Round setting technique for pipe end of large-size pipe fitting

A process method and pipe end technology, which is applied in the field of large-scale pipe end rounding technology, can solve the problems of difficulty in butt welding of pipe fittings, poor consistency of pipe end dimensions, and dependence on workers' operating experience. Improve the dimensional accuracy and shape consistency of the pipe end, and the effect of little dependence on operating experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. The production of tube blanks

[0027] Pre-bend the longitudinal edge of the milling and welding groove with a specification of 12000mm×3190mm×20mm, and then send the slab into the forming machine to make the slab into an O shape, and perform pre-welding, internal welding, and external welding on the formed tube blank. Welding treatment, welding the longitudinal sides of the tube blank to obtain the tube blank 1 with a specification of Ф1016×20mm.

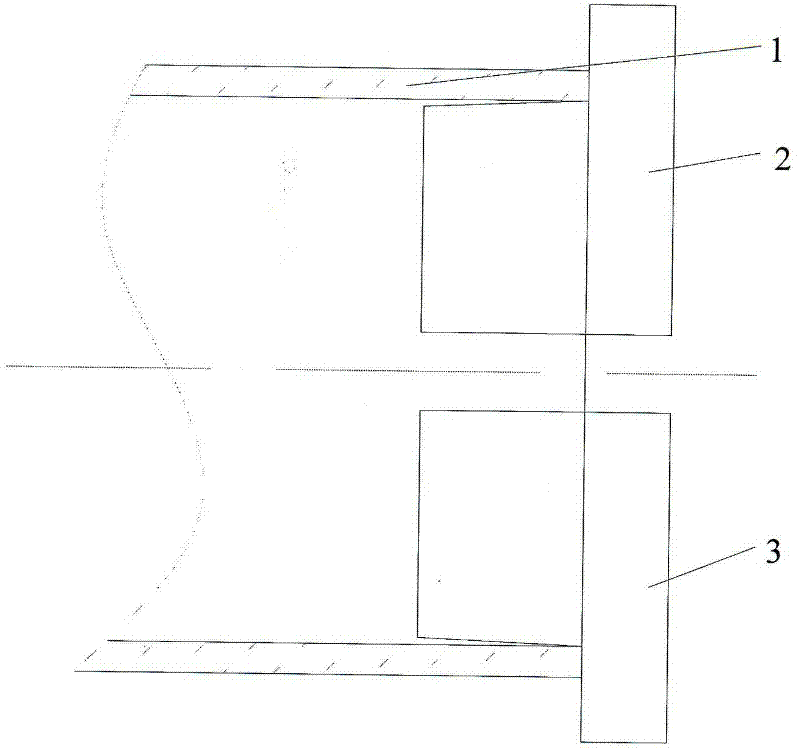

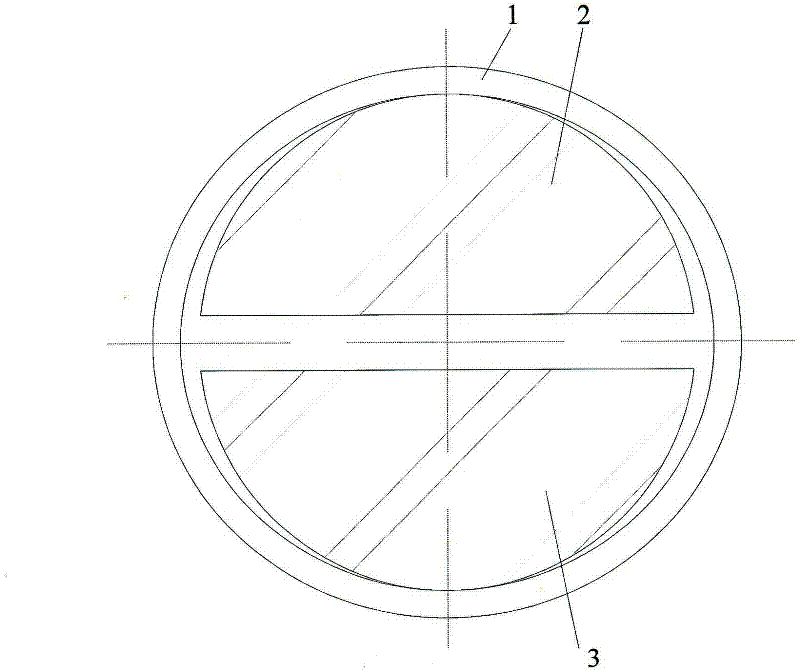

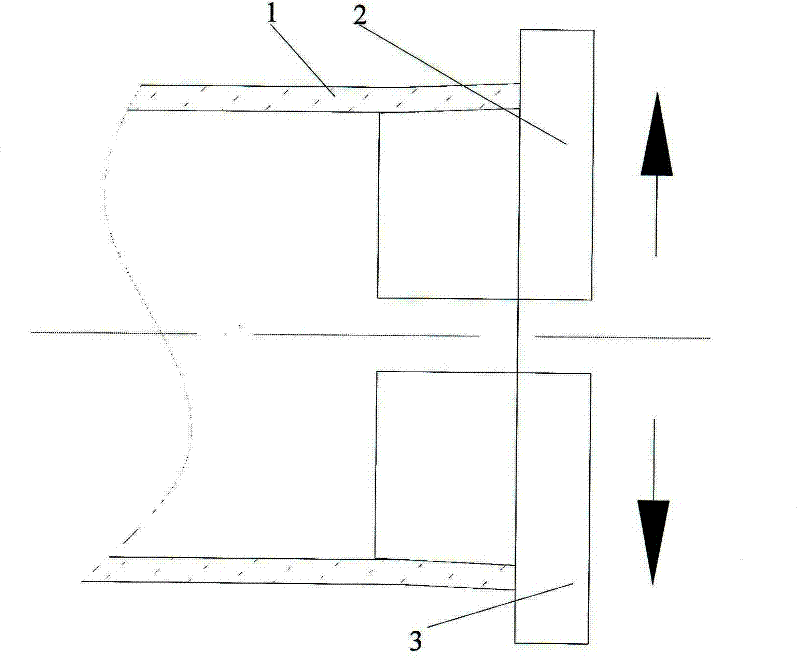

[0028] 2. Rounding of end face diameter

[0029] Convey the tube blank 1 from the track to the internal expansion mold, such as figure 1 , 2 shown. The shape of the expansion mold is as Figure 5 As shown, the axial section of the cone is arc-shaped, the radius of the big end is R460mm, the cone angle is 3°, and the length of the cone is 150mm. Then the two internal expansion molds move towards each other under the drive of the driving device to expand the tube blank, such as image 3 , 4 As shown, make the circumf...

Embodiment 2

[0031] After the welding described in Example 1 is completed, the tube blank 1 is delivered to the expanding four-lobe module by the conveying device, such as Figure 6 shown. The shape of the expanded four-lobe module is as follows Figure 8 As shown, the large end arc radius of the cone part is R460mm, the cone angle is 3°, and the cone length is 150mm. Subsequently, the expansion four-lobe module moves towards each other under the drive of the driving device, and the tube blank is expanded, such as Figure 7 As shown, the circumference dimension of the end of the tube blank is finally made, that is Figure 7 The four times of the sum of C dimension and D dimension is 3222mm. Subsequently, the expanded tube blank is sent by the conveying device between the upper and lower pressing valve molds installed on the general press, and the tube end of the tube blank is pressed and rounded to complete the rounding process of the tube end tube end. The cavity radius of the pressin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com