Method for preparing ultrafine copper powder by adopting microemulsion

A technology of ultra-fine copper powder and microemulsion, which is applied in the field of preparation of ultra-fine copper powder, can solve the problems of difficulty in meeting the requirements of industrialization, copper powder is easy to adhere to the cathode, and the particle size distribution is wide, so as to achieve self-desorption Good performance, easy to clean, and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

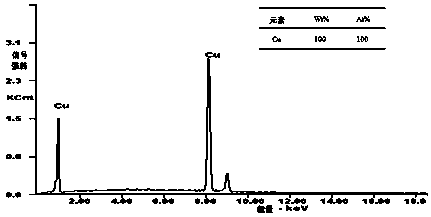

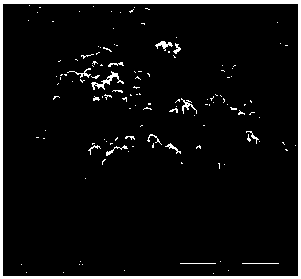

Image

Examples

Embodiment 1

[0029] A kind of method that adopts microemulsion to prepare ultrafine copper powder of the present embodiment, comprises the following steps:

[0030] (1) Preparation of electrolyte: Weigh the following raw materials according to the ratio per liter of electrolyte: anionic surfactant sodium dibutylnaphthalene sulfonate 1.0g, nonionic surfactant fatty alcohol polyoxyethylene ether 3.0g, CuSO 4 ·5H 2 0.25.0g; The anionic surfactant sodium dibutylnaphthalene sulfonate and the nonionic surfactant fatty alcohol polyoxyethylene ether are added to the water of 200ml, and mechanical stirring 10min obtains the composite surfactant solution; The CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solution, and sulfuric acid was added to adjust the pH value of the solution to 4; ultrasonic dispersion was used for 30 minutes to prepare int...

Embodiment 2

[0036] A kind of method that adopts microemulsion to prepare ultrafine copper powder of the present embodiment, comprises the following steps:

[0037](1) Preparation of electrolyte: Weigh the following raw materials according to the proportion of each liter of electrolyte: anionic surfactant sodium dibutylnaphthalene sulfonate 0.5g, nonionic surfactant Tween 80 5.0g, CuSO 4 ·5H 2 O 25.0g; The anionic surfactant sodium dibutylnaphthalene sulfonate and the nonionic surfactant Tween 80 are added to the water of 200ml, mechanically stirred for 30min to obtain a composite surfactant solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solution, and sulfuric acid was added to adjust the pH value of the solution to 5; mechanical dispersion was used for 60 minutes to prepare into electrolyte;

[0038] (2) Electrodeposition...

Embodiment 3

[0043] A kind of method that adopts microemulsion to prepare ultrafine copper powder of the present embodiment, comprises the following steps:

[0044] (1) Preparation of electrolyte: Weigh the following raw materials according to the proportion per liter of electrolyte: 7.0 g of anionic surfactant sodium dibutylnaphthalene sulfonate, 3.0 g of nonionic surfactant (including 2.4 g of fatty alcohol polyoxyethylene ether, Polyvinylpyrrolidone 0.6g), CuSO 4 ·5H 2 0.50g; the anionic surfactant sodium dibutylnaphthalene sulfonate and the nonionic surfactant (fatty alcohol polyoxyethylene ether and polyvinylpyrrolidone) are added to the water of 200ml, and mechanically stirred for 20min to obtain a composite surface Activator solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the composite surfactant solution was added to the copper sulfate solution, water was added to prepare a 1L aqueous solution, and sulfuric acid was added to adju...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com