Board nailing machine for wood packaging

A nailing machine and wood packaging technology, applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., can solve the problems of high risk, low efficiency, and bulky pressurized air pump, so as to achieve simple equipment structure and avoid safety No risk, high nailing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

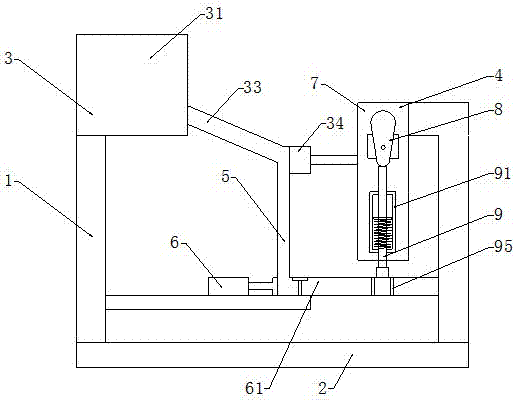

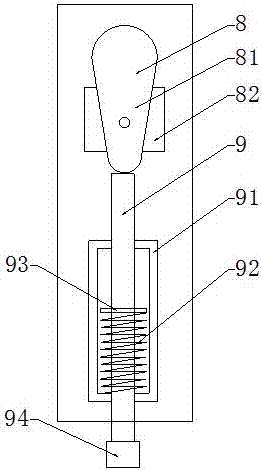

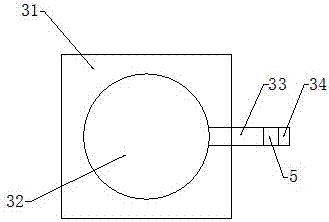

[0019] The present invention relates to a wood nailing machine for wooden packaging, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a workbench 2, a frame 1 is arranged on the workbench 2, and an automatic unloading device 3 and a nailing device 4 are fixedly connected to both sides of the frame 1, wherein the automatic unloading device 3 includes a The box body 31 of the iron nail is provided with a vibration plate 32 in the box body 31, the right side of the vibration plate 32 is connected with a slip nail channel 33, and the bottom of the slip nail channel 33 is connected with a vertical channel 34, between the vertical channel 34 and the slip nail channel 33 The right side of the joint is provided with a guide magnet 5, and the left side of the vertical channel 33 is provided with a pushing mechanism 6, and the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com