A fixed chuck for an automobile accelerator cable

A technology for pulling the throttle and fixing the card, which is applied to the layout, transportation and packaging of vehicle components and power unit control mechanisms, and can solve problems such as early wear and abnormal noise, easy wear and tear of the claws, and the inability to reliably fix the throttle cable. , to increase the service life and avoid early wear and abnormal noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

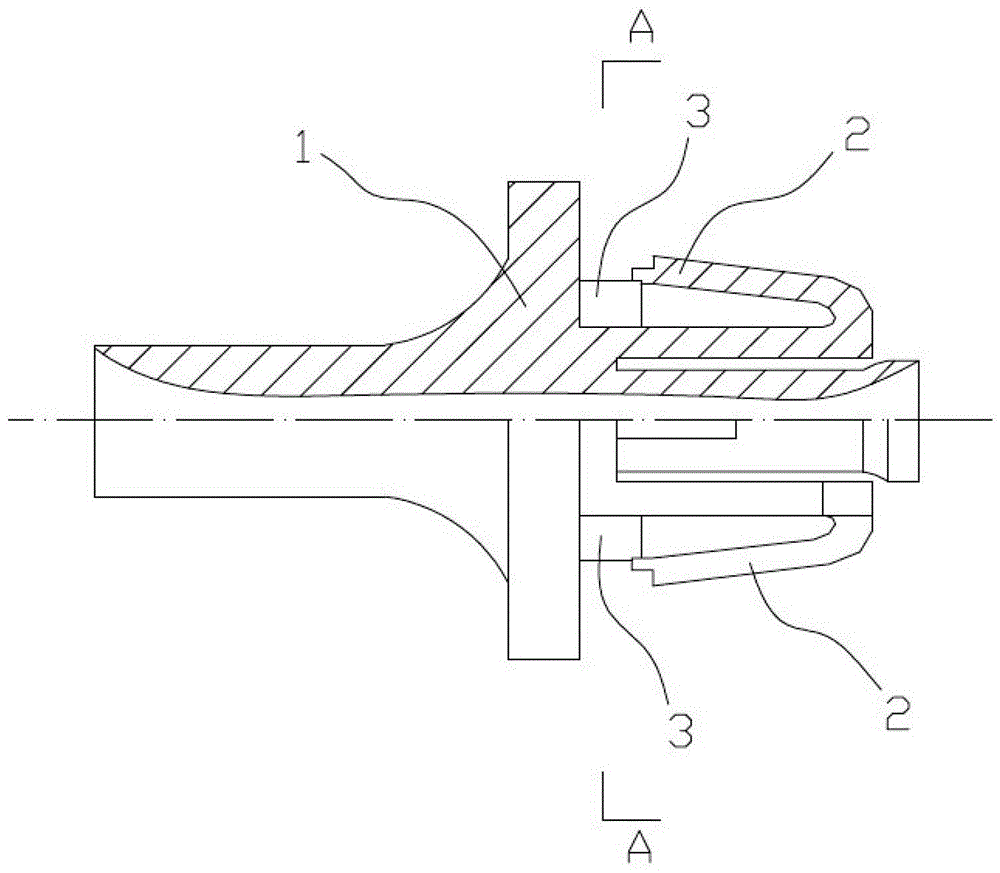

[0014] The present invention will be further described below in conjunction with accompanying drawing.

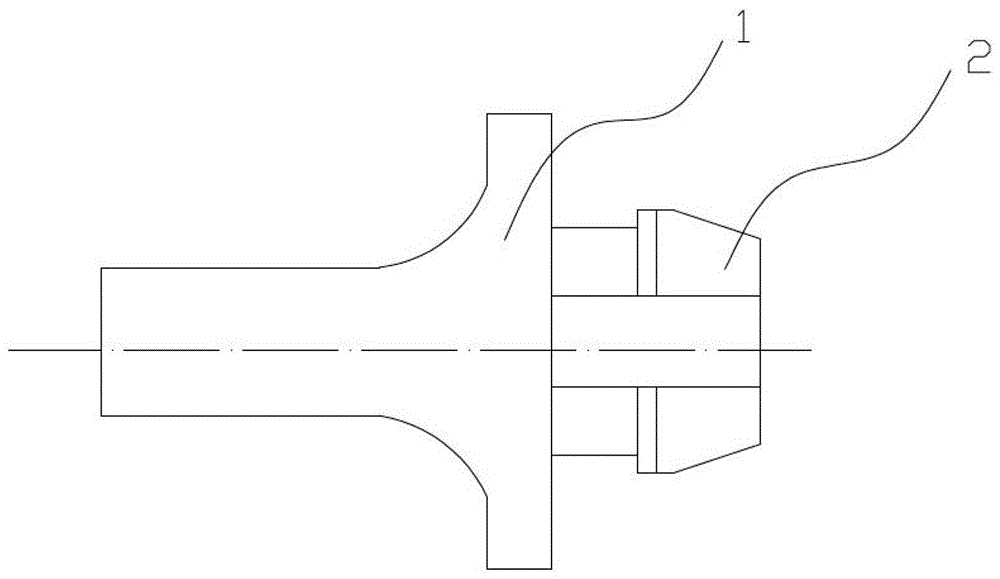

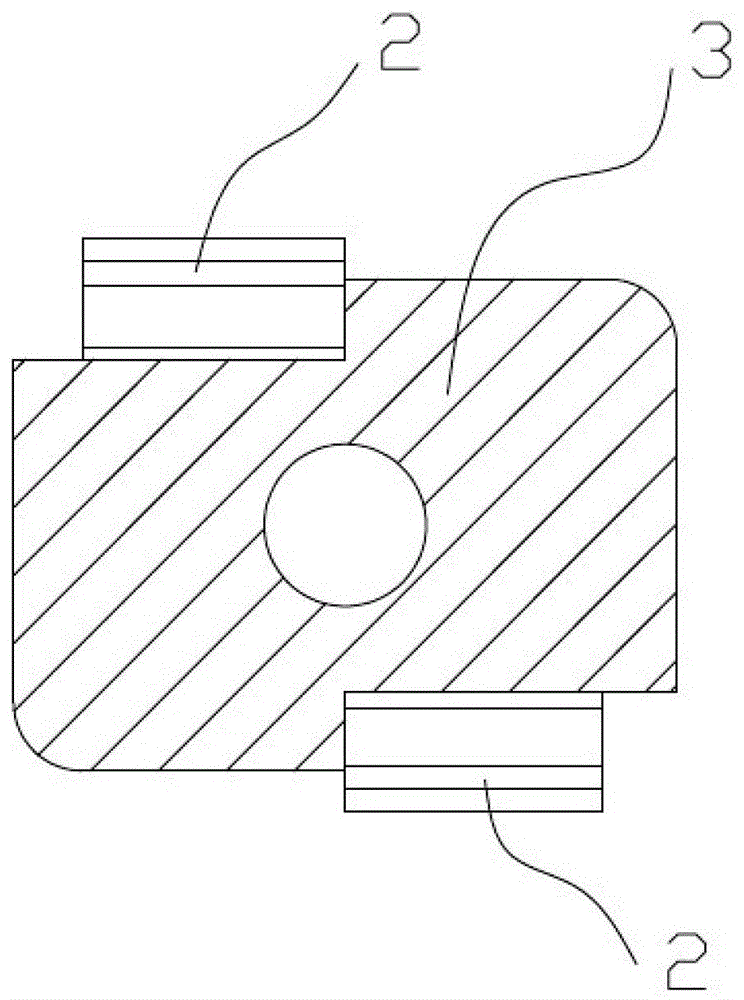

[0015] Such as figure 2 , image 3 , Figure 4 The fixed chuck of the automobile throttle cable shown includes a base 1 and two claws 2 arranged on the base 1, and the surface of the base 1 that is attached to the front wall panel 4 of the automobile is provided with a clamp that limits the axial direction of the automobile accelerator cable. Rotating stop protrusion 3, the stop protrusion 3 is formed by opening a square notch on the upper left and lower right parts of the square with rounded corners, the plane formed by the square notch is in line with the clamping hole provided on the front wall plate 4 of the car The walls fit together, and the claws 2 are in an inverted V shape (or an arrow shape), one of which is located at the square gap on the upper left of the limiting protrusion 3, and the other claw 2 is located at the lower right of the limiting protrusion 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com