Integrated main reducer assembly with oil throwing blades

A main reducer, one-piece technology, applied in the direction of elements with teeth, belts/chains/gears, gear lubrication/cooling, etc., can solve the problems of poor through-shaft bearing lubrication, poor gear lubrication, through-shaft fractures, etc. Achieve the effect of avoiding through shaft fracture, simple structure and reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

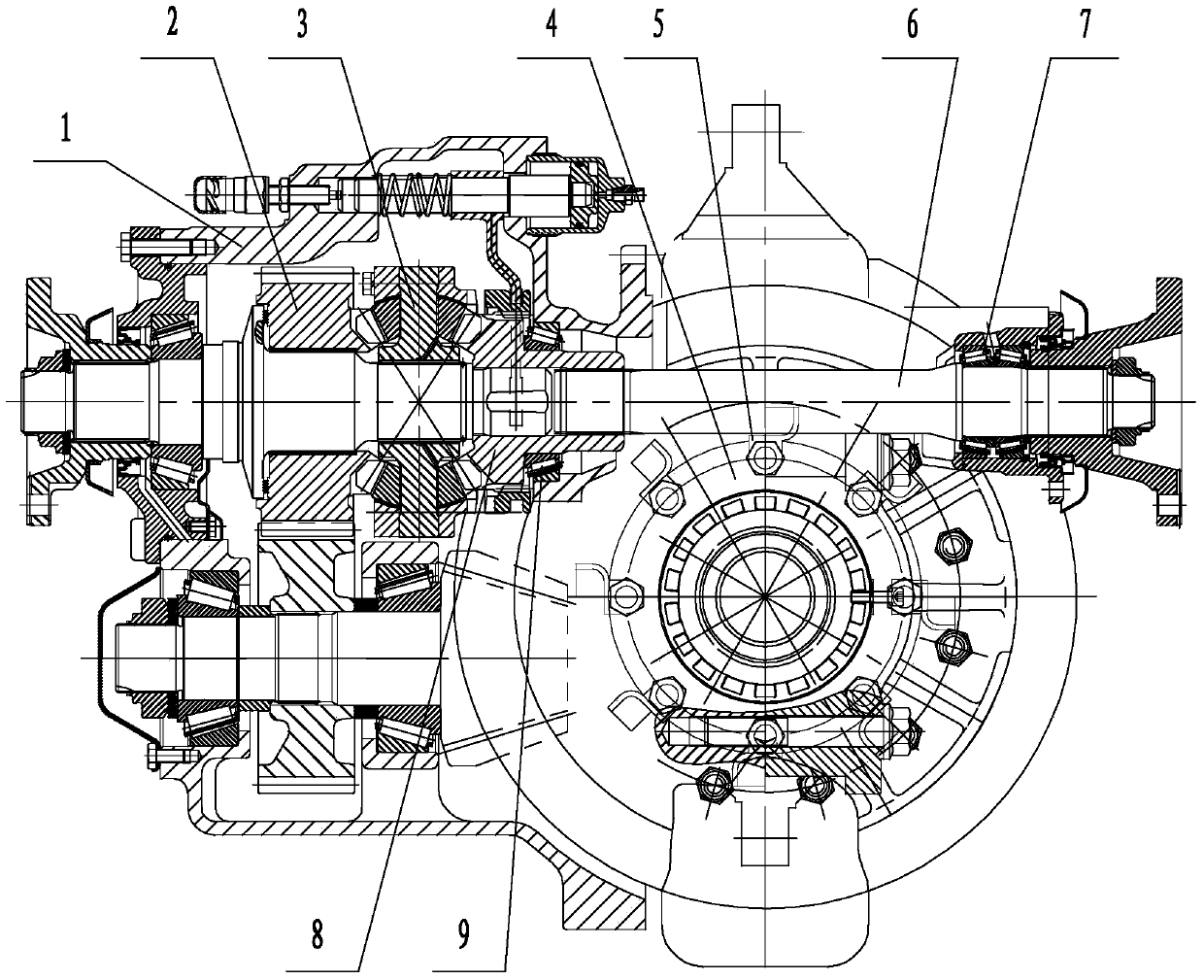

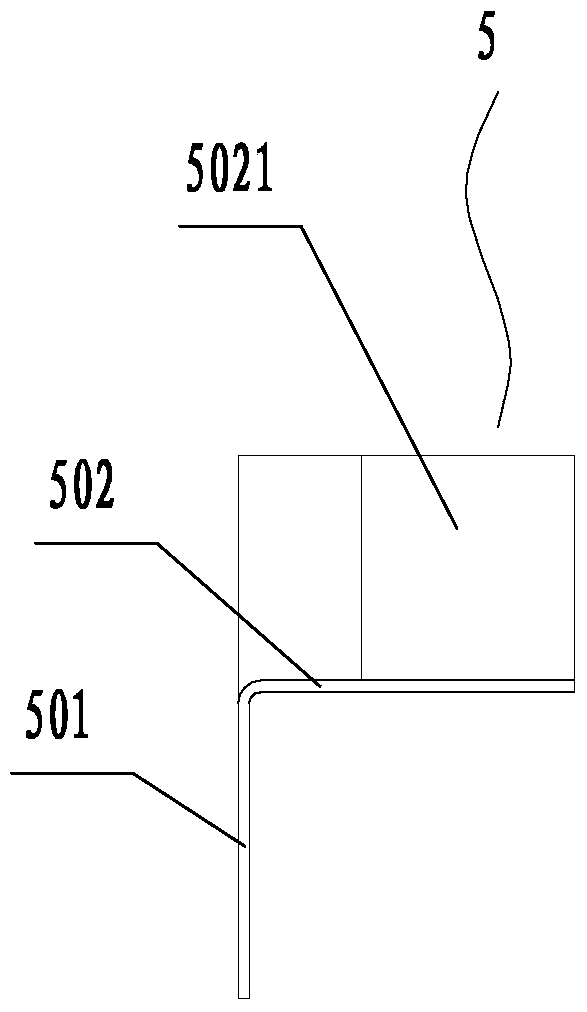

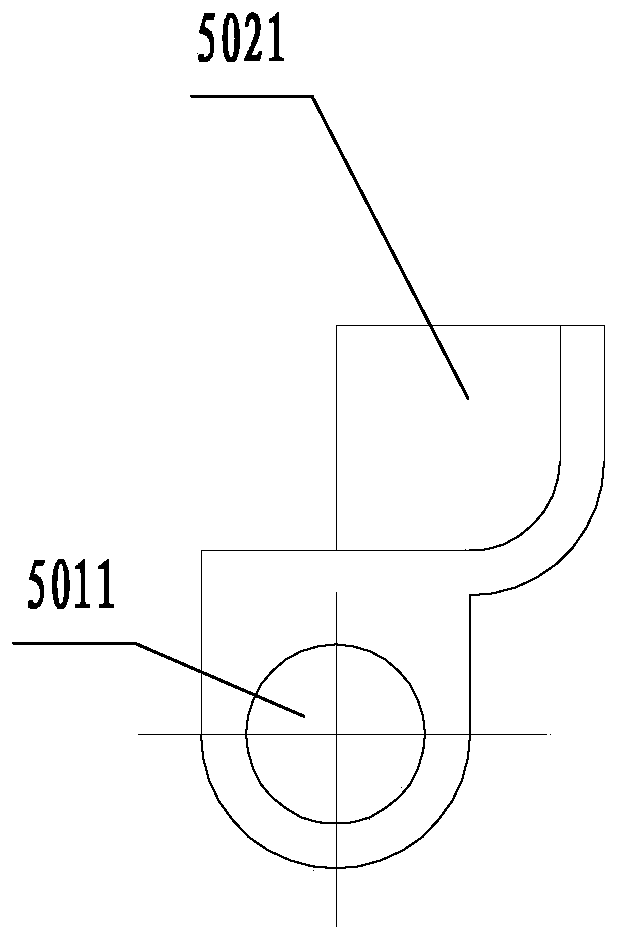

[0032] An integrated main reducer assembly with oil throwing blades (see figure 1 ), including the integral housing 1, the final drive 2 located in the integral housing 1, the inter-axle differential 3 and the inter-wheel differential 4 located outside the integral housing, the inter-wheel differential 4 includes differential The differential case 401, the differential located in the differential case 401, the differential case 401 includes a differential left case 4011, a differential right case 4012, a differential left case 4011, a differential The right shells 4012 are connected together by bolts 4013 . The differential case 401 is also connected with an oil throwing blade 5, and the oil throwing blade 5 is formed by vertically connecting the A end face 501 and the B end face 502 to form an approximate 7-shaped structure (see Figure 2-Figure 4 ), the A end surface 501 of the oil throwing blade is attached to the end surface of the right differential case 4012, and the A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com