A kind of preparation method of high compaction density micron-scale single crystal ternary positive electrode material

A positive electrode material, micron-scale technology, applied in the direction of electrical components, battery electrodes, structural parts, etc., can solve the problems of limiting the application of ternary materials, low compaction density, secondary particle breakage, etc., and achieve good product shape consistency , increase the compaction density, improve the effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Add 18.3220g Ni 0.5 co 0.2 mn 0.3 (OH) 2 Add it into the ball mill tank, and ball mill it at 100r / min for 1h; then the ball milled Ni 0.5 co 0.2 mn 0.3 (OH) 2 Mix well with 0.1832g polyvinyl alcohol and 0.0092g boric acid, mix well and then place it at 400°C for 3h to get substance A;

[0028] Step 2. Add the substance A obtained in step 1 and 7.6107g lithium carbonate into a ball mill tank, and ball mill and mix for 3h at 200r / min to obtain the mixed substance B;

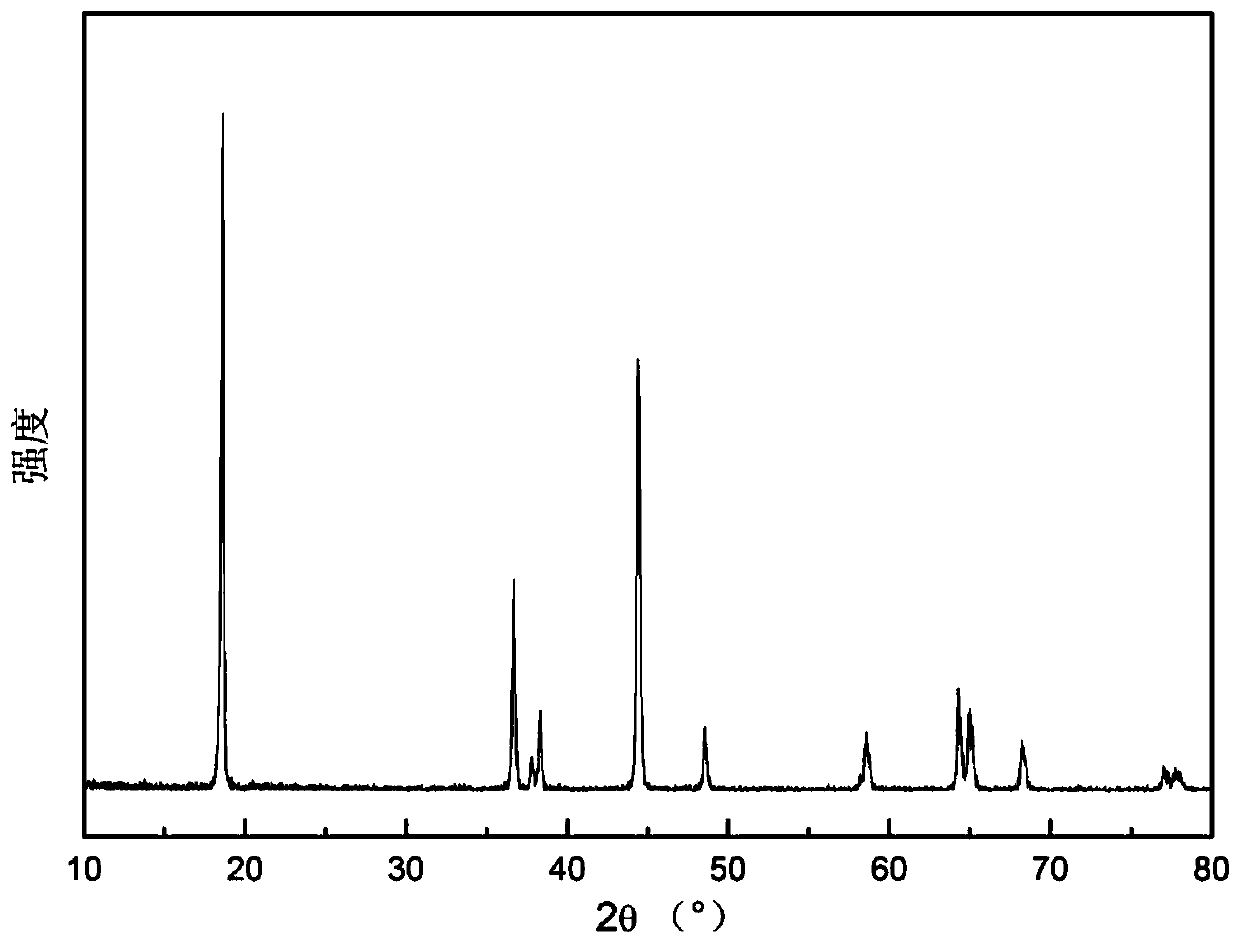

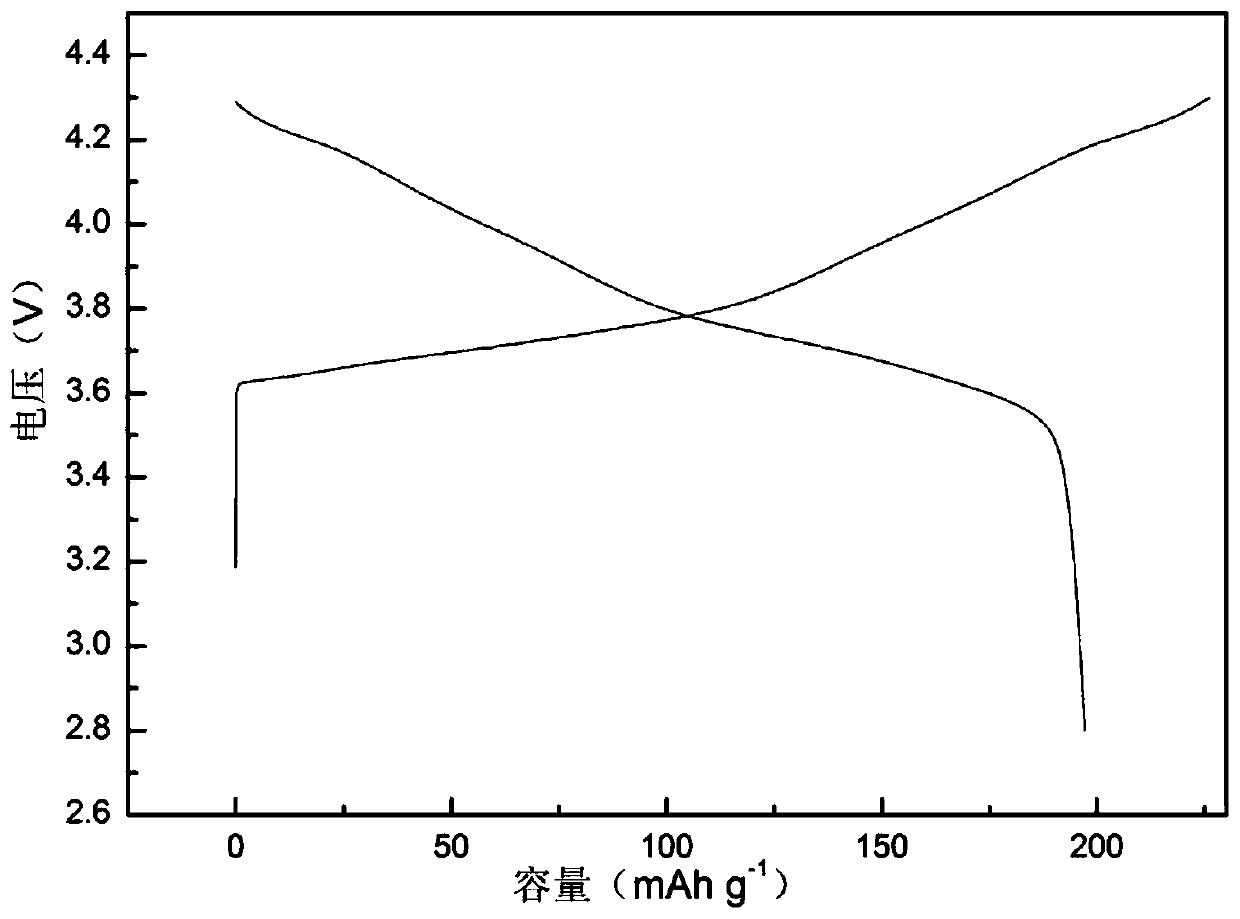

[0029] Step 3. Place the mixed substance B obtained in step 2 in a tube furnace, and feed into the tube furnace an oxygen-nitrogen mixed gas with an oxygen volume fraction of 20%, and heat it to 900° C. at a heating rate of 0.1° C. / min. After calcination at constant temperature for 10 hours, the temperature is naturally lowered to obtain a high compacted density micron-sized single crystal ternary positive electrode material.

[0030] From figure 1 It can be seen from the SEM image of the te...

Embodiment 2

[0033] Step 1. 32.608g (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 2 o 3 Add in the ball mill jar, ball mill and pulverize at 600r / min for 6h; then the ball mill pulverized (Ni 1 / 3 co 1 / 3 mn 1 / 3 ) 2 o 3 Mix well with 0.1630g of lithium fluoride and 3.2608g of polyvinylpyrrolidone, mix well and then place it at 550°C for 8h to obtain substance A;

[0034] Step 2. Add the substance A obtained in step 1 and 8.6438g of lithium hydroxide into a ball mill tank, and ball mill and mix at 500r / min for 2.5h to obtain the mixed substance B;

[0035] Step 3. Place the mixed substance B obtained in step 2 in a tube furnace, and feed an oxygen-nitrogen mixed gas with an oxygen volume fraction of 80% in the tube furnace, and heat it to 800 °C at a heating rate of 3.0 °C / min. After calcination at constant temperature for 15 hours, the temperature was naturally lowered to obtain a high compacted density micron-sized single crystal ternary positive electrode material.

[0036] It can be seen from the SEM...

Embodiment 3

[0039] Step 1. Add 18.4678g Ni 0.8 co 0.1 mn 0.1 (OH) 2 Add it into the ball mill tank, and ball mill it at 300r / min for 2h; then the ball milled Ni 0.8 co 0.1 mn 0.1 (OH) 2 Mix with 0.3417g of boron oxide evenly, and after mixing evenly, place it at 800°C for 6h to obtain substance A;

[0040] Step 2. Add the substance A obtained in step 1 and 14.4795g lithium nitrate into a ball mill tank, and ball mill and mix for 3h at 550r / min to obtain the mixed substance B;

[0041] Step 3. Place the mixed substance B obtained in step 2 in a tube furnace, feed pure oxygen into the tube furnace, heat it up to 700 °C at a heating rate of 5.0 °C / min, and naturally cool down after calcination at a constant temperature for 20 hours to obtain high Compacted density micron-scale single crystal ternary cathode material.

[0042] It can be seen from the SEM image of the ternary cathode material prepared in this embodiment that the particle size of the ternary cathode material is 4 μm˜7 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com