Split-type brake disc

A brake disc, split technology, applied in the direction of brake disc, brake type, brake components, etc., can solve the problems of cumbersome installation and removal, affecting driving safety, brake disc cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

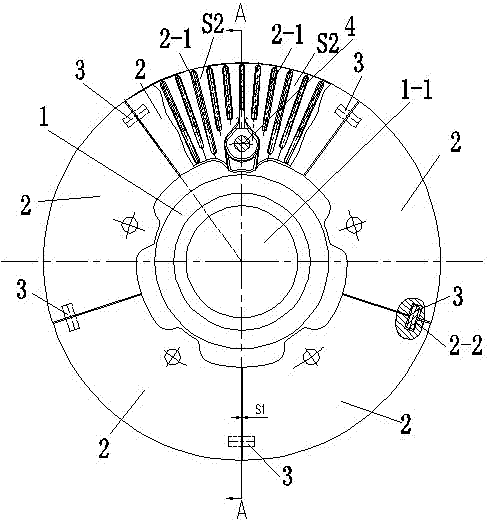

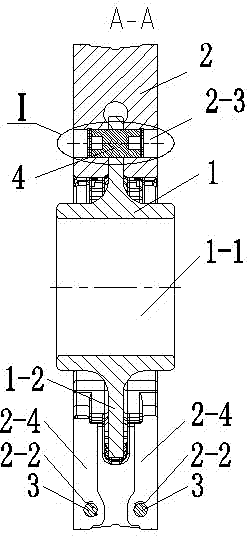

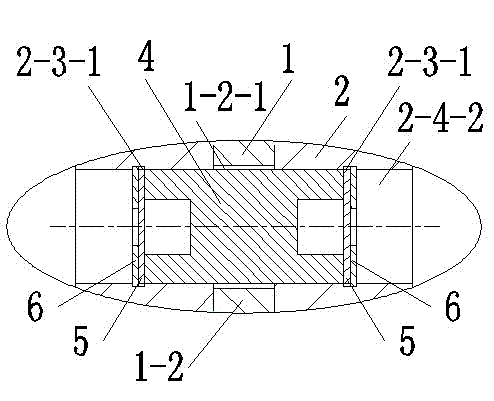

[0021] see figure 1 , 2 As shown in , 3 and 4, a split brake disc includes a disc hub 1, which is provided with a middle hole 1-1, and also has a friction block 2 and a mounting pin 4, and the friction block 2 includes two friction plates 2-4 and several heat dissipation ribs 2-1, the heat dissipation rib 2-1 is located between two friction plates 2-4, and the two friction plates 2-4 and several heat dissipation ribs 2-1 are integrated or fixedly connected, A heat dissipation gap S2 is formed between two adjacent heat dissipation ribs 2-1, and each friction plate 2-4 is provided with a mounting boss 2-4-1, and the mounting boss 2-4-1 is provided with a mounting hole 2 -4-2, the flange 1-2 of the disc hub 1 is also provided with a flange hole 1-2-1, and the mounting pin 4 passes through the mounting hole 2-4-2 and the flange hole 1-2-1, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com