Bed net side iron machine and bed net integrated machine

An integrated machine and iron machine technology, which is applied in the field of bed and mesh integrated machines, can solve the problems of time-consuming and laborious, manual placement of side irons, bed net string springs and side iron installation cannot be performed at the same time, etc., and achieves the effect of convenient use and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention and specific implementation thereof are described in further detail below in conjunction with accompanying drawing:

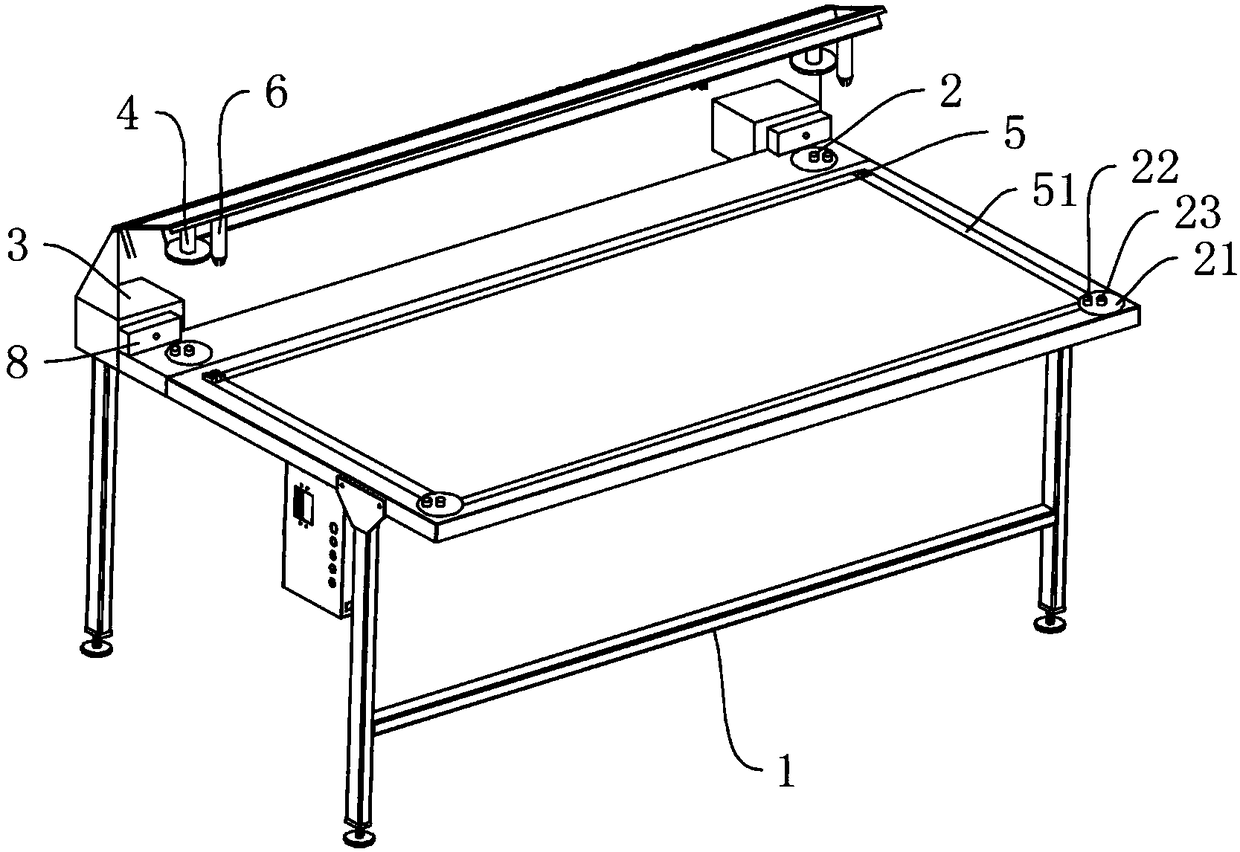

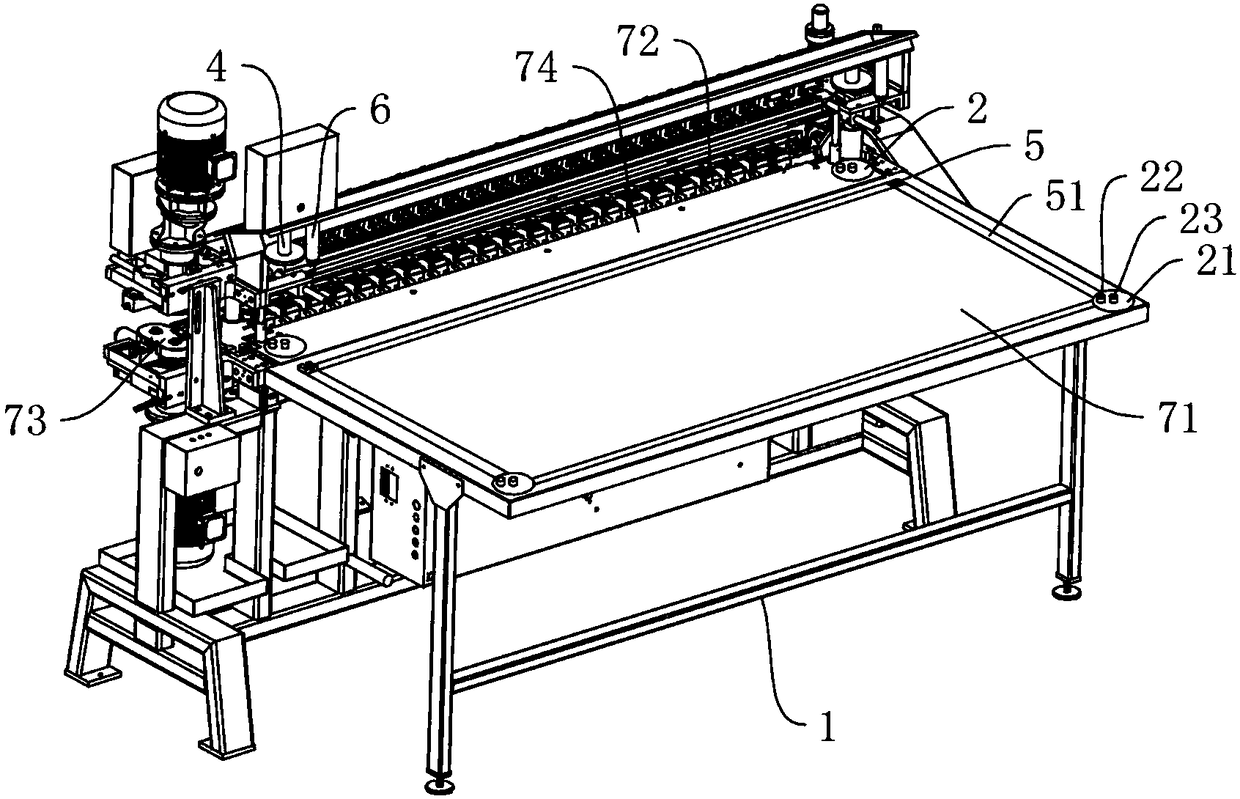

[0021] A kind of bedside iron machine, see figure 1 , including a bracket 1, a side iron bender 2 arranged on the bracket 1 to bend the side iron, characterized in that: it also includes a control device, which is arranged on the bracket 1 to push the side iron through the edge of the side iron bender The iron pusher 3, the side iron bender 2 and the side iron pusher 3 are respectively electrically connected to the control device. The control device can automatically control the side iron pusher 3 to push the side iron according to the set length to the side iron bender 2 for bending, without manually placing the side iron and opening the bending action, which is convenient and quick.

[0022] It also includes a first telescopic rod 4 that drives the edge iron bender 2 to move up and down, the first telescopic rod 4 is electrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com