Garment nailing device realizing integral compacting and realizing rapidness and high precision

A high-precision, integrated technology, applied in the direction of sewing tools and other directions, can solve the problems of low nailing efficiency and accuracy, waste of time in fixing and disassembling, and offset, and achieve the effect of high nailing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

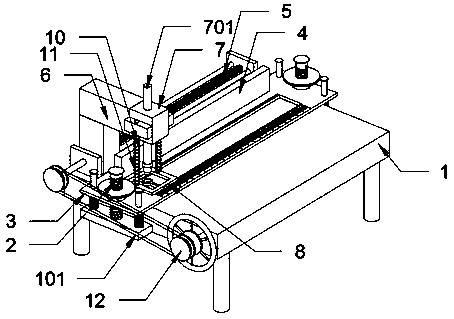

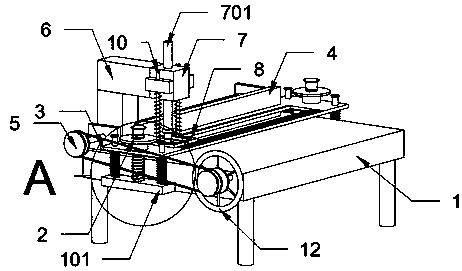

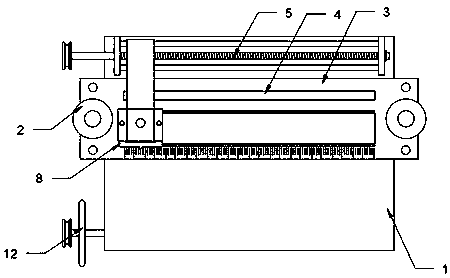

[0030] as attached figure 1 To attach Figure 8 Shown:

[0031] The present invention provides fast and high-precision clothing nailing equipment with integrated compression, including: table body 1, support plate 101, lifting structure 2, cylindrical rod A201, spring A202, threaded rod 203, adjustment nut 204, pressing plate 3, Press plate main body 301, rectangular hole A302, rectangular hole B303, semicircular groove 304, scale 305, track plate 4, screw drive shaft 5, main body fixing arm 6, nailing machine main body 7, nailing shaft 701, calibration plate 8 , pointer 801, iron ball 802, rivet placement seat 9, cylindrical rod B10, spring B11 and adjustment wheel 12; a support plate 101 is w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com