Method for preparing copper powder through environment-friendly surface active agent

A surfactant and green technology, applied in the field of copper powder preparation, can solve the problems of non-degradable chemical surfactants, environmental and ecological system hazards, etc., and achieve the effects of good self-desorption performance, easy biodegradation, and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

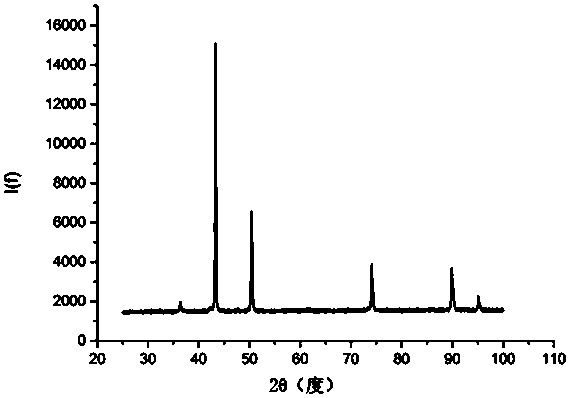

Image

Examples

Embodiment 1

[0031] A kind of method that adopts green surfactant to prepare copper powder in the present embodiment comprises the following steps:

[0032] (1) Preparation of electrolyte: Weigh the following raw materials according to the proportion of each liter of electrolyte: 3.6g of green surfactant (sodium sulfate of fatty alcohol polyoxyethylene ether), 6.0g of additive (ethylene glycol), CuSO 4 ·5H 2 O 30.0g; The green surfactant (sodium fatty alcohol polyoxyethylene ether sulfate) and the auxiliary agent (ethylene glycol) are added to the water of 200ml, and mechanically stirred for 10min to obtain the green surfactant solution; CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the green surfactant solution was added to the copper sulfate solution, and water was added to prepare a 1L aqueous solution; ultrasonic dispersion was used for 30 minutes to prepare an electrolyte;

[0033] (2) Electrodeposition electrolyte: heat the electrolyte prepare...

Embodiment 2

[0038] A kind of method that adopts green surfactant to prepare copper powder in the present embodiment comprises the following steps:

[0039] (1) Preparation of electrolyte: Weigh the following raw materials according to the ratio per liter of electrolyte: 5.0g of green surfactant (1g of lauryl glucoside, 2g of sucrose fatty acid polyester, 2g of sodium carboxymethylcellulose), additives (ethanol and methanol each 5g) 10.0g, CuSO 4 ·5H 20.50.0g; the green surfactant (lauryl glucoside, sucrose fatty acid polyester, sodium carboxymethylcellulose) and the auxiliary agent (ethanol and methyl alcohol) are added to the water of 200ml, and mechanically stirred for 30min to obtain Green surfactant solution; the CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the green surfactant solution was added to the copper sulfate solution, and water was added to make a 1L aqueous solution; ultrasonic dispersion was used for 60 minutes to prepare an electr...

Embodiment 3

[0045] A kind of method that adopts green surfactant to prepare copper powder in the present embodiment comprises the following steps:

[0046] (1) Preparation of electrolyte: Weigh the following raw materials according to the ratio per liter of electrolyte: 0.3g of green surfactant (0.15g each of alkyl glycoside and alcohol ether carboxylate), 3.0g of additive (n-butanol), CuSO 4 ·5H 2 0.36g; The green surfactant (alkyl glucoside and alcohol ether carboxylate) and the auxiliary agent (n-butanol) are added to the water of 200ml, and mechanically stirred for 20min to obtain the green surfactant solution; CuSO 4 ·5H 2 O was dissolved in 200ml of water to obtain a copper sulfate solution; the green surfactant solution was added to the copper sulfate solution, and water was added to prepare a 1L aqueous solution; ultrasonic dispersion was used for 45 minutes to prepare an electrolyte;

[0047] (2) Electrodeposition electrolyte: heat the electrolyte prepared in step (1), control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com