Design method of shock absorber support locating device

A technology of positioning device and design method, applied in auxiliary devices, welding equipment, auxiliary welding equipment and other directions, can solve the problems of shock absorber wear, installation of shock absorbers not in place, shock absorber tilt, etc., to reduce errors, The effect of preventing early wear and improving comfort and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The invention is suitable for the positioning of the bus chassis and shock absorber bracket during welding, and is generally applicable to the positioning welding of the shock absorber bracket in welded air suspension vehicles.

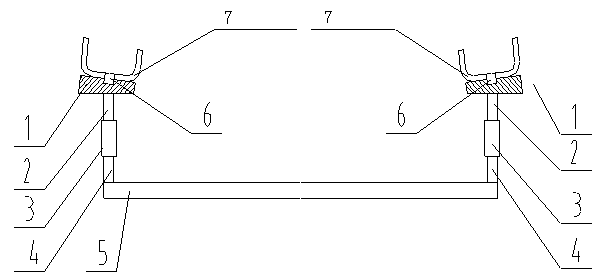

[0016] see figure 1 , the specific structure of the design method of a shock absorber bracket positioning device related to the present invention is,

[0017] It includes an angle adjustment disc 1 with a cross-section of a wedging angle, a height adjustment device, a positioning beam 5 and a positioning pin 6, wherein the height adjustment device is two sets, which are respectively arranged at two ends of the positioning beam 5, wherein each set of height adjustment device One end is fixedly connected with the positioning beam 5, and the other end is fixed with an angle adjustment disc 1; the angle adjustment disc 1 is connected with the shock absorber bracket 7 through the positioning pin 6. The angle adjustment disc 1 is concentric with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com