Inner and outer rolling wheel type rocking arm with lubricating structure

A kind of lubrication structure, roller type technology, applied in the lubrication of valve accessories, engine components, machines/engines, etc., can solve the problems of difficult rotation, concentrated force on the outer roller, cam phase deviation, etc., to increase the lubrication area, avoid early Wear, improve lubrication and heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in conjunction with the embodiments and accompanying drawings.

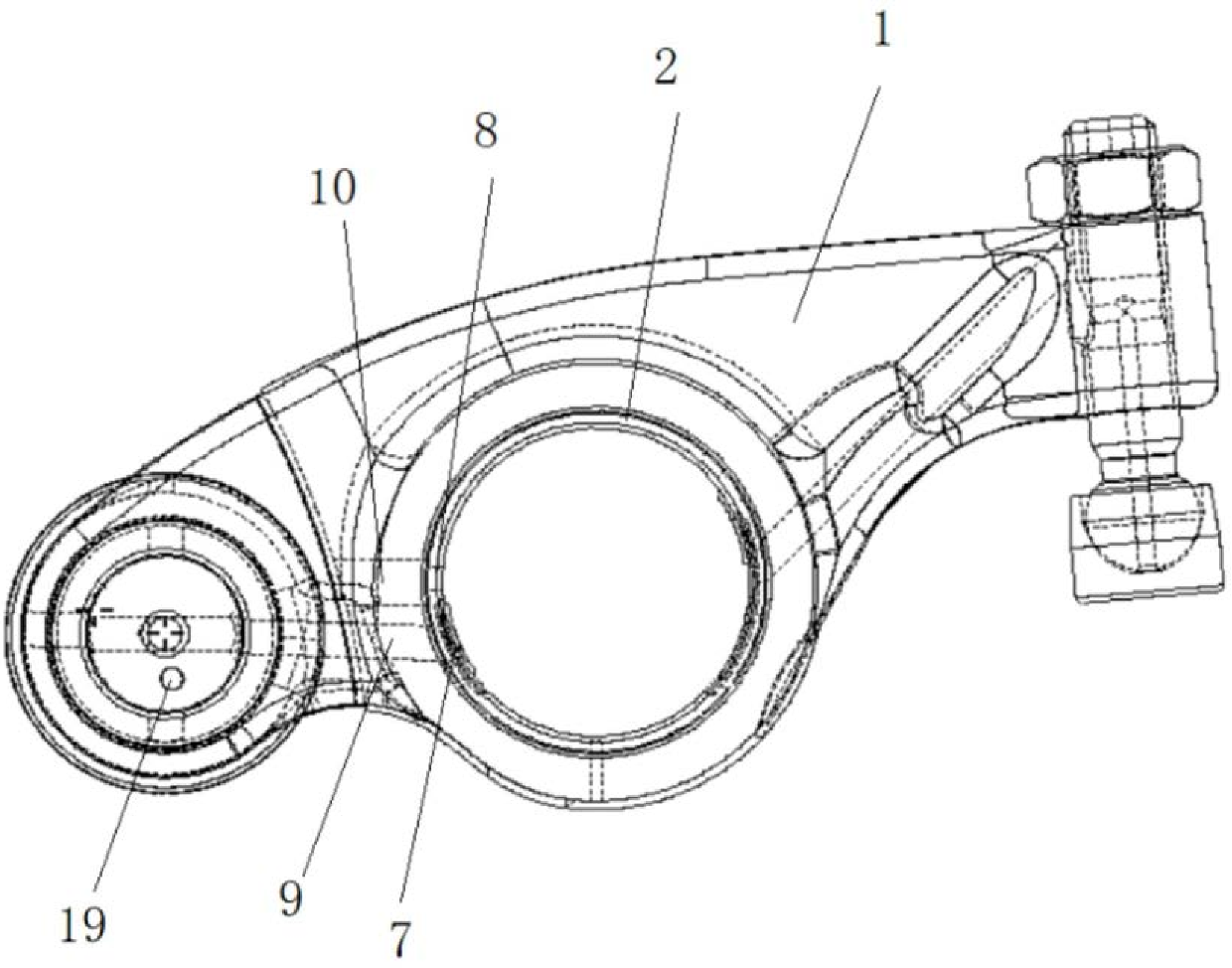

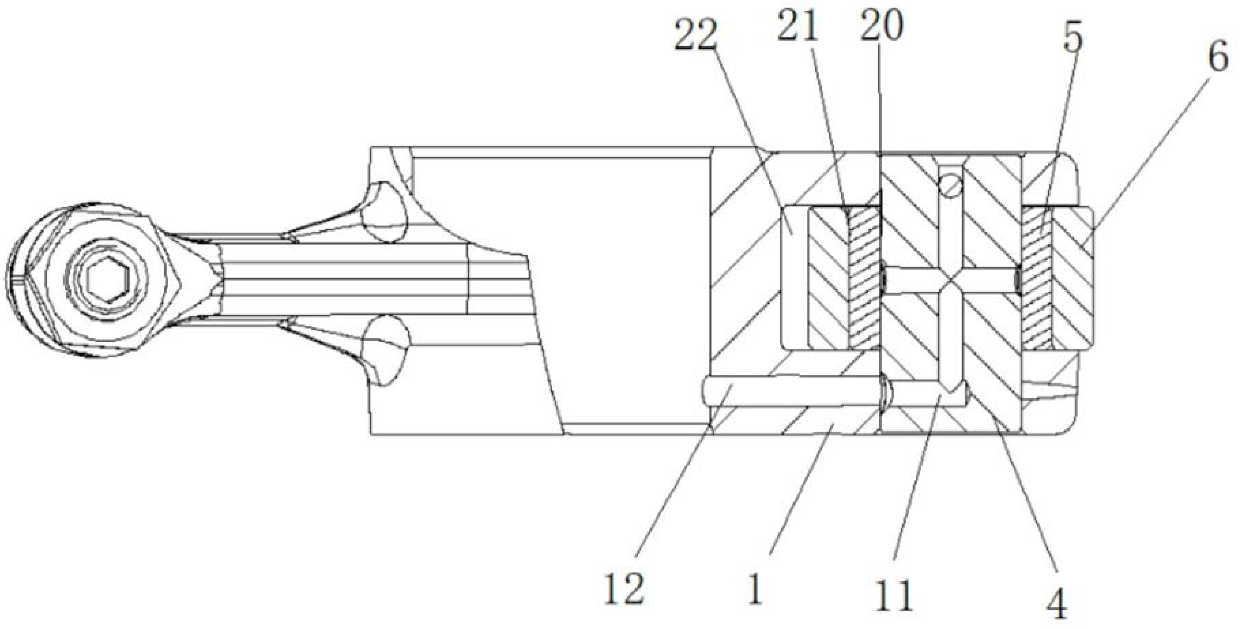

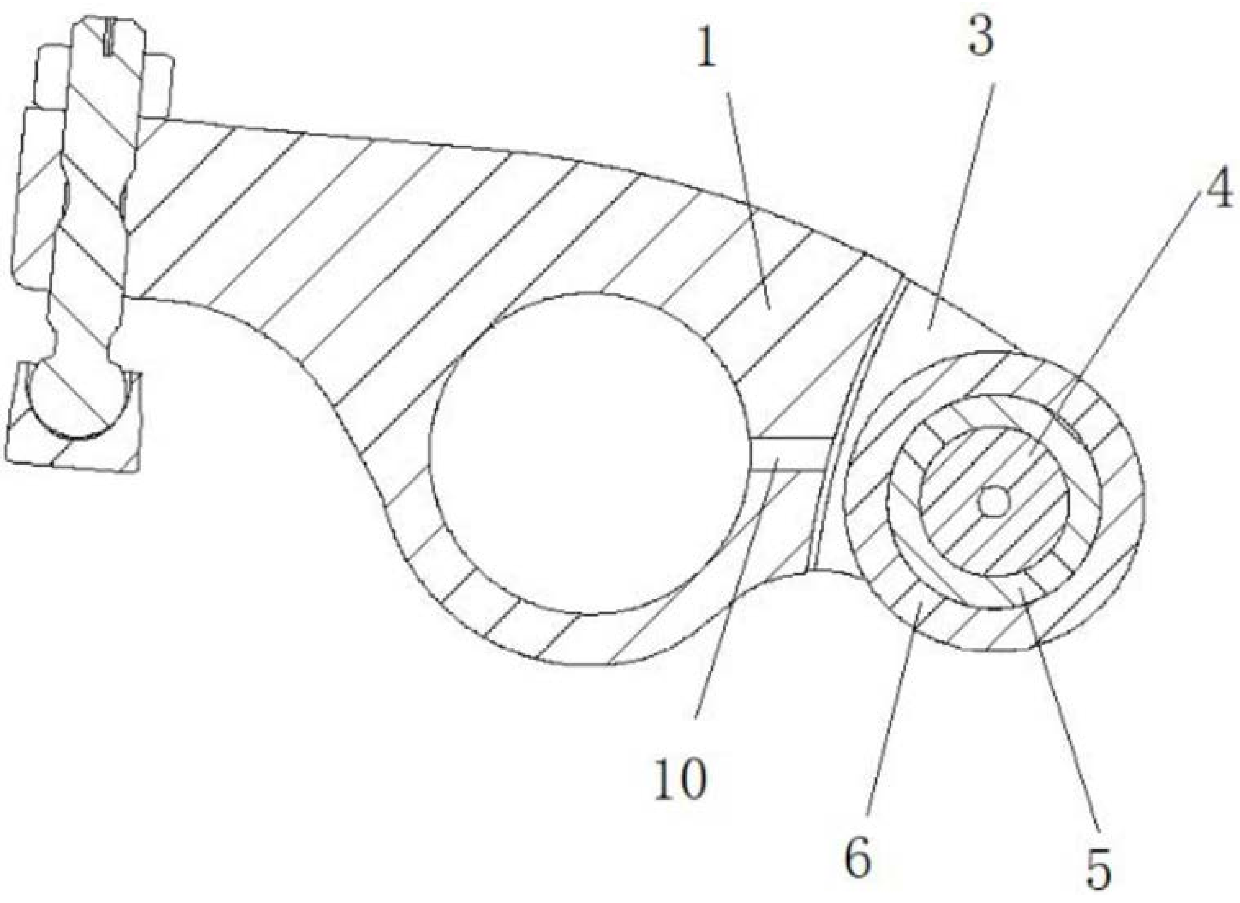

[0030] like Figure 1-7 As shown, the present invention provides an inner and outer roller rocker with a lubricating structure, including a rocker body 1 , a rocker shaft 2 , a rolling shaft 4 , an inner roller 5 and an outer roller 6 . The middle part of the rocker arm body 1 is set on the rocker arm shaft 2, and forms a rotating pair with the rocker arm shaft 2; one end of the rocker arm body 1 is provided with a relief area 3, and the rolling shaft 4 is installed on the relief area 3 through interference fit. The roller 3 is rotatably sleeved on the rolling shaft 4 through a clearance fit, and the outer roller 6 is rotatably sleeved on the inner roller 5 through a clearance fit. Wherein, the gap formed by the clearance fit between the roller shaft 4 and the inner ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com