Multi-layer parking system for all-electric vehicle

A multi-layer, pure electric technology, applied in the field of vehicle transmission system, can solve the problems that do not meet the electric powertrain of pure electric vehicles, high radial dimension requirements of electric powertrain, small axial length of parking system, etc. , to achieve the effect of reducing the moment of gravity, facilitating assembly and maintenance, and reducing the radial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

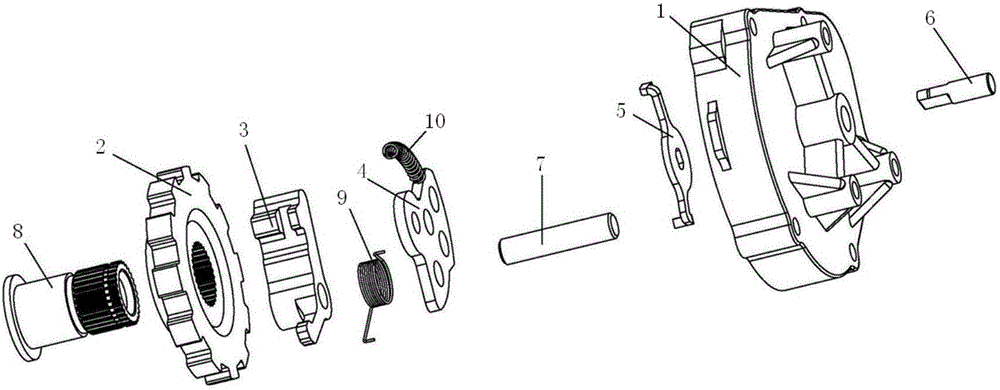

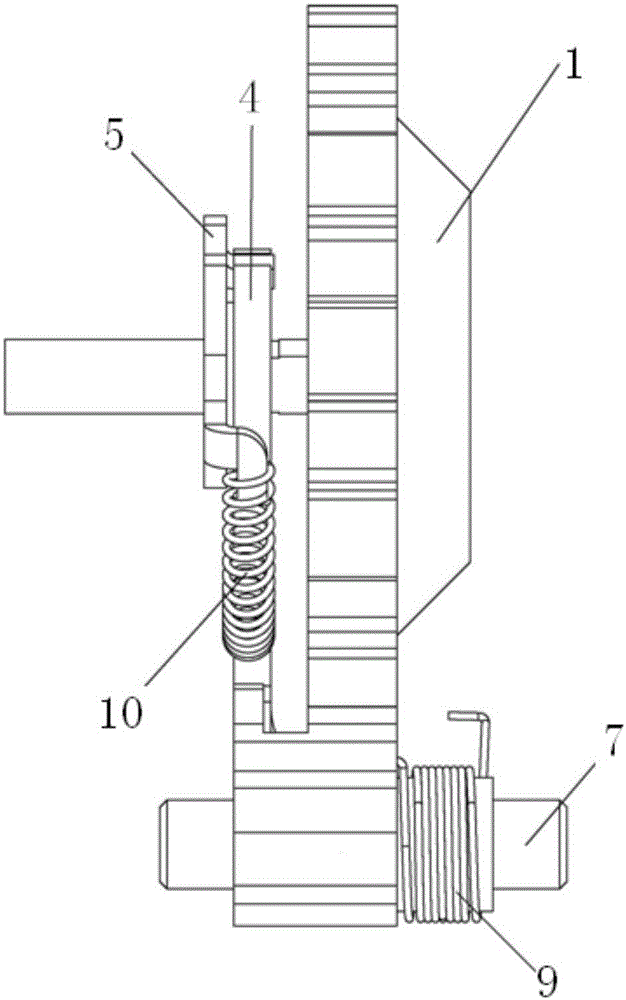

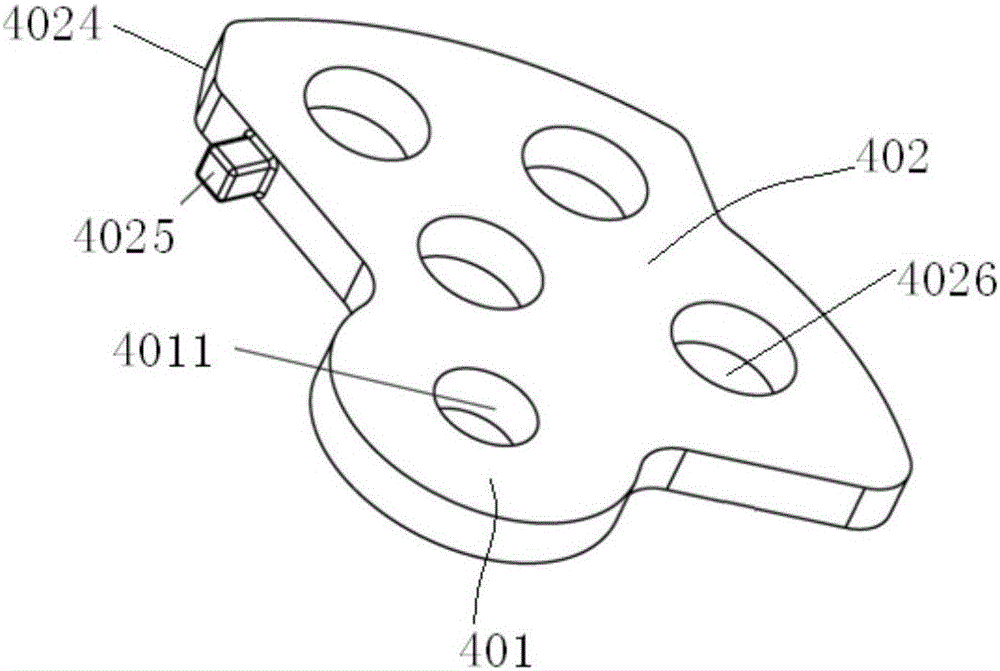

[0033] like figure 1 and figure 2As shown, a multi-level parking system for pure electric vehicles includes a housing 1, a ratchet 2, a pawl 3, a pawl shaft 7, a torsion spring 9, a cam disc 4, a drive member 5 and a drive shaft 6 The ratchet is fixedly installed on the rotating shaft 8 in the transmission that maintains power transmission with the wheels all the time; the rotating shaft 8 of the ratchet 2 can be arranged coaxially with the drive shaft 6 or not. In this embodiment, the rotation shaft 8 of the ratchet 2 is coaxially arranged with the drive shaft 6 . A hole for supporting the pawl shaft 7 and the drive shaft 6 is arranged on the housing 1, the pawl shaft and the drive shaft are not coaxially arranged on the housing, and one end of the pawl shaft is fixed on the housing 1, The other end can be installed on the transmission housing, the pawl is rotatably arranged on the pawl shaft; the cam disc is rotatably arranged on the drive shaft, and the driving member is...

Embodiment 2

[0059] like Figure 8 As shown, compared with Embodiment 1, the difference between the multi-level parking system for pure electric vehicles shown in Embodiment 2 is that the housing is fixed with a The limit block A101 and the limit block B102 that prevent the cam plate from exceeding the fully unlocked position. That is, the limit block A and the limit block B are fixed on the housing 1, respectively corresponding to the fully parked position and the fully unlocked position, to limit the limit rotation position of the cam disc, and prevent the cam disc from exceeding the fully parked position or the fully unlocked position.

[0060] Preferably, a limit block C for preventing the driving member from exceeding the fully parked position and a limit block D for preventing the drive member from exceeding the fully unlocked position are affixed to the housing. That is, the limit block C and the limit block D are fixed on the housing 1, respectively corresponding to the fully park...

Embodiment 3

[0062] like Figure 9 As shown, compared with Embodiment 1, the multi-storey parking system for pure electric vehicles shown in Embodiment 3 also includes a sensor 11, and the sensor 11 detects the angular position of the drive shaft rotation, thereby detecting in real time the parking system used for pure electric vehicles. The working state of the multi-storey parking system of the vehicle realizes the closed-loop control of the parking system.

[0063] The multi-layer parking system of the present invention is arranged on the outside of the transmission, which is beneficial to the installation and maintenance of the parking system, and enables the same parking system to be matched to similar vehicles, thereby improving the multi-layer parking for pure electric vehicles The application range of the system improves the safety of pure electric vehicles. Since each mechanism of the parking system is arranged in multiple layers, the radial dimension of the parking system can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com