Nail gun guide rail positioning device for mounting code nails of automatic nail gun

A positioning device and installation technology, applied in nailing tools, nailing staple tools, manufacturing tools, etc., can solve problems such as affecting production efficiency, fast consumption of automatic nail guns, and difficulty in meeting the consumption rate. Realize the effect of automatic nailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is further described below in conjunction with specific embodiments:

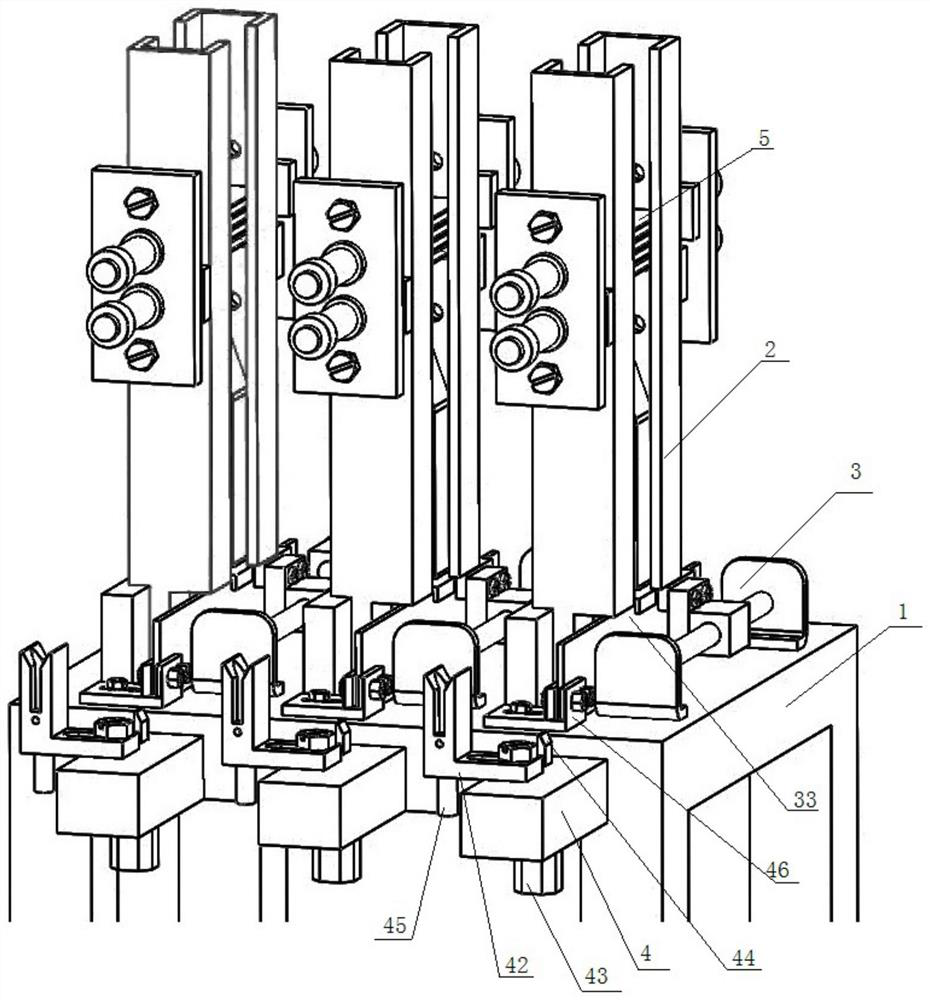

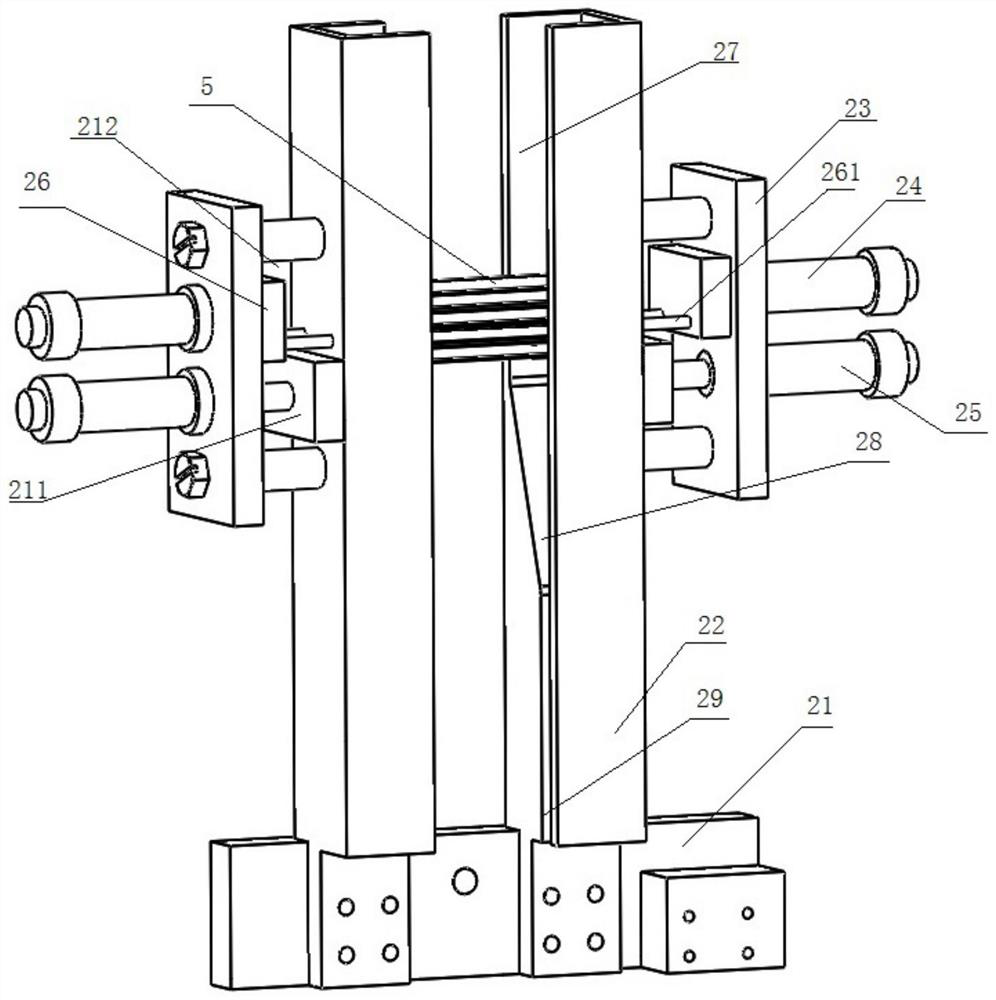

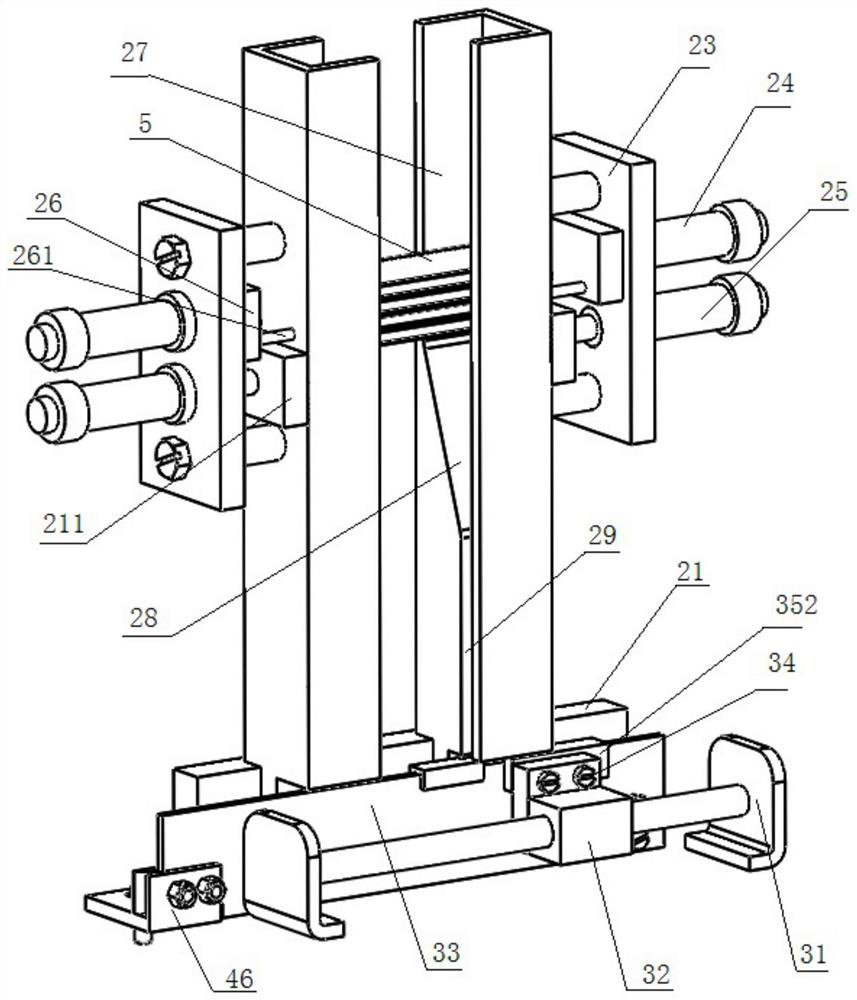

[0027] A nail gun guide rail positioning device for automatic nail gun code nail installation, which is used for positioning when the automatic nail gun is automatically nailed, such as Figure 1-10 As shown, a nail gun guide rail positioning device 4 is installed on one side of the platform 1. The nail gun guide rail positioning device 4 includes a base 41, a positioning frame 42, a hook unloading lever 44, a hook unloading lever cylinder 43, a detection switch 45, and the base 41 is installed. On one side of the platform 1 at one end of the nailing track 33, the positioning frame 42 is installed above the base 41, and an interface groove 46 is installed on the platform 1 at one end of the nailing track 33, and the interface groove 46 is located between the nailing track 33 and the base 41 , the interface groove 46 is convenient for the nail gun guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com