Large array high uniformity microlens array preparation method

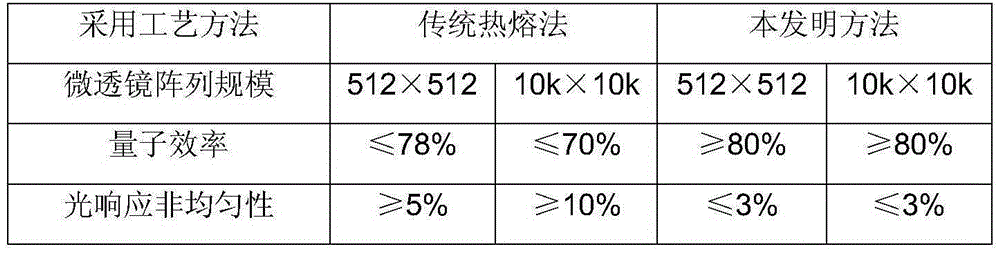

A microlens array and uniformity technology, which is applied to lenses, optics, instruments, etc., can solve the problems of large differences in microlens morphology, poor microlens pattern uniformity, and deterioration of microlens concentration uniformity. Light effect and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

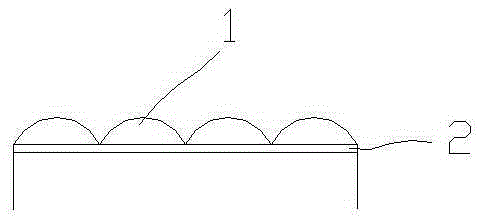

Image

Examples

Embodiment Construction

[0023] A method for preparing a large-array and high-uniform microlens array, the innovation of which lies in the following steps:

[0024] 1) cleaning the wafer surface of the device;

[0025] 2) coating the mixture of propylene glycol monomethyl ether ester, ethoxypropyl acetate and acrylic resin on the surface of the wafer to form a mixture coating;

[0026] 3) Exposure treatment is carried out to the mixture coating, so that the mixture coating is completely cured;

[0027] 4) coating the PMMA material on the mixture coating surface, then heating the PMMA material to solidify to form a microlens material layer;

[0028] 5) using a thermal evaporation process or a magnetron sputtering process to grow a mask layer on the surface of the microlens material layer;

[0029] 6) using a photolithography process to photoetch a photoresist mask pattern on the mask layer;

[0030] 7) transfer the photoresist mask pattern to the mask layer by using an etching process;

[0031] 8) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com