Full-automatic locking barrel type sampling, sample preparation and packaging system for bulk materials

A technology of bulk material and packaging system, applied in the direction of automatic control of packaging, types of packaging items, special packaging items, etc., can solve the problems of packaging barrels without identification function of packaging barrels, inability to achieve automatic lofting, automatic packaging, and high labor intensity. Achieve the effect of intelligent packaging process, realize human-like separation, and avoid artificial cheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

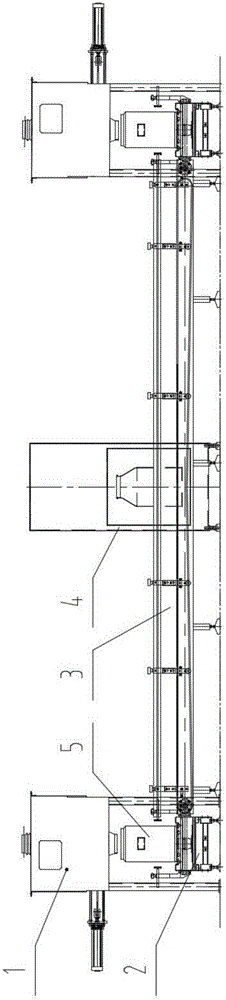

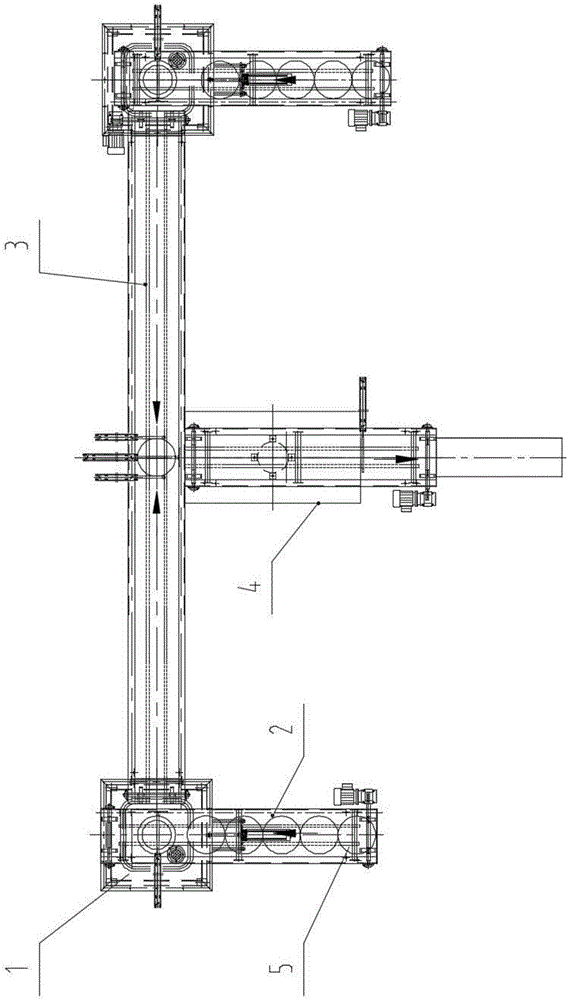

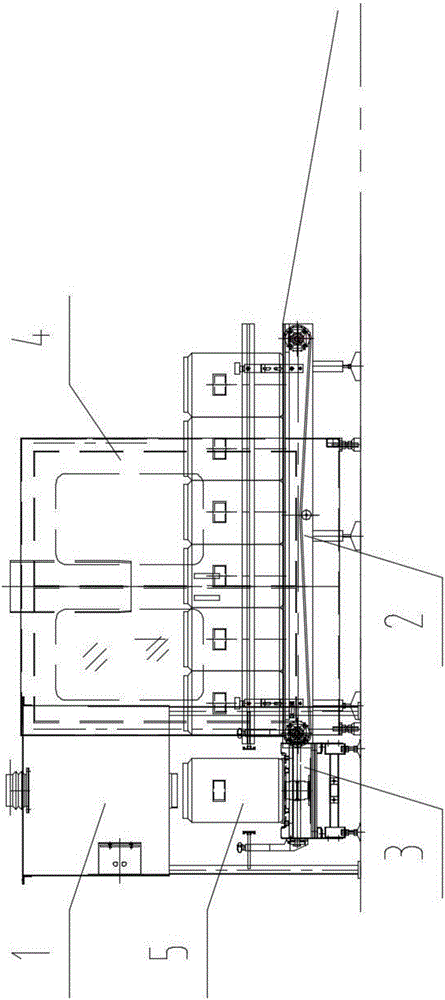

[0026] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the moving direction of the packaging barrel 5 is used as the front description).

[0027] Such as figure 1 , figure 2 , image 3 As shown, the automatic locking barrel type bulk material sampling and packaging system includes a filling device 1, a barrel feeding device 2, a reloading and conveying device 3, a sealing device 4, a packaging barrel 5 and an electric control device.

[0028] The filling device 1 is fixedly installed on the ground through the support frame of the filling device. The filling device 1 includes a storage hopper and a weighing platform; the upper end of the storage hopper is airtightly connected with the feeding system through a pipeline, and the lower end is connected to the The blanking cylinder is fixedly connected and communicated, and the blanking cylinder is vertically set on the weighing platform; the weighing platform is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com