Automatic nailing device

An automatic and clamping device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low nailing efficiency, difficult operation, and low processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

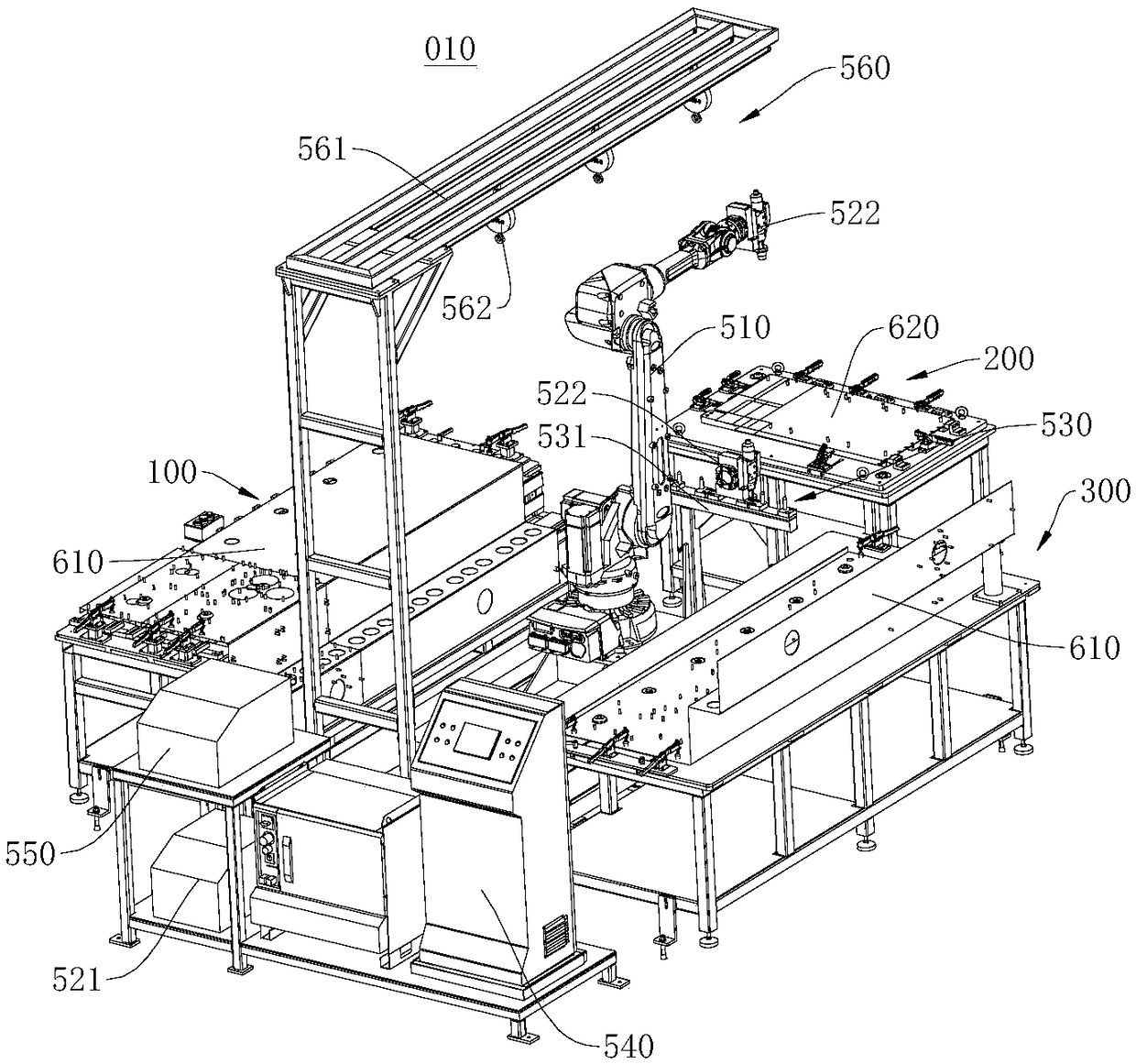

[0043] figure 1 A schematic diagram of the overall structure of the automatic nailing device 010 provided in this embodiment. Please refer to figure 1, the present embodiment provides an automatic nailing device 010 , which includes an operating table 540 , a nail feeding machine 550 , a nailing robot 510 , and a first clamping mechanism 100 and a second clamping mechanism 200 . The first clamping mechanism 100 is used to fix the first workpiece 610 to be nailed, and the second clamping mechanism 200 is used to fix the second workpiece 620 to be nailed. The nailing robot 510 is fixedly connected with a nailing mechanism, and the nail feeding machine 550 is used to deliver screws to the nailing mechanism. Perform nailing operations in different positions. Moreover, the nail feeder 550, the nailing robot 510, and the nailing mechanism are all connected to the control console 540. Under the control of the console 540, the nail feeder 550 can automatically deliver the screws to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com