Pulse coefficient calculation method for automatic voltage control system of thermal power plant

A technology of automatic voltage and control system, applied in the direction of single-network parallel feeding arrangement, etc., can solve the problems of limitation and loss of coefficient accuracy, and achieve the effect of improving speed and accuracy, and improving calculation accuracy and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

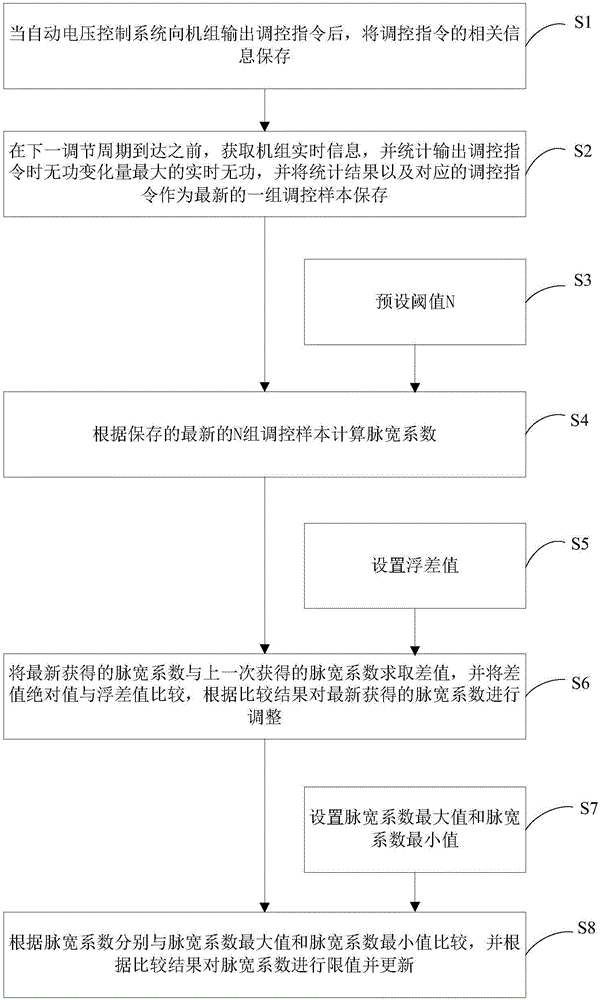

[0024] refer to figure 1 A method for calculating the pulse width coefficient of an automatic voltage control system of a thermal power plant proposed by the present invention includes the following steps.

[0025] S1. After the automatic voltage control system outputs the control command to the unit, save the relevant information of the control command.

[0026] The relevant information of the control command includes the pulse signal, that is, the pulse width of magnetization increase or pulse width of demagnetization output by the excitation regulator (AVR) of the unit, and the pulse width length can be obtained directly from the pulse signal. In this embodiment, by saving the control command, it is convenient to count the real-time data and directly call the relevant information of the control command, such as the pulse width.

[0027] S2. Before the arrival of the next adjustment period, obtain the real-time information of the unit, and count the real-time reactive power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com