A processing method and a pocket hole processing device for an integral cage of a wind power equipment bearing

A technology for wind power equipment and processing devices, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as difficult guarantee of technical requirements, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

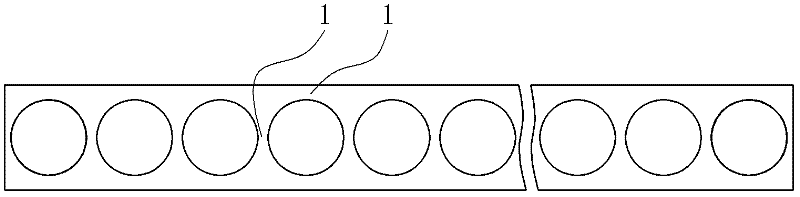

[0038] The processing method of the integral cage of the wind power bearing includes the steps of blanking, rough rounding, welding, fine rounding, and shaping; it also includes the step of processing pocket holes; A strip-shaped plate without pockets; the step of processing the pockets is located after the fine rounding step and before the shaping step.

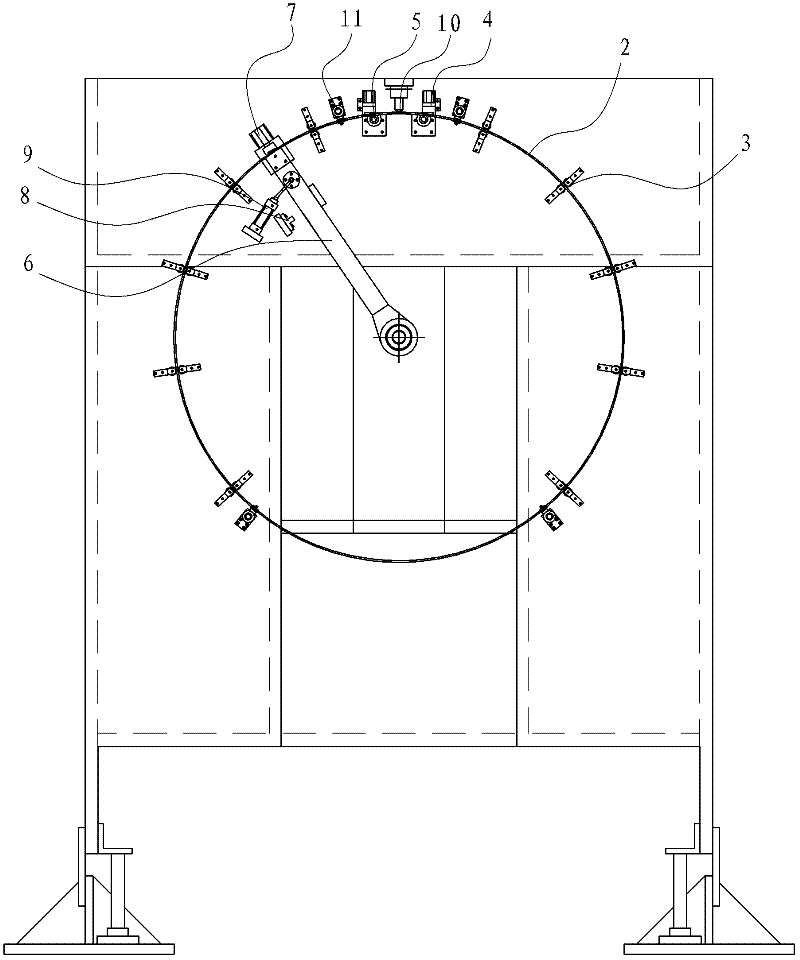

[0039] Such as figure 2 As shown, the wind power bearing overall cage pocket hole processing device mainly includes a support mechanism 3, a radial positioning mechanism 4, an axial positioning mechanism 5, a drive cage moving mechanism, a boom limit mechanism, and a cage movement limit mechanism 11.

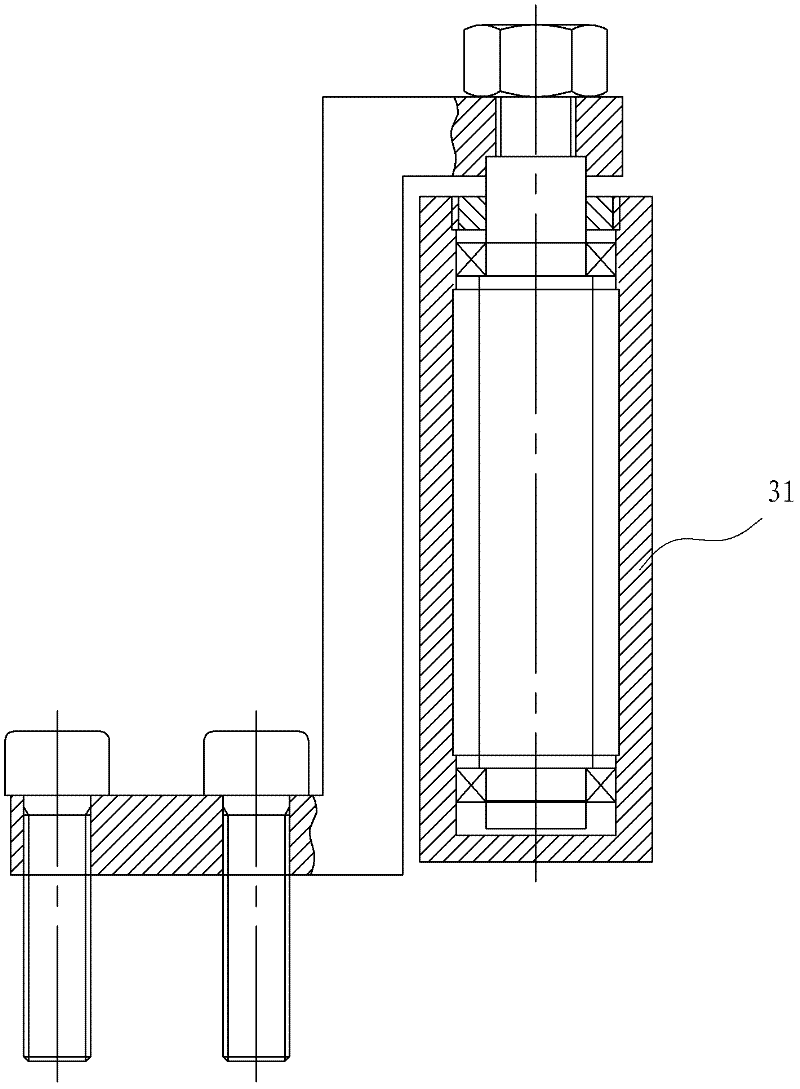

[0040] Such as image 3 , 4 As shown, the support mechanism 3 includes 20 pairs of rollers 31 with relatively fixed positions; each pair of rollers is arranged in parallel and the axial direction is parallel to the axial direction of the cage 2, and there is a gap for placing the cage 2 between the two rollers 31; multiple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com