Anode production line hanger detergent as well as preparation method and cleaning method thereof

A cleaning agent and production line technology, applied in the field of cleaning agents, can solve problems such as reducing cleaning efficiency and prolonging cleaning process, and achieve the effects of improving cleaning efficiency, simple cleaning method, and short cleaning time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

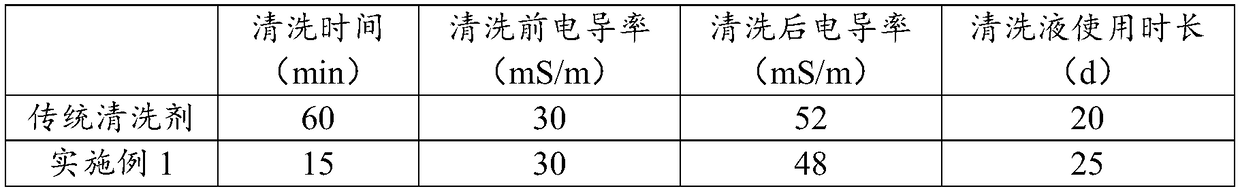

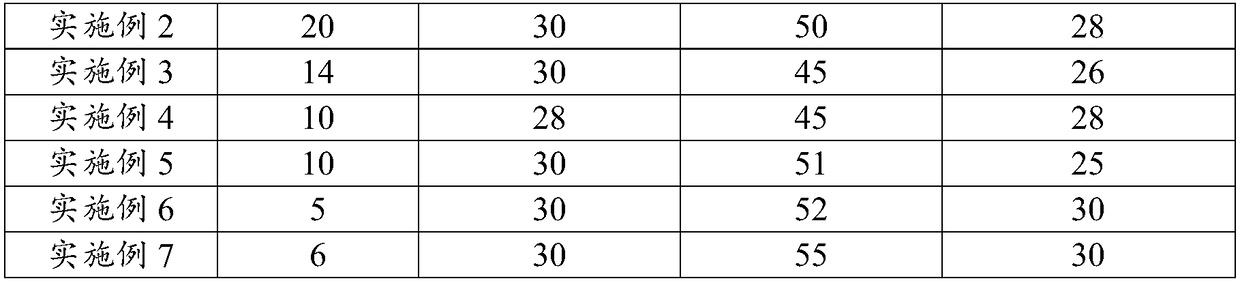

Examples

Embodiment 1

[0043] formula:

[0044] 10 parts of softener; 3 parts of hydrogen peroxide (industrial pure, 33%); 1 part of decomposition inhibitor; 0.4 part of hydrofluoric acid (98%); 0.05 part of accelerator; 100 parts of water.

[0045] Wherein, the softening agent is selected hydrochloric acid (industrial pure, 36%); the decomposition inhibitor is selected water glass; the accelerator is selected ferric chloride.

[0046] Preparation:

[0047] Prepare the above raw materials according to the formula, stir and mix to obtain the finished cleaning agent.

[0048] the cleaning method:

[0049] (1) Soak the hanger in the above cleaning agent for a certain period of time;

[0050] (2) Wash the soaked hanger with pure water to obtain the washed hanger.

Embodiment 2

[0052] formula:

[0053] 12 parts of softener; 2 parts of hydrogen peroxide (industrial pure, 33%); 1.5 parts of decomposition inhibitor; 0.5 parts of hydrofluoric acid (98%); 0.02 parts of accelerator; 1.4 parts of corrosion inhibitor; 140 parts of water.

[0054] Among them, nitric acid (industrial pure, 68%) is selected as the softener; sodium tripolyphosphate is selected as the decomposition inhibitor; ferric chloride is selected as the accelerator; and benzotriazole is selected as the corrosion inhibitor.

[0055] Preparation:

[0056] Prepare the above raw materials according to the formula, stir and mix to obtain the finished cleaning agent.

[0057] the cleaning method:

[0058] (1) Soak the hanger in the above cleaning agent for a certain period of time;

[0059] (2) Wash the soaked hanger with pure water to obtain the washed hanger.

Embodiment 3

[0061] formula:

[0062] 14 parts of softener; 2.5 parts of hydrogen peroxide (industrial pure, 33%); 1.6 parts of decomposition inhibitor; 0.1 part of hydrofluoric acid (98%); 0.05 parts of accelerator; 1.4 parts of corrosion inhibitor; 120 parts of water.

[0063] Among them, 8 parts of sulfuric acid (industrial pure 98%) and 6 parts of hydrochloric acid (industrial pure, 36%) are selected as the softening agent; alcohol is selected as the decomposition inhibitor; hypochlorous acid is selected as the accelerator; zinc carbonate is selected as the corrosion inhibitor.

[0064] Preparation:

[0065] Prepare the above raw materials according to the formula, stir and mix to obtain the finished cleaning agent.

[0066] the cleaning method:

[0067] (1) Soak the hanger in the above cleaning agent for a certain period of time;

[0068] (2) Wash the soaked hanger with pure water to obtain the washed hanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com