Automatic tightening equipment

An automatic and equipment technology, applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

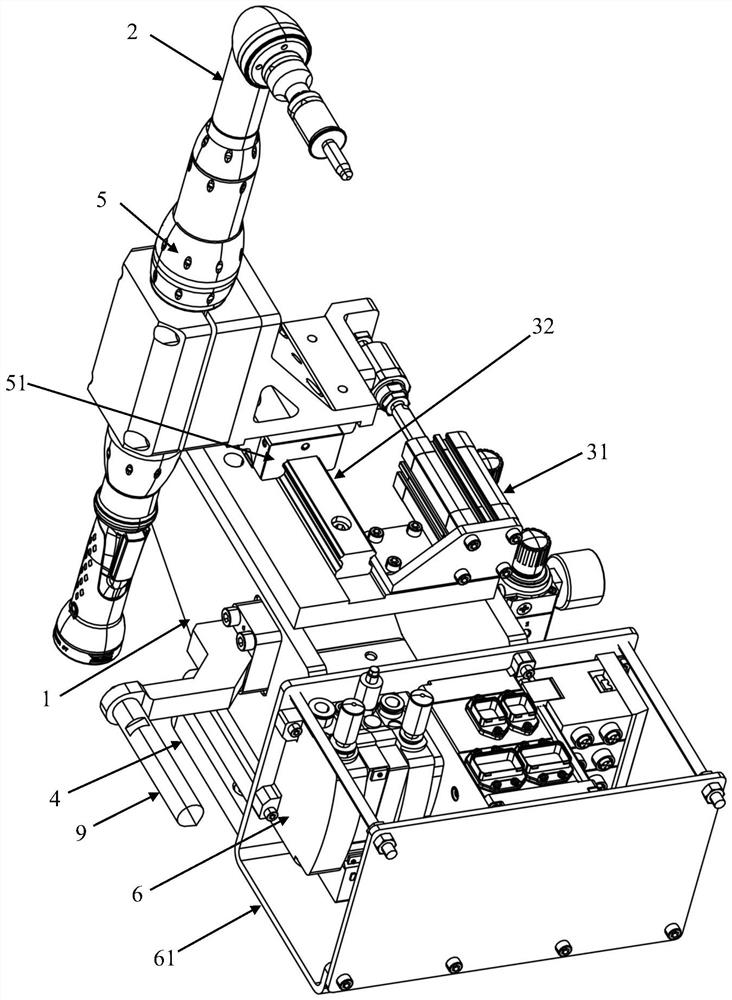

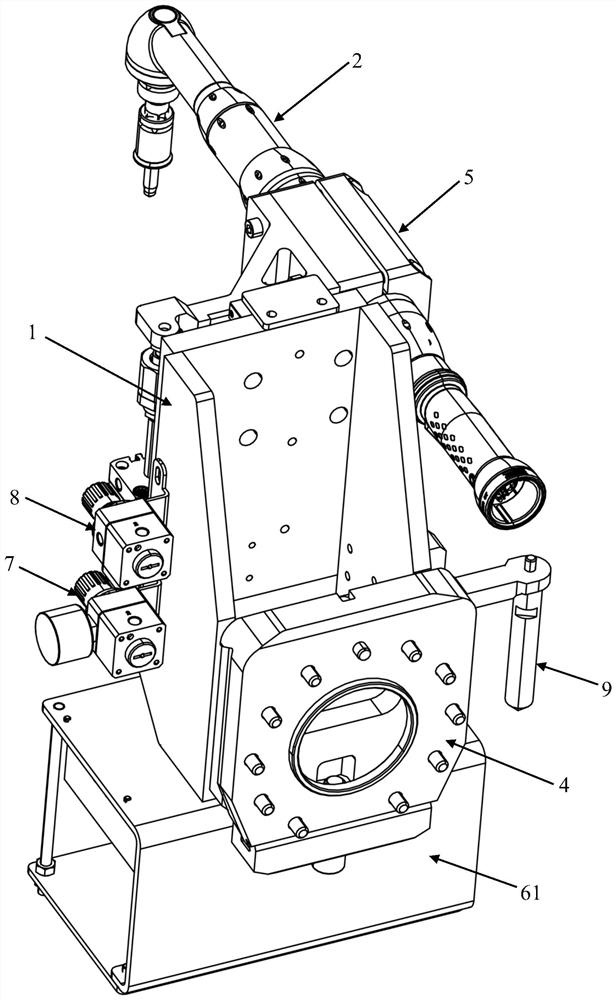

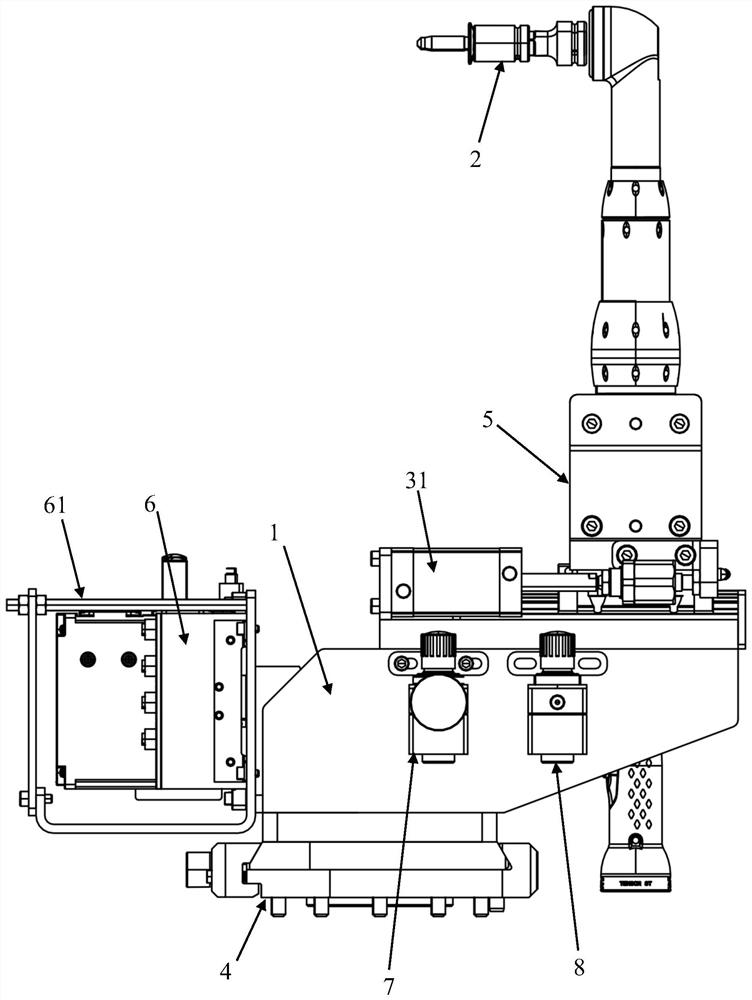

[0041] refer to Figure 1 to Figure 4 , automatic tightening equipment, including the main body base frame 1, the main body base frame 1 is provided with a tightening gun 2, a movable component, a quick change disc 4, a hoop structure 5, a valve island 6, a control room 61, a cylinder pressure gauge 7, a tightening gun Pressure gauge 8, calibration pin 9. The movable assembly includes a linear cylinder 31 and a linear slide rail 32 . A robot, a control unit, nail feeding equipment and fixing pins are arranged away from the main body base frame 1 .

[0042] The main body base frame 1 is used to install all the components. The main body base frame 1 is a welded structure, and each mounting surface is finished after welding, which can ensure strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com