Automatic soldering instantaneous welder

A technology for welding machines and welding manipulators, which is applied to welding equipment, connections, tin feeding devices, etc., can solve problems such as low efficiency, heavy workload, and high labor intensity, and achieve simple operation structure, convenient maintenance, and improved welding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

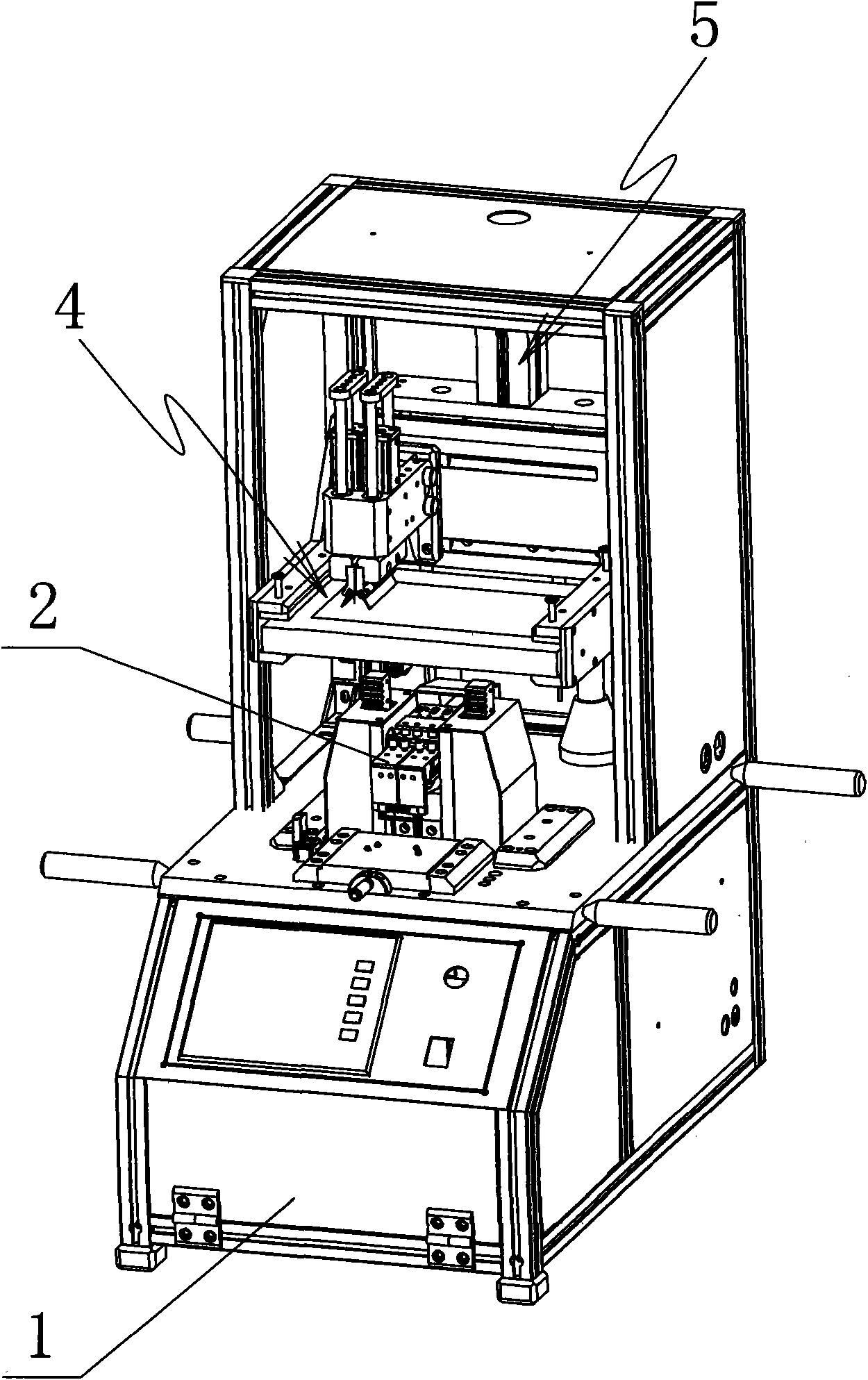

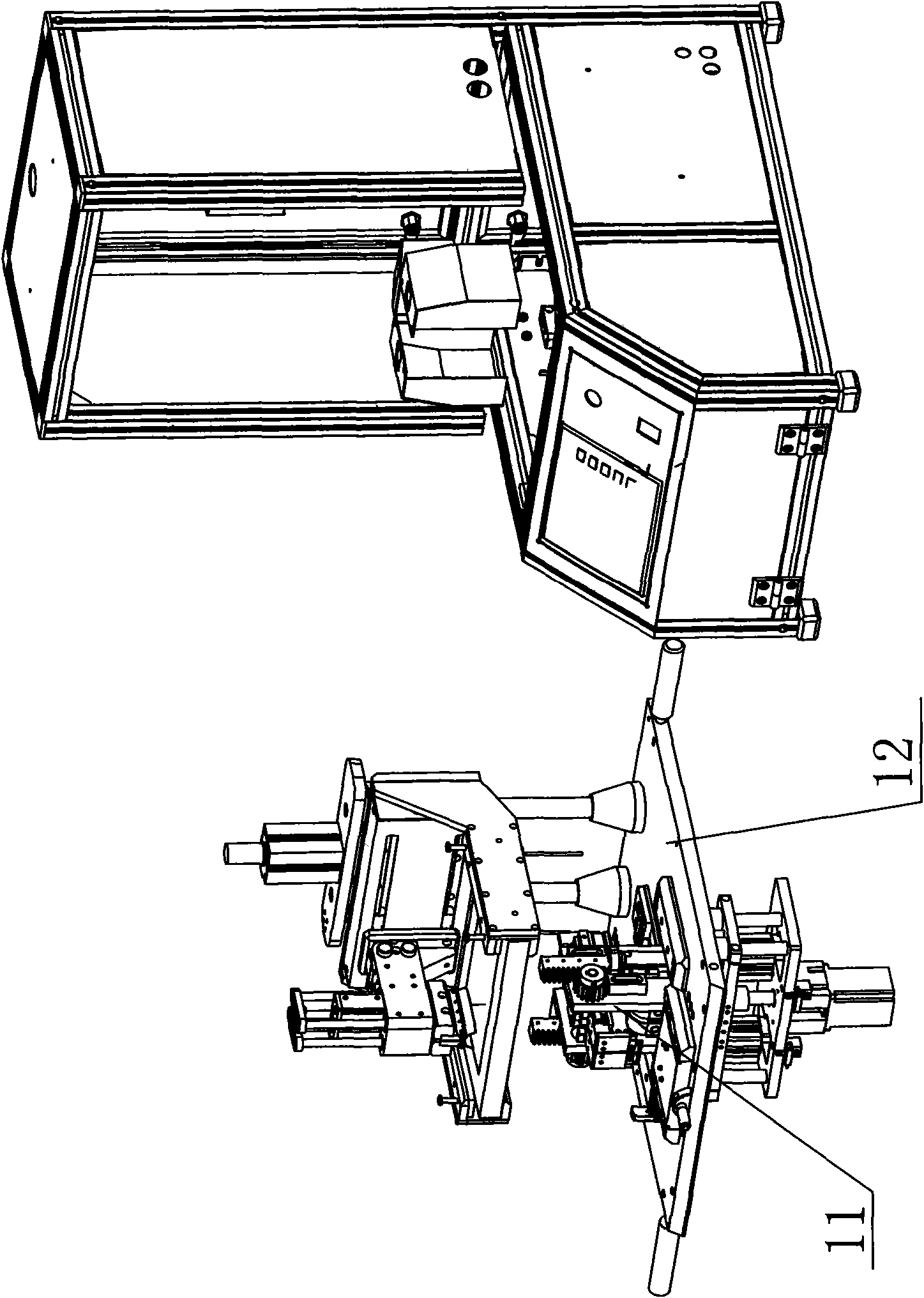

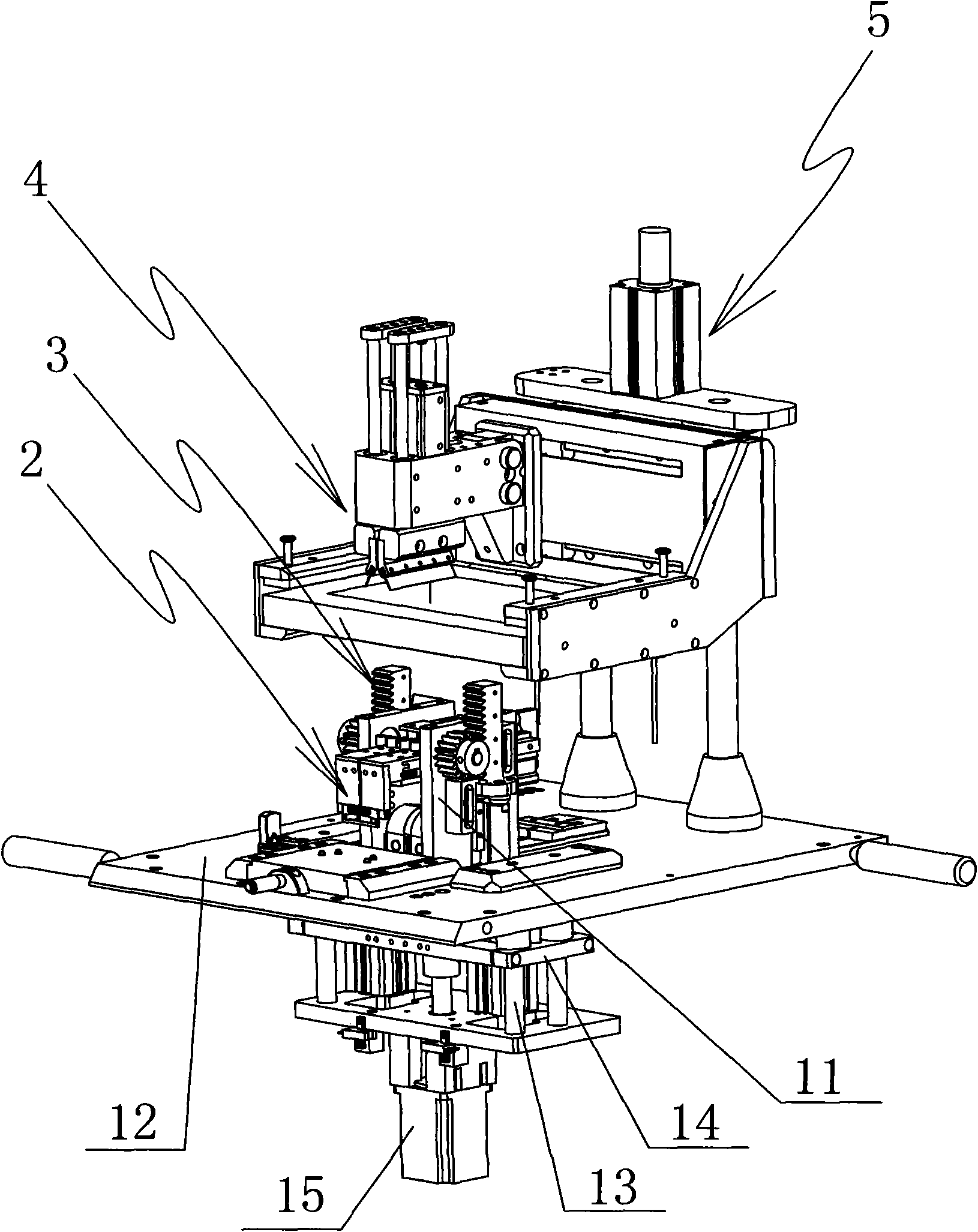

[0026] As shown in the figure, the automatic tinning instant welding machine includes a frame 1, a base 11 is provided on the frame 1, a welding manipulator 2 is rotatably connected to the base 11, and a welding head 21 is provided at the front end of the welding manipulator 2. The seat 11 is also provided with a first driving assembly 3 that can drive the welding manipulator 2 to turn back and forth so that the welding head 21 can switch back and forth between the welding station and the tin brushing station. The tinning assembly 4 for brushing the solder paste and the second drive assembly 5 that drives the tinning assembly 4 to move in translation, the tinning assembly 4 is located above the soldering head 21 tin brushing station.

[0027] Wherein, the welding manipulator 2 is provided with a positive electrode conductive block 81 and a negative electrode conductive block 82 spaced apart, the positive electrode conductive block 81 and the negative electrode conductive block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com