Automatic logistics forklift capable of achieving stable inserting mounting of weight

A heavy object and logistics technology, applied in the direction of lifting devices, etc., can solve the problems of high labor intensity, low efficiency, and reduced automation of logistics and warehousing for operators, and achieve the effect of improving loading and unloading efficiency and realizing intelligent operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings (hereinafter, the direction in which the working part 5 is installed on the support platform 4 is described as the front).

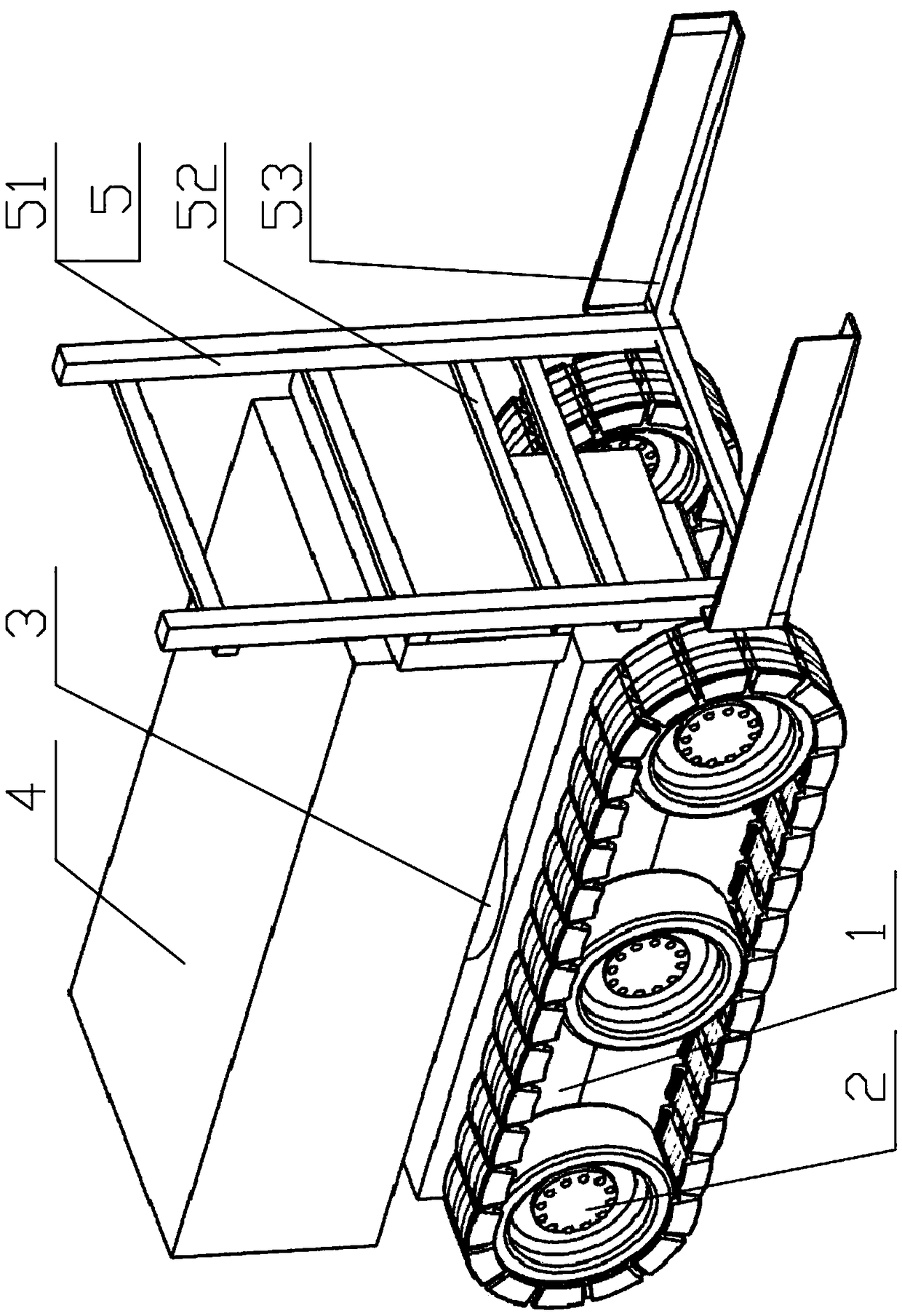

[0018] Such as figure 1 As shown, the automatic logistics forklift that can stably insert heavy objects includes a frame 1, a running part 2, a slewing bearing 3, a supporting platform 4, a working part 5, a hydraulic system and an electric control system.

[0019] The support platform 4 is erected and installed on the vehicle frame 1 through the slewing bearing 3. The slewing bearing 3 is provided with a hydraulic slewing drive. The setting of the slewing bearing 3 can make the automatic logistics forklift that can stably insert heavy objects free The height is increased, and it is suitable for a narrow loading and unloading space. The working part 5, hydraulic system and electric control system are all installed on the support platform 4.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com