Bolt automatic placing unit for net rack connecting rod automatic welding production system

An automatic welding and production system technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the influence of welding quality, the unbalanced load force of the grid connecting rod, and the inability to accurately ensure the through hole of the sealing plate or the cone head Coaxial and other issues, to achieve a high degree of automation, to avoid the effect of manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The grid connecting rod automatic welding production system is a digital control system, which can be seamlessly connected with the digital bus of the digital factory to realize centralized digital management. The present invention will be further described below in conjunction with the accompanying drawings (below, the length direction of the steel pipe workpiece 6 is described as the left-right direction).

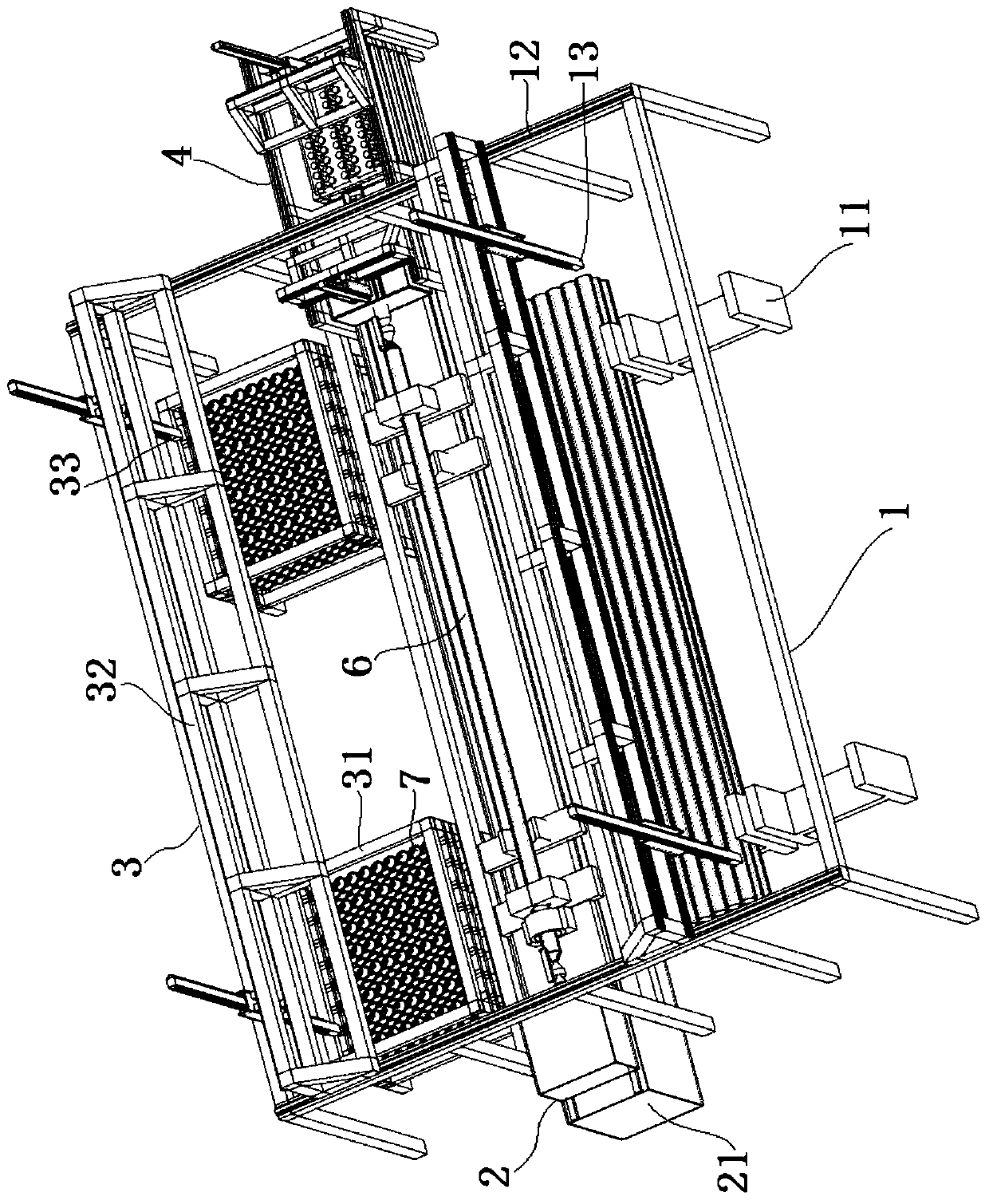

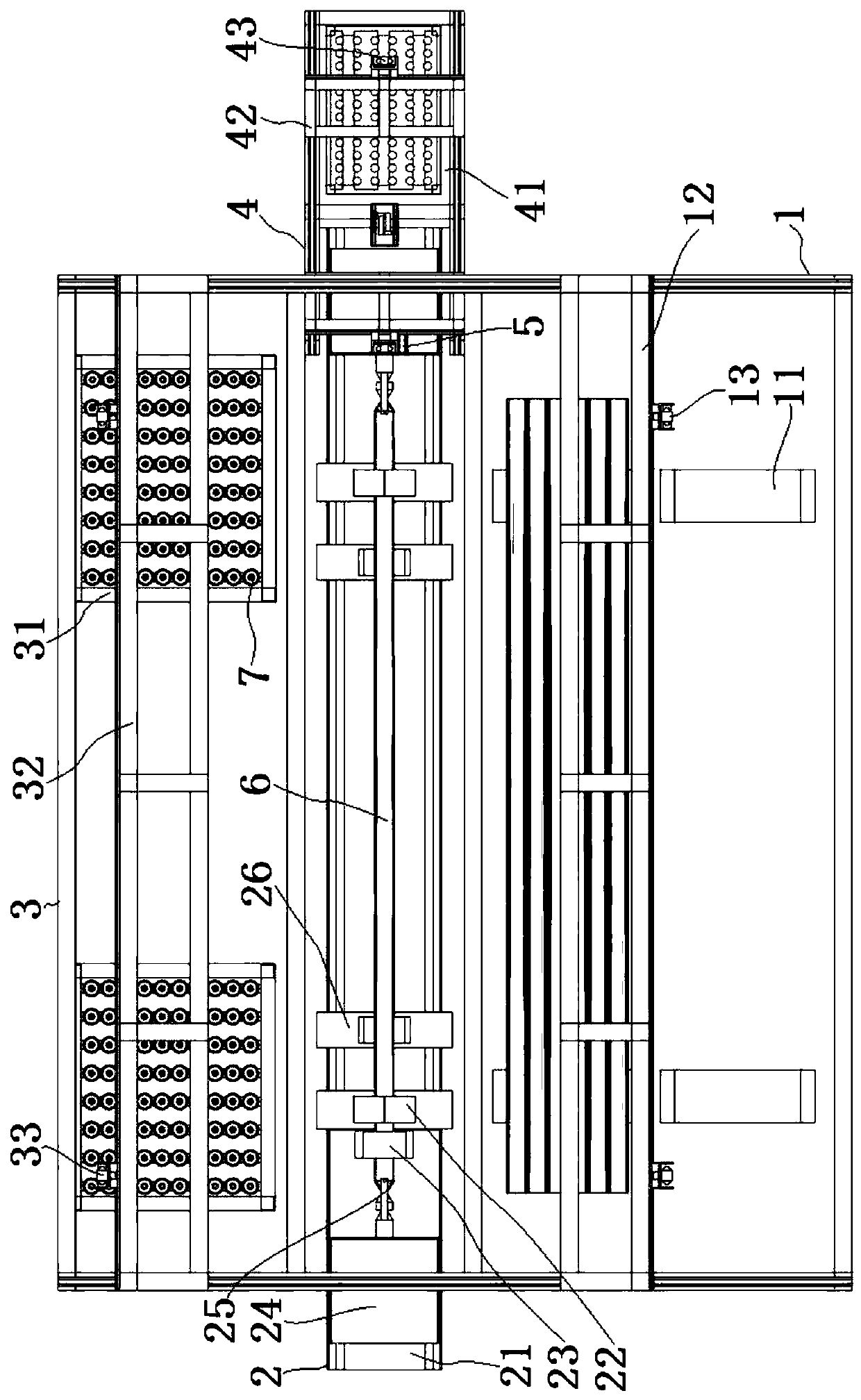

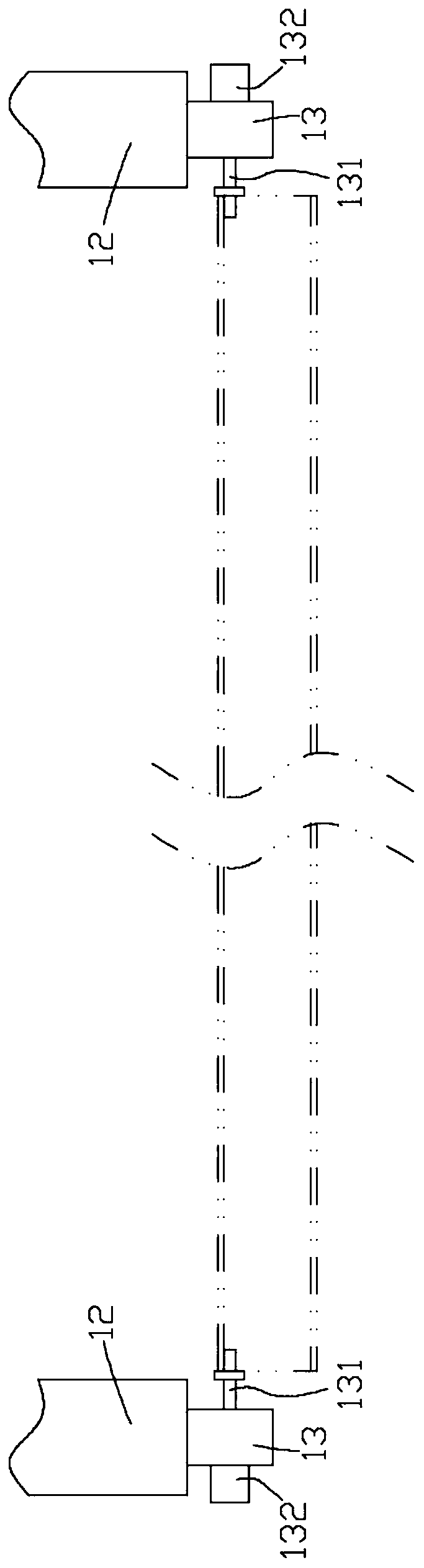

[0037] Such as figure 1 , figure 2 As shown, the grid connecting rod automatic welding production system includes a steel pipe loading and unloading unit 1, an automatic welding unit 2, a sealing plate or cone head supply unit 3, an automatic bolt insertion unit 4 and a centralized electric control unit.

[0038] The steel pipe upper and lower line unit 1 is set at a set position within the range around the automatic welding unit 2, such as figure 2 As shown, the steel pipe loading and unloading unit 1 is arranged directly behind the automatic welding unit 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com