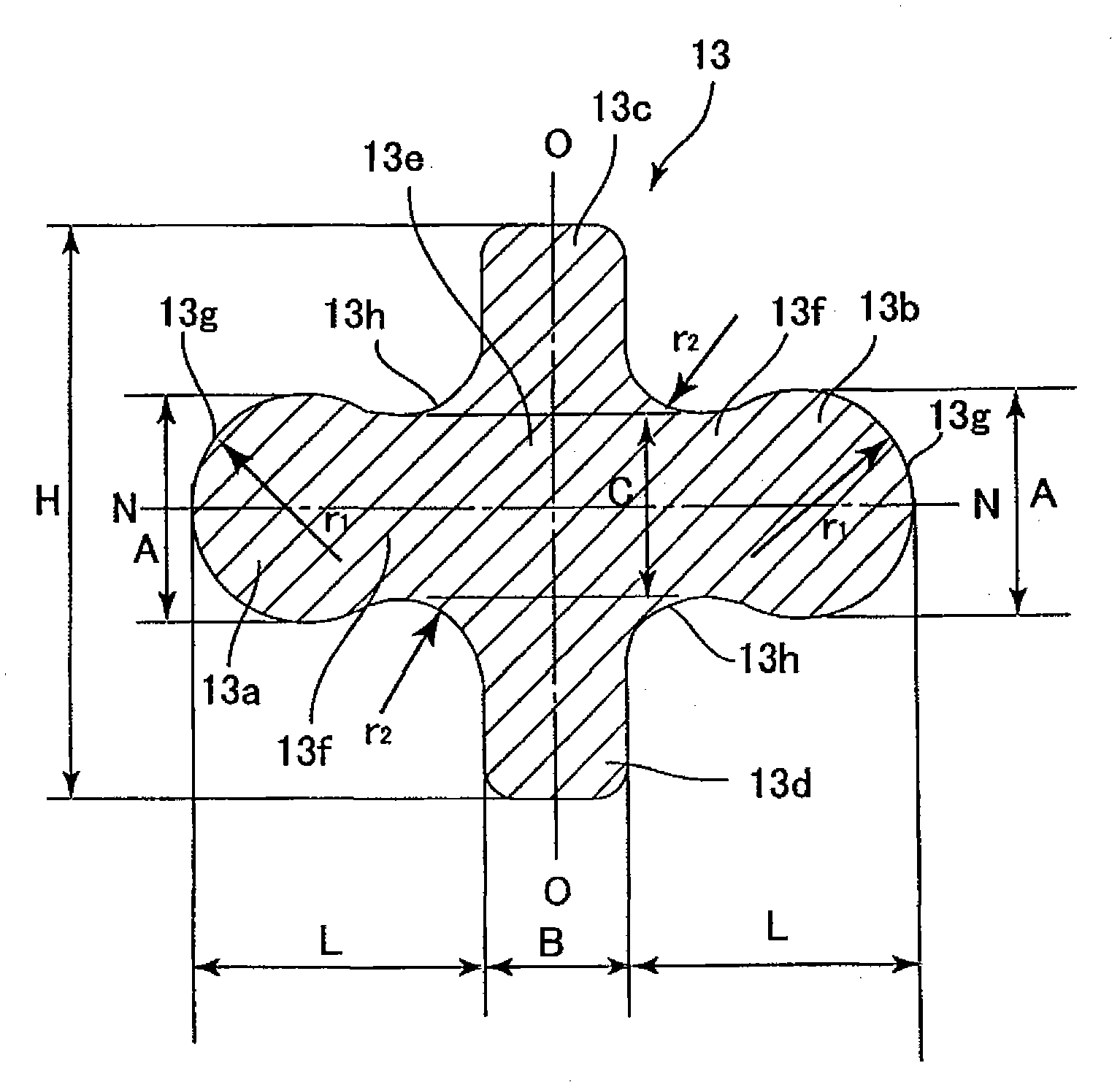

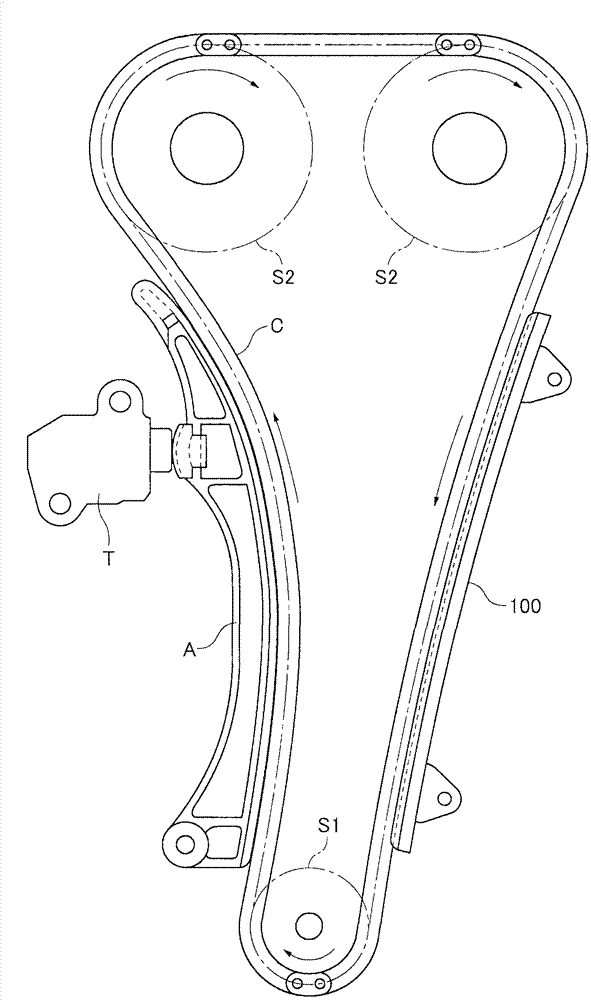

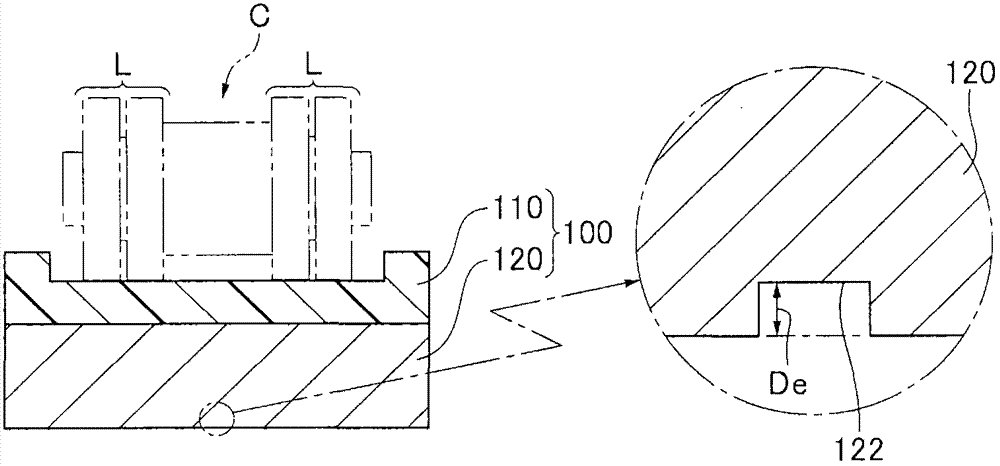

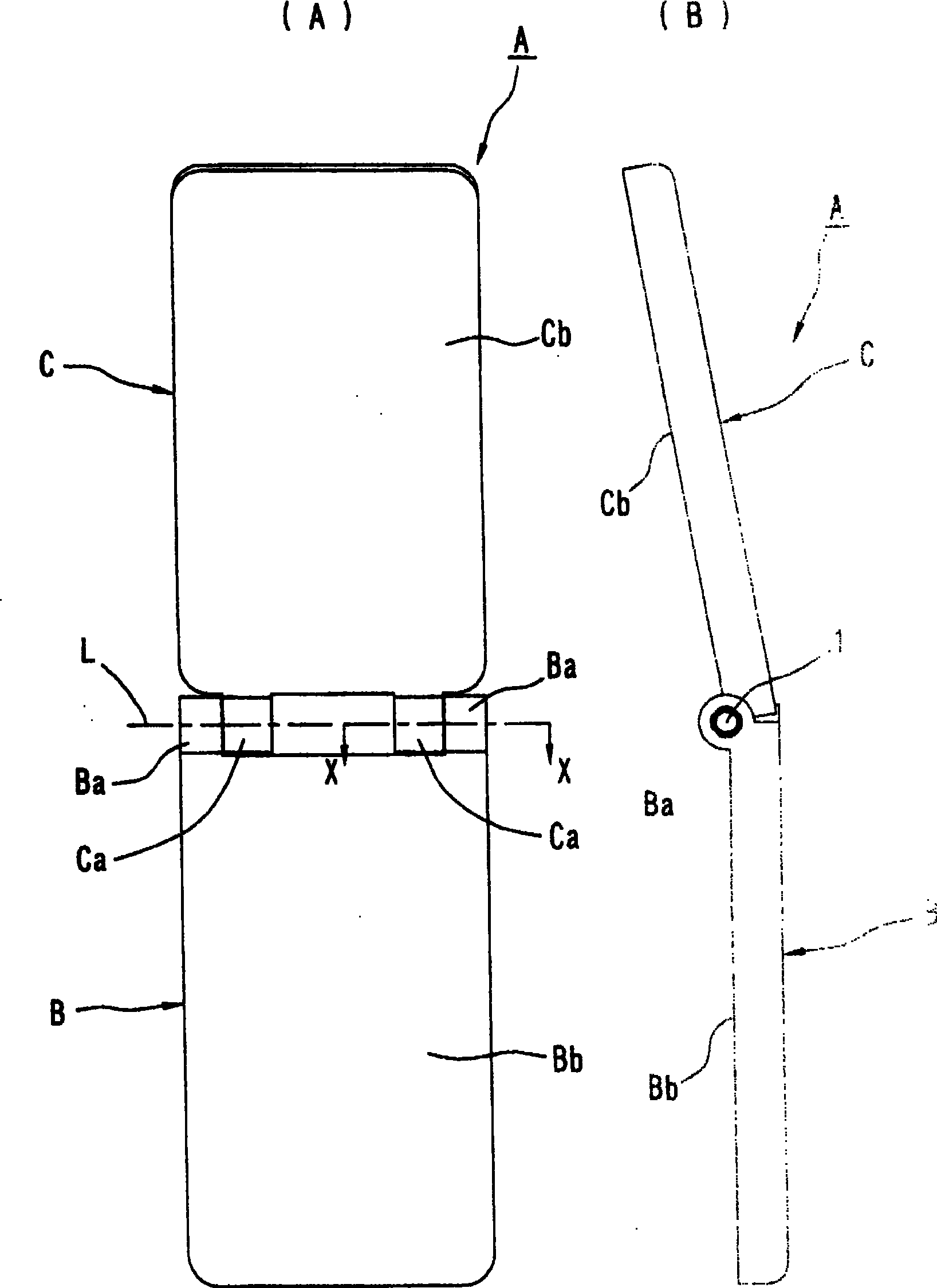

Sealing chain

ActiveCN102146984AEnsure contact pressureIncrease contact pressureDriving chainsStress concentrationContact pressure

The invention discloses a sealing chain, which can appropriately ensure the contacting pressure between a first lip part (13a) of a sealing component (13) and a plate, inhibits the unevenness of the contacting pressure even when the sealing chain is obliquely erected and the sealing compression amount becomes uneven, and eases the stress concentration of each lip part (13a, 13b, 13c, 13d) under the state that the sealing component (13) is compressed. The first and second lip parts (13a, 13b) extending along a radial direction from a central base (13e) are characterized in that the widths (C, A) of the radial middle parts are larger than the width (B) of the third and the fourth lip parts (13c, 13d); a necking part (13f) having a width being smaller than the radial middle part is disposed at the radial base end; the necking part (13f) is provided with a bending recessed surface (13h).

Owner:DAIDO KOGYO CO LTD

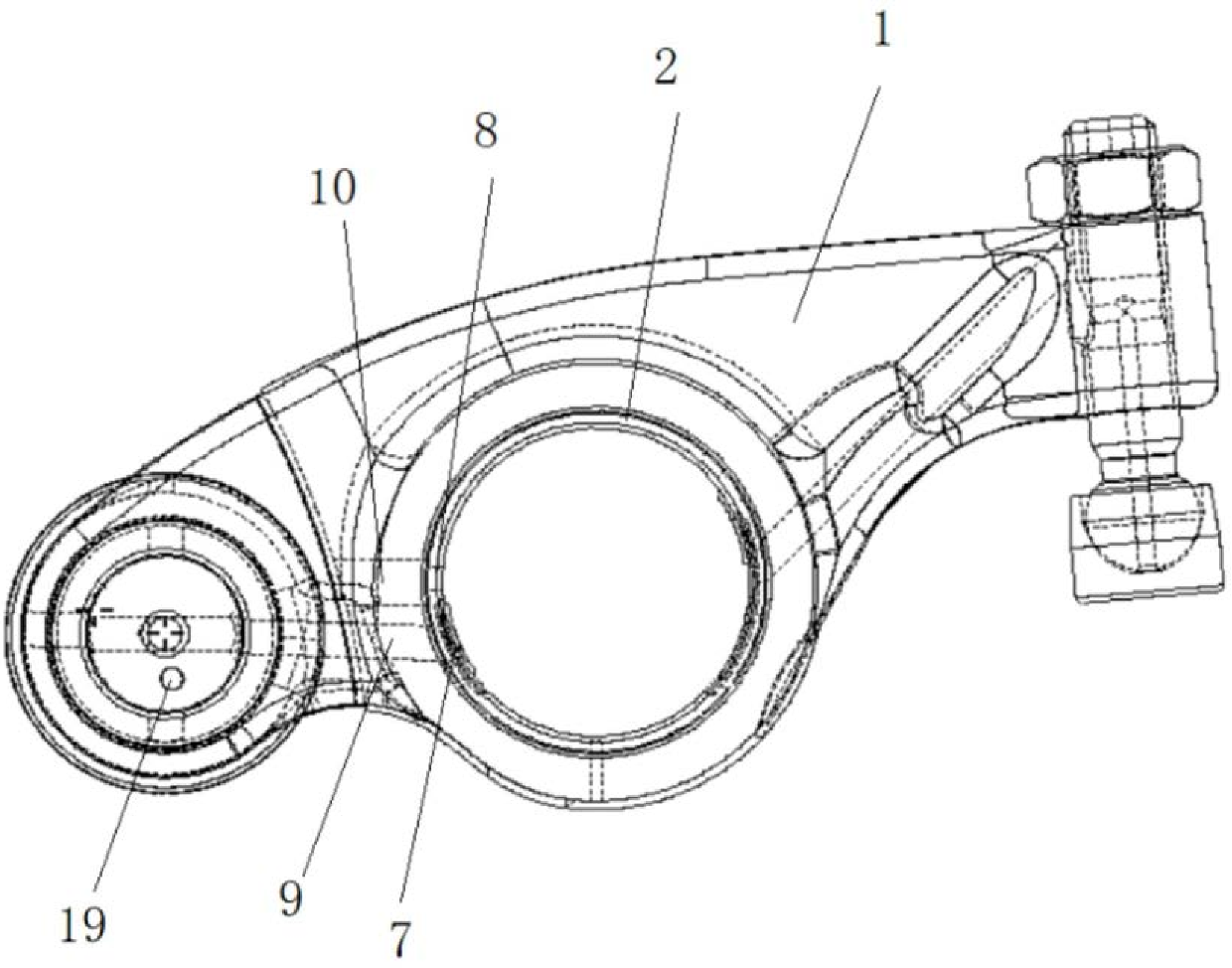

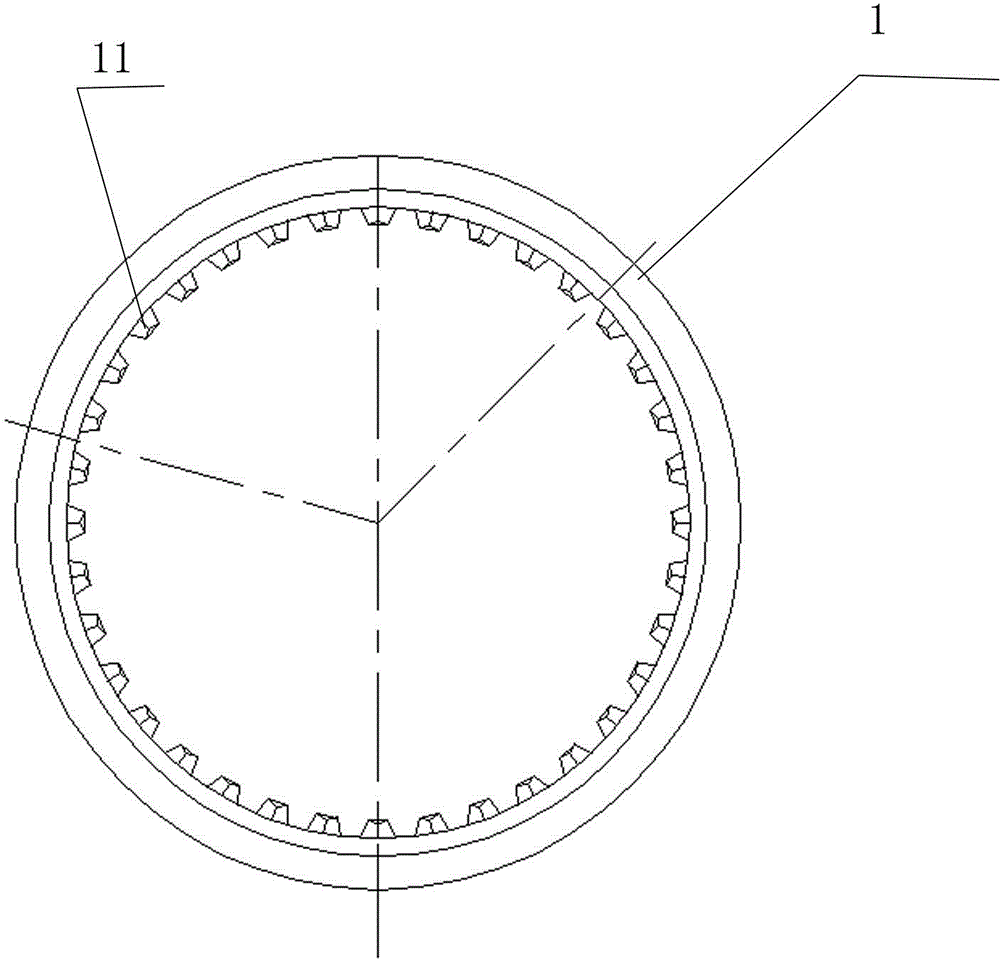

Inner and outer rolling wheel type rocking arm with lubricating structure

PendingCN110552751AAvoid early wearImprove lubrication and heat dissipationValve arrangementsLubrication of auxillariesRocker armFast flow

The invention discloses an inner and outer rolling wheel type rocking arm with a lubricating structure. The inner and outer rolling wheel type rocking arm with the lubricating structure is characterized in that a rocking arm shaft is provided with a first radial oil outflow hole and a second radial oil outflow hole communicating with a machine body main oil channel; a first oil passing channel anda second oil passing channel communicating with the first radial oil outflow hole and the second radial oil outflow hole correspondingly are arranged in a rocking arm body; a lubricating oil way is arranged in a rolling wheel shaft; one end of the lubricating oil way communicates with the first oil passing channel, and the other end of the lubricating oil way communicates with a gap between the rolling wheel shaft and an inner rolling wheel; the inner rolling wheel is internally provided with a radial oil channel; one end of the radial oil channel communicates with the gap between the rollingwheel shaft and the inner rolling wheel, and the other end of the radial oil channel communicates with a gap between an outer rolling wheel and the inner rolling wheel; and the second oil passing channel communicates with a gap between the outer rolling wheel and an avoiding area of the rocking arm body. The inner and outer rolling wheel type rocking arm with the lubricating structure makes machine oil fast flow to various gaps of rocking arm shaft parts to perform sufficient and in-time lubricating, abrasion caused by impacting and friction is reduced, and the service life of the rocking armis prolonged.

Owner:GUANGXI YUCHAI MASCH CO LTD

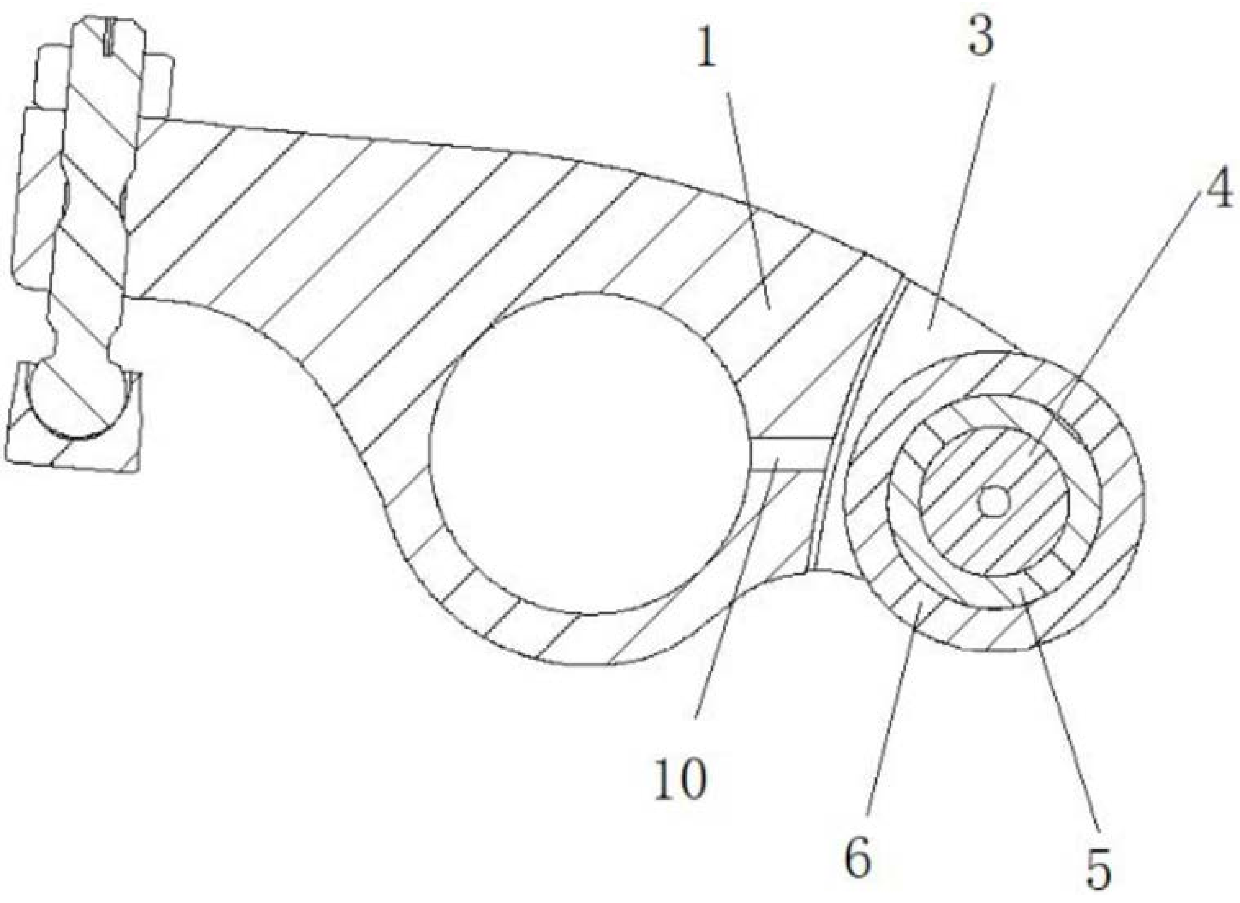

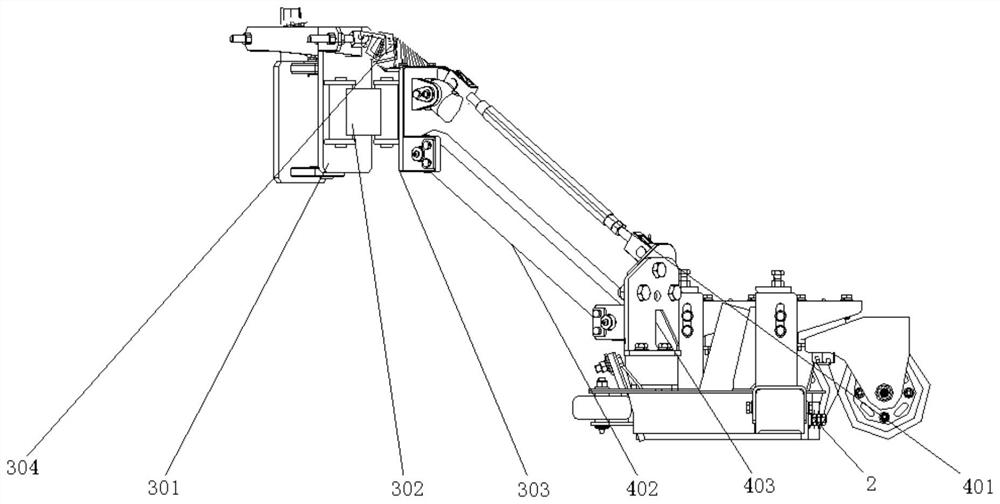

Lock ring type circular arc locking surface automobile synchronization regulator

InactiveCN104315018ALightweight and flexible gear shiftingImprove comfortMechanical actuated clutchesEngineeringLinkage concept

The invention discloses a lock ring type circular arc locking surface automobile synchronization regulator. A synchronization sliding sleeve (1) sleeves the outer circle of a synchronization tooth holder (4); a supporting assembly is arranged between part of the synchronization tooth holder (4) and the synchronization sliding sleeve (1); the rest of the synchronization tooth holder (4) is in transmission linkage with the synchronization sliding sleeve (1) through a spline combination; the synchronization sliding sleeve (1) rotates along with the synchronization tooth holder (4); two synchronization tooth rings (3) are pressed against two surfaces of the synchronization tooth holder (4); two synchronization cone hubs (2) are correspondingly arranged on the outer sides of the two synchronization tooth rings (3); each synchronization cone hub (2) is provided with an outer cone surface, and each synchronization tooth ring (3) is provided with an inner cone surface; the inner cone surface of each synchronization tooth ring (3) is combined with the outer cone surface of the corresponding synchronization cone hub (2); a tooth-end locking chamfering surface I (5) of an inner spline (11) of the synchronization sliding sleeve (1) is set as a circular arc locking surface I; a tooth-end locking chamfering surface II (6) of an outer spline (12) of each synchronization tooth ring (3) is set as a circular arc locking surface II.

Owner:李汉祥

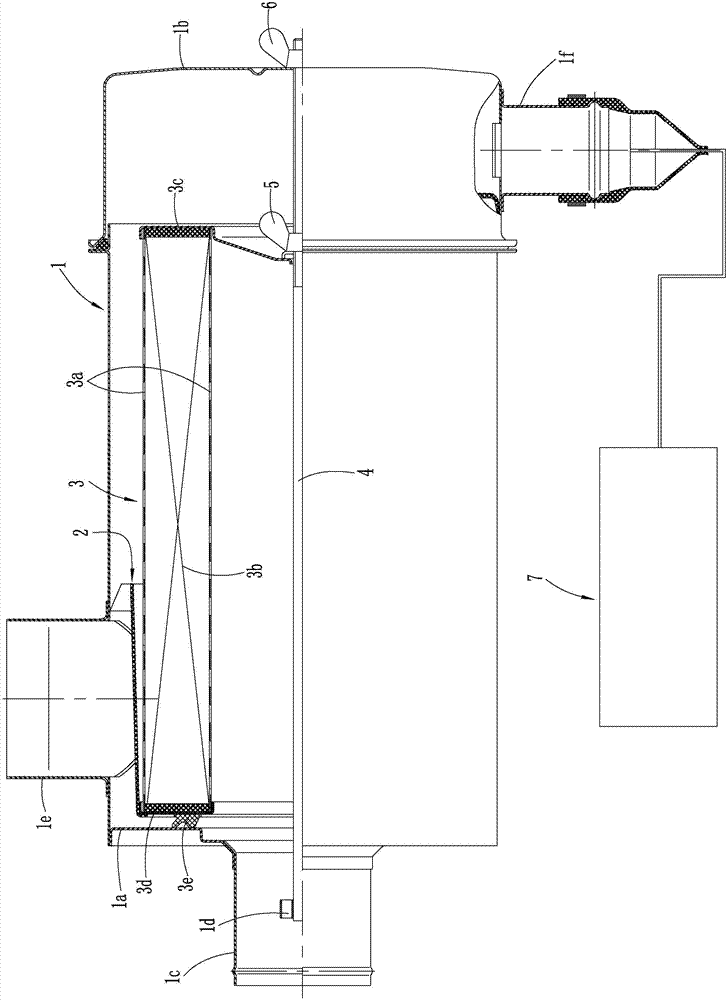

Air filter assembly

The invention discloses an air filter assembly, which structurally comprises a shell, a blade ring, a filter cartridge and a pull rod, wherein a stop cover is arranged on one end in an axial direction of the shell, a sealing cover is arranged on the other end in the axial direction, the stop cover is provided with an exit pipe coaxial to the shell, and the pull rod is arranged in the exit pipe through a support; the filter cartridge externally sleeved with the blade ring penetrates through the other end in the axial direction of the shell, the penetration end of the pull rod is arranged in the shell, the blade ring is arranged on one side in the axial direction in the shell, the flange of the blade ring is in contact with a retainer ring of the filter cartridge, the pull rod is screwed with a nut of the sealing ring in contact with the filter cartridge, so that the sealing ring of the filter cartridge is in tight contact with the inner wall of the stop cover, and an intake pipe is arranged on a place on one side in the axial direction of the circumferential sidewall of the shell, which corresponds to the blade ring; the sealing cover penetrates through the penetration end of the pull rod, and the pull rod is screwed with a nut in contact with the sealing cover, so that the sealing cover is connected with the other end in the axial direction of the shell, and the sealing cover is provided with a dust removal bag; and the dust removal bag is communicated with a dust collector. The air filter assembly has the advantages of better filtering performance, stronger reliability, and capability of avoiding early abrasion of a locomotive engine to a certain degree.

Owner:BENGBU HUATAI FILTER

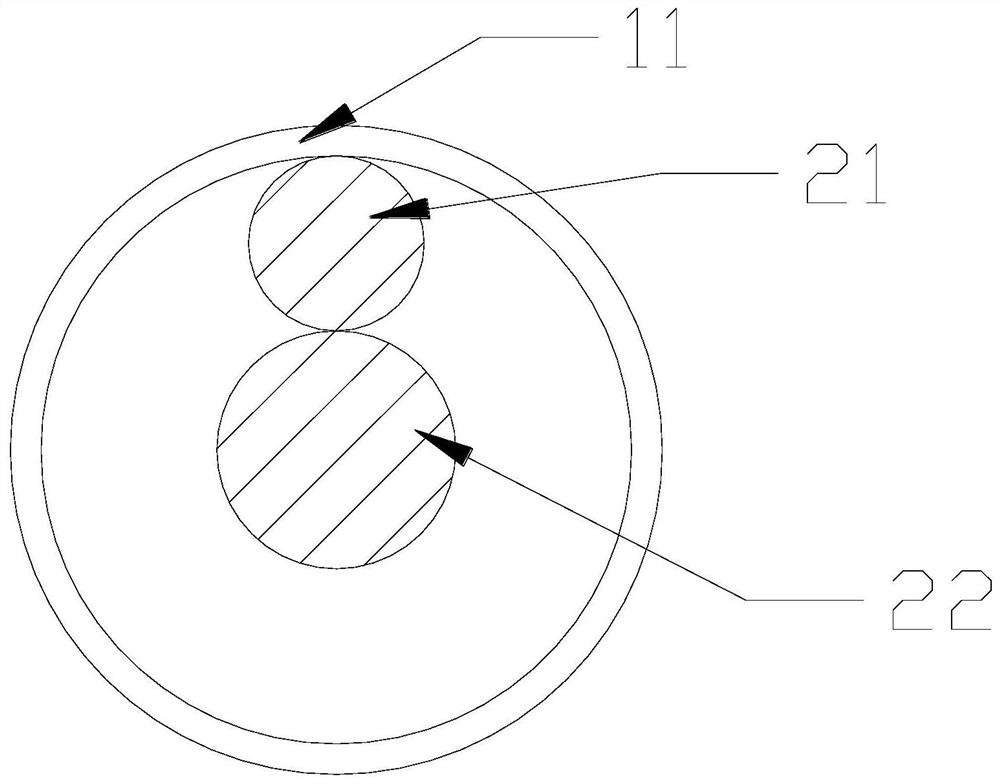

Engine balance shaft structure

The invention discloses an engine balance shaft structure. The engine balance shaft structure comprises a balance shaft cavity; two corresponding bearing holes are formed in the two opposite side walls of the balance shaft cavity respectively, a first balance shaft and a second balance shaft are installed in the two bearing holes through bearing bushings respectively, and revolute pairs are formedamong the first balance shaft, the second balance shaft and the corresponding bearing bushings; a cover plate is arranged on one outer side of the balance shaft cavity, and the cover plate and the balance shaft cavity are connected with each other to form a gear cavity; a driving gear and a transmission gear which are meshed with each other are arranged in the gear cavity, inner holes of the driving gear and the transmission gear are fixed to one ends of the first balance shaft and the second balance shaft respectively, an oil way for lubricating the bearing bushings is arranged in the balance shaft cavity, and an oil return hole and an oil return opening are formed in the bottom of the balance shaft cavity and the bottom of the gear cavity respectively. According to the engine balance shaft structure, the problems of accelerated aging of engine oil of the balance shafts and low oil pressure of the bushings at the two ends are solved, and the damping effect of the balance shafts is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

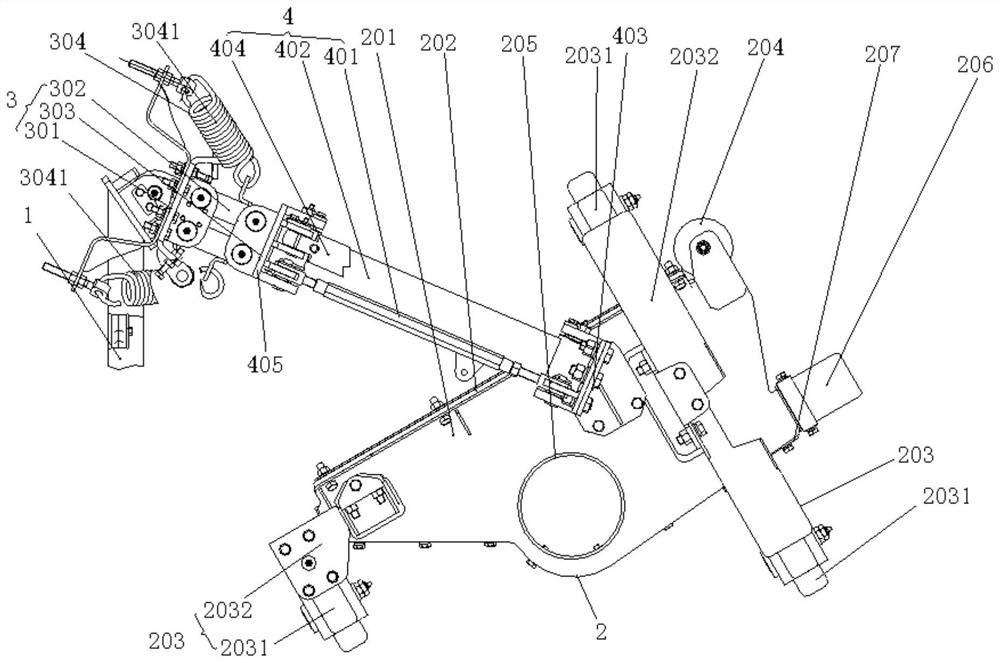

Side suction nozzle device for road sweeper and road sweeper

The invention discloses a side suction nozzle device for a road sweeper and the road sweeper. The side suction nozzle device for the road sweeper comprises a mounting base which is used for being mounted and fixed on the road sweeper, and a side suction nozzle which is used for walking in a manner of being attached to a curb and sucking garbage on a curb strip. A horizontal elastic translation mechanism for forcing the side suction nozzle to perform self-adaptive translation in the horizontal direction by utilizing elastic force so as to enable the side suction nozzle to stably fit the curb towalk and a vertical translation mechanism for controlling the side suction nozzle to perform translation motion in the vertical direction are arranged between the mounting base and the side suction nozzle; and the side suction nozzle is connected to the mounting base through the horizontal elastic translation mechanism and the vertical translation mechanism and deflects to the outside of the vehicle body from the side direction of the vehicle body of the road sweeper. It can be ensured that the side suction nozzle has the functions of horizontal and vertical translation collision prevention,dust collection close to the curb and real-time lifting during operation, and the device can be suitable for water-free dust suppression pure suction type operation of dry type dust removal of the curb strips on the two sides of a vehicle.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

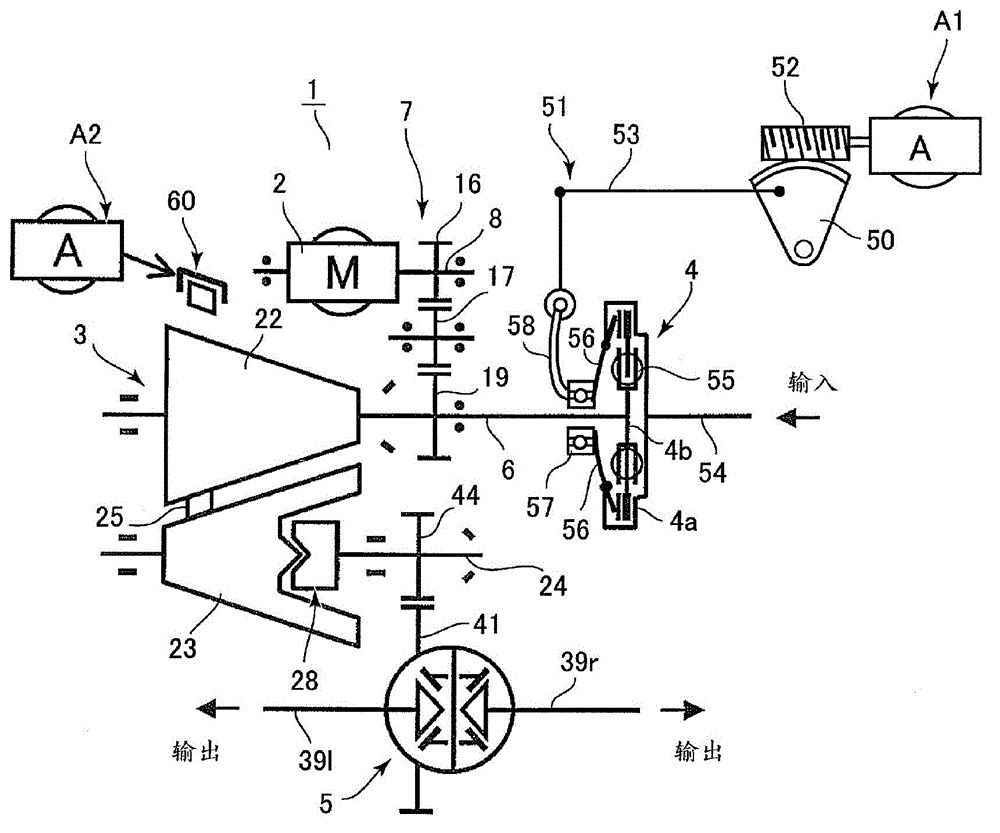

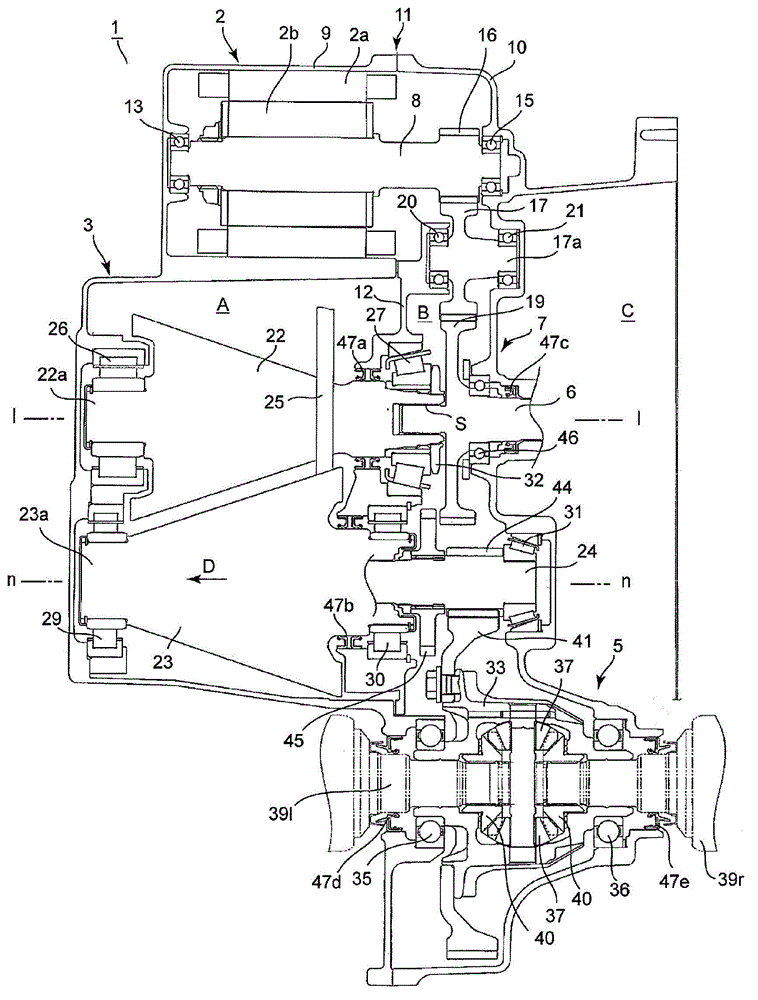

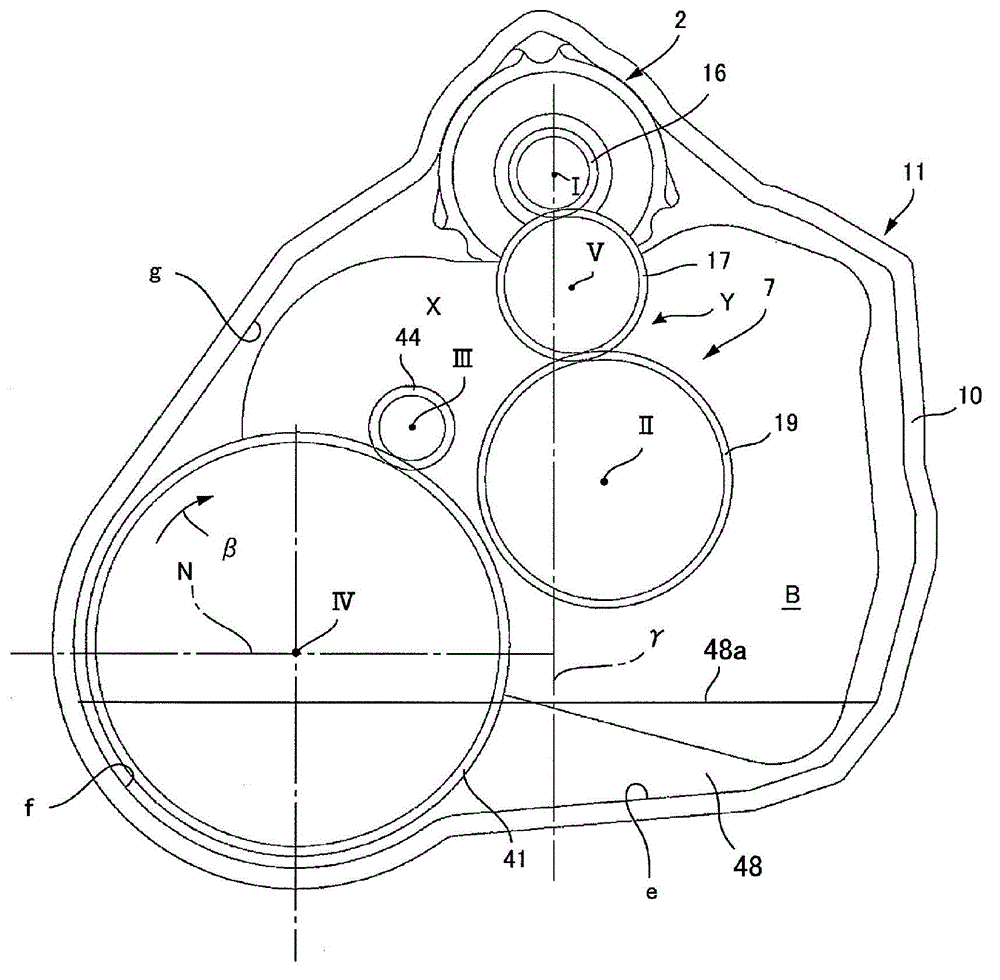

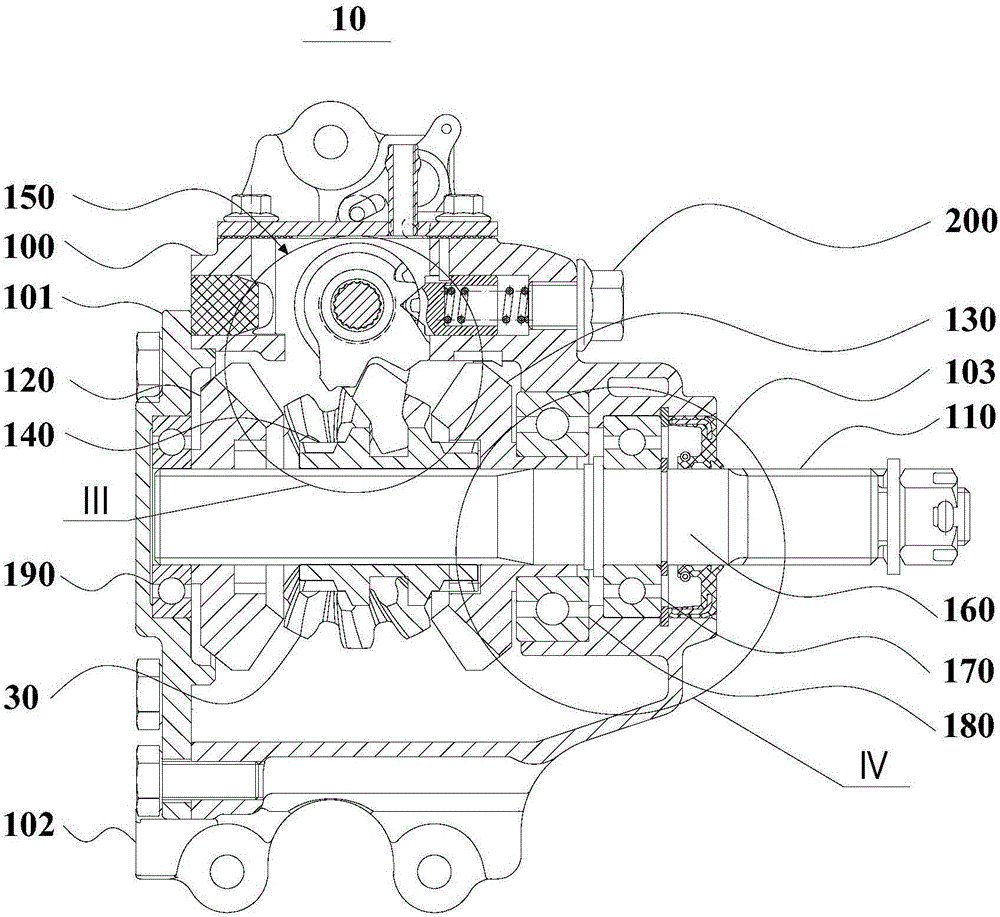

hybrid drive

ActiveCN102725162BAvoid early wearImprove consumption rateRoad transportGas pressure propulsion mountingEngineeringActuator

Owner:AISIN AW CO LTD

Design method of shock absorber support locating device

InactiveCN103157937AHigh positioning accuracyImprove comfortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOblique angle

The invention relates to a design method of a shock absorber support locating device. The shock absorber support locating device comprises an angular adjustment disc, height adjusting devices, a locating beam and a locating pin, wherein a cross section of the angular adjustment disc is of a carving-lined oblique angle. The number of the height adjusting devices is two sets and the height adjusting devices are respectively arranged at two ends of the locating beam. One end of each set of the height adjusting device is fixedly connected with the locating beam and the other end of the each set of the height adjusting device is fixed with the angular adjustment disc. The angular adjustment disc is connected with a shock absorber support through the locating pin. The design method of the shock absorber support locating device has the advantages of improving the locating precision of cars in the vertical direction, up and down heights and the front and down directions.

Owner:SHAANXI EUROSTAR AUTOMOBILE

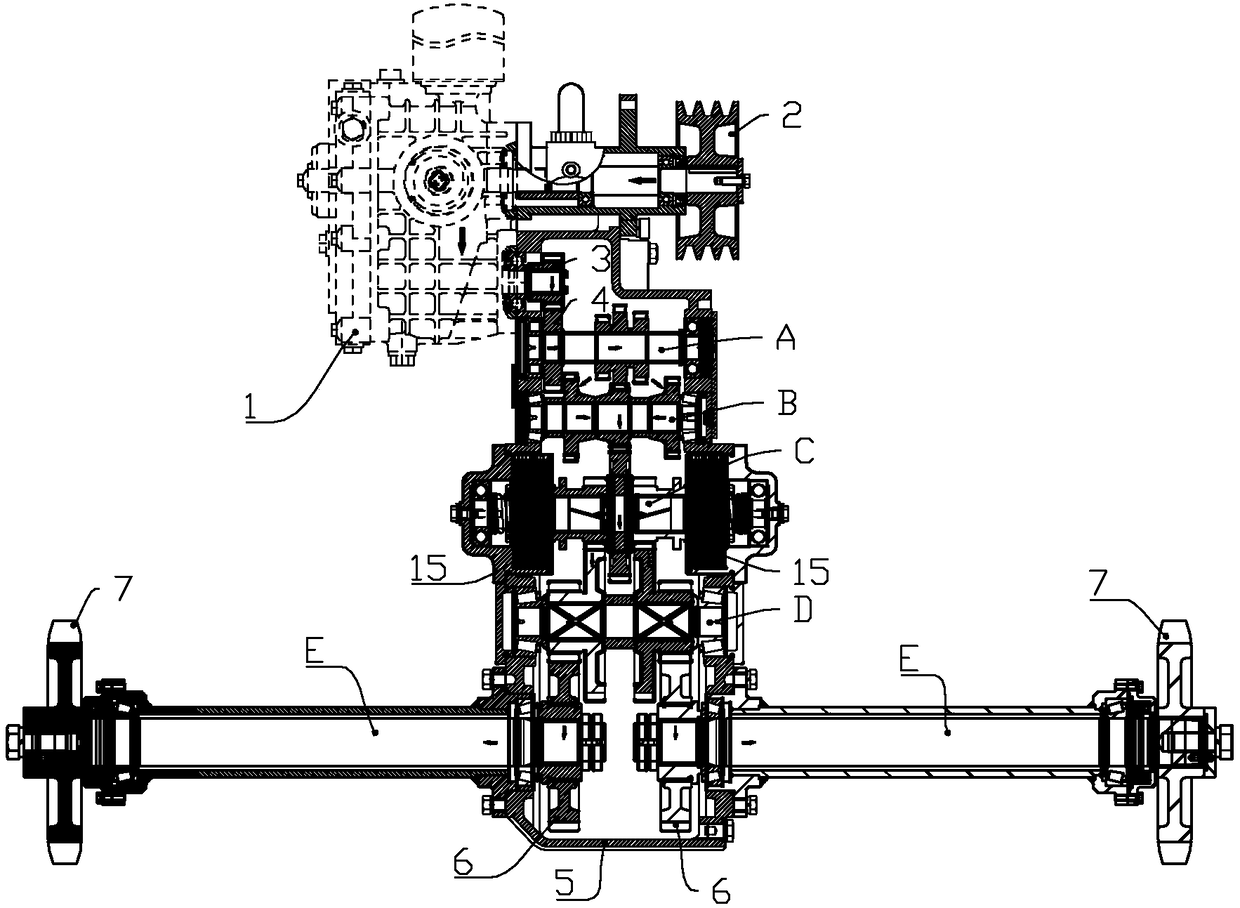

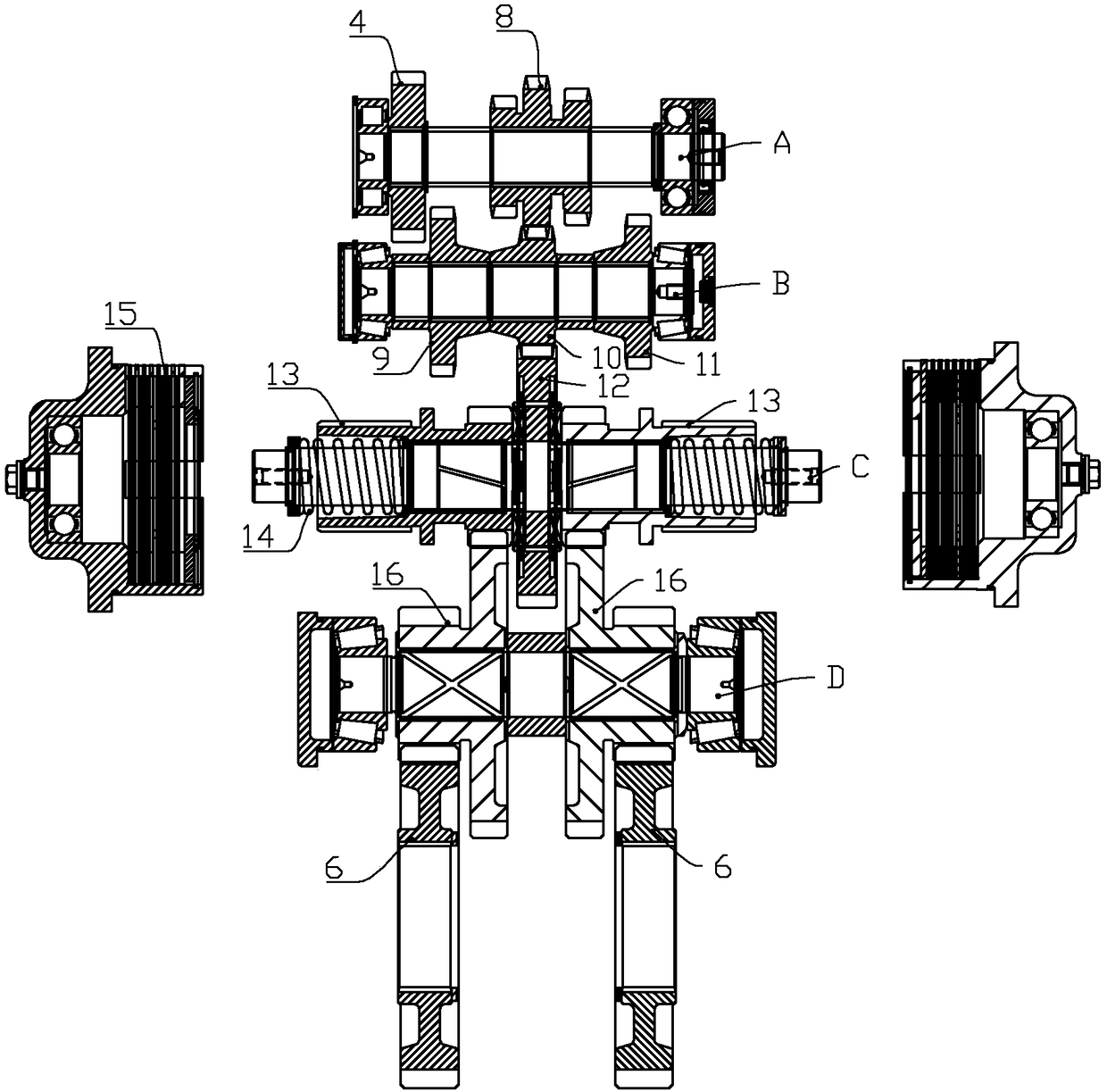

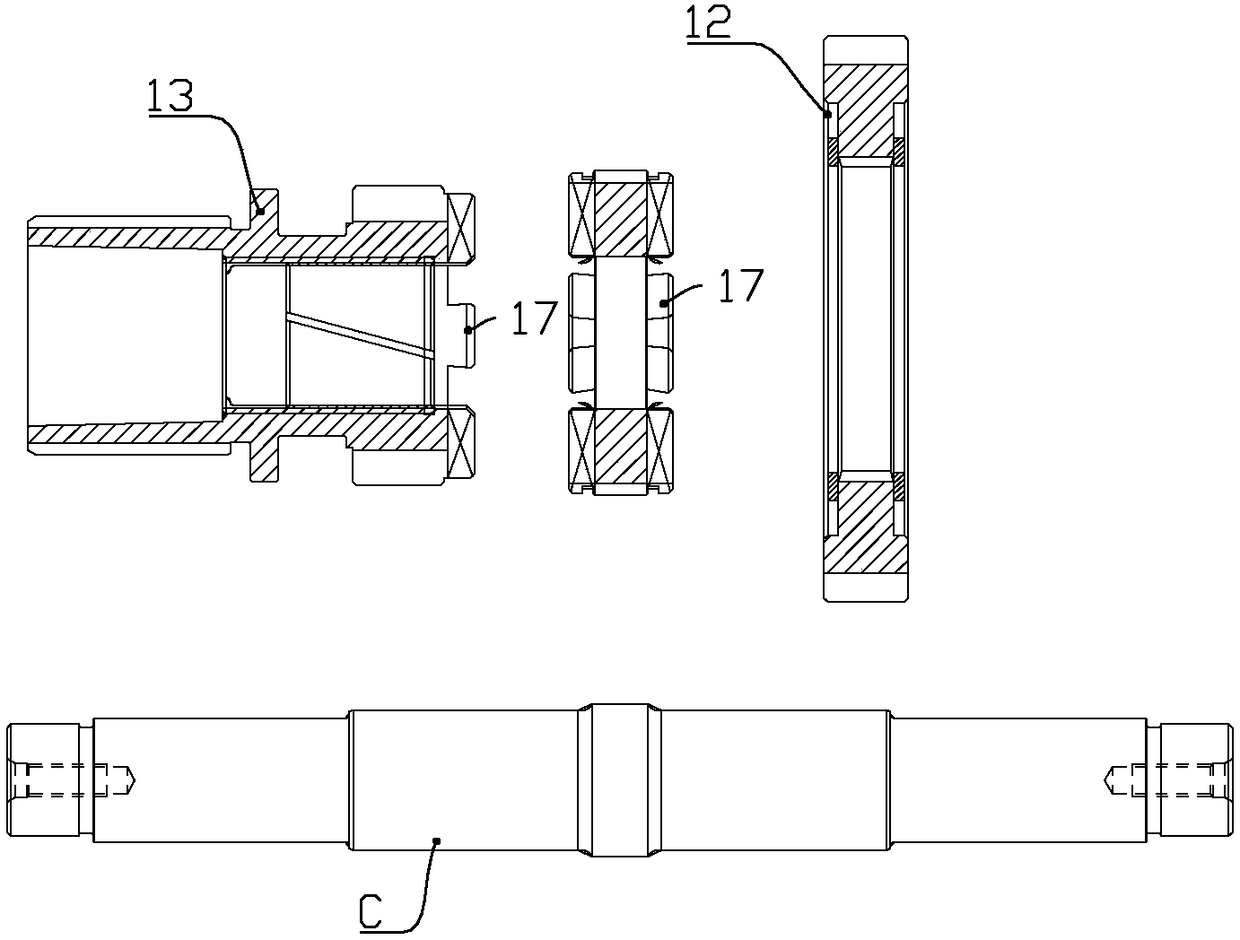

Rice harvester driving axle

PendingCN108124600AOutstanding and Beneficial Technical EffectsHigh precisionHarvestersLow noiseDrive shaft

The invention provides a rice harvester driving axle. The rice harvester driving axle comprises an integral type driving axle box shell body, wherein a shaft I, a shaft II, a shaft III and a shaft IVare sequentially mounted in the driving axle box shell body in parallel; two ends of four transmission shafts are matched on two side walls of the driving axle box shell body through bearings respectively; an input end of a driving axle box is matched with a static oil pressure speed changer; the input end of the static oil pressure speed changer is connected with an input belt wheel and an outputend of the static oil pressure speed changer stretches into the driving axle box shell body and is connected with an input gear; an output shaft transversely stretches out two sides of the output endof the driving axle respectively; the output shaft is connected with a final transmission large gear in the driving axle box shell body. The rice harvester driving axle provided by the invention is compact in structure; the driving axle box shell body adopts an integral type structure and has the advantages of good gear contact, low noise and long service life.

Owner:WENLING MINGHUA GEAR

Reverse gear device and motor tricycle

The invention discloses a reverse gear device and a motor tricycle and relates to the field of reverse gear devices. The reverse gear device comprises a shell, a spline shaft, a reverse gear bevel gear, a forward gear bevel gear, a clutch, a gear shifting fork part and an axial limiting part. The clutch is matched with a spline of the spline shaft and is located between the reverse gear bevel gear and the forward gear bevel gear. The gear shifting fork part is rotationally arranged in the shell so as to drive the clutch to be selectively matched with the reverse gear bevel gear or the forward gear bevel gear. The axial limiting part is arranged between the spline shaft and the shell and is used for limiting the axial movement of the spline shaft. The reverse gear device can solve the problem that the reverse gear device axially moves in the shell due to axial force of the spline shaft, and consequently the shell is punctured and is damaged, the installation precision and the transmission rigidity of the gears in the reverse gear device are improved, the problem that the gears of the reverse gear device are abraded in the early stage is solved, the service life of the reverse gear device is prolonged, and the risk brought to locomotives and users due to failure of the reverse gear device is avoided.

Owner:CHONGQING CHUANYU JINGGONG MACHINERY PARTS DEV

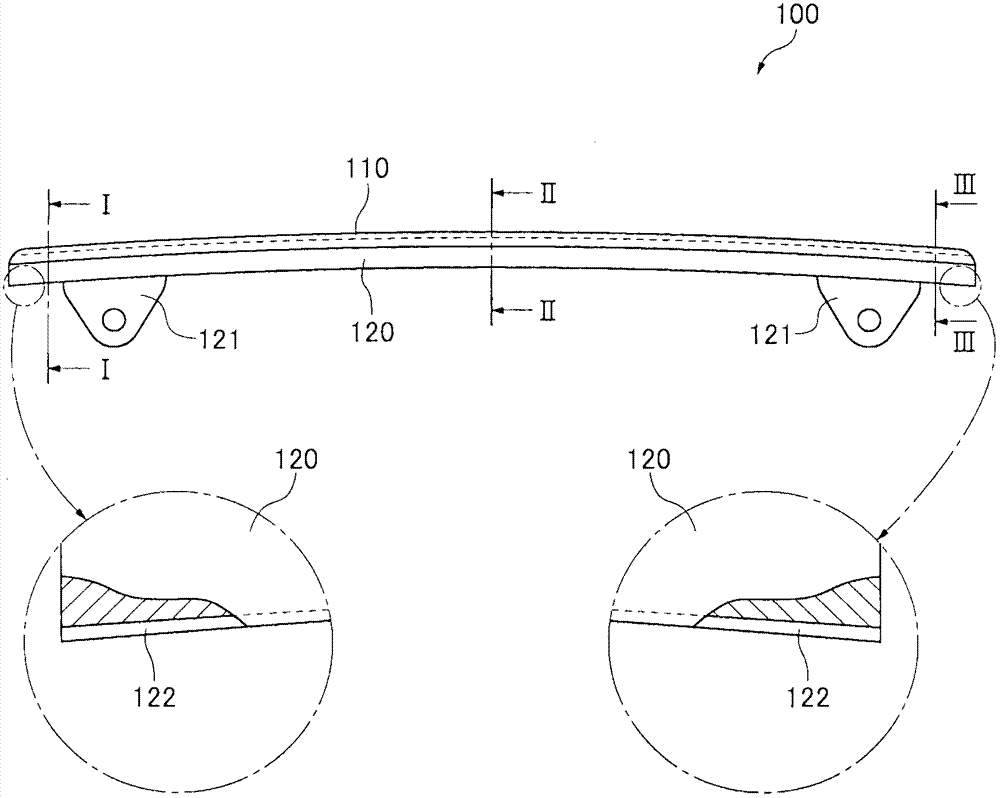

Stationary chain guide

Owner:TSUBAKIMOTO CHAIN CO

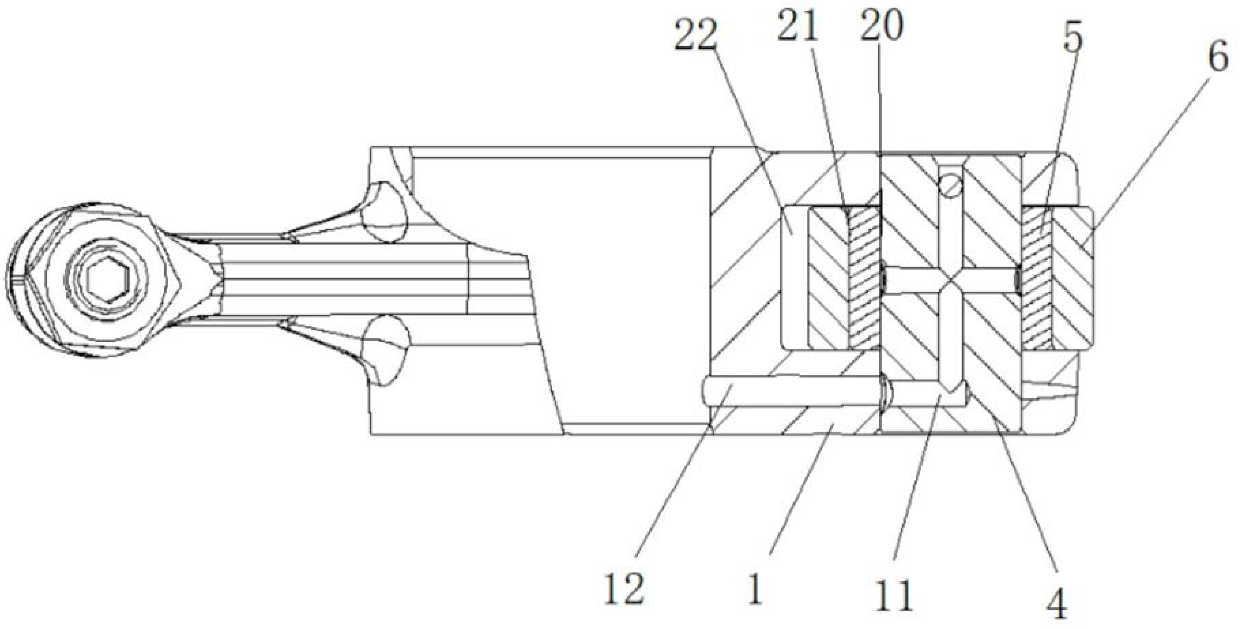

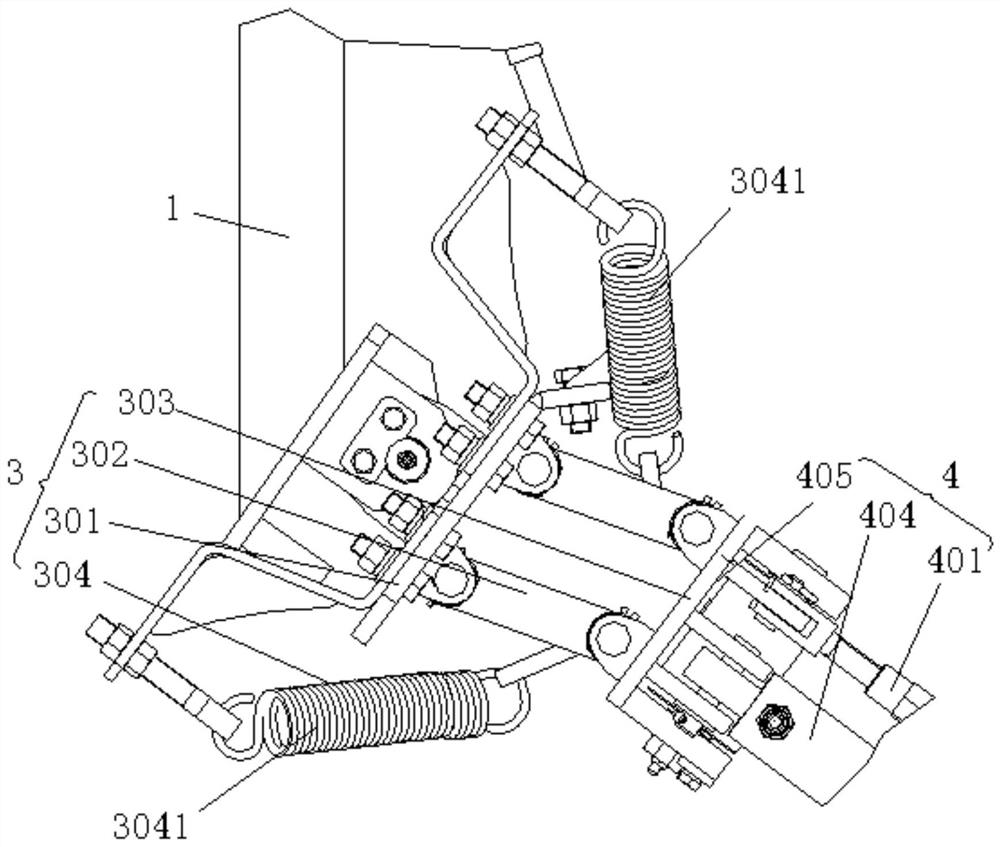

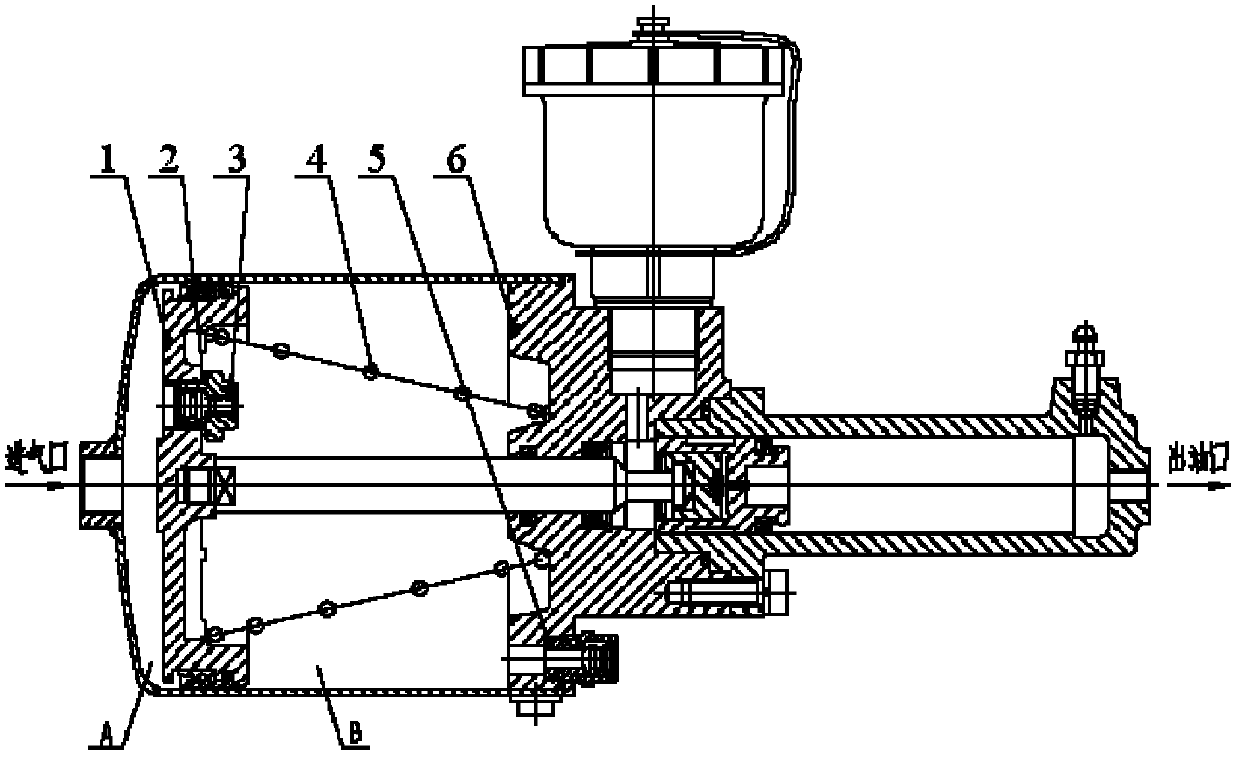

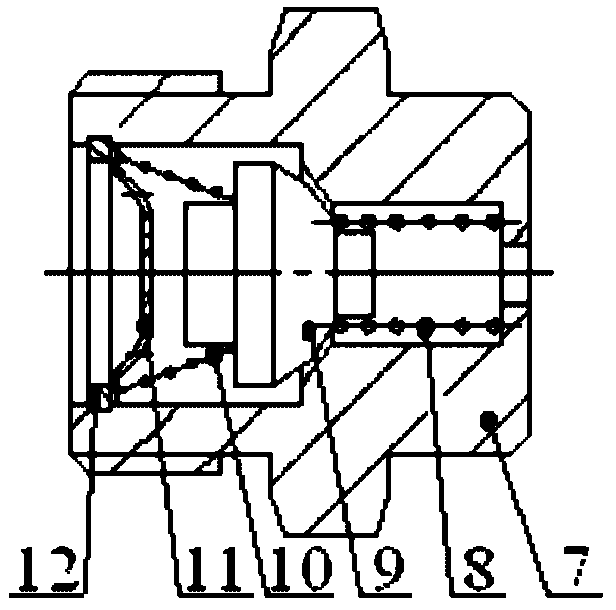

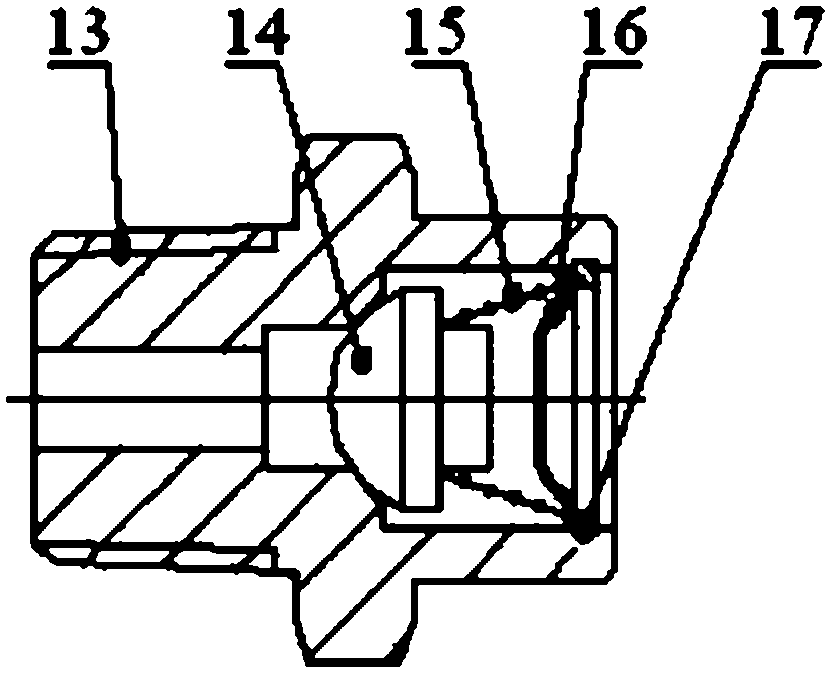

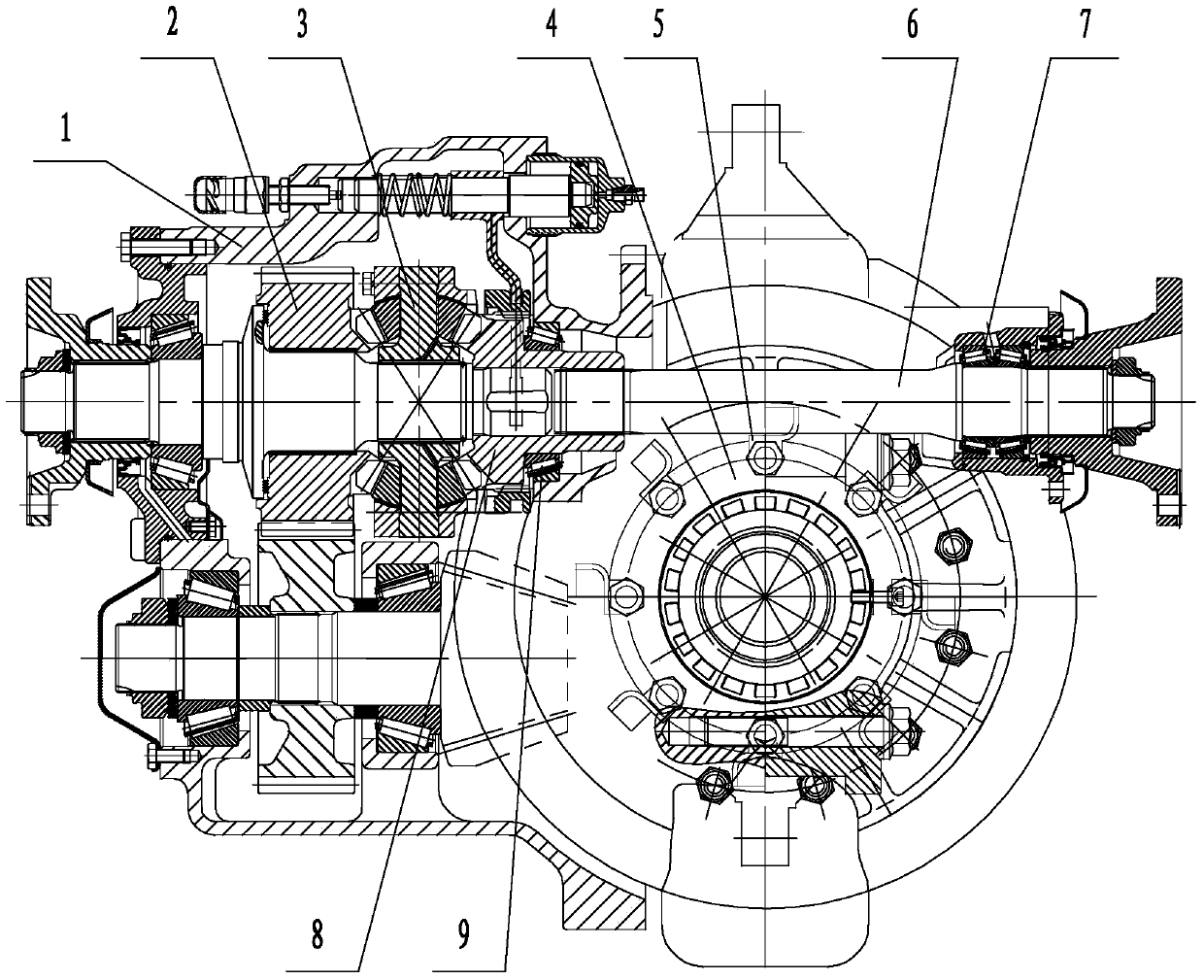

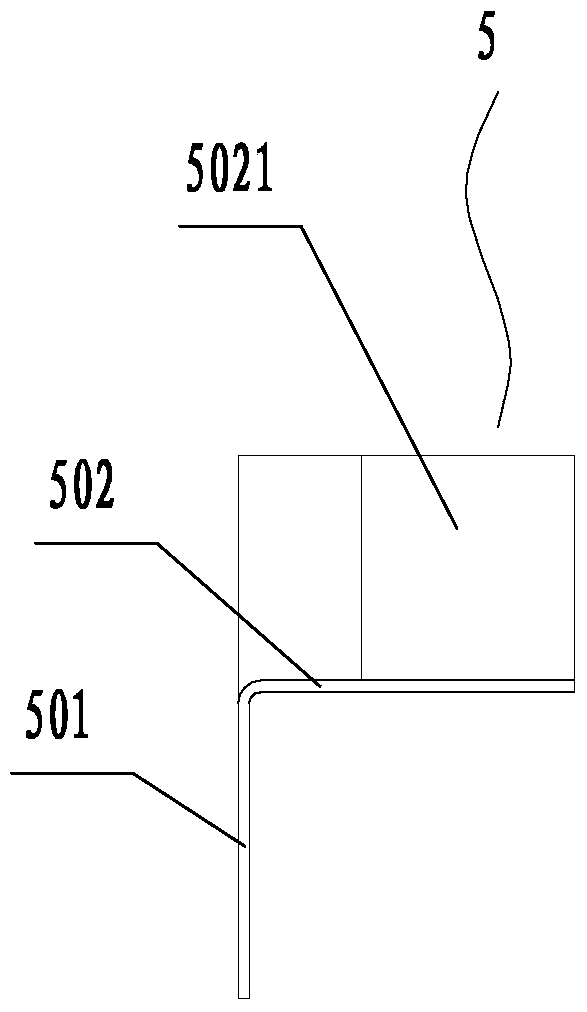

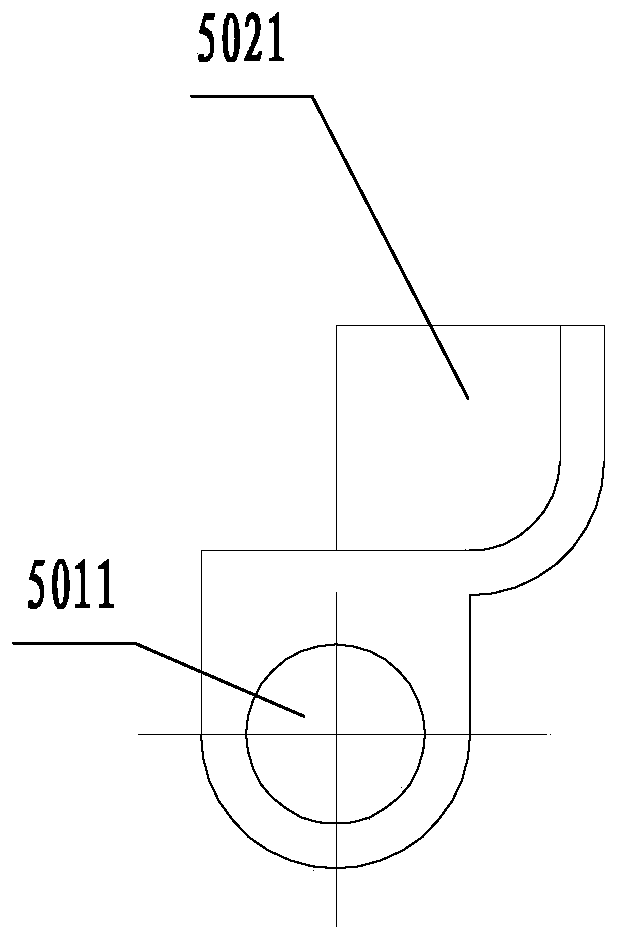

Air boost pump of engineering mechanical braking system

InactiveCN102431537AGuaranteed cleanlinessAvoid early wearBraking action transmissionReservoir arrangementsInternal respirationEngineering

The invention discloses an air boost pump of an engineering mechanical braking system. The air boost pump comprises a cylinder and a braking oil cylinder, wherein the cylinder comprises a cylinder shell, an air piston, an air piston return spring and an oil cylinder connecting cover; a piston rod of the gas piston passes through a hole of the oil cylinder connecting cover and is connected with an oil piston of the braking oil cylinder; a rodless cavity and a rod cavity are formed in the cylinder; an air inlet of the air boost pump is communicated with the rodless cavity of the cylinder; a two-way valve assembly is arranged on the air piston; and a one-way valve assembly (5) is arranged on the oil cylinder connecting cover. With the adoption of the above technical scheme, dust gas of an external severe environment cannot enter an air chamber by using a structure of an internal respiration type boost pump and working principles of a one-way valve and a two-way valve; as long as an air source is ensured to be clean, the cylinder can be ensured not to be polluted, the cleanness of the air chamber is guaranteed, premature wear of an air piston leather ring is overcome, and the product reliability and durability are improved.

Owner:WUHU SHENGLI TECH SHARES

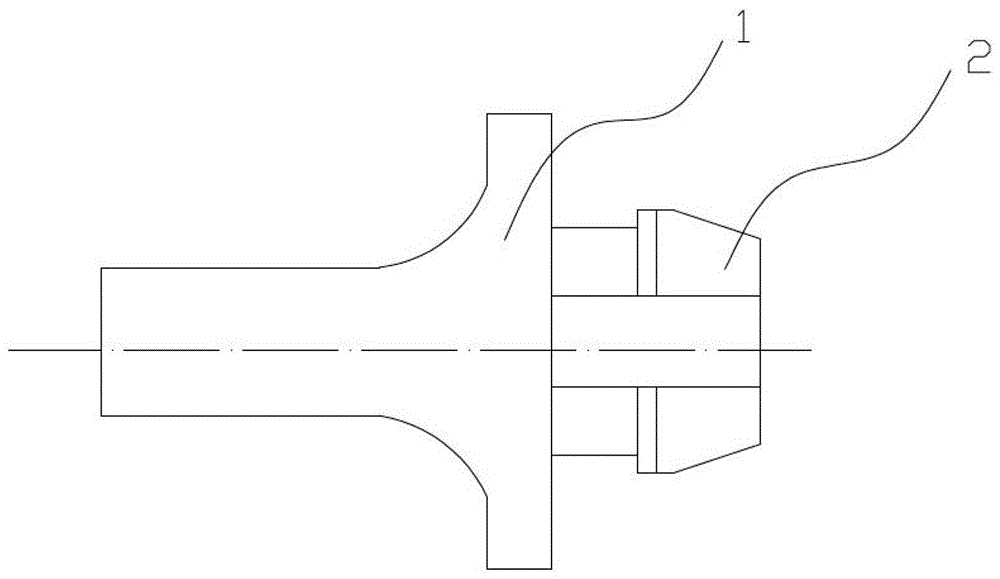

Rotary crusher and running method of raw material supply device used therein

This material feeding device is equipped with the material feeding rotary chute; a vertical directional support mechanism provided on a main spindle upper end supporting mechanism of the gyratory crusher and rotatably supporting the chute via a rolling bearing provided at a lower part of the chute; horizontal support rings disposed on the outer peripheral surface of the upper part of the chute with equal angular spaces; a horizontal support ring position adjuster for adjusting the position of the rings advancingly and retreatingly in relation to a center of the chute; and a motor connected to one horizontal support ring among the support rings for rotating the chute. To uniformly feed crushing raw material to a crushing chamber of a crusher by stably and smoothly rotating a material feeding rotary chute, and to prevent early damage of horizontal and vertical mechanical support parts for rotatably supporting the rotary chute.

Owner:日本阿尔斯泰克

A fixed chuck for an automobile accelerator cable

ActiveCN103863113BRestricted degrees of freedomInhibit sheddingPropulsion unit arrangementsAxial rotationThrottle

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Dustproof filtering air filter for automobile

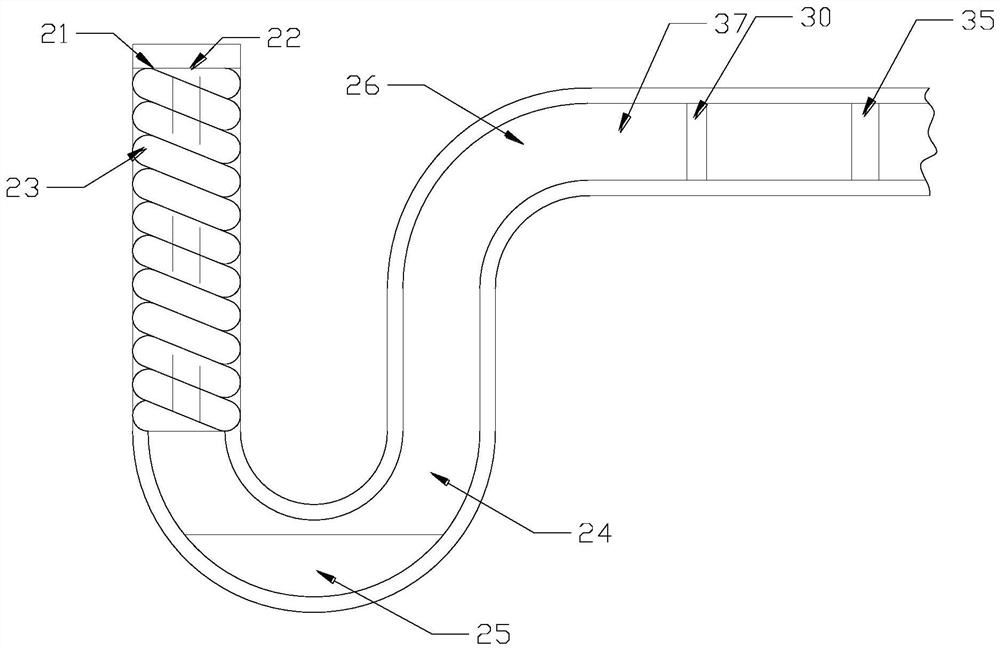

PendingCN112761831AAvoid early wearAvoid damageAir-treating devicesMachines/enginesPipeline.airAir filter

The invention belongs to the field of air purification, and particularly relates to a dustproof filtering air filter for an automobile. The dustproof filtering air filter for the automobile comprises an air suction structure, a filtering structure and an induction structure, wherein an air inlet is formed in the inner wall of the filter; a first fixing support frame is fixedly connected onto the inner wall of the filter; the first fixing support frame is connected with a first air suction fan through a first rotating shaft; a pipeline air inlet is formed in the front end of the filtering structure; a filtering element is fixed in the filtering structure; a spiral filtering pipeline is connected to the outer side of the filtering element; a first U-shaped pipe is connected to the lower end of the filtering structure; filtering oil is contained in the first U-shaped pipe; a second U-shaped pipe is connected to the other side of the first U-shaped pipe; an air outlet is connected to the other side of the second U-shaped pipe; a second air suction fan is arranged on the inner wall of the air outlet; a second fixing support frame is fixedly connected to the inner wall of the air outlet; an inductor is arranged on the second fixing support frame; the second fixing support is rotationally connected with the second air suction fan through a second rotating shaft; and an opening and closing opening is formed in a valve. The dustproof filtering air filter for the automobile solves the problems of big size and poor filtering effect of a conventional filter.

Owner:安徽法西欧汽车部件有限公司

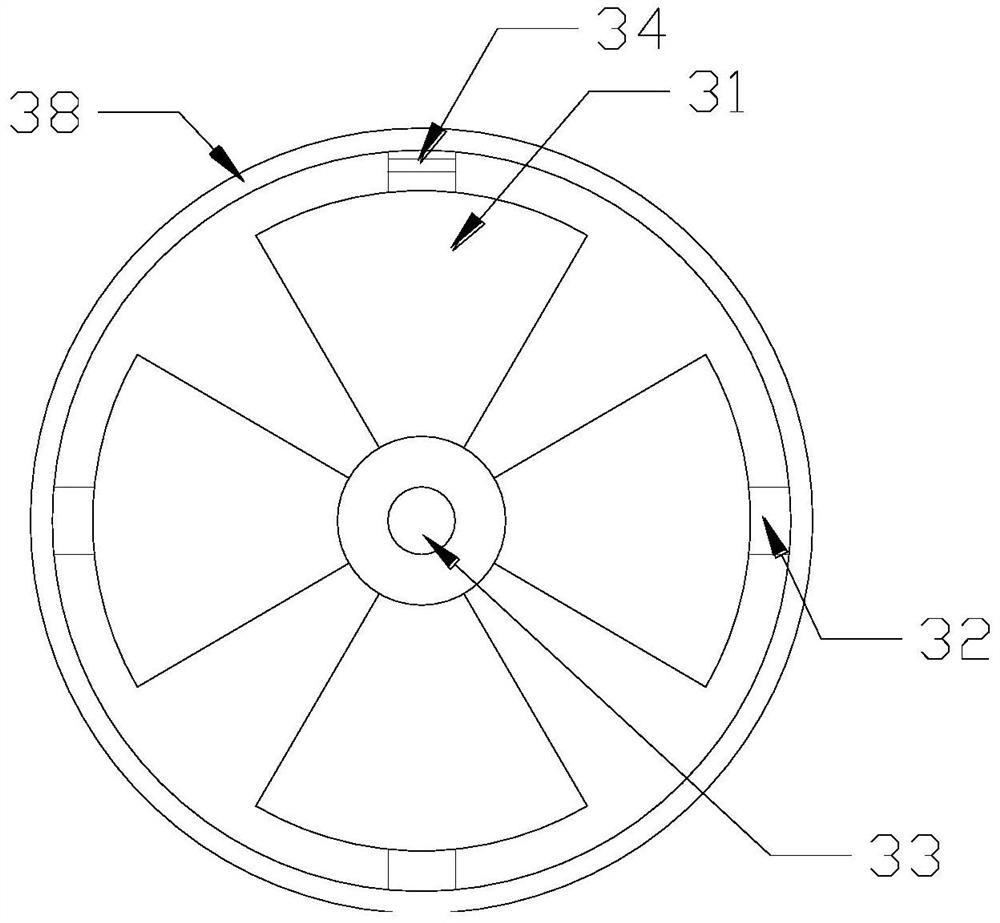

Integrated main reducer assembly with oil throwing blades

ActiveCN106015539BFully lubricatedAvoid early wearGearboxesGear lubrication/coolingReduction driveReducer

Owner:FANGSHENG AXLE LIUZHOU

Hydraulic system, hoisting mechanism and engineering machinery

InactiveCN102874704BPrevent movementAvoid slip hook phenomenonServomotor componentsServomotorsControl valvesClosed state

The invention discloses a hydraulic system, a hoisting mechanism and engineering machinery. The hydraulic system comprises an execution part, a main valve used for reversing of the execution part and a brake used for braking the execution part, wherein the brake is in an open state during oil-taking and in a closed state during oil-returning. The hydraulic system further comprises a brake oil way which is connected between an oil source and the brake, and a first control valve is arranged on the brake oil way, and opens or closes the brake oil way according to load pressure of the execution part and output pressure of the main valve. The hydraulic system can effectively prevent a load from driving the execution part to move, can avoid hook gliding when applied to the hoisting mechanism, and has the advantages of high safety, high reliability, small braking block abrasion and the like.

Owner:SANY HEAVY IND CO LTD (CN)

Door weather stripping for motor vehicles

ActiveCN103847484BImprove sealingImprove air tightnessEngine sealsVehicle sub-unit featuresEngineeringMotorized vehicle

Owner:HYUNDAI MOTOR CO LTD +1

Supercharger oil inlet gasket for engine test run

ActiveCN103807007AAvoid early wearLow costMachines/enginesPressure lubricationForced inductionLower face

The invention discloses a supercharger oil inlet gasket for the engine test run. The supercharger oil inlet gasket is installed between a supercharger oil inlet flange and a supercharger oil inlet connector, and comprises a gasket body, the gasket body is of a multilayer structure with the sealing function, and is provided with an oil inlet, and a filter net is arranged at the oil inlet and used for filtering impurities in engine oil. Aluminum sheets are arranged on the upper face and the lower face of the multilayer structure, a filling layer is arranged in the middle of the multilayer structure, and framework steel sheets for supporting are arranged in the filling layer. According to the supercharger oil inlet gasket, the filter net is arranged on the oil inlet of the gasket, and the engine oil can be filtered before entering a supercharger; due to the fact that metal materials are adopted for the surface of the oil inlet gasket, the supercharger oil inlet gasket is not prone to being adhered when being disassembled, and can be repeatedly used.

Owner:GUANGXI YUCHAI MASCH CO LTD

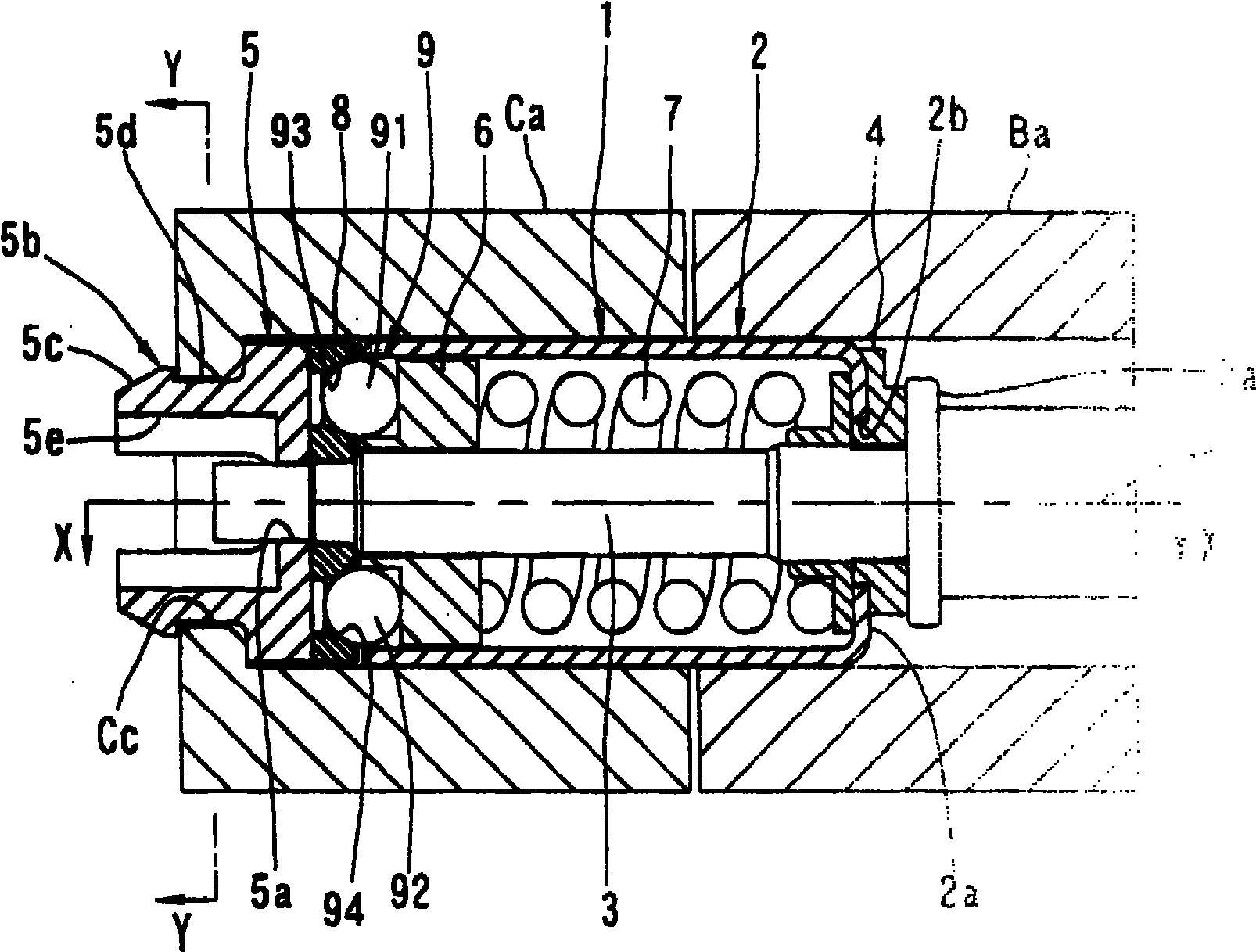

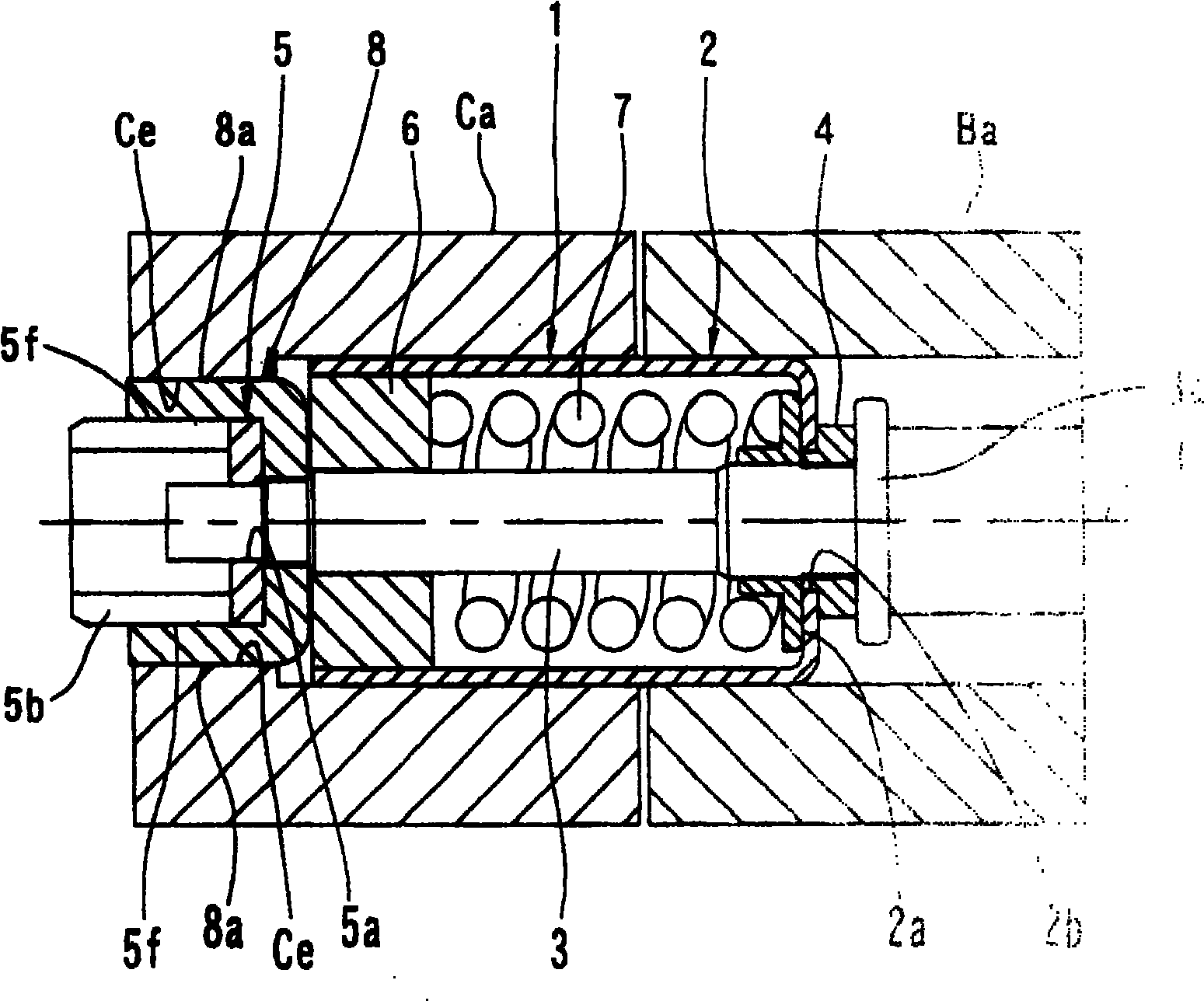

Hinge device and portable device

InactiveCN100520095CAvoid early wearPivotal connectionsTelephone set constructionsRotational axisEngineering

The invention relates to a hinge device and a portable device using the hinge device. To provide a hinge device capable of preventing looseness between a transmitting-side housing and a receiving-side housing of a cellular phone for a long period of time. Planar portions (5f), (5f) extending parallel to the rotation axis (L) are formed on the outer peripheral surface of a fixing member (5) fixed in position to a receiver-side housing (not shown). A flat plate portion (8a) extending parallel to the rotation axis (L) and substantially in contact with the flat portion (5f) is formed on the cam member (8) made of metal. By engaging the flat plate portion (8a) with the inner peripheral surface of the receiver-side housing, the cam member (8) is non-rotatably coupled to the receiver-side housing.

Owner:SUGATSUNE IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com