High-speed intelligent automatic screw fastening assembly machine

A technology for assembling mechanisms and screws, which is used in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of simple structure, safe and stable supply state, and rapidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the examples.

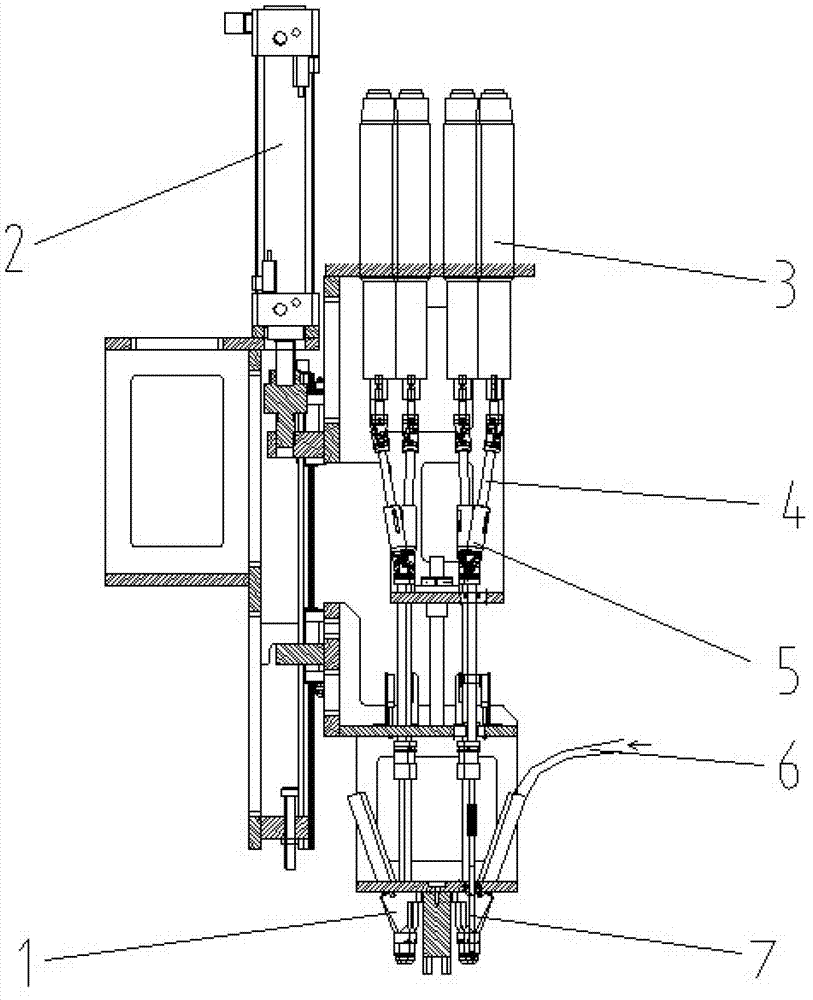

[0018] Such as figure 1 As shown, the cylinder 2 is connected with the pneumatic screwdriver 3 through the transmission part, and the pneumatic screwdriver 3 drives eight screwdriver heads 7 to work through the universal joint 5, and a buffer spring 4 is set on the upper part of the universal joint 5; On the nail receiver 1, a screwdriver head 7 is installed above the discharge port of the soft material tube 6.

[0019] When the equipment is working, the screw reaches the nail receiver 1 through the soft material tube 6 under blowing, and the screw blown to the nail receiver 1 keeps the nut on the vertical position, and the pneumatic screwdriver 3 is placed in the position of the cylinder 2. It rotates and descends under the drive to complete the screw fastening assembly, and it goes on and on like this. Among them, the buffer spring 4 acts as a buffer to prevent excessive down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com