Air boost pump of engineering mechanical braking system

A technology of braking system and construction machinery, applied in the direction of brake, brake transmission, reservoir layout, etc., can solve the problems of reducing product durability, wear of gas piston apron, harsh working environment of loader, etc., to overcome the early stage Effects of wear, improved reliability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

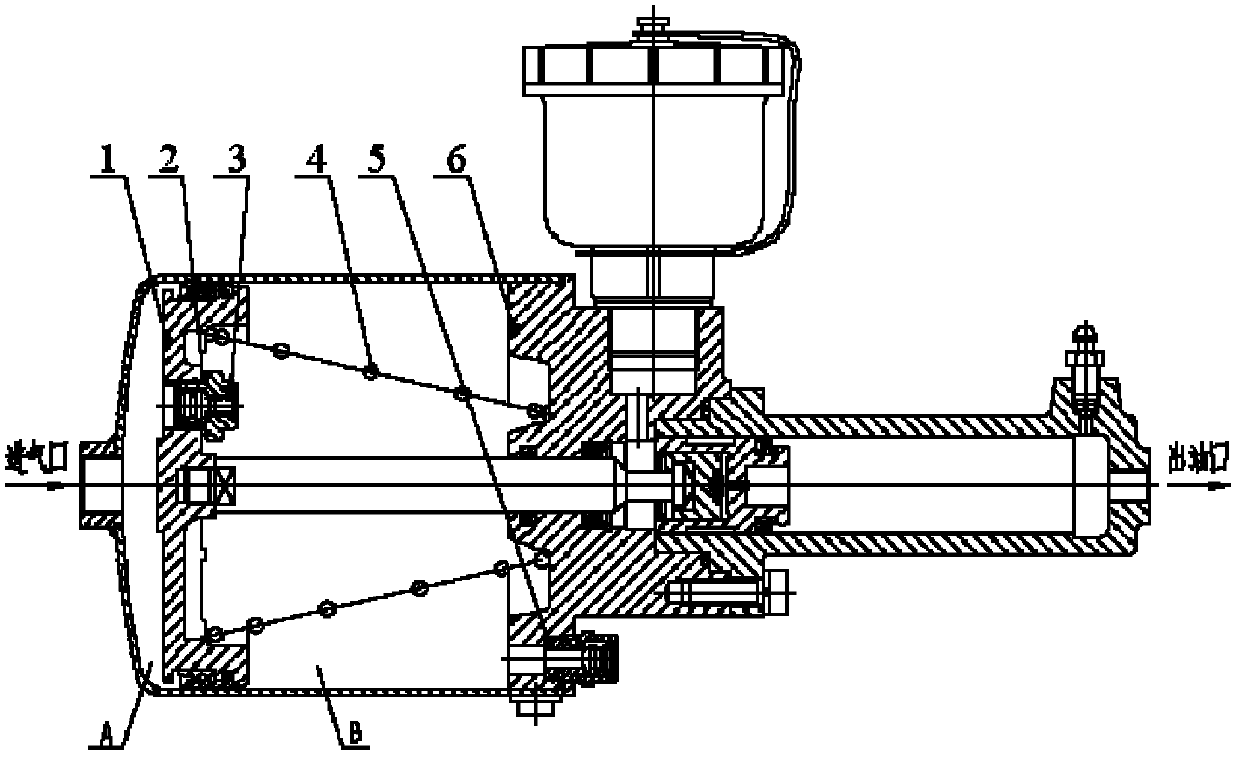

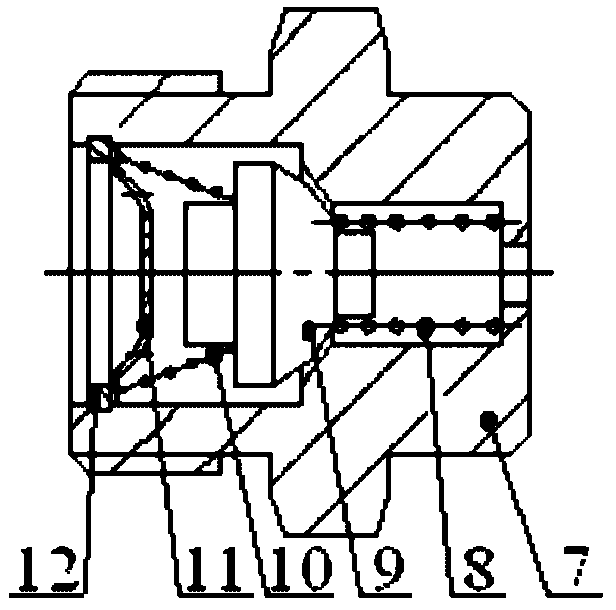

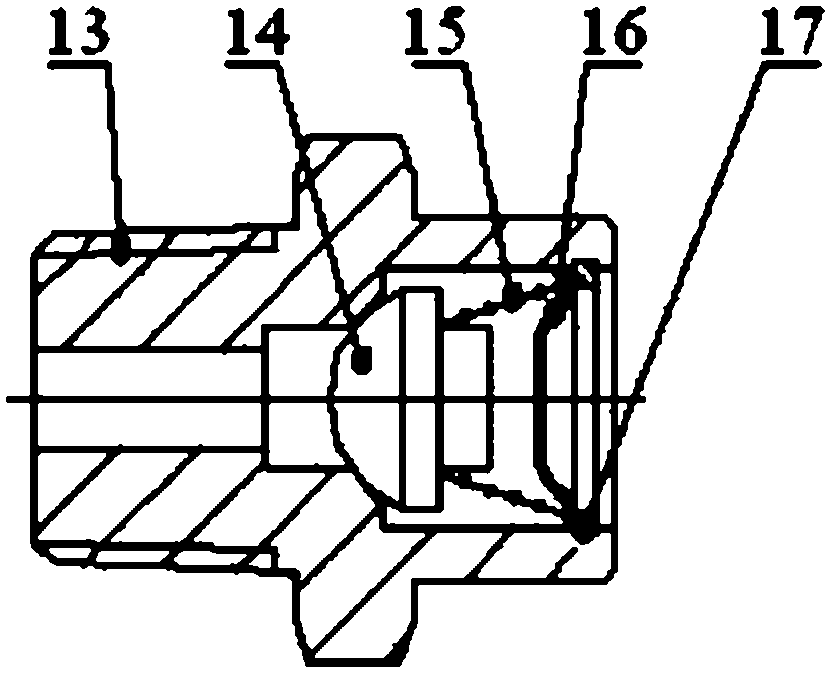

[0017] Such as figure 1 , figure 2 and image 3 According to the structure of the present invention expressed, the present invention is an air booster pump for the braking system of construction machinery, including a cylinder and a brake oil cylinder. The cylinder includes a cylinder housing, an air piston 1, an air piston return spring 4, Oil cylinder connection cover 6; the cylinder housing is connected with the brake cylinder through the oil cylinder connection cover 6; the two ends of the air piston return spring 4 are respectively in contact with the end faces of the air piston 1 and the oil cylinder connection cover 6; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com