Automatic nailing machine

A nail embedding machine and automatic technology, applied in the field of assembly, can solve the problems of low production efficiency, high processing cost, high scrap rate, etc., and achieve the effect of improving efficiency and avoiding the waste of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

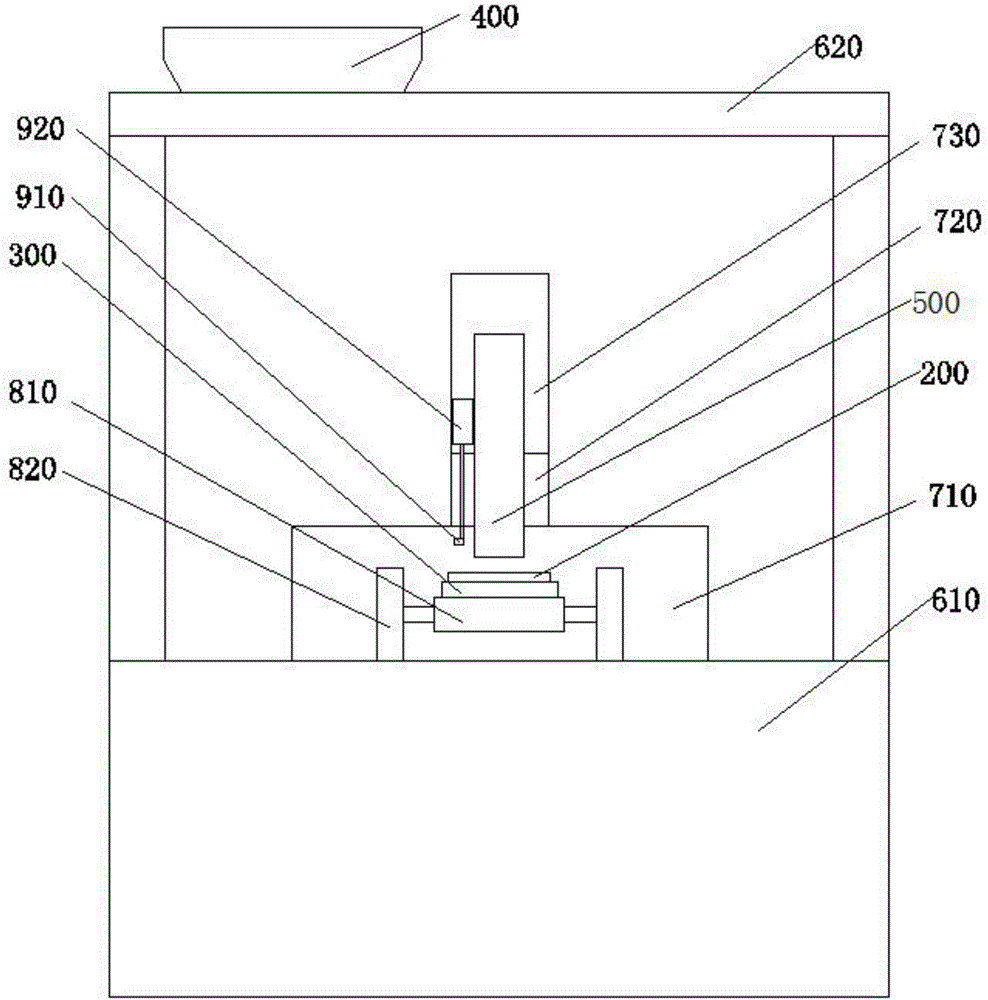

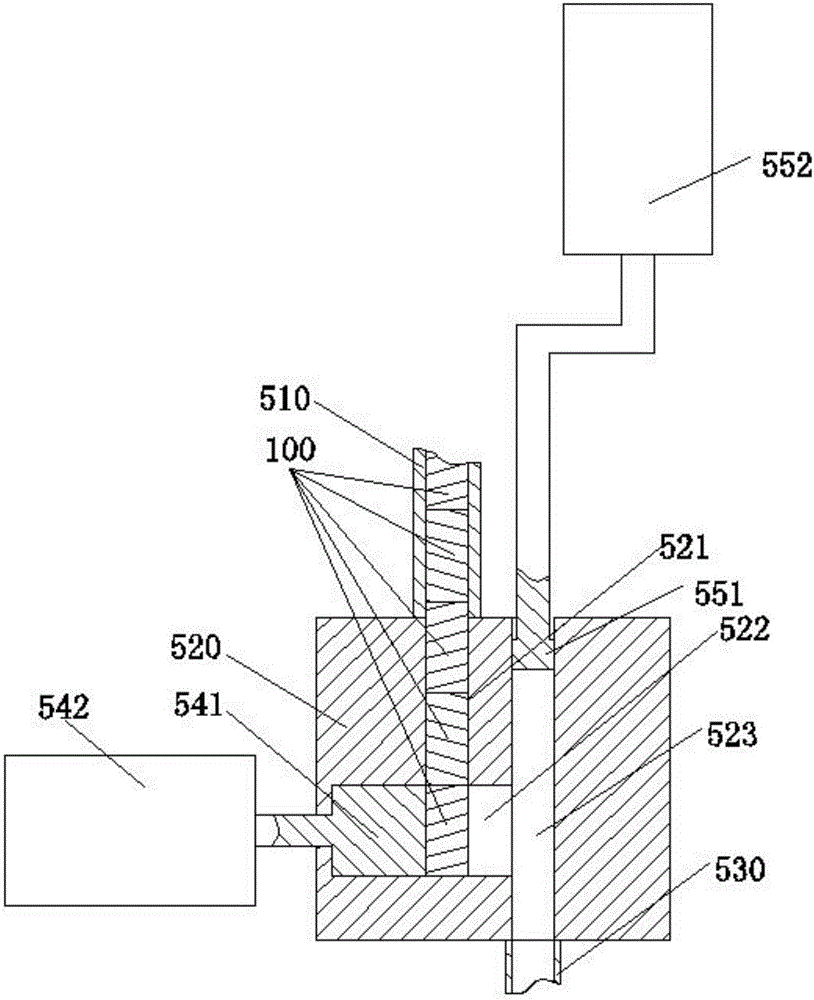

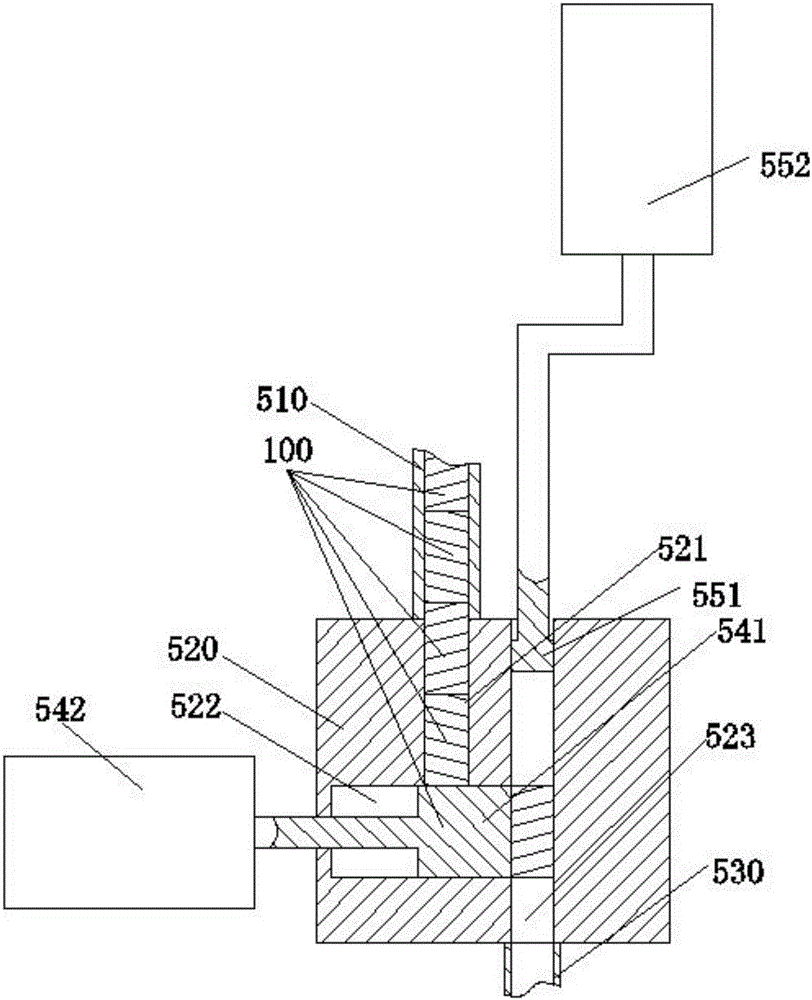

[0026] see Figure 1 to Figure 4 , as shown in the legend therein, an automatic nail embedding machine is used for embedding copper nails 100 into plastic products 200, the above automatic nail embedding machine includes a positioning jig 300 for positioning plastic products 200, and is used for making several The copper nails 100 are arranged in an orderly manner, the vibrating plate 400 and the nailing mechanism 500 for embedding the copper nails 100 into the set position of the plastic product 200, the positioning fixture 300 is installed on the workbench 610, and the vibrating plate 400 is installed on the On the top support 620, the nailing mechanism 500 includes:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com