Engine balance shaft structure

A technology for balancing shafts and engines, applied in mechanical equipment, vibration suppression adjustment, springs/shock absorbers, etc., can solve problems such as oil aging and acceleration, and achieve the effect of extending the oil change cycle, avoiding early wear, and compact layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following will be described in conjunction with the embodiments and accompanying drawings.

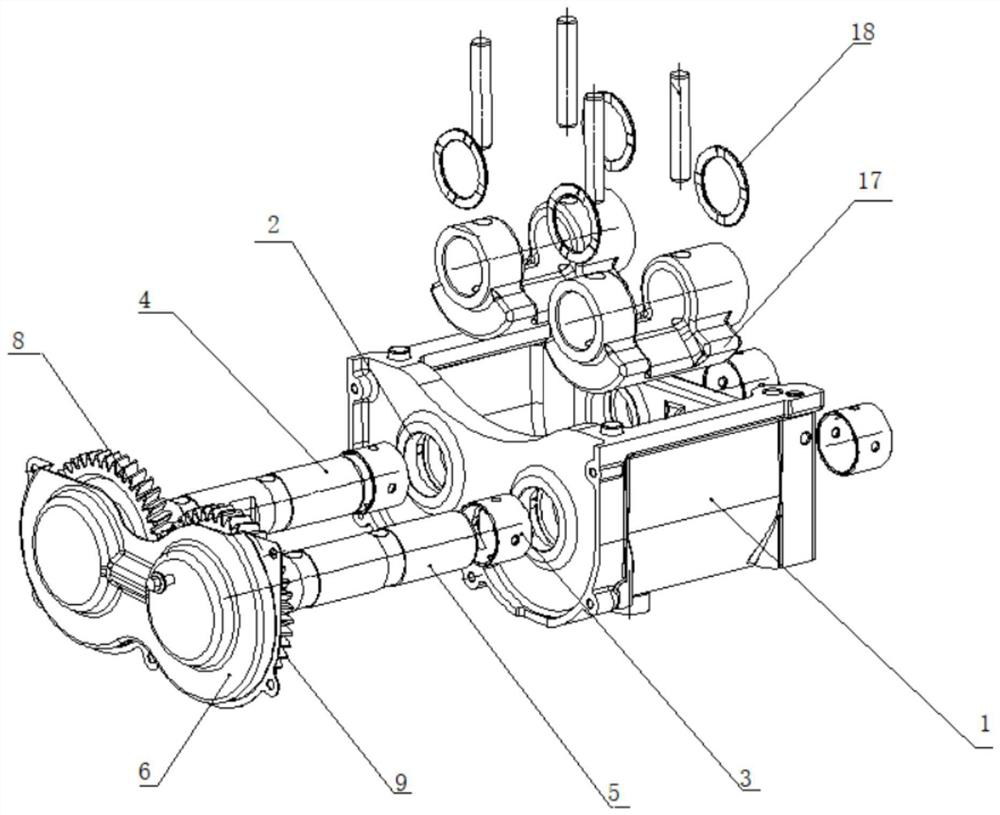

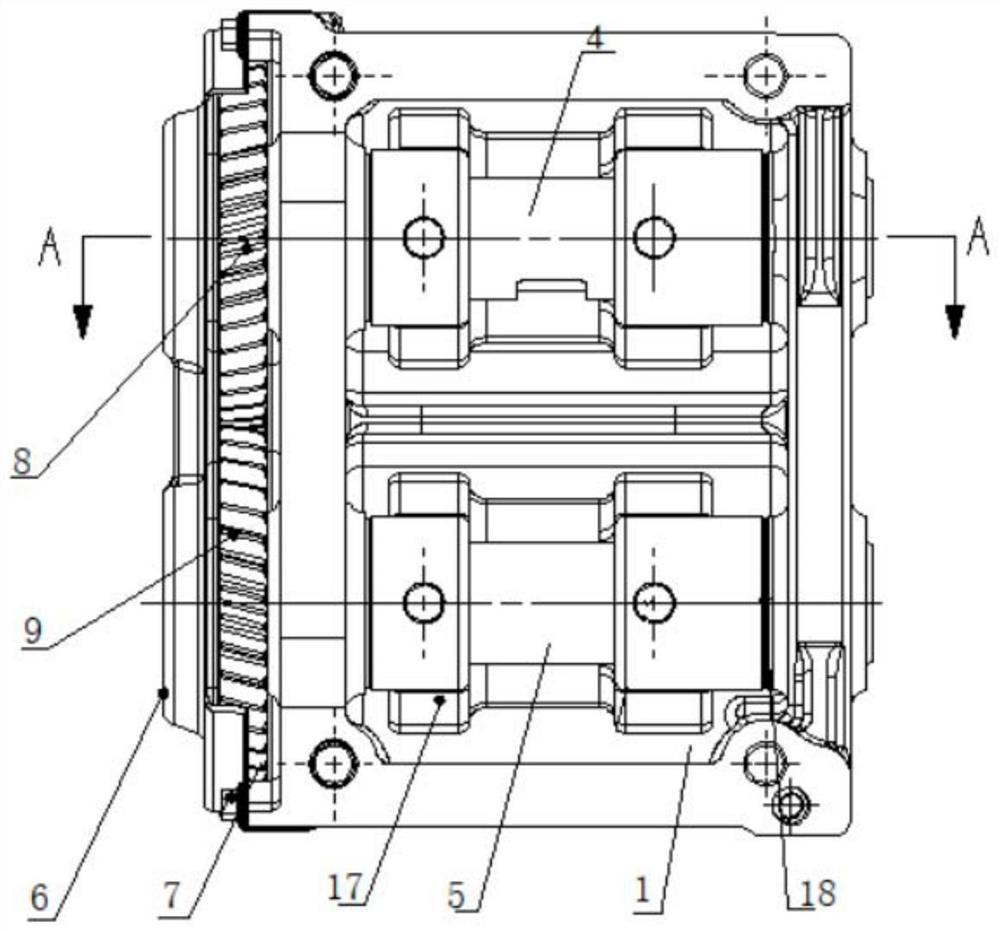

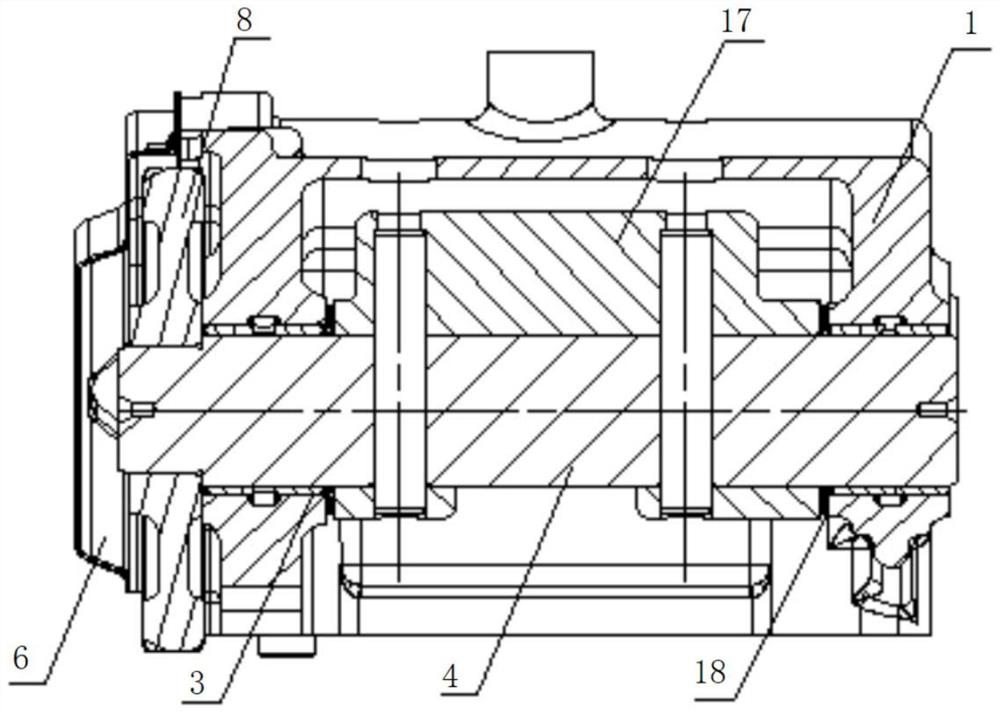

[0025] Such as Figure 1-3 As shown, the present invention provides an engine balance shaft structure, including a balance shaft chamber 1, a cover plate 6, a bearing bush 3, a first balance shaft 4 and a second balance shaft 5, a driving gear 8 and a transmission gear 9, Among them, the balance shaft chamber 1 is used as an installation carrier, integrating the oil circuit; the bearing bush 3 is installed on the bearing hole 2 of the balance shaft chamber 1, and forms a rotating pair with the first balance shaft 4 and the second balance shaft 5 at the same time; The gear 8 and the transmission gear 9 are installed on the first balance shaft 4 and the second balance shaft 5 respectively, and the gears mesh with each other and are located outside the balance shaft chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com