Rice harvester driving axle

A drive axle and harvester technology, applied to harvesters, agricultural machinery and implements, and other applications, can solve the problems of early wear of steering cogs, poor braking effect of steering brakes, and low combination accuracy of left and right housings. Improve the service life, improve the braking effect, and the effect of reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

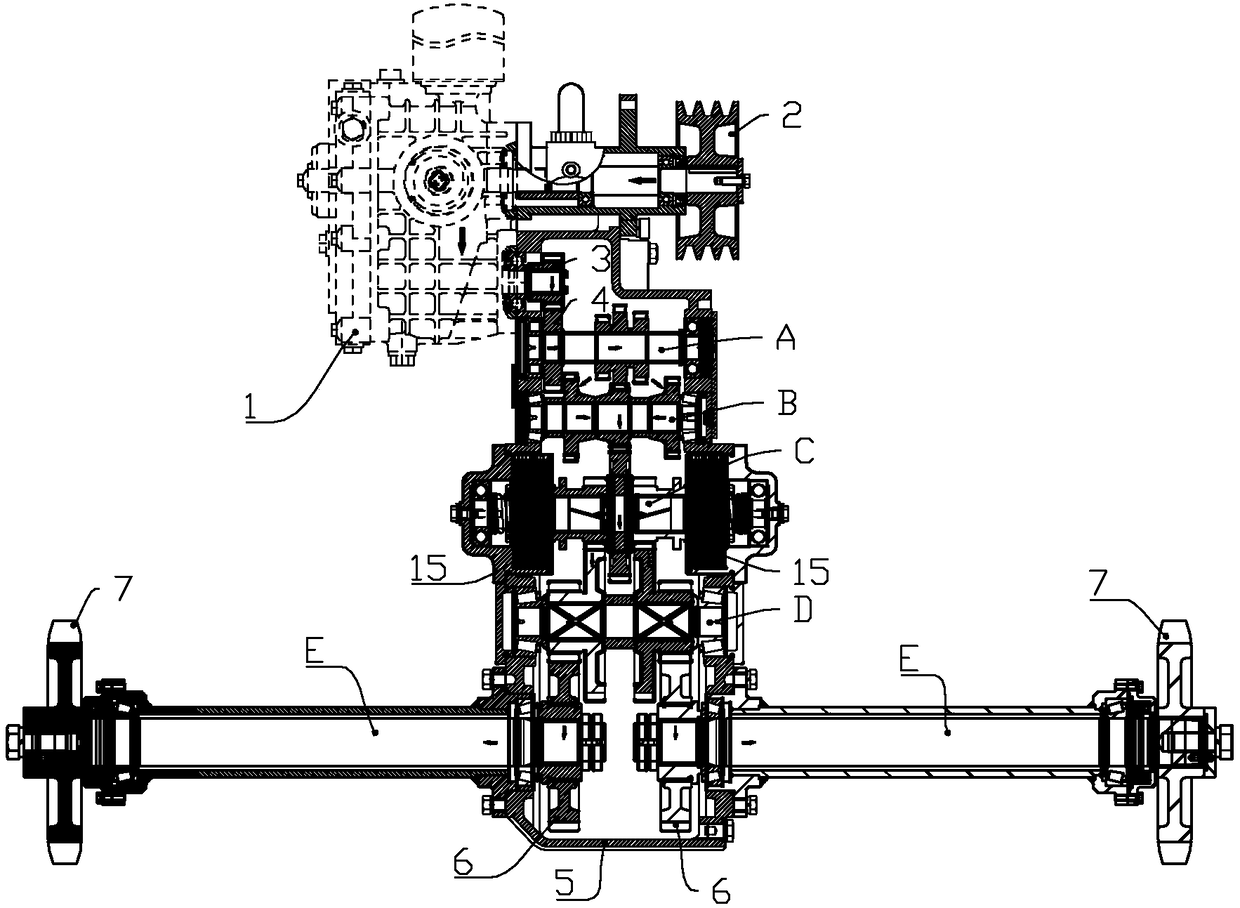

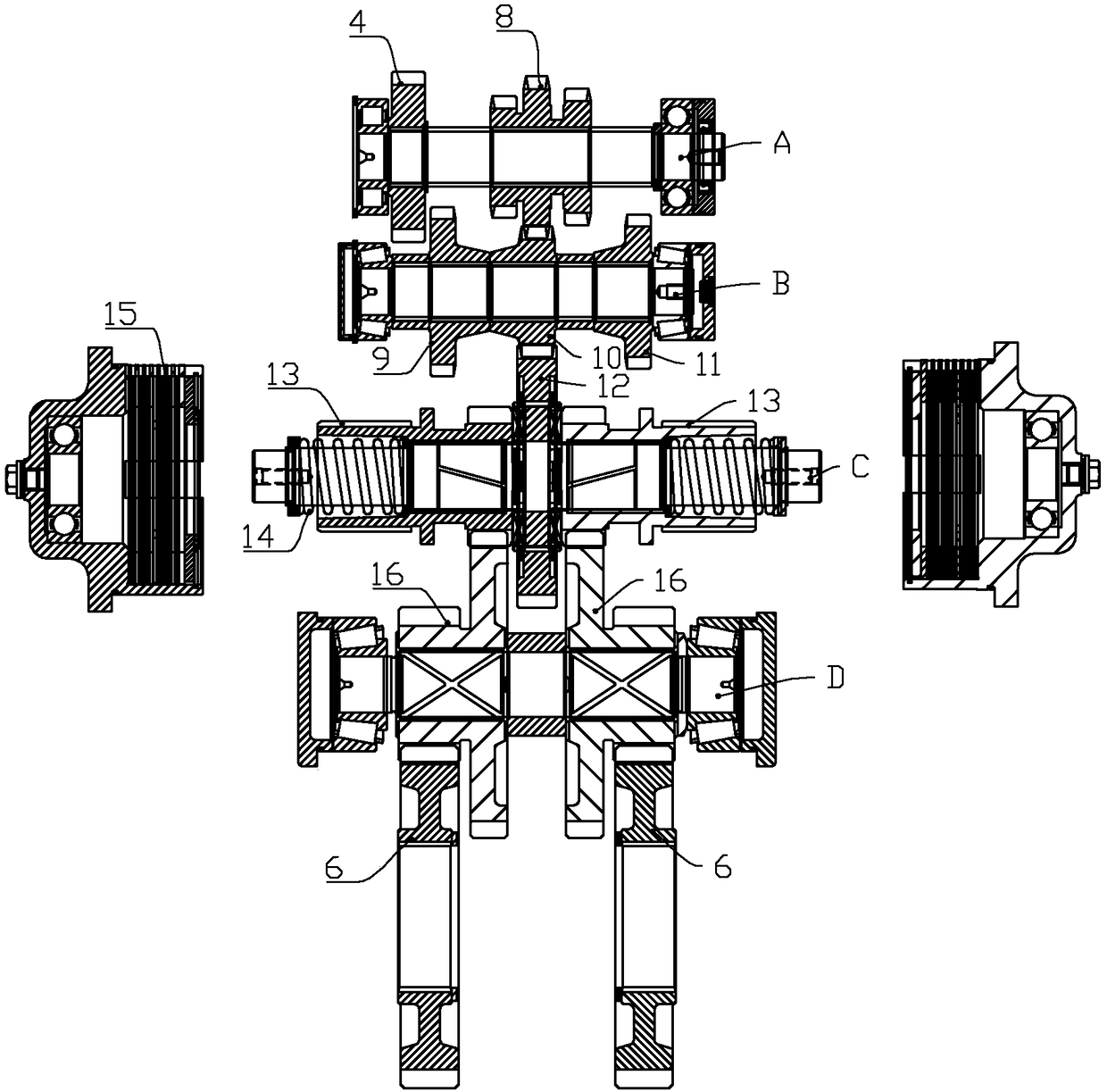

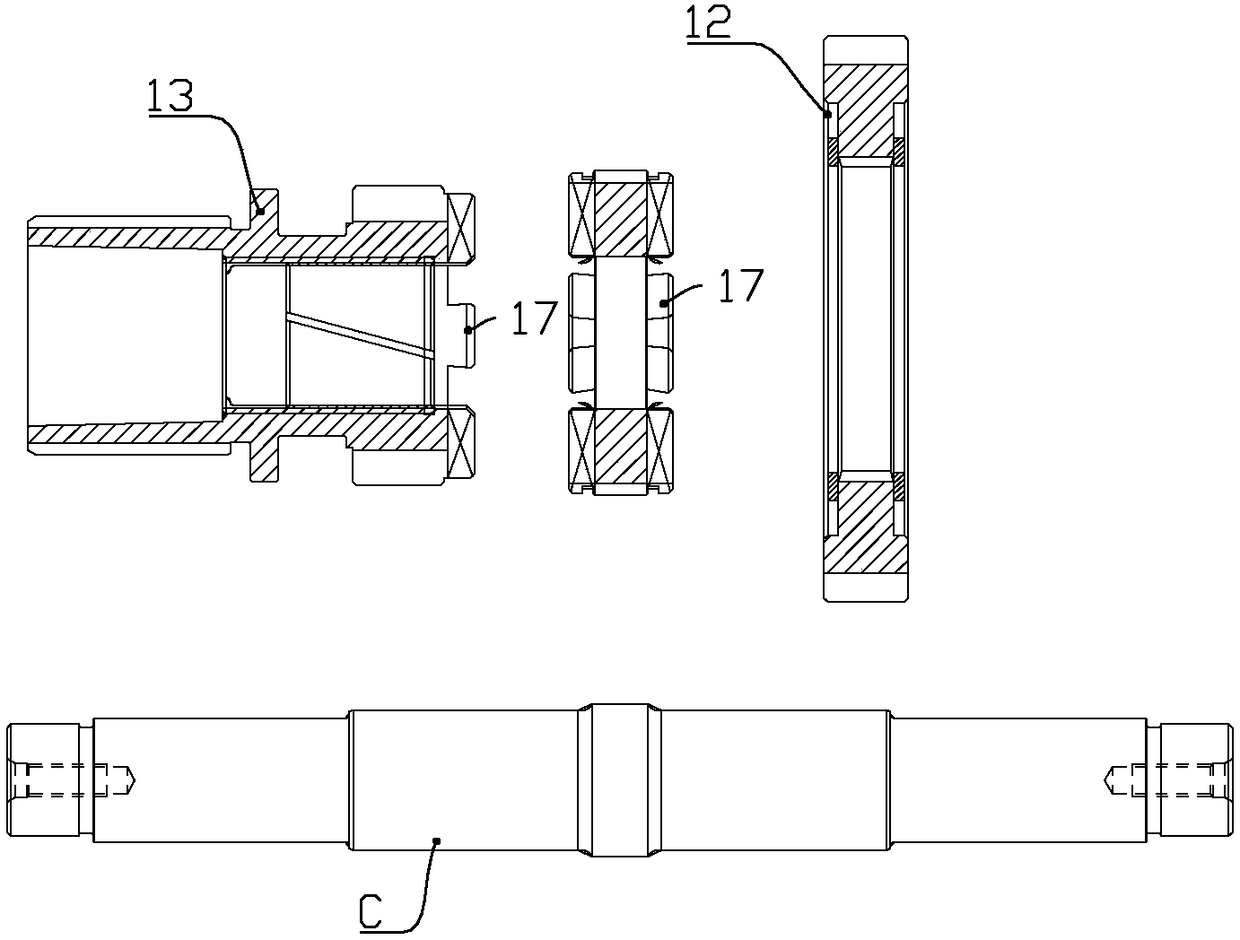

[0027] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-6 :

[0028] A rice harvester driving axle, combined with figure 1 and figure 2 , comprising an integral transaxle case housing 5, in which there are one shaft A, two shafts B, three shafts C, and four shafts D installed in parallel in turn, and the two ends of the four transmission shafts are fitted in the drive shaft through bearings respectively. The two side walls of the axle box housing 5; the input end of the drive axle box is equipped with a hydrostatic transmission 1, the input shaft of the hydrostatic transmission 1 is connected to the input pulley 2, and the output end extends into the drive axle box housing 5 and is connected with Input gear 3; output shaft E protrudes laterally on both sides of the drive axle output end, and the output shaft E is connected with final transmission gear 6 in the drive axle box housing 5;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com