Bearing unit for supporting transmission shaft and gear reducer

A technology of gear reduction and transmission shaft, applied in the direction of rotating bearing, bearing element, shaft and bearing, etc., can solve the problems of false pretension test, larger bearing pair clearance, change of main shaft preload, etc. Achieve the effect of overcoming the illusion of preload, prolonging life and optimizing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

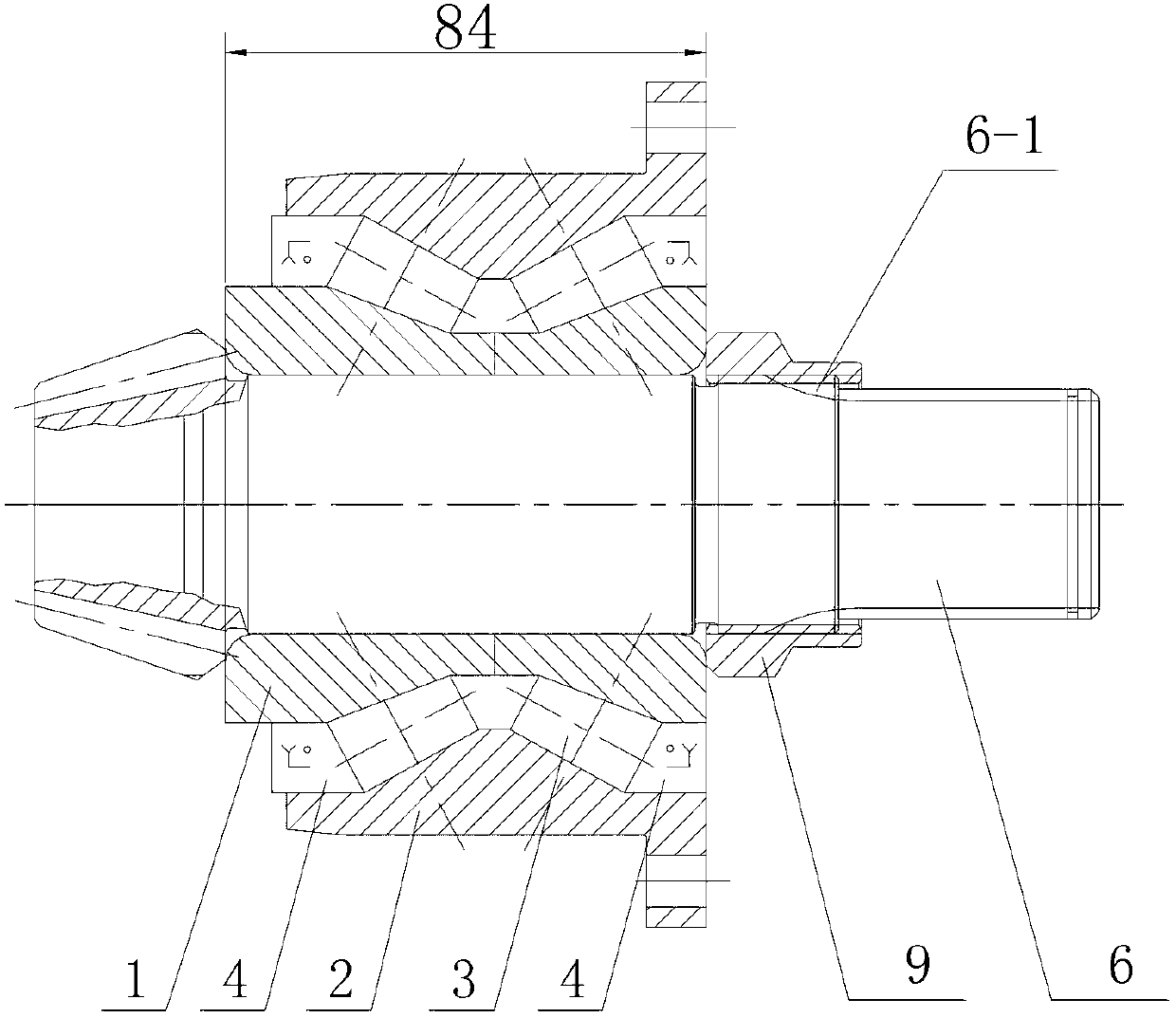

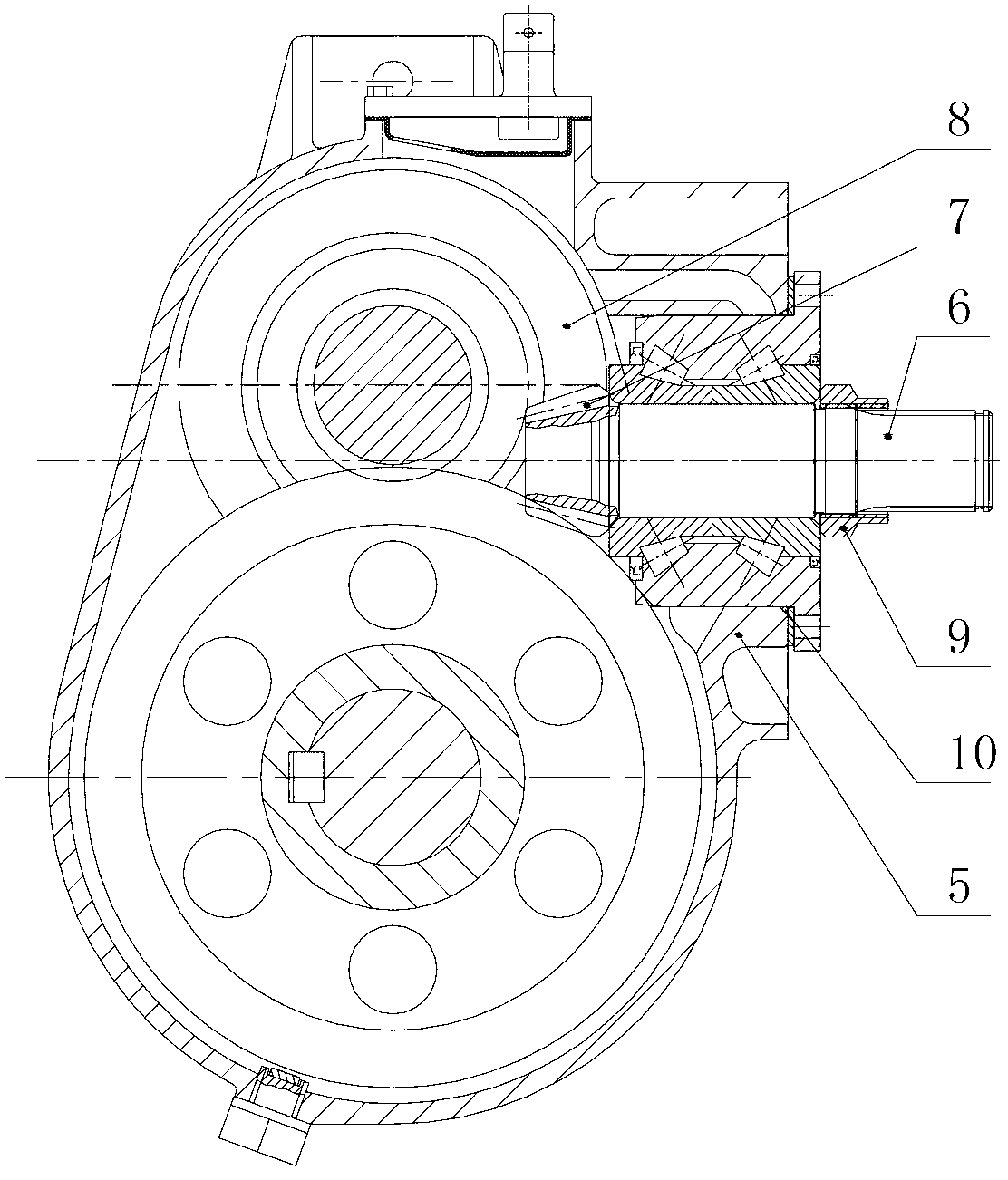

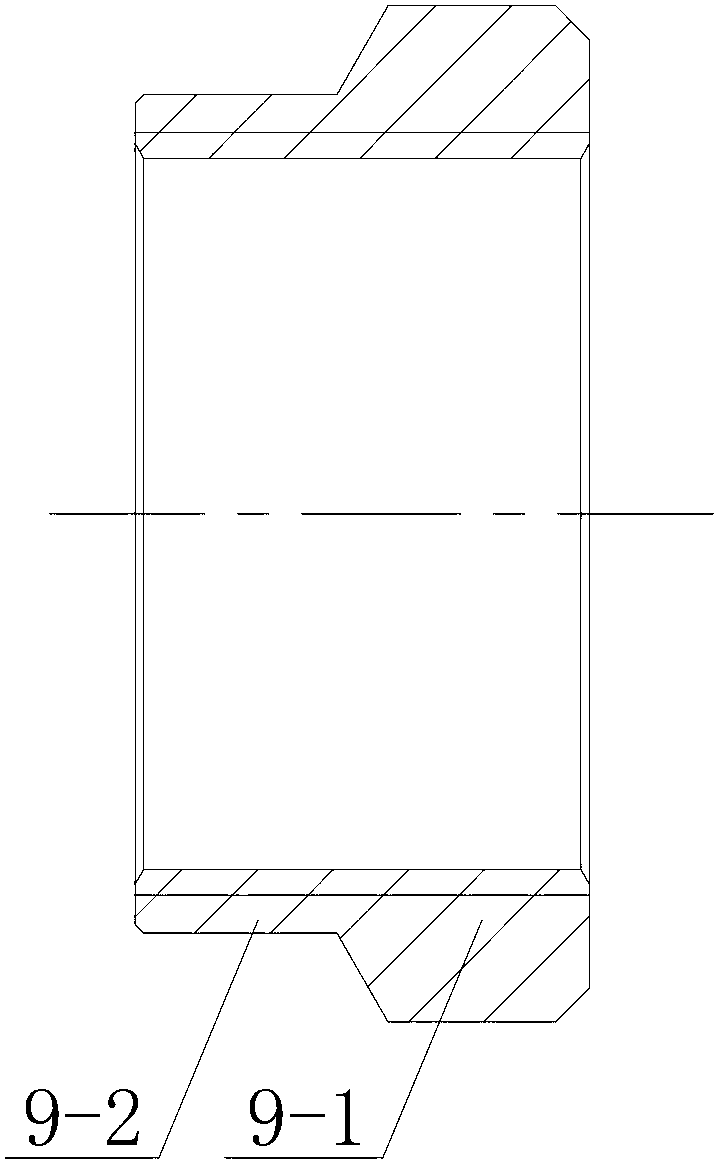

[0041] see Figure 1 to Figure 2 , a bearing unit for supporting a drive shaft, the bearing unit includes an inner ring 1, an outer ring 2 and tapered rollers 3, the tapered rollers 3 adopt two groups, located between the inner ring 1 and the outer ring 2 respectively , the inner ring 1 adopts a split structure, the outer ring 2 adopts a one-piece structure, and a sealing member 4 is provided between the outer ring 2 and the inner ring 1, and the sealing member is different from the existing sealing method The biggest difference is that the existing sealing gland is reduced, and it is directly embedded between the inner ring and the outer ring, so that the structure is more compact, the sealing performance is more reliable, and the manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com