Efficient nailing gun

A nailing gun and high-efficiency technology, applied in nailing tools, manufacturing tools, etc., can solve the problems of low nailing efficiency and the inability of the nailing gun to automatically supply nails, etc., and achieve the effect of improving nailing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

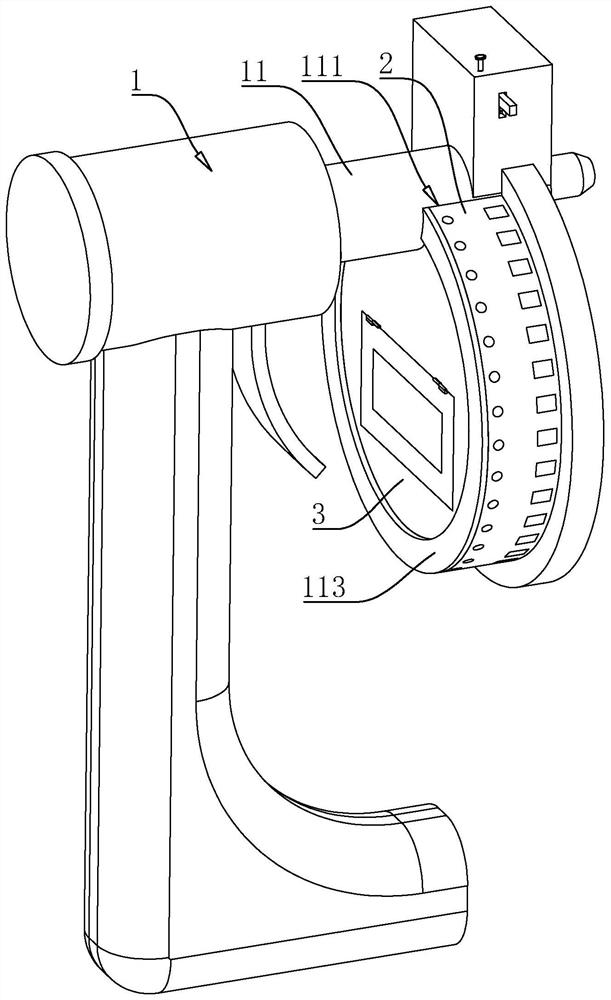

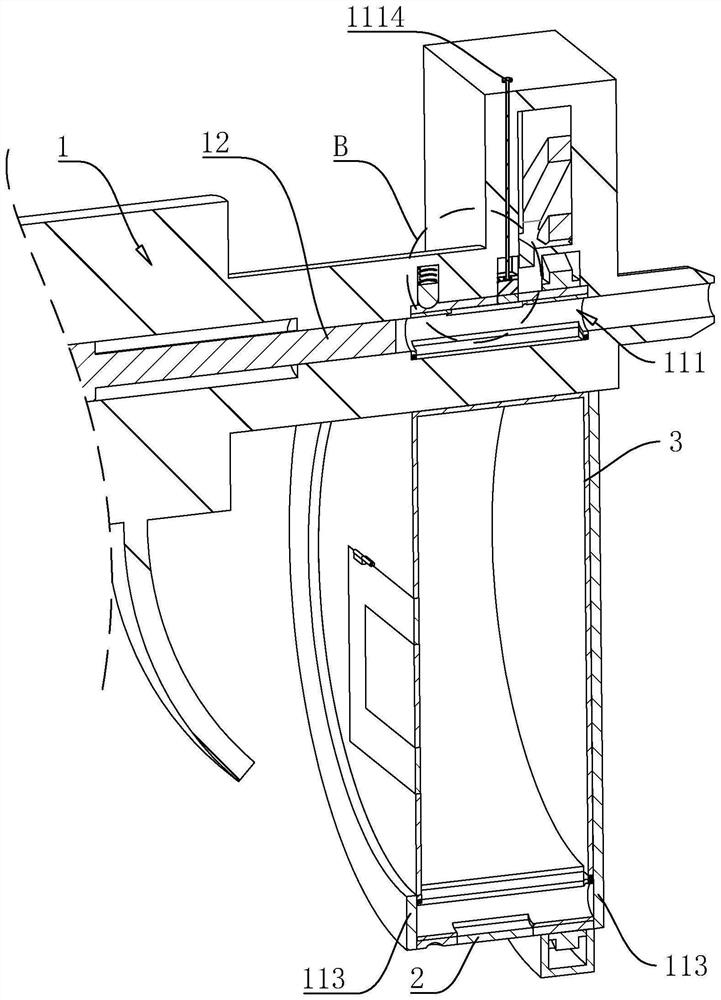

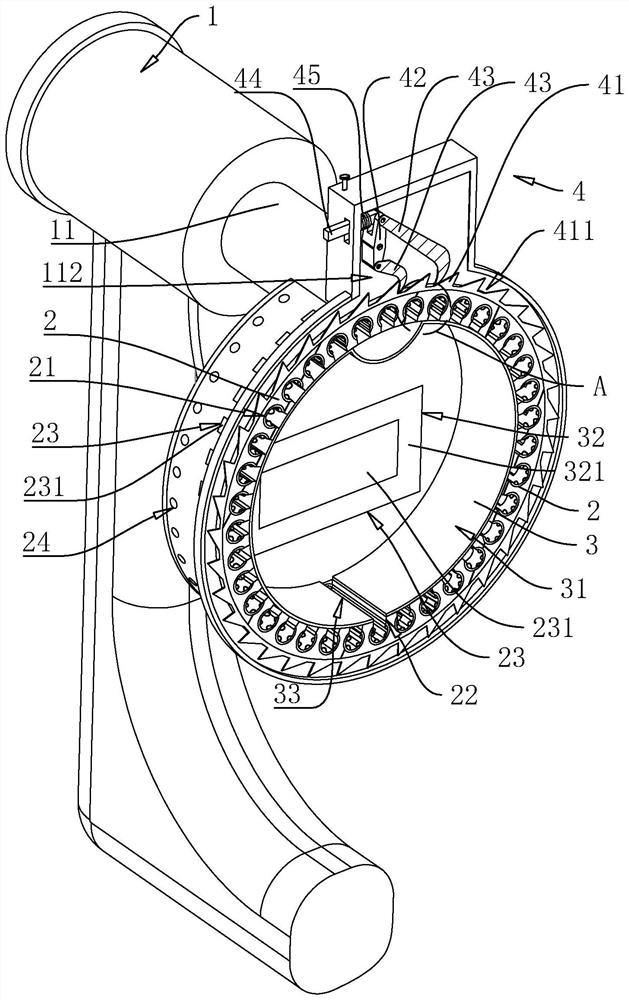

[0037] Attached to the following Figure 1-5 This application will be described in further detail.

[0038] The embodiment of the present application discloses an efficient nailing gun. refer to figure 1 and figure 2 , the high-efficiency nail gun includes a nail gun body 1, the nail gun body 1 includes a nail outlet pipe 11 arranged at the end, and a striker 12 arranged in the nail outlet pipe 11 for striking the nails to shoot the nails out of the nail pipe 11 ; The side wall of the nail pipe 11 is provided with a communication hole 111, and a ring-shaped nail magazine 2 is inserted through the communication hole 111.

[0039] refer to figure 2 and image 3 , a number of placement holes 21 are opened inside the annular magazine 2 along its circumferential direction, the placing holes 21 are evenly arranged along the circumferential direction of the annular magazine 2, each placing hole 21 is only for placing a single nail, and the length direction of the placing hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com