Automatic nail loading equipment and automatic nail loading type nail gun system

A nailing type, automatic technology, applied in the direction of nailing tools, U-shaped nailing tools, manufacturing tools, etc., can solve the problems of waste of resources, difficult nailing, nails in the wrong position, etc., to improve the efficiency of nailing , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

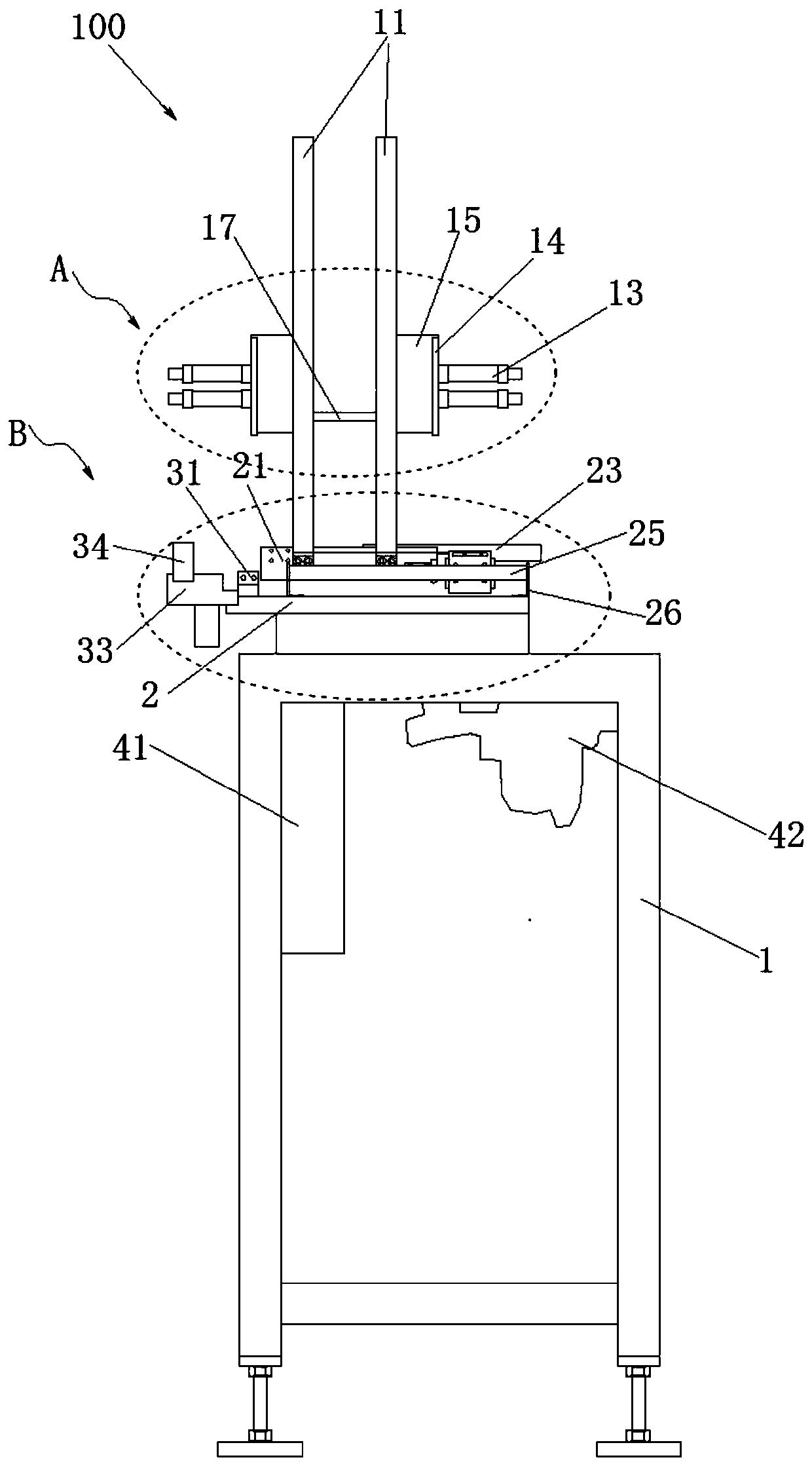

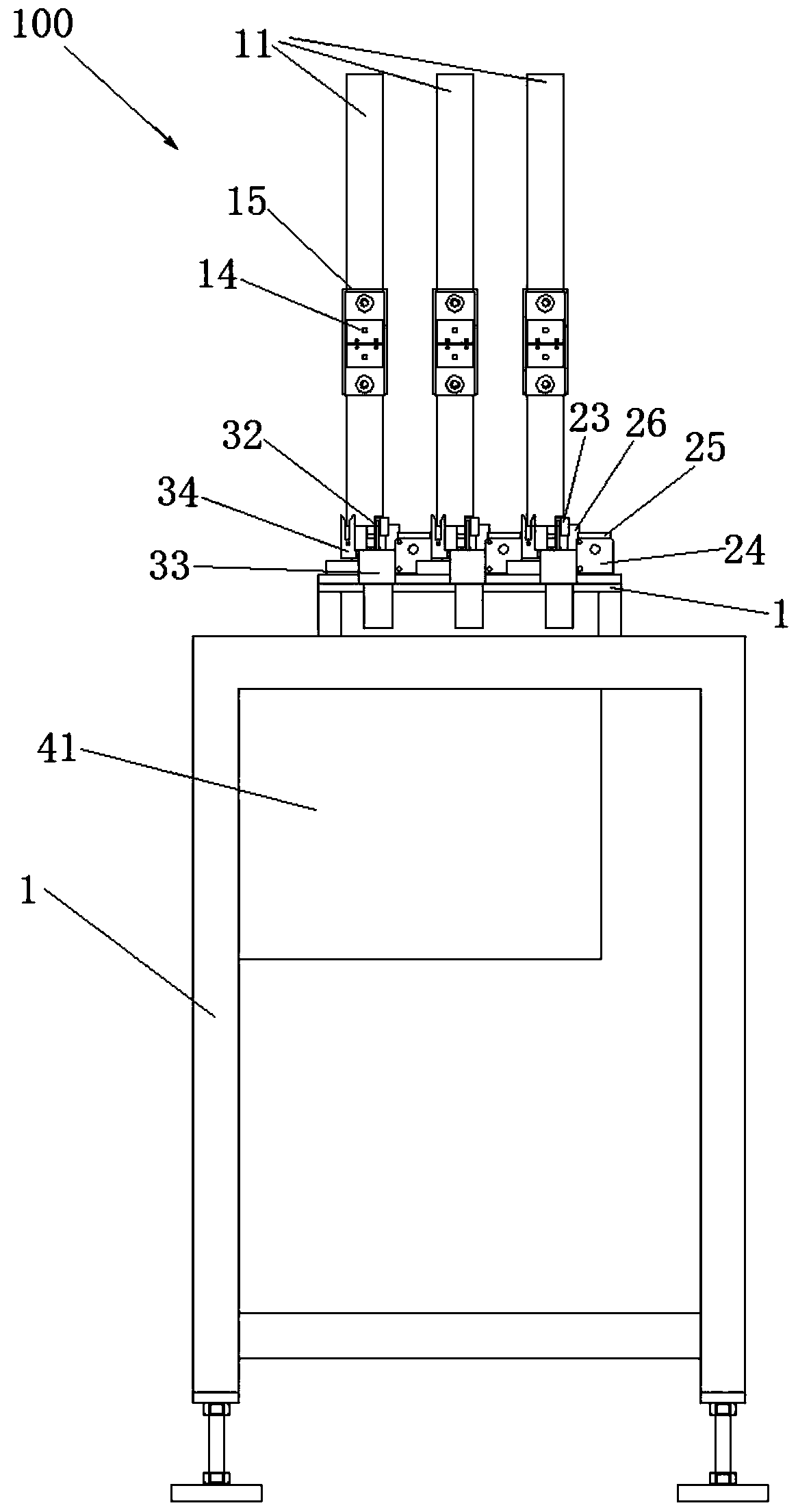

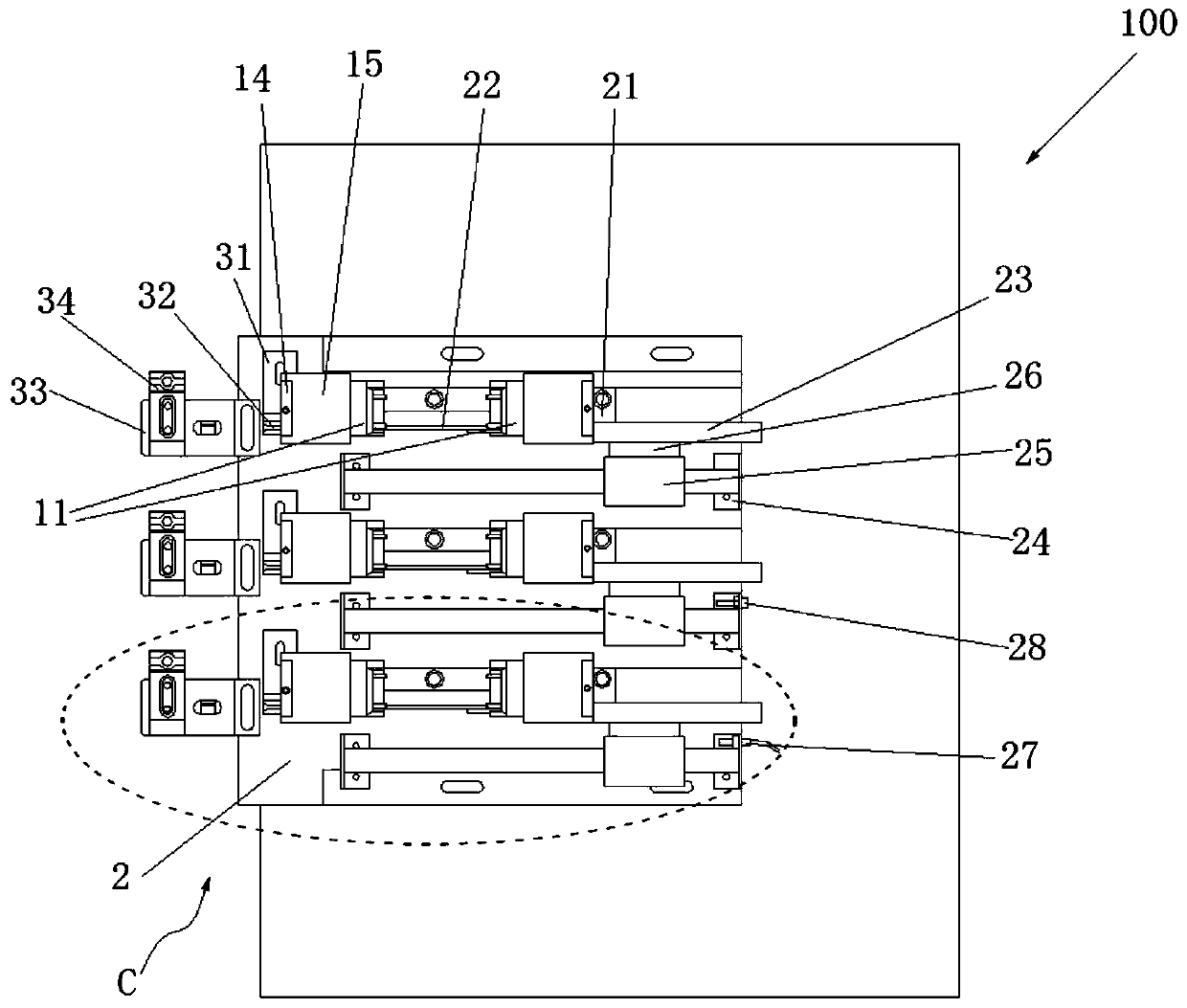

[0022] The specific embodiments of the present invention will be described below with reference to the accompanying drawings and implementations.

[0023] In the following embodiments, the up and down directions are used as reference to describe the directions of the drawings, that is, the left and right directions respectively refer to the left and right directions of the drawings, and the up and down directions respectively refer to the up and down directions of the drawings.

[0024]

[0025] The automatic nailing device and the automatic nailing type nail gun system provided by the embodiment of the present invention are used to push the nail row into the automatic nailing type nail gun and perform automatic nailing operation.

[0026] The automatic nailing device and the automatic nailing type nail gun system provided in this embodiment include at least one automatic nailing type nail gun and an automatic nailing device 100 for pushing the nail row into the automatic nai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com