Automatic nailing device for wood boards

A wooden and automatic technology, applied in the direction of nailing tools, nailing tools, manufacturing tools, etc., can solve the problems of low efficiency and high work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

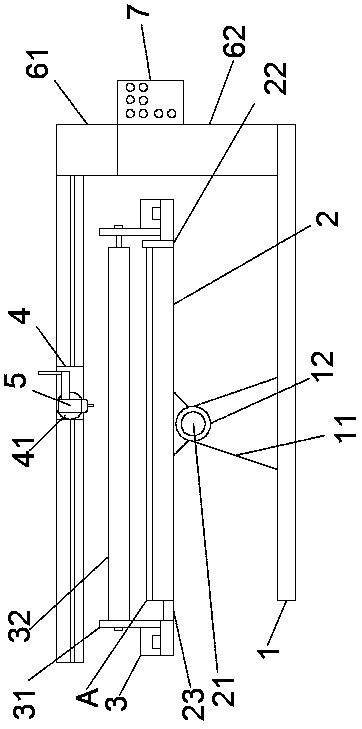

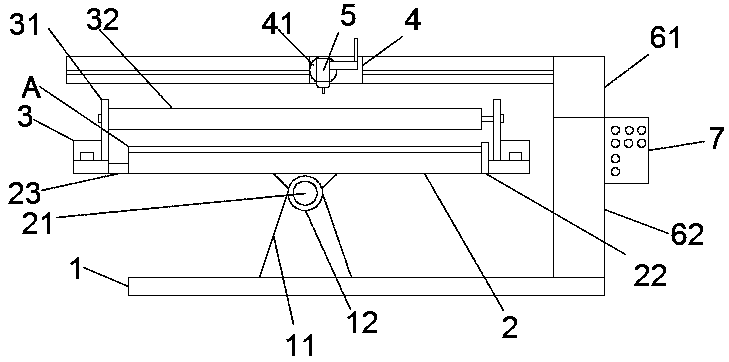

[0025] An automatic nailing device for wooden boards, comprising a machine table, a machine arm and a nailing gun, characterized in that a control box is installed on one side of the machine table, the machine arm is located above the machine table, and the top of the machine table is an operating There is a rotating shaft at the bottom of the operating flat plate, and a base under the flat plate, which is hinged to the rotating shaft. The flat plate is provided with a deflection drive, and the crossbeam of the machine arm is provided with an electric sliding table. The nail gun is fixedly installed on the electric sliding table. The upper part of the machine arm is screwed to the lower part of the machine arm. The lower part of the machine arm is provided with a rotating motor. It is electrically connected with each component, and each component is controlled by the control box.

[0026] The control box includes a plurality of control parts, specifically including control of ...

Embodiment 2

[0039] An automatic nailing device for wooden boards, comprising a machine table, a machine arm and a nailing gun, characterized in that a control box is installed on one side of the machine table, the machine arm is located above the machine table, and the top of the machine table is an operating There is a rotating shaft at the bottom of the operating flat plate, and a base under the flat plate, which is hinged to the rotating shaft. The flat plate is provided with a deflection drive, and the crossbeam of the machine arm is provided with an electric sliding table. The nail gun is fixedly installed on the electric sliding table. The upper part of the machine arm is screwed to the lower part of the machine arm. The lower part of the machine arm is provided with a rotating motor. It is electrically connected with each component, and each component is controlled by the control box.

[0040] One side of the machine platform is provided with a baffle, the baffle is on the same sid...

Embodiment 3

[0052]An automatic nailing device for wooden boards, comprising a machine table, a machine arm and a nailing gun, characterized in that a control box is installed on one side of the machine table, the machine arm is located above the machine table, and the top of the machine table is an operating There is a rotating shaft at the bottom of the operating flat plate, and a base under the flat plate, which is hinged to the rotating shaft. The flat plate is provided with a deflection drive, and the crossbeam of the machine arm is provided with an electric sliding table. The nail gun is fixedly installed on the electric sliding table. The upper part of the machine arm is screwed to the lower part of the machine arm. The lower part of the machine arm is provided with a rotating motor. It is electrically connected with each component, and each component is controlled by the control box.

[0053] One side of the machine platform is provided with a baffle, the baffle is on the same side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com