Molding method for casting and forging structure piece of wheelchair frame

A forming method and technology of structural parts, applied in the field of casting and forging processing, can solve the problems of heavy weight, low material utilization rate, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

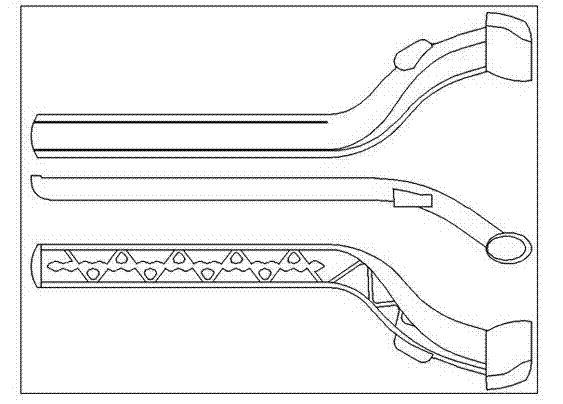

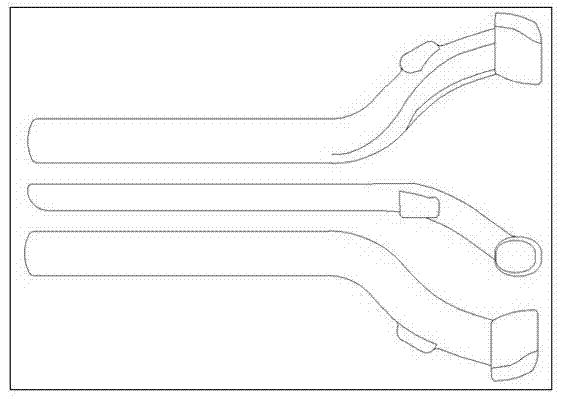

[0032] Example 1: Combination Figure 1-Figure 6 , The present invention is a method for casting and forging a wheelchair frame structure. The steps are as follows:

[0033] Step 1: Cutting: Saw the outer circle φ200mm aluminum ingot with the material grade of 6061 into 800mm long blanks;

[0034] Step 2: Melting: place the billet in a crucible and heat it at a constant temperature of 650°C to melt;

[0035] Step 3: Molding: Apply release agent on the surface of the riser and cavity of the casting mold, close the casting mold, and tighten the fixing clip;

[0036] Step 4: Pouring: Use a crucible to take 4.5 kg of liquid aluminum after the billet is melted, and pour from the pouring port to the cavity until the cavity is completely filled;

[0037] Step 5: Molding: Open the fixing clip, open the casting mold, and take out the molding blank;

[0038] Step 6: Cut the riser: Use a toothless saw to cut the riser to obtain the cast billet;

Embodiment 2

[0052] Example 2: Combination Figure 1-Figure 6 , The present invention is a method for casting and forging a wheelchair frame structure. The steps are as follows:

[0053] Step 1: Cutting: Saw the outer circle φ200mm ingot with the material grade of 6061 into a billet of 800mm length;

[0054] Step 2: Melting: Place the billet in a crucible and heat it at a constant temperature: 650°C, and heat it to completely melt;

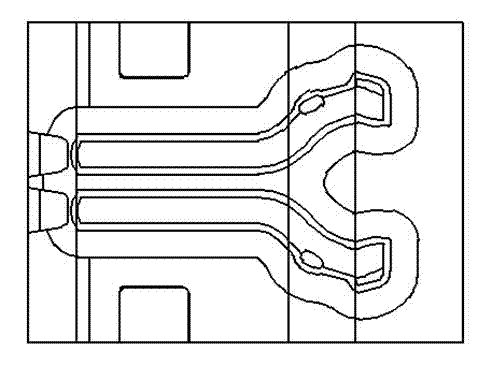

[0055] Step 3: Molding: in the casting mold ( Image 6 ) Apply release agent to the surface of riser and cavity, close the casting mold and tighten the fixing clip;

[0056] Step 4: Pouring: Use a crucible to hold 4.5 kg of liquid aluminum after the billet is melted from the pouring port 1 ( Image 6 1) Pouring until the cavity is completely filled, and then pouring from the riser 2, 3 to the riser cavity is filled with liquid aluminum;

[0057] Step 5: Molding: Open the fixing clamp, slowly separate the upper and lower molds of the casting mold, and take out the moldi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com