Stationary chain guide

A guide device and engine technology, which is applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve problems such as deflection and deformation in the length direction of the bottom plate guide device, breakage of bolt installation positions, and complicated manufacturing, and achieve excellent durability properties, improving board strength, and suppressing deflection deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

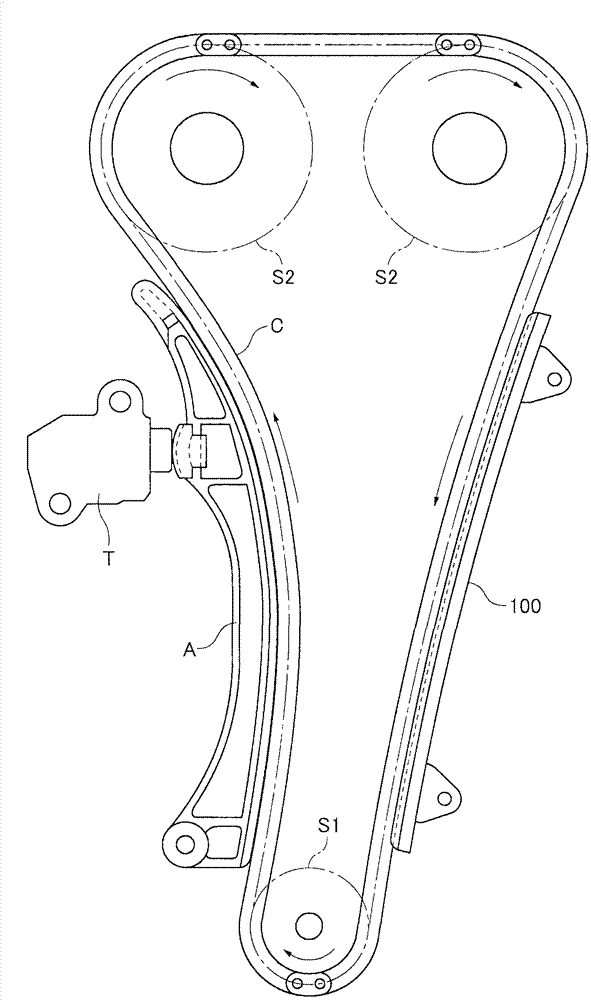

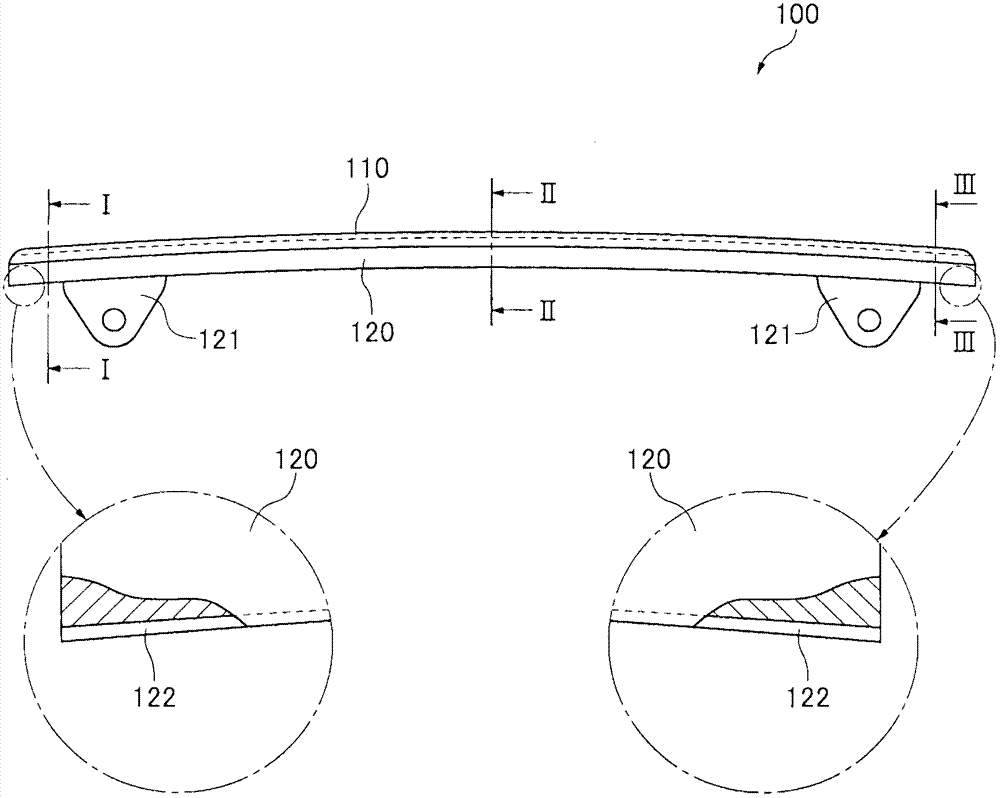

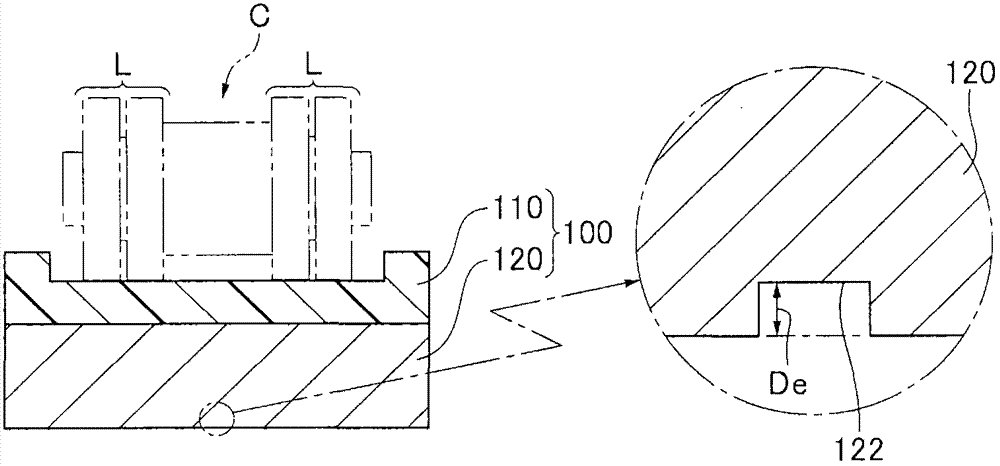

[0060] Next, a fixed guide device for an engine according to a first embodiment of the present invention will be described based on the drawings.

[0061] here, figure 1 It is a usage diagram of the fixed guide device for the engine of the first embodiment of the present invention, figure 2 yes figure 1 The schematic and partial enlarged view of the fixed guide for the engine shown, image 3 is in figure 2 The cross-sectional view and partial enlarged cross-sectional view of the I-I line, Figure 4 is in figure 2 The sectional view and partial enlarged view of the II-II line, Figure 5 is in figure 2 Sectional view and partial enlarged view of line III-III.

[0062] First, if figure 1 As shown, the engine fixed guide device 100 of the first embodiment of the present invention is used together with the following components in the timing system of the automobile engine. The components are the driving side sprocket S1 in the engine; the driven side chain in the engine...

Embodiment 2

[0077] Next, a fixed guide device for an engine according to a second embodiment of the present invention will be described based on the drawings.

[0078] here, Figure 6 It is a schematic view and a partially enlarged view of a fixed guide device for an engine according to a second embodiment of the present invention, Figure 7 is along Figure 6 The sectional view and partial enlarged view of the IV-IV line, Figure 8 is along Figure 6 The cross-sectional view and partial enlarged view of the V-V line, Figure 9 is along Figure 6 The cross-sectional view and partial enlarged view of the VI-VI line.

[0079] Compared with the fixed guide device 100 for the engine of the first embodiment, the fixed guide device 200 for the engine of the second embodiment of the present invention is only different in the structure of the thin groove part for reinforcement, and the structure of the remaining parts basically does not have any structure. As for the changes, the same compo...

Embodiment 3

[0083] Next, a fixed guide device for an engine according to a third embodiment of the present invention will be described based on the drawings.

[0084] here, Figure 10 It is a schematic view and a partially enlarged view of a fixed guide device for an engine according to a third embodiment of the present invention, Figure 11 is along Figure 10 Sectional view and partial enlarged view of line VII-VII. The engine fixed guide device 300 of the third embodiment of the present invention is compared with the engine fixed guide device 100 of the above-mentioned first embodiment, only the structure of the reinforcing thin groove part is different, and the structure of the remaining parts basically does not have any structure. As for the changes, the same components as those of the fixed guide device 100 for the above-mentioned engine are marked with the corresponding symbols of No. 300, and the repeated description thereof will be omitted.

[0085] The groove end 323 of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com