Klingelnberg bevel gear contact regulating method

A technology of gears and contact areas, applied in the field of contact adjustment of Klingenberg bevel gears, which can solve problems such as local stress concentration, broken teeth, and gear wear, and achieve the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

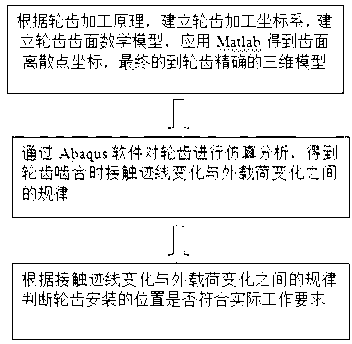

[0030] Concrete implementation steps of the present invention are as follows:

[0031] The first step: according to the principle of Klingenberg bevel gear tooth surface machining, establish an accurate three-dimensional model of gear teeth

[0032] Step (1): Establish gear tooth machining coordinate system and tooth surface mathematical model

[0033] Klingenberg bevel gears are cycloidal bevel gears with equal-height teeth, that is, the tooth line in the tooth length direction is an extended epicycloid, and the tooth height is equal along the sub-cone busbar. The processing method of Klingenberg bevel gear adopts the full generation method, that is, the tool shaft cannot be tilted, and the contact area of the tooth surface is controlled by adjusting the center offset of the inner and outer tool rotation and the radius of the outer tool for synchronous rotation. figure 1 Schematic diagram of a cycloid tooth incisor.

[0034] According to the structure and motion character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com