Air filter assembly

An air filter and assembly technology, applied in the field of air filter assembly, can solve the problems of motor vehicle engine wear, poor reliability, clogged filter paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

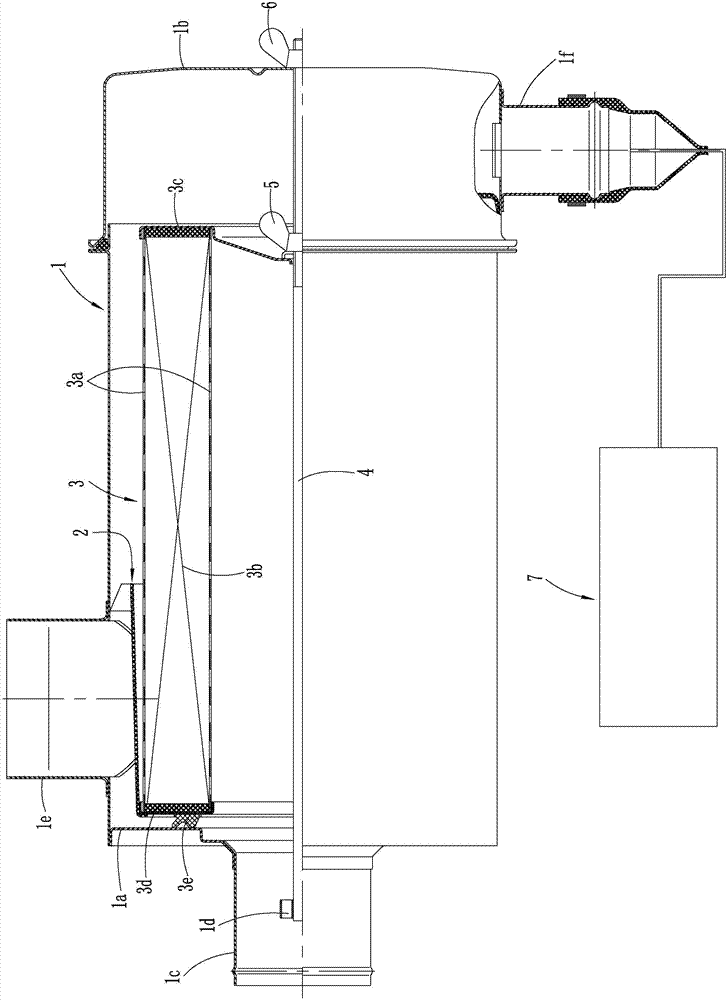

[0019] see figure 1 :

[0020] The assembly includes a casing 1, a blade ring 2, a filter element 3, and a pull rod 4.

[0021] The axial left end of the cylindrical shell 1 has a cover 1a, and the axial right end has a cover 1b. The cover 1a has a circular air outlet pipe 1c coaxial with the outer shell 1. The inside of the air outlet pipe 1c is provided with a bracket 1d. A pull rod 4 coaxial with the shell 1, the pull rod 4 passes through the axial right end of the shell 1 and the end of which is threaded.

[0022] The filter element 3 is composed of a filter paper 3b sandwiched between two layers of circular protection tubes 3a inside and outside, a circular sealing ring 3c respectively arranged at both axial ends of the protection tube 3a, and a circular retaining ring 3d with a sealing ring 3e. The sealing ring 3e and retaining ring 3d are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com