A bearing wall board and a method of producing the same

An endurance and slurry technology, which is applied in the field of endurance surface materials, can solve the problems of high specific gravity of endurance surface materials, can not be said to fully improve workability, dimensional changes of endurance surface materials, no improvement in frost resistance or water resistance, etc. Effects of dehydration, low energy cost, superior strength or flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

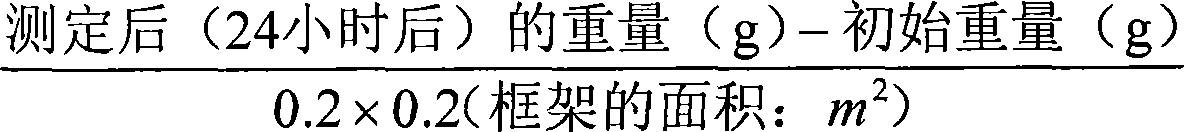

Image

Examples

Embodiment 1

[0058] Each of the endurance surface materials shown in Examples 1 to 8 and Comparative Examples 1 to 8 was produced under each of the production conditions listed below.

[0059] Example 1, 30 mass % of Portland cement in water, 4 mass % of wood pulp with a freeness of 500 ml beaten by a beater, 6 mass % of wood pulp with a freeness of 780 ml without beating, and 8 mass % of unbeaten waste paper % by mass, 10% by mass of perlite, 42% by mass of blast furnace slag and fly ash for dispersion of raw materials, add stearic acid emulsion solution, which is 0.5% by mass of the total solid content of the slurry. After mixing, let the slurry flow on a dehydration blanket, and form a sheet while being dehydrated. The prepared sheet was laminated in 6 layers with a production roll to form a laminated mat.

[0060] Apply a pressure of 2.5 MPa to the above-mentioned laminated mat, press a high-pressure press for 7 seconds, then steam cure at 70°C, and obtain the endurance surface materi...

Embodiment 2

[0061] Example 2, in the slurry obtained by dispersing the same raw material composition as in Example 1 in water, a stearic acid emulsion solution was added, and the stearic acid emulsion solution was 1.0% by mass of the total solid content of the slurry. After mixing, the endurance surface material is obtained through the same method of making, dehydration, pressing, and curing as in Example 1.

Embodiment 3

[0062] Example 3, in the slurry obtained by dispersing the same raw material composition as in Example 1 in water, a stearic acid emulsion solution was added, and the stearic acid emulsion solution was 2.0% by mass of the total solid content of the slurry. After mixing, the endurance surface material is obtained through the same method of making, dehydration, pressing, and curing as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com