Reverse gear device and motor tricycle

A technology of three-wheeled motorcycles and reverse gears, which is applied to gear transmissions, belts/chains/gears, components with teeth, etc., and can solve gear wear, damage to reverse gear casings, early wear of gears, etc. problems, to achieve the effect of increasing service life, solving early wear, improving installation accuracy and transmission rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

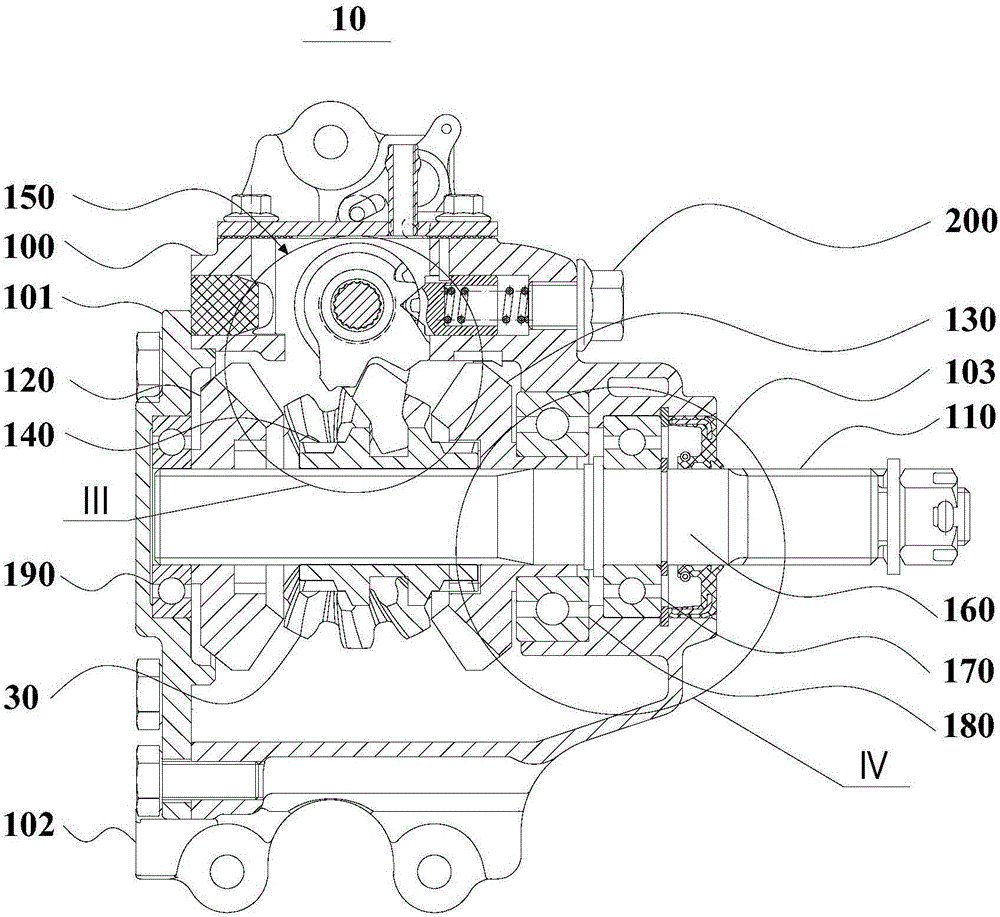

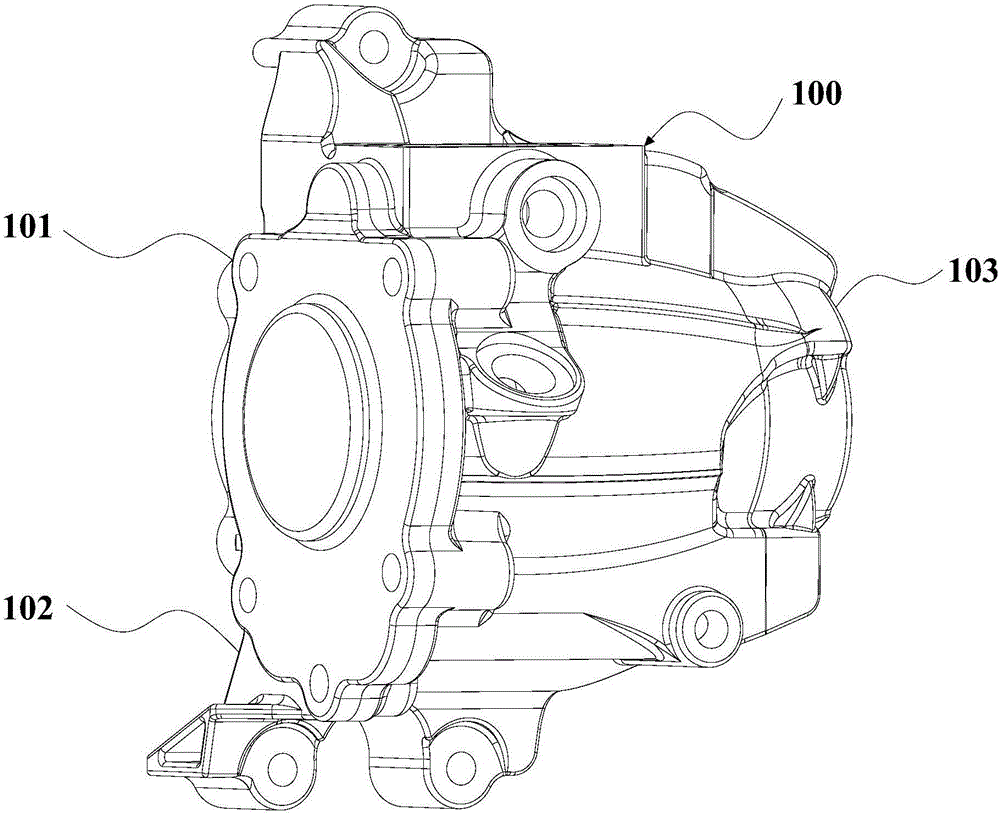

[0042] Please refer to figure 1 , figure 1 The specific structure of the reverse gear 10 provided in Embodiment 1 is shown.

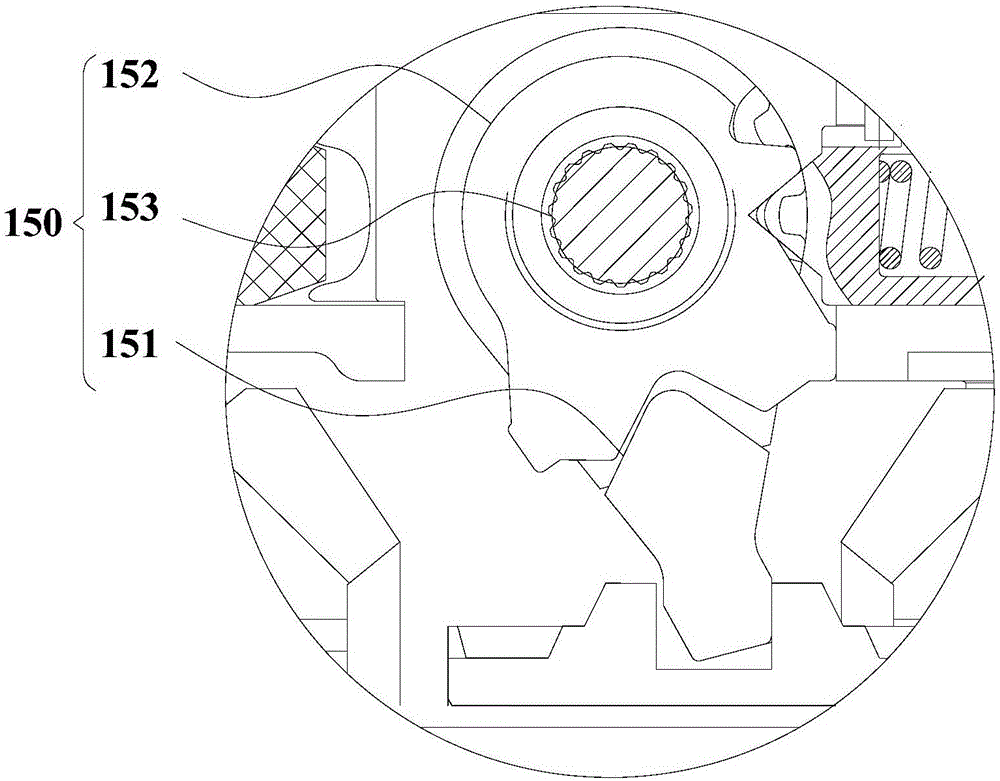

[0043] Please refer to figure 1 The reverse gear 10 includes a casing 100, a rear end cover 101, a spline shaft 110, a reverse bevel gear 120, a forward bevel gear 130, a clutch 140, a shift fork 150, an axial limiter 160, a second A bearing 170 , a second bearing 180 , a third bearing 190 and a shift positioning part 200 .

[0044]Among them, the reverse bevel gear 120, the forward bevel gear 130, the clutch 140, the shift fork part 150, the axial limit part 160, the first bearing 170, the second bearing 180, the third bearing 190 and the shift positioning part 200 It is arranged in the case 100. One end of the spline shaft 110 is located inside the housing 100 , and the other end is located outside the housing 100 . The casing 100 is closed by a rear end cover 101 . The axial limiting portion 160 is used to limit the relative position of the spl...

Embodiment 2

[0068] Please refer to Figure 5 , Figure 5 The specific structure of the three-wheeled motorcycle 20 provided by this embodiment is shown.

[0069] The three-wheeled motorcycle 20 has the reverse gear 10 provided in the above-mentioned embodiment 1. The three-wheeled motorcycle 20 is provided with the reverse gear 10 to realize the backward or forward movement of the locomotive, which can solve the damage to the reverse gear 10 casing and the early wear and tear of the gears. The problem of solving the problem increases the service life of the reverse gear 10, and avoids the danger brought to the three-wheeled motorcycle 20 and the user due to the failure of the reverse gear 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com