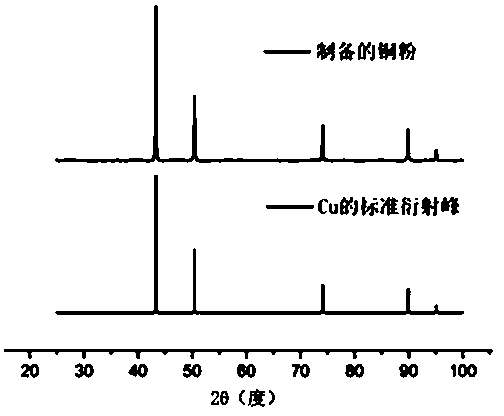

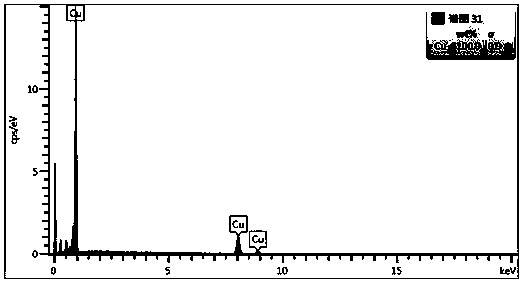

Method for preparing nano copper powder through fluorocarbon surfactant

A composite surfactant and fluorocarbon surface technology, applied in the direction of nanotechnology, can solve the problems of poor solution stability and uniformity, copper powder particle size, shape, and inability to achieve self-desorption, so as to achieve self-desorption Good attachment performance, good shape consistency, easy to clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a method for preparing nano-copper powder using a fluorocarbon surfactant comprises the following steps:

[0033] (1) Preparation of microemulsion: Weigh the following raw materials according to the ratio per liter of microemulsion: anionic fluorocarbon surfactant (sulfonate anionic fluorocarbon surfactant) 1.2g, nonionic surfactant (coconut oil fatty acid diethanolamide ) 3.6g, additive (ethanol) 12g, CuSO 4 ·5H 2O 30.0g; The anionic fluorocarbon surfactant (sulfonate anionic fluorocarbon surfactant), nonionic surfactant (coconut oil fatty acid diethanolamide) and auxiliary agent (ethanol) are added to the water of 200ml, Mechanically stirred for 10min to obtain a composite surfactant solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solution, and sulfuric acid was added to adjust the ...

Embodiment 2

[0039] In this embodiment, a method for preparing nano-copper powder using a fluorocarbon surfactant comprises the following steps:

[0040] (1) Preparation of microemulsion: Weigh the following raw materials according to the ratio per liter of microemulsion: anionic fluorocarbon surfactant (sulfonate anionic fluorocarbon surfactant) 0.5g, nonionic surfactant (Tween 80) 6.0g , additive (ethylene glycol) 15g, CuSO 4 ·5H 2 O 50.0g; Add the anionic fluorocarbon surfactant (sulfonate anionic fluorocarbon surfactant), the nonionic surfactant (Tween 80) and auxiliary agent (ethylene glycol) to 200ml of water , mechanically stirred for 30min to obtain a composite surfactant solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solution, and sulfuric acid was added to adjust the pH value of the solution to 2; ultrasonic disp...

Embodiment 3

[0046] In this embodiment, a method for preparing nano-copper powder using a fluorocarbon surfactant comprises the following steps:

[0047] (1) Preparation of microemulsion: Weigh the following raw materials according to the ratio per liter of microemulsion: 5.0 g of anionic fluorocarbon surfactant (sulfate anionic fluorocarbon surfactant), 20.0 g of nonionic surfactant (Tween 40 and Tween 40 Wen 61 is 15.0g, 5.0g respectively), additives (5g each of n-butanol and methanol) 10g, CuSO 4 ·5H 2 O 10 g; the anionic fluorocarbon surfactant (sulphate anionic fluorocarbon surfactant), the nonionic surfactant (Tween 40 and Tween 61) and adjuvants (n-butanol and methanol) were added to In 200ml of water, mechanically stirred for 20min to obtain a composite surfactant solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com