Patents

Literature

67 results about "Nail operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

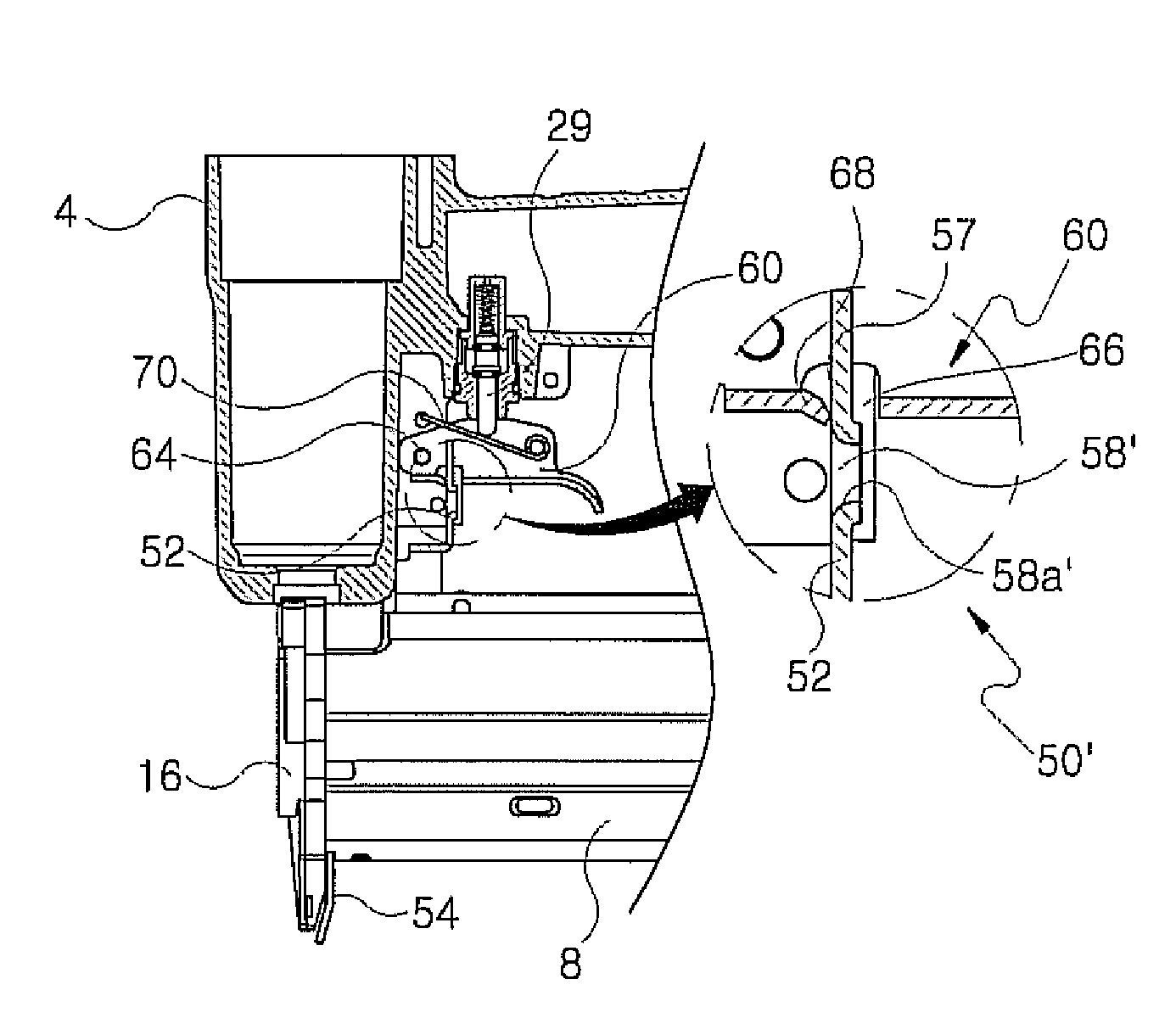

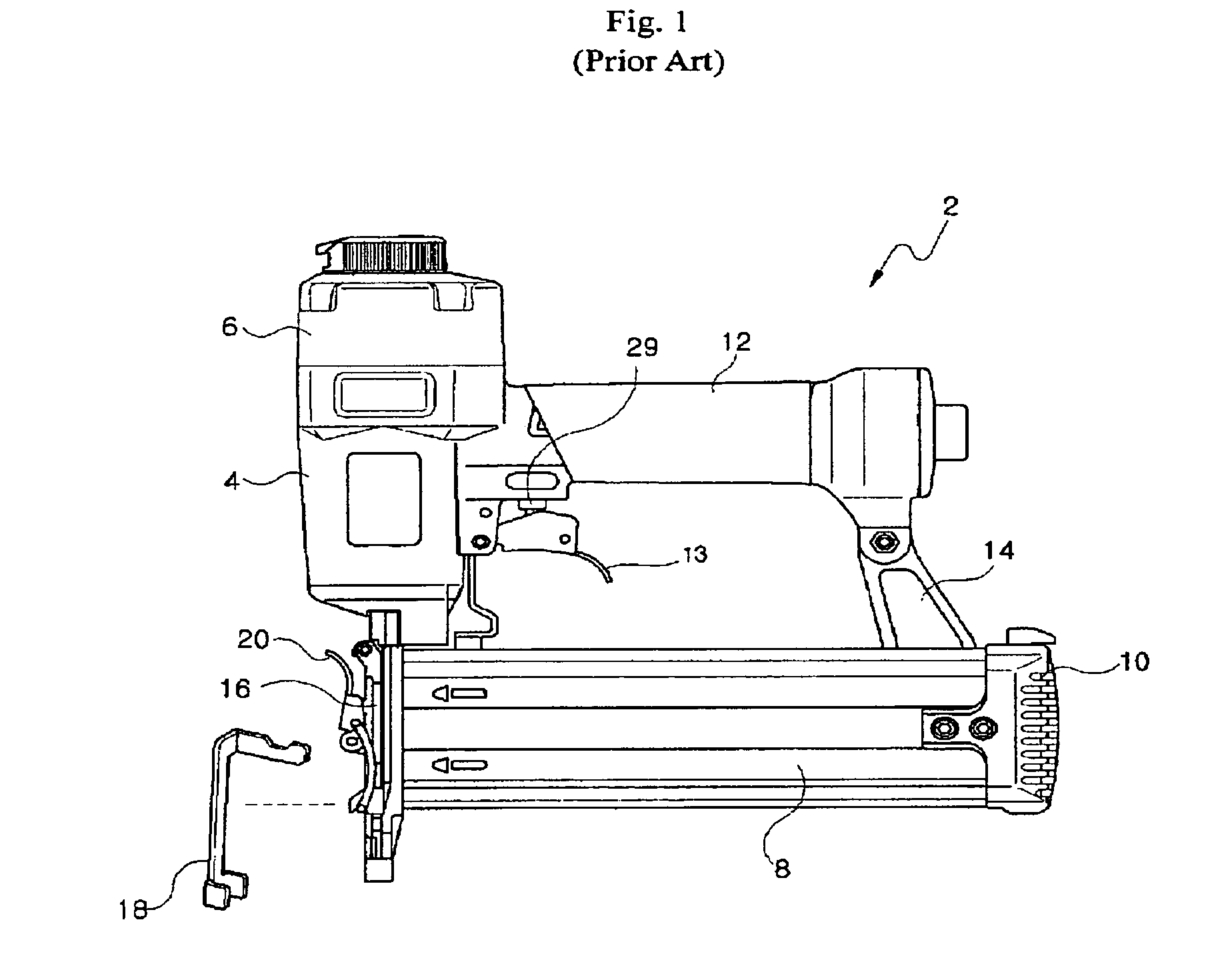

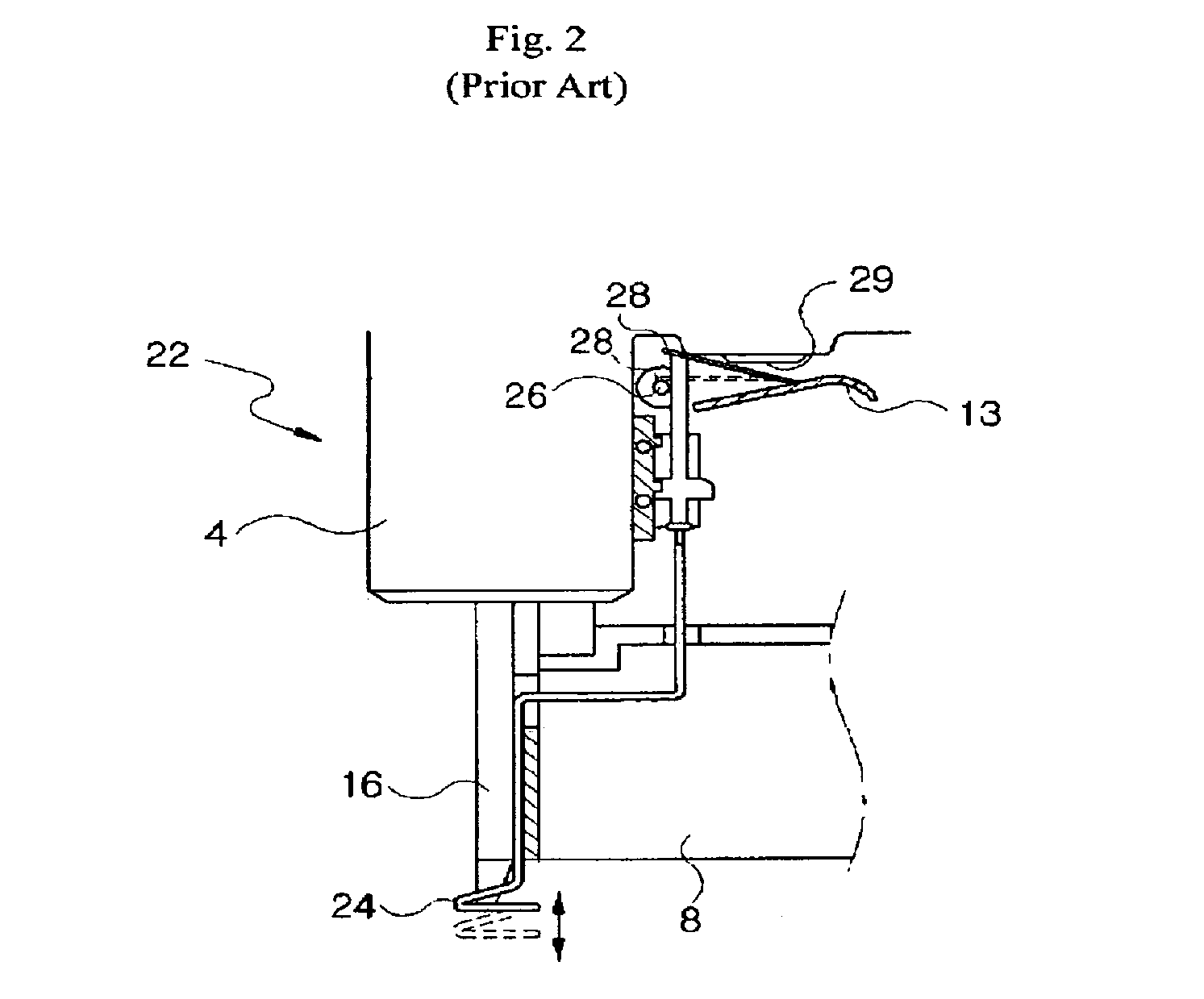

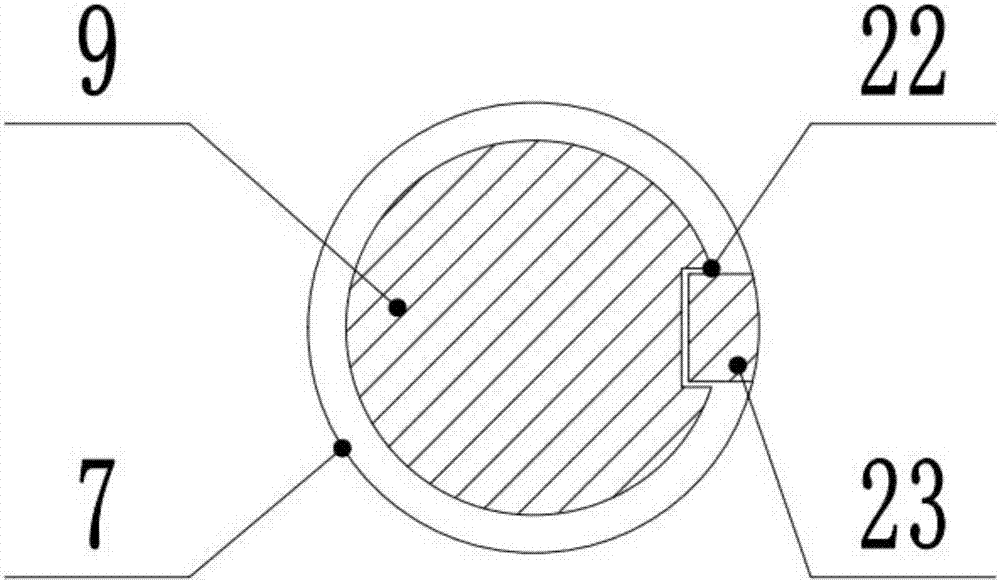

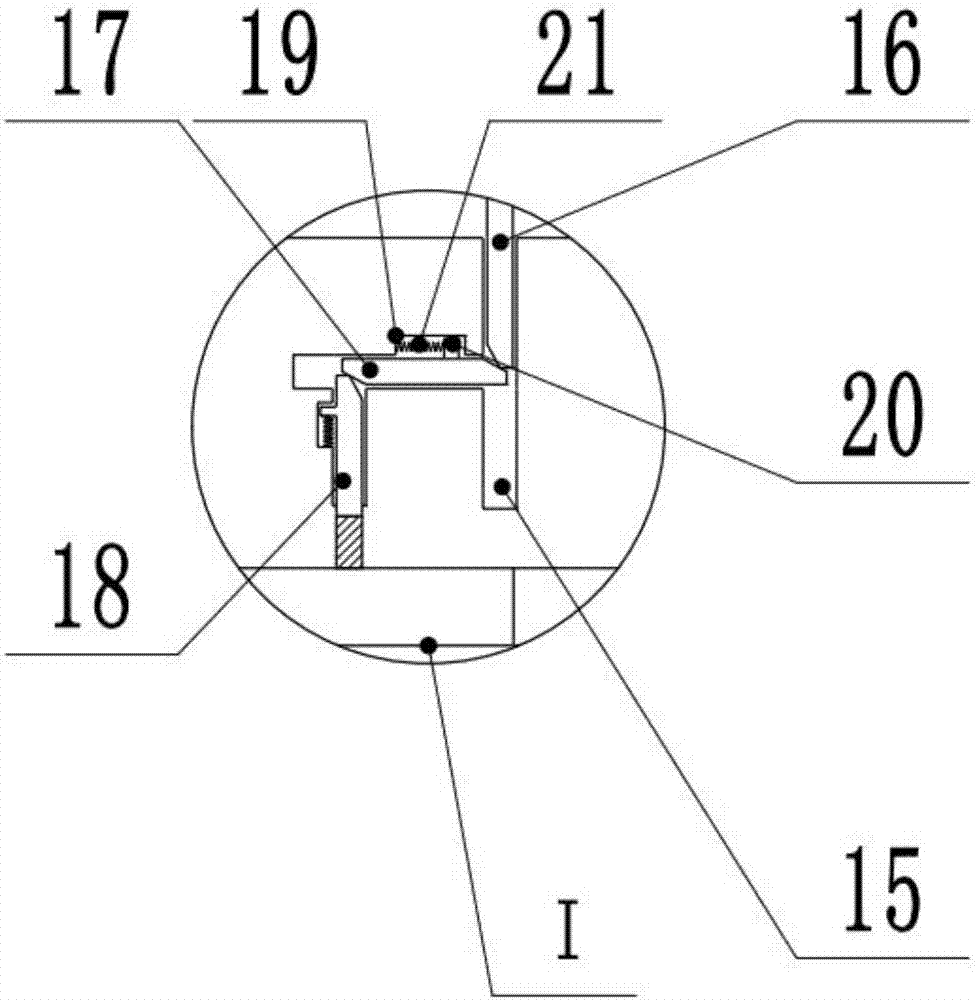

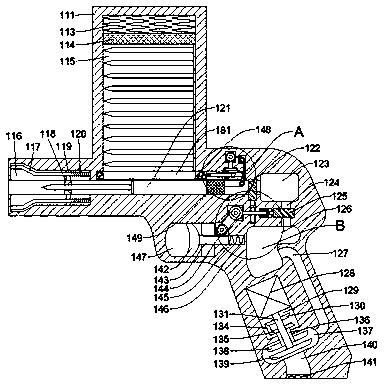

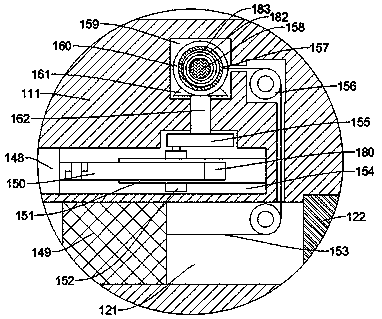

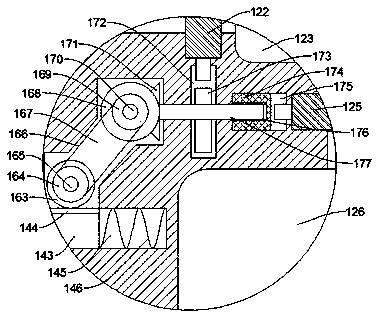

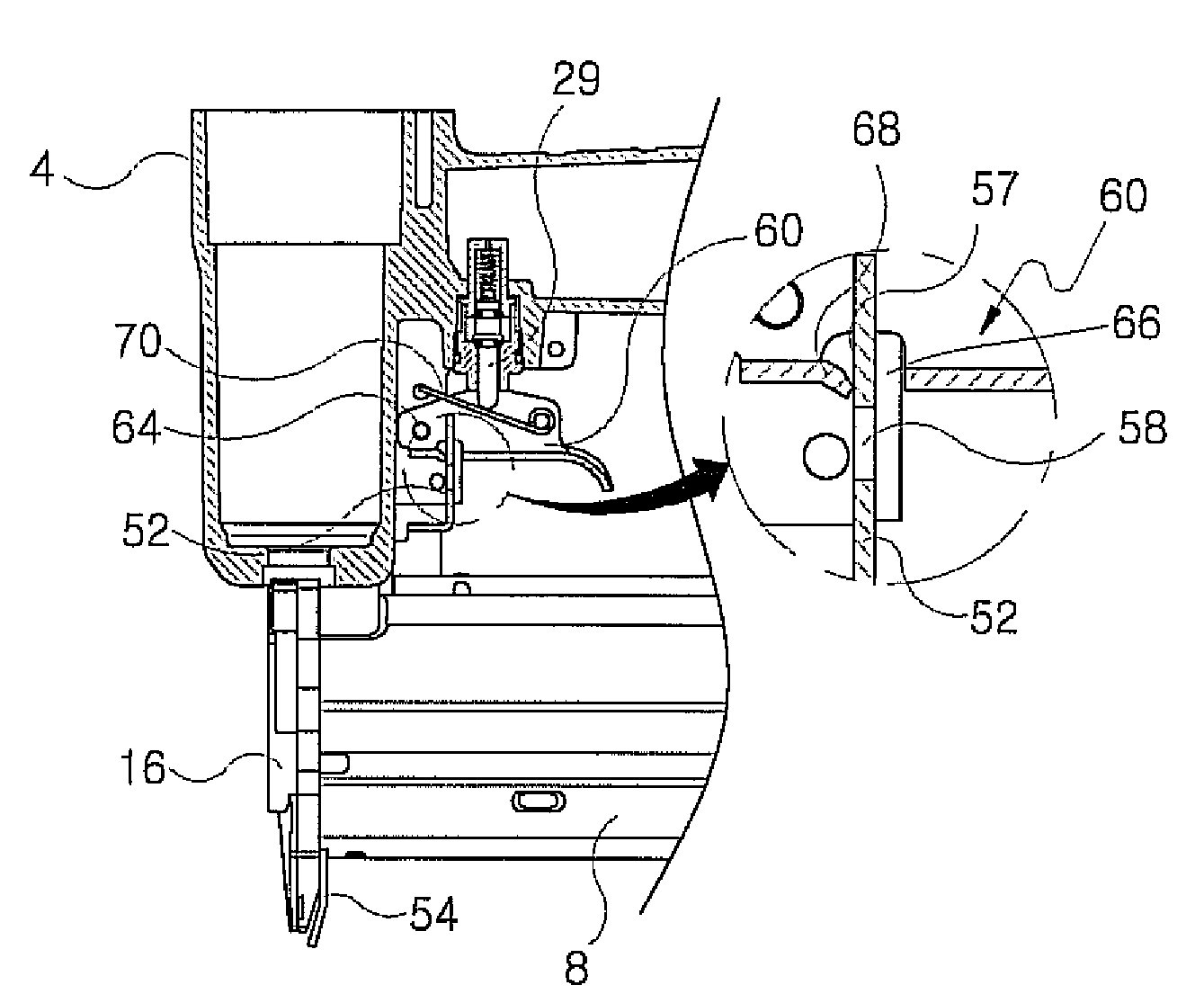

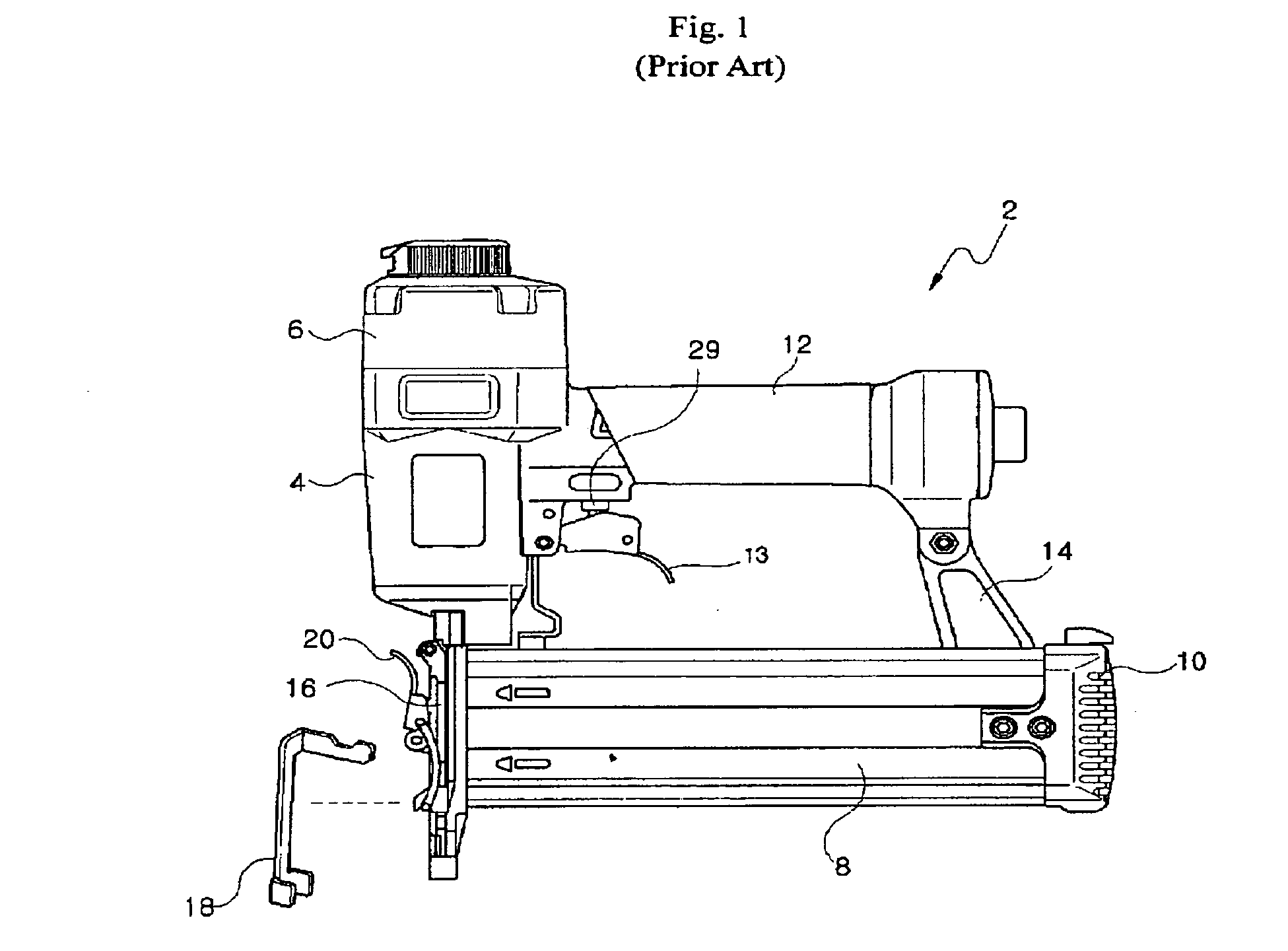

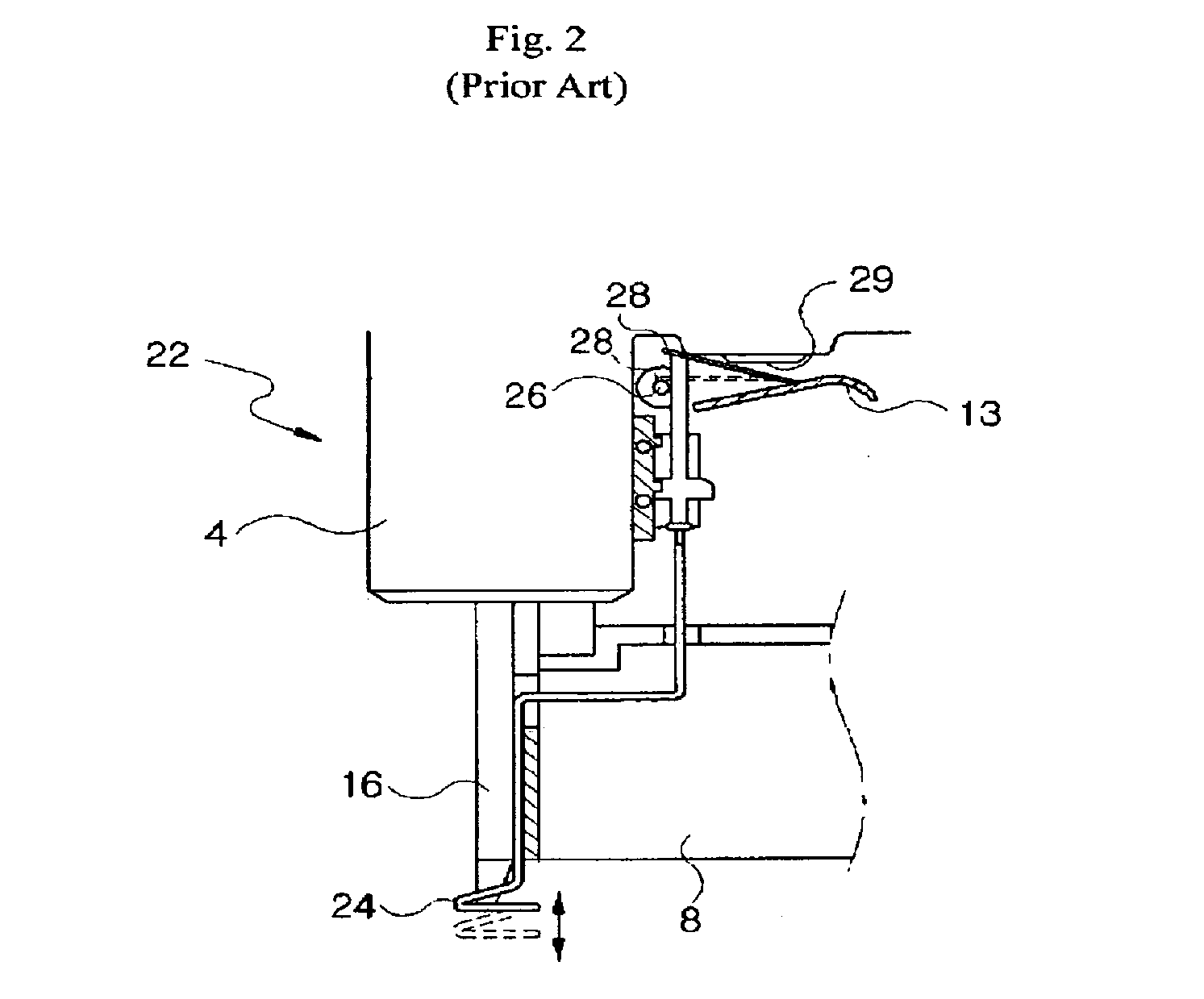

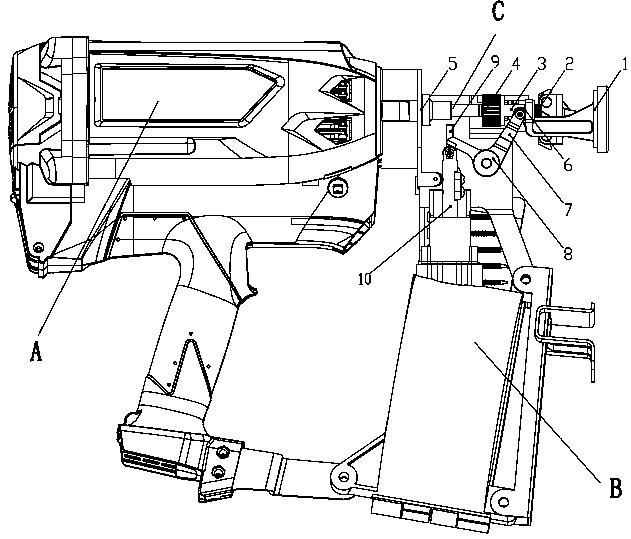

Nailer with a safety device

InactiveUS7389901B2Eliminate riskStapling toolsPortable percussive toolsEngineeringMechanical engineering

Disclosed herein is a nailer having an improved safety device. With the improved safety device, a movable plate, which is adapted to slidably move along a lower surface of a guiding unit, is formed, at a certain location thereof, with an insertion hole for the insertion of a protrusion formed at a trigger. Thereby, if the trigger is pulled in a pressed state of the movable plate, a nailing operation is accomplished. Also, in the course of pulling the trigger, the movable plate can be further inserted rearward by a predetermined distance under interaction of the insertion hole and protrusion. This has the effect of eliminating the risk of causing scratches on a nailing surface of a target structure even if the movable plate is moved while coming into close contact, at a front end thereof, with the nailing surface, resulting in several advantages, such as for example, easy nailing operation, operator's convenient working posture, and rapid and safe nailing operation.

Owner:JEIL TACKER

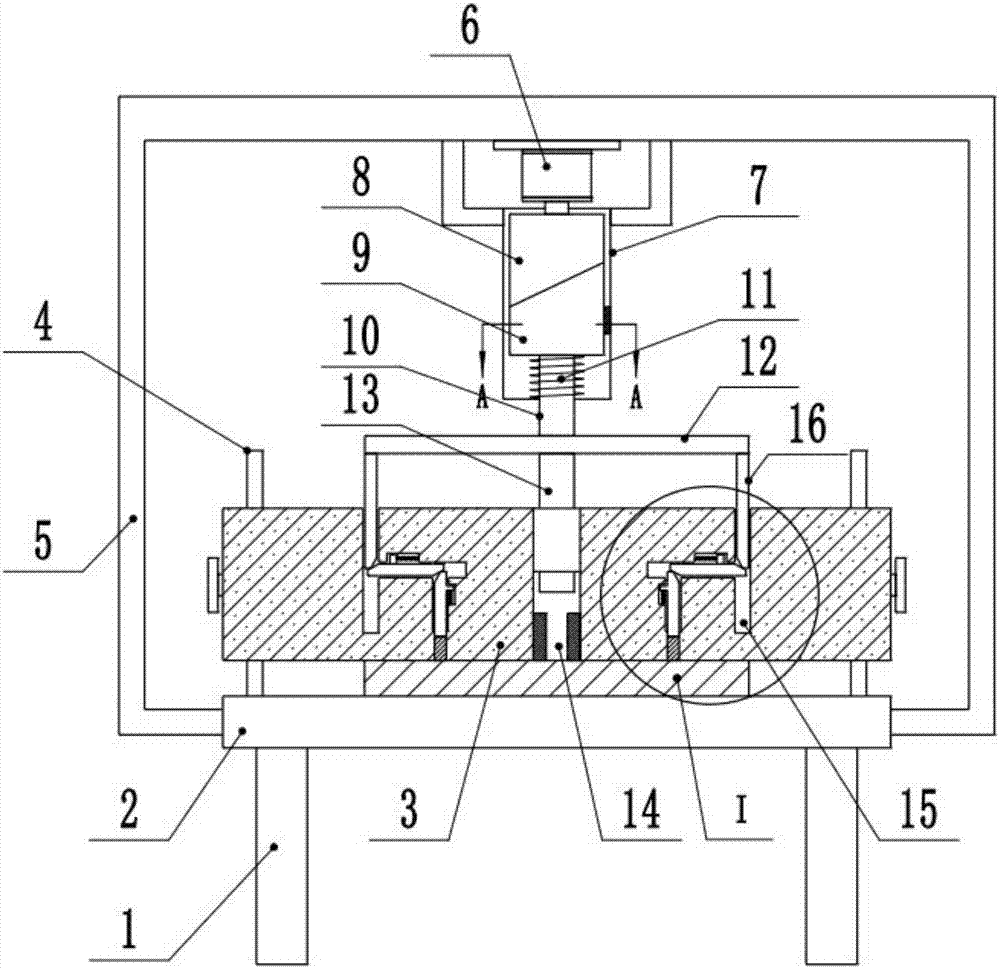

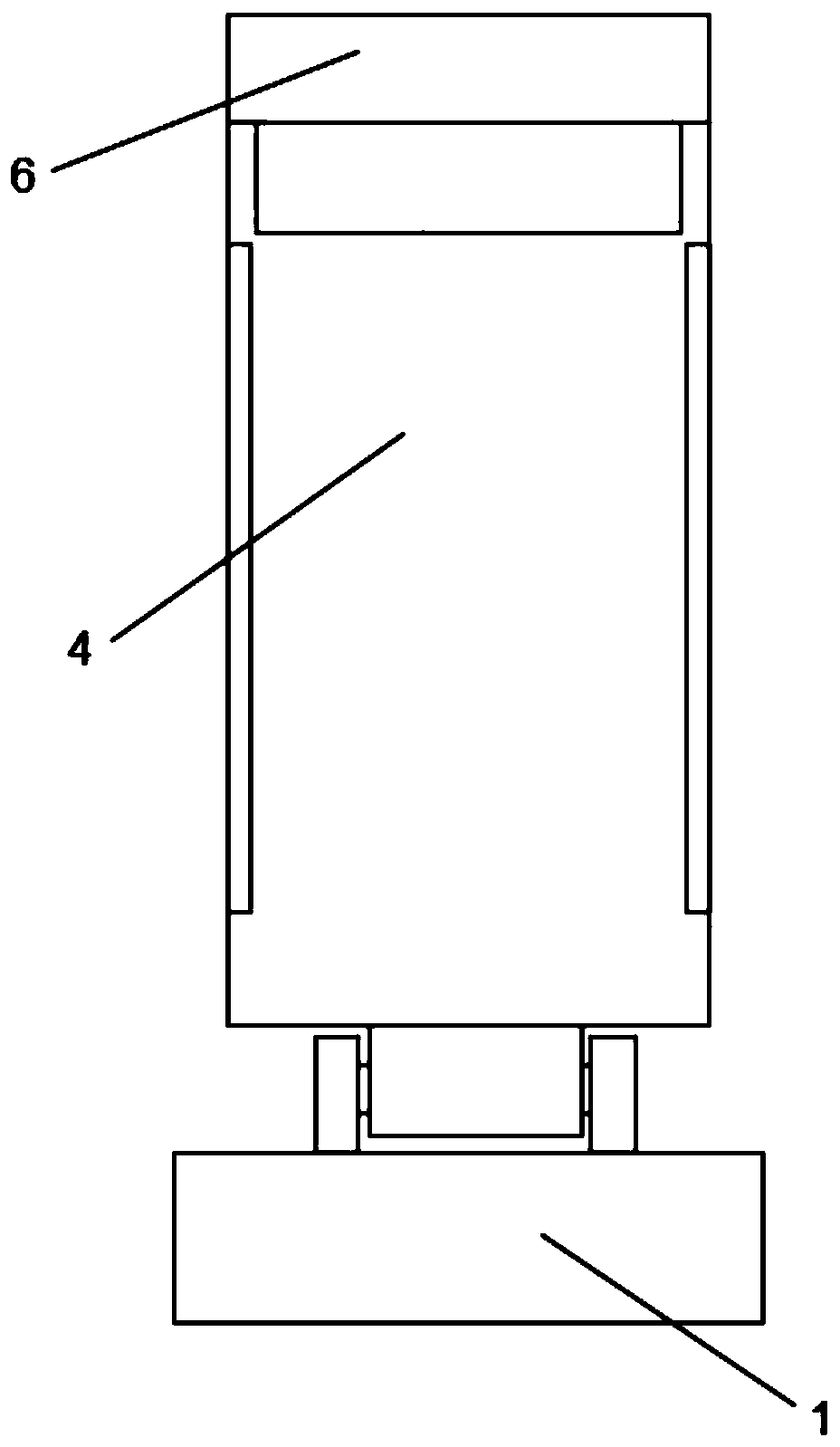

Self-fixing plate nailing device for constructional engineering

ActiveCN107097308AAvoid misalignmentQuality improvementStapling toolsNailing toolsFixed frameIndustrial engineering

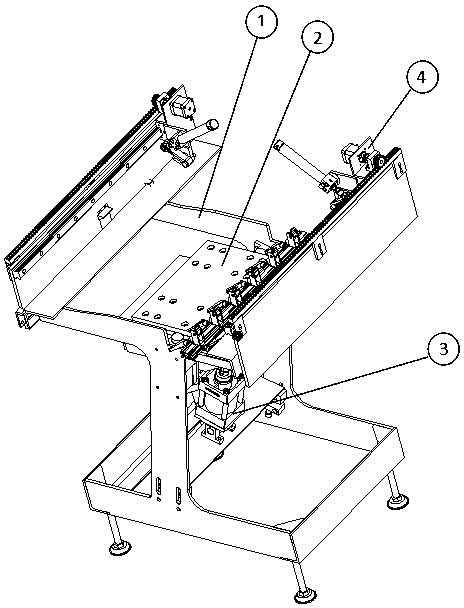

The invention discloses a self-fixing plate nailing device for constructional engineering. The self-fixing plate nailing device comprises a device body, the device body is provided with support frames, a workbench is arranged on the support frames, a positioning plate is arranged over the workbench, a nailing cavity is formed in the middle of the positioning plate, a fixing frame is arranged on the side face of the workbench, a motor is arranged on the top of the fixing frame, a sleeve is arranged at the bottom of the motor, a rotating block and a sliding block are arranged in the sleeve, a connecting rod is arranged at the bottom of the sliding block, a connecting support is arranged at the bottom of the connecting rod, a moving cavity is formed in the positioning plate, and a pressing rod is arranged in the middle of the bottom of the connecting support. According to the self-fixing plate nailing device for constructional engineering, the structure is simple, use is convenient, a workpiece can be fixed under the action of a device body while nailing is conducted, therefore, the workpiece is more stable, nailing operation is more stable, the condition that the workpiece is displaced is avoided, the working efficiency is effectively improved, the workpiece nailing quality is improved, and the practicability is high.

Owner:四川华映大地文化科技有限公司

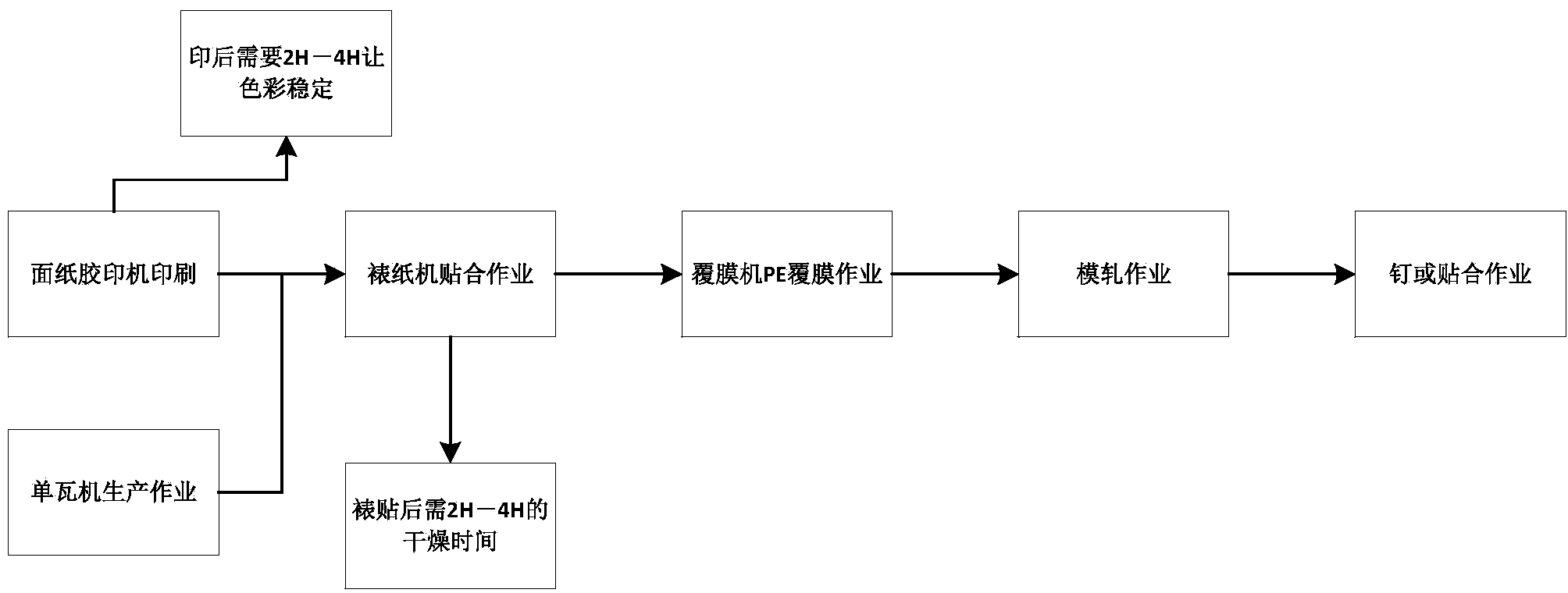

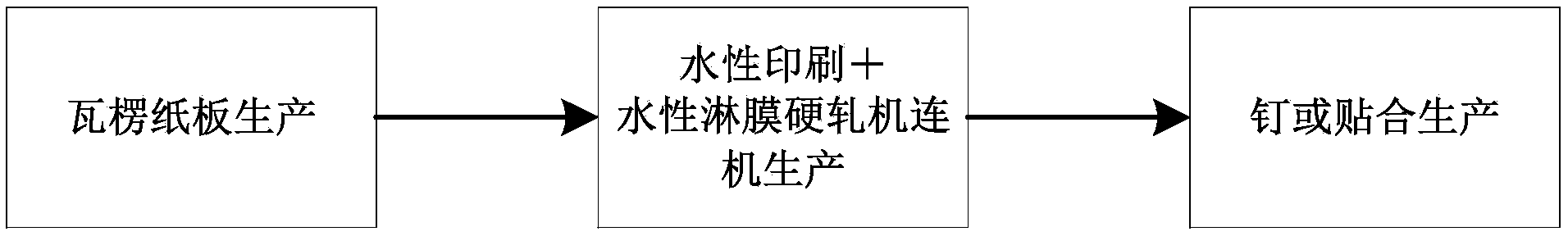

Method preparing environment-friendly corrugated board packaging box

The invention discloses a method preparing an environment-friendly corrugated board packaging box. The method is characterized by comprising the following steps: (1) producing corrugated board: the corrugated board is produced according to the requirement of a product to be packaged; (2) printing patterns and producing with a laminating and hard rolling machine: patterns required by the packaging box is conducted by water-based printing on the surface board of the corrugated board; then water-based film paint is taken as laminating liquid to conduct laminating and coating operation on the printing side of the corrugated board to complete water-based film forming on the printing side; finally hard rolling operation is conducted; (3) conduct of nailing operation or gluing operation on the corrugated board after the hard rolling to produce the corrugated board packaging box. According to the invention, materials are basically environment-friendly; heavy coating of which the gram weight is 200 g-300 g can be replaced by light coating of which the gram weight is 140 g-170 g; the material cost is reduced; three times of processing are reduced in the producing procedures; the defective rate is low; the surface board need not to reserve 10 mm; paper is saved to achieve energy conservation; processing wage is reduced by more than 30%.

Owner:佘文龙

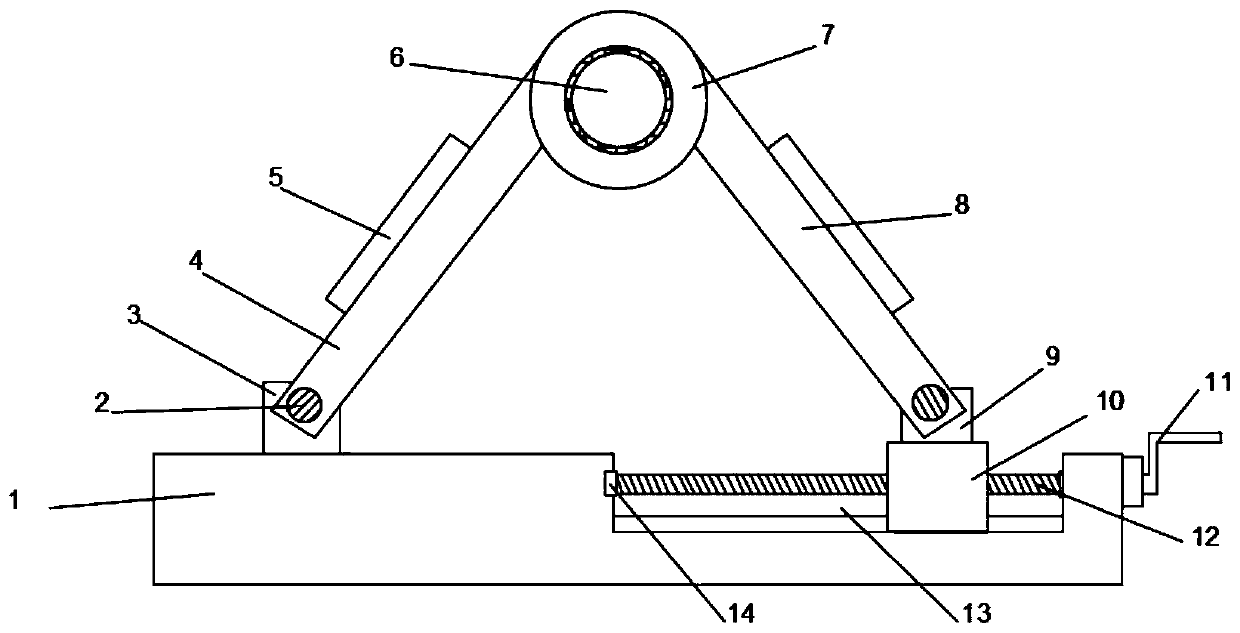

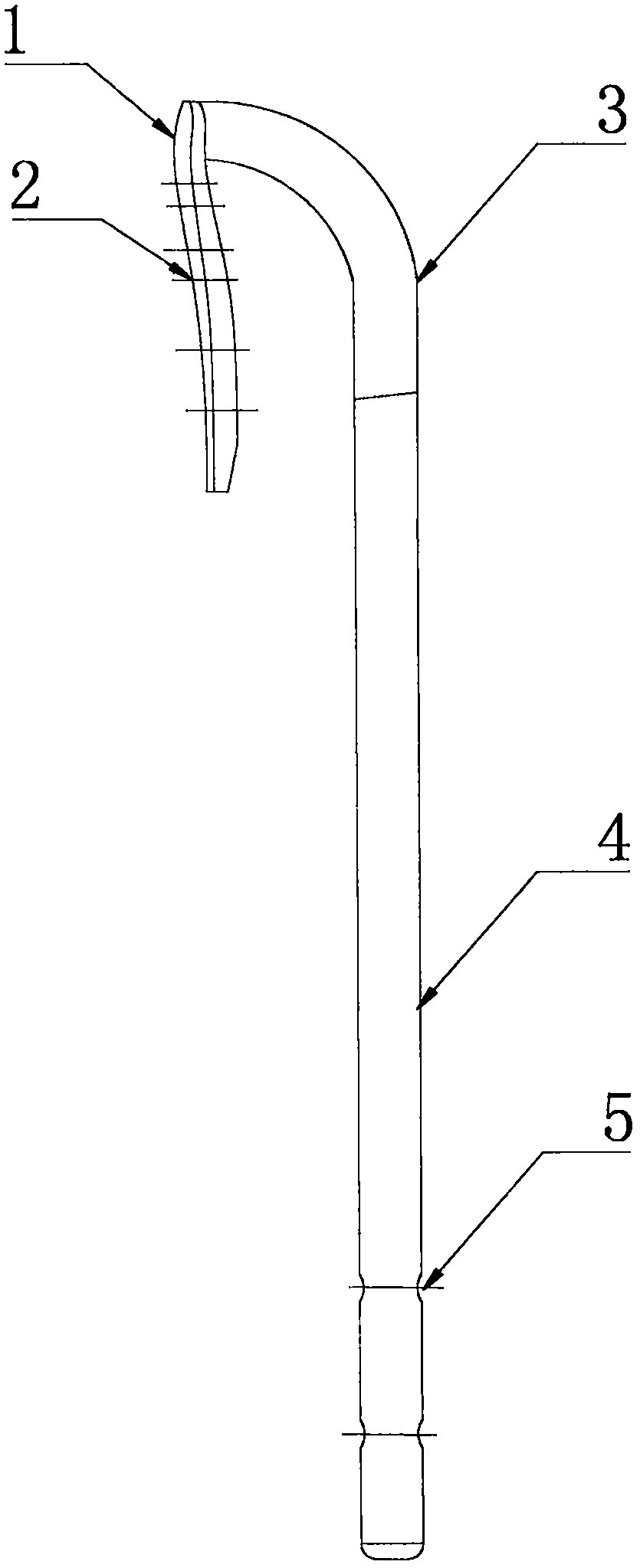

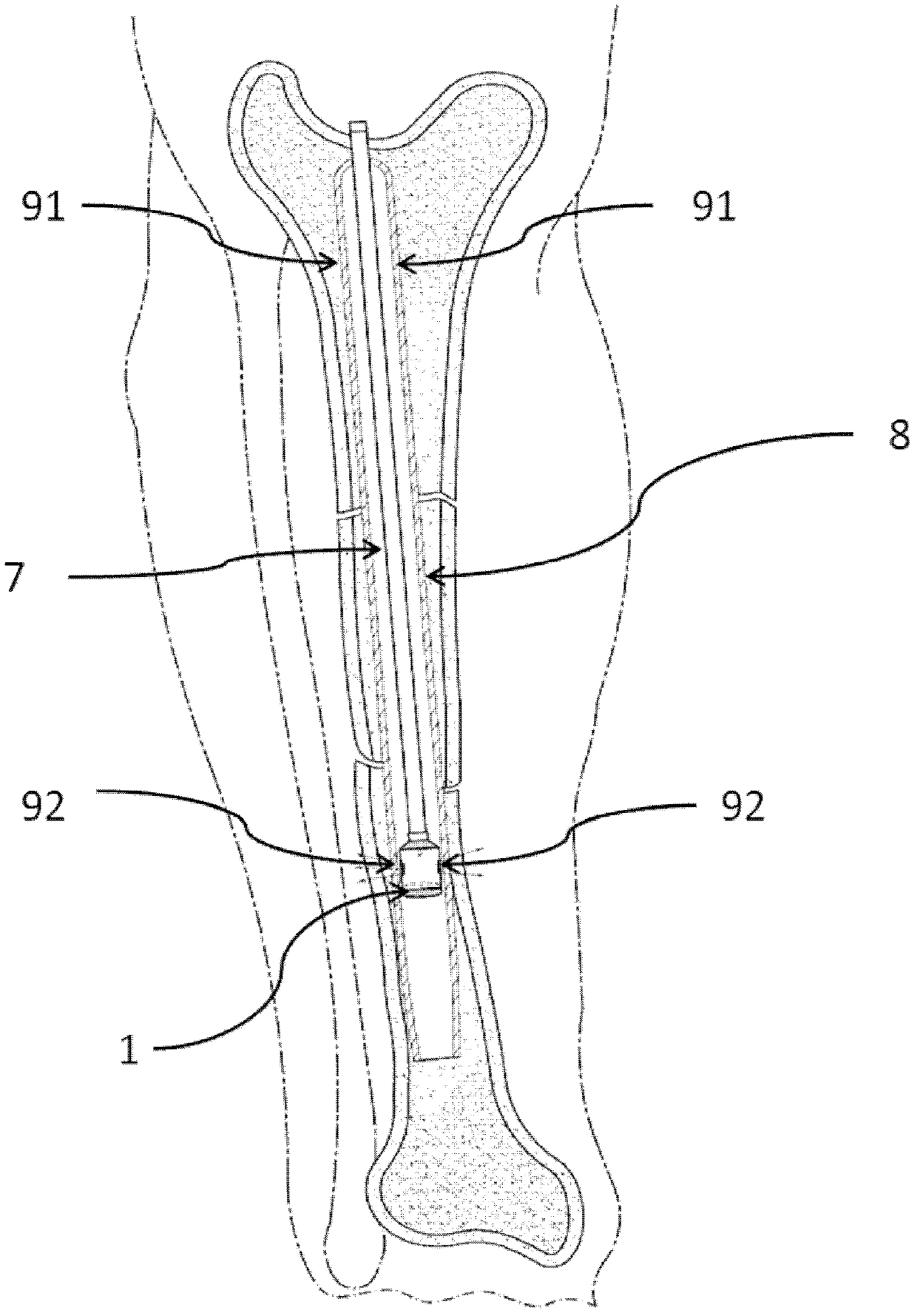

Knee bending support for tibia intramedullary nail operation

InactiveCN110974593AAvoid secondary damageAccurate adjustmentOperating tablesInstruments for stereotaxic surgeryThighPhysical medicine and rehabilitation

The invention provides a knee bending support for a tibia intramedullary nail operation. According to the invention, the knee bending support comprises a base provided with a guide chute formed at oneside; a knee bending device is arranged on the base; the knee bending device comprises a rotating device, and a first supporting plate and a second supporting plate which are connected with the rotating device and are respectively positioned on two sides of the rotating device; the bottom of the first supporting plate and the bottom of the second supporting plate are rotationally connected with afirst fixing plate and a second fixing plate correspondingly, an adjusting device arranged in the guide sliding groove is fixed to the bottom of the second fixing plate, and the adjusting device adjusts an included angle between the first supporting plate and the second supporting plate. The included angle between the thigh and the shank is adjusted through the adjusting device, so that adjustment is more accurate, secondary damage to the fracture of a patient due to manual adjustment is avoided, manpower input is reduced, and operation efficiency is improved.

Owner:CHANGZHOU NO 2 PEOPLES HOSPITAL

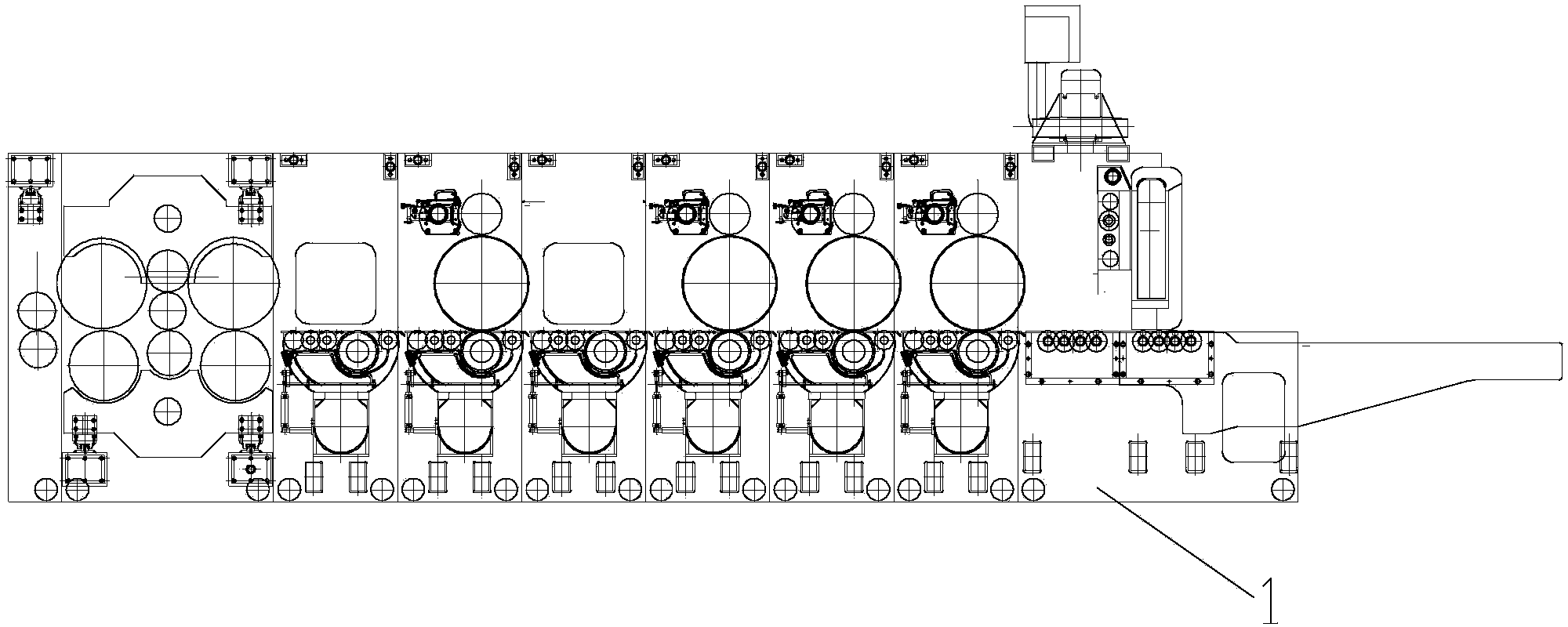

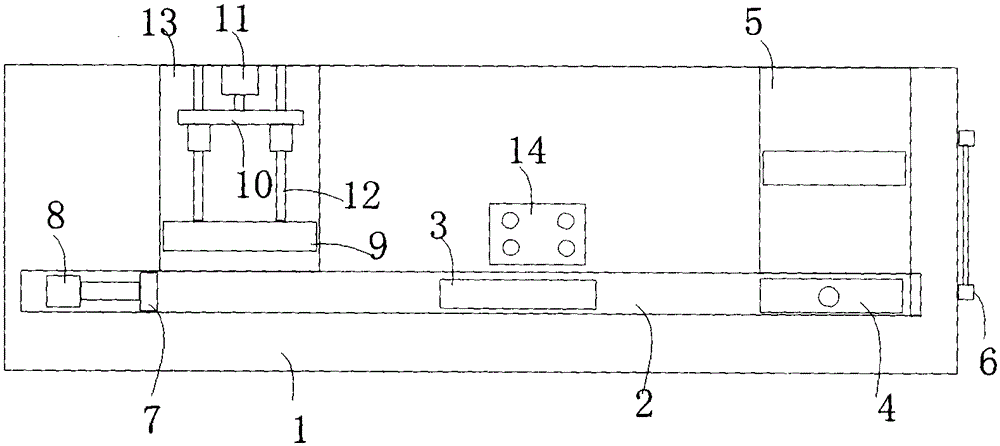

Printing nailing machine

The invention relates to the technical field of board machining, in particular to a printing nailing machine. Feeding, printing and nailing operation of boards can be automatically completed, and the efficiency is improved. The printing nailing machine comprises a base and is characterized in that a conveying belt is arranged on the base, and a stockpiling bin plate, a printing device and a feeding nailing device are sequentially mounted on the base in the conveying direction of the conveying belt; and the feeding nailing device comprises a nailing device and two pushing devices; and the two pushing devices are arranged on the two sides of the nailing device.

Owner:WUXI FORMEN TECHN

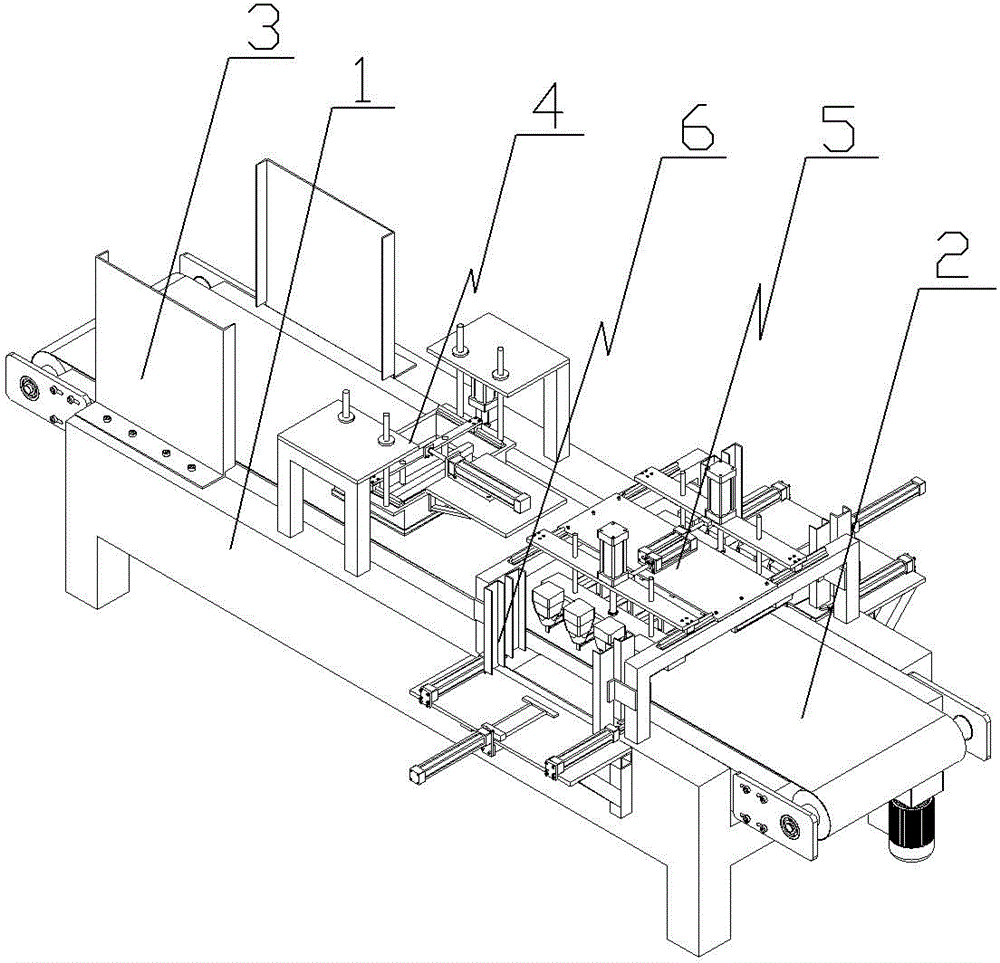

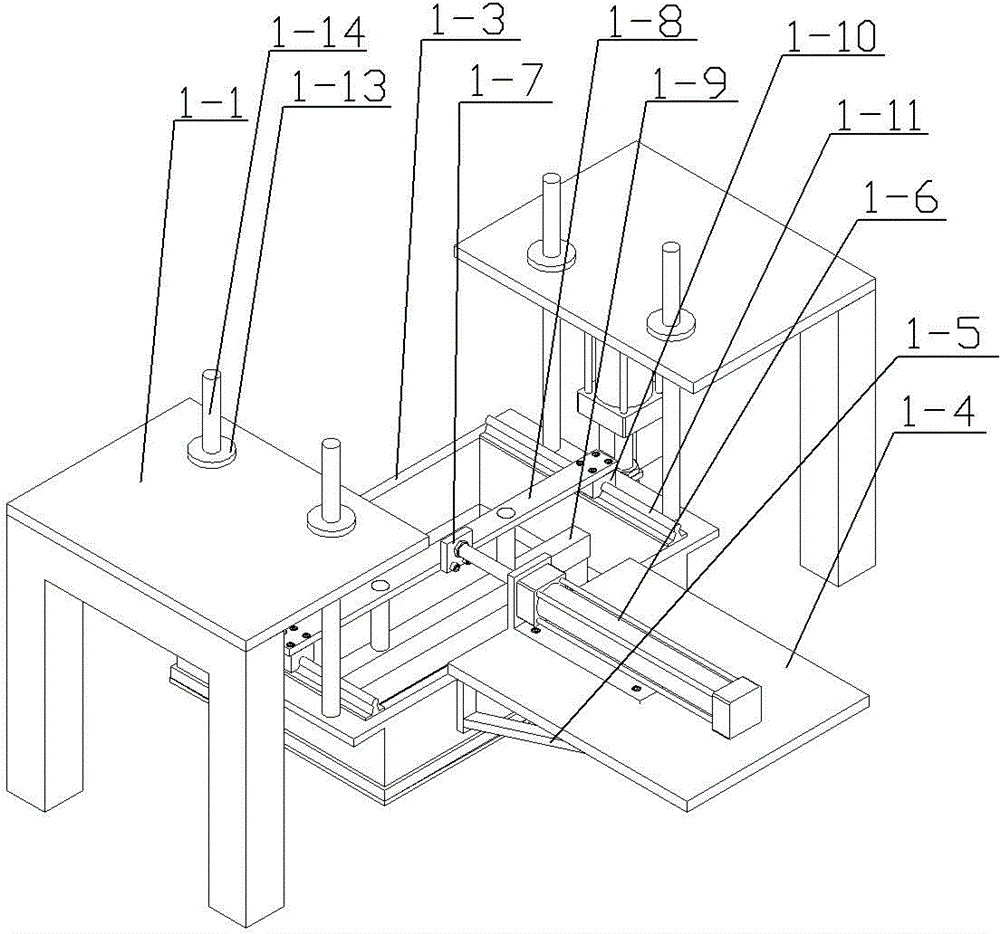

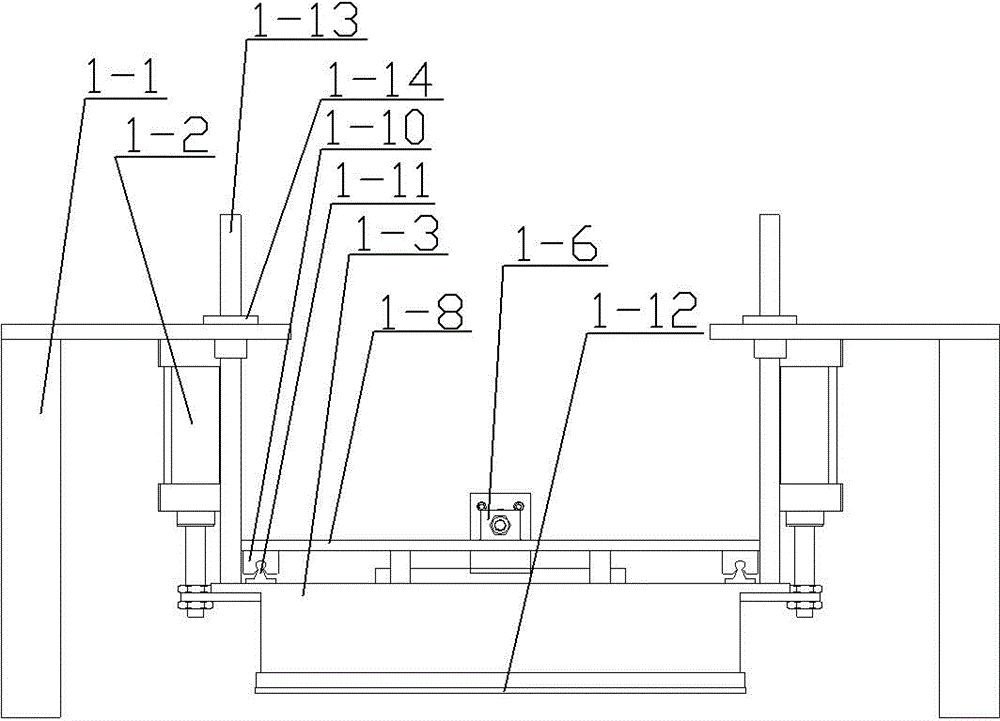

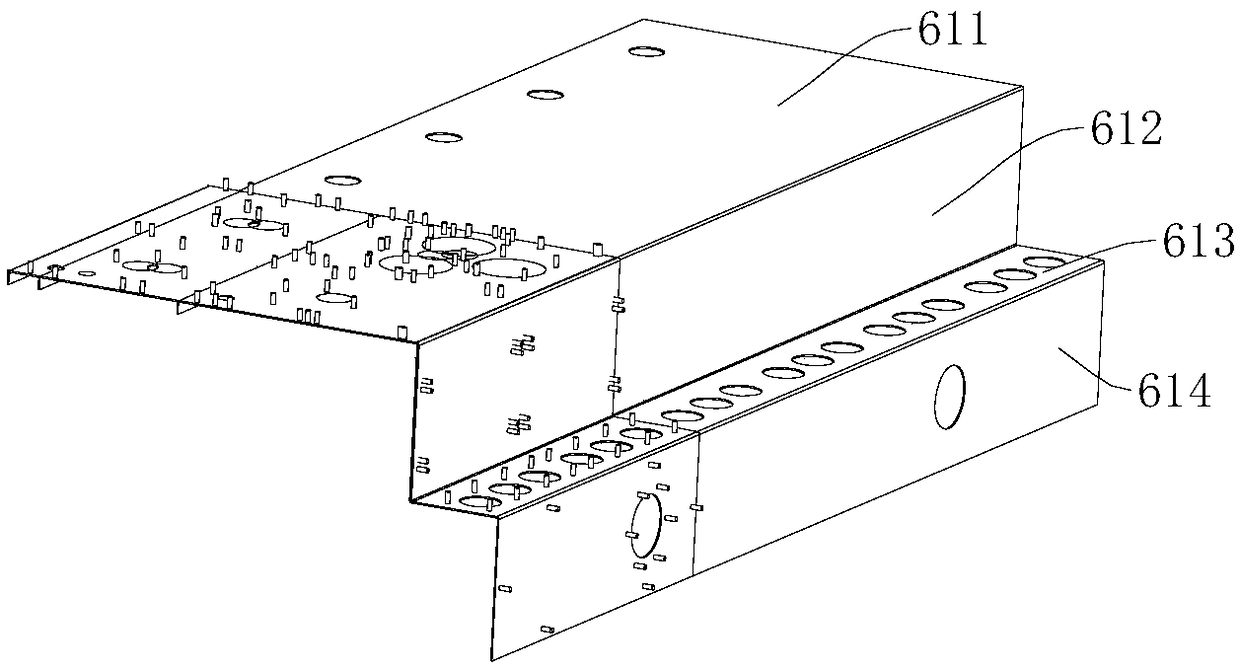

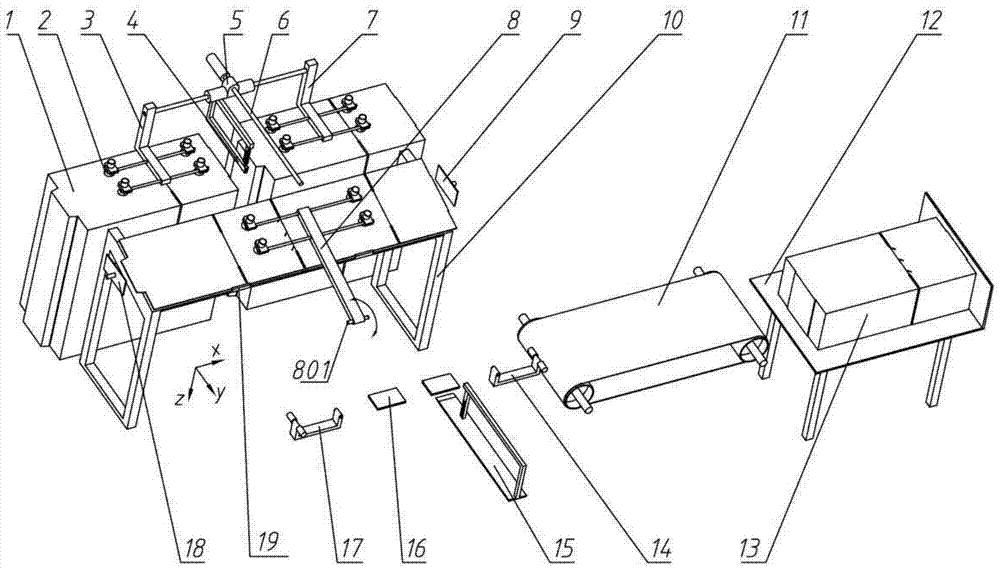

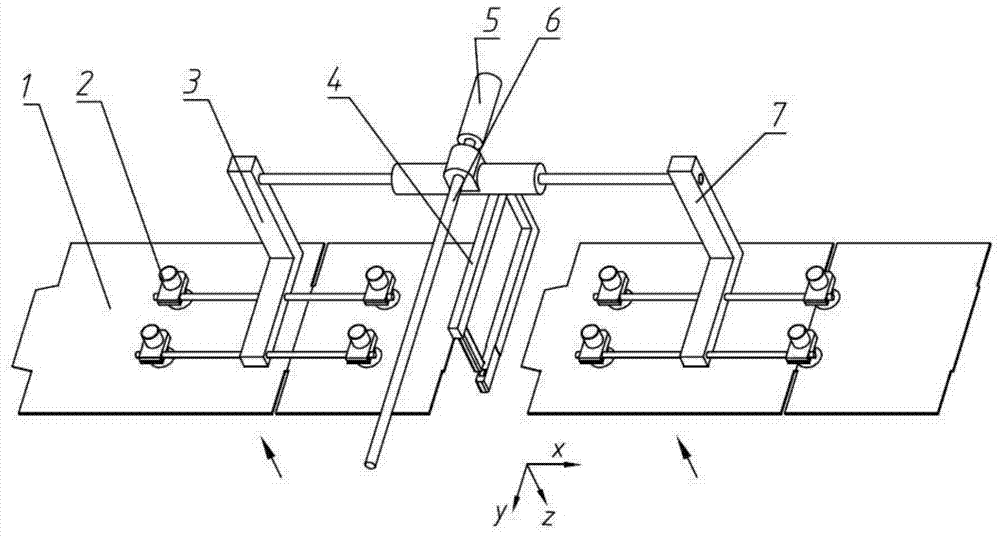

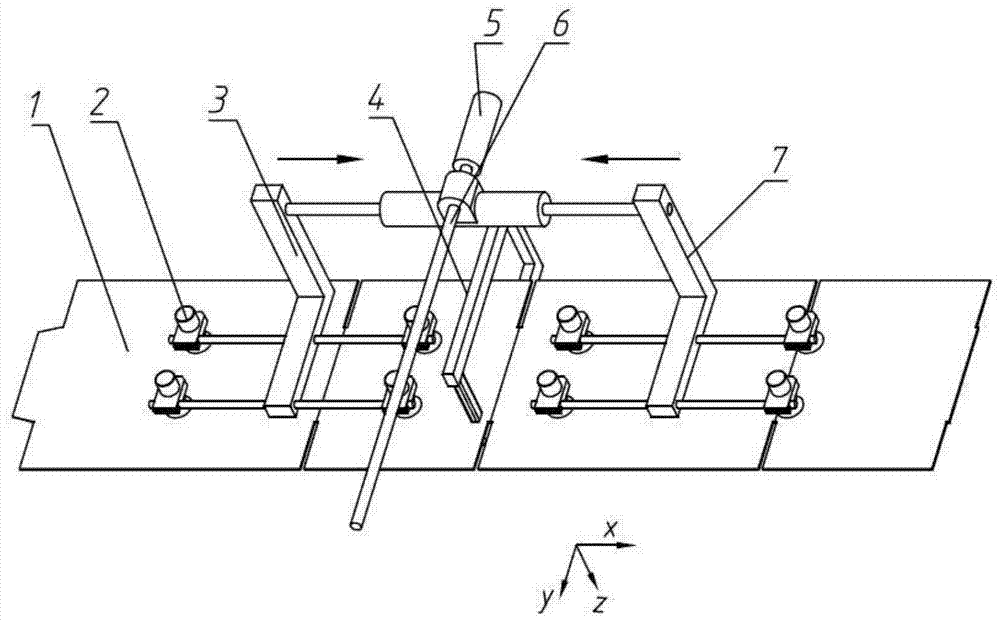

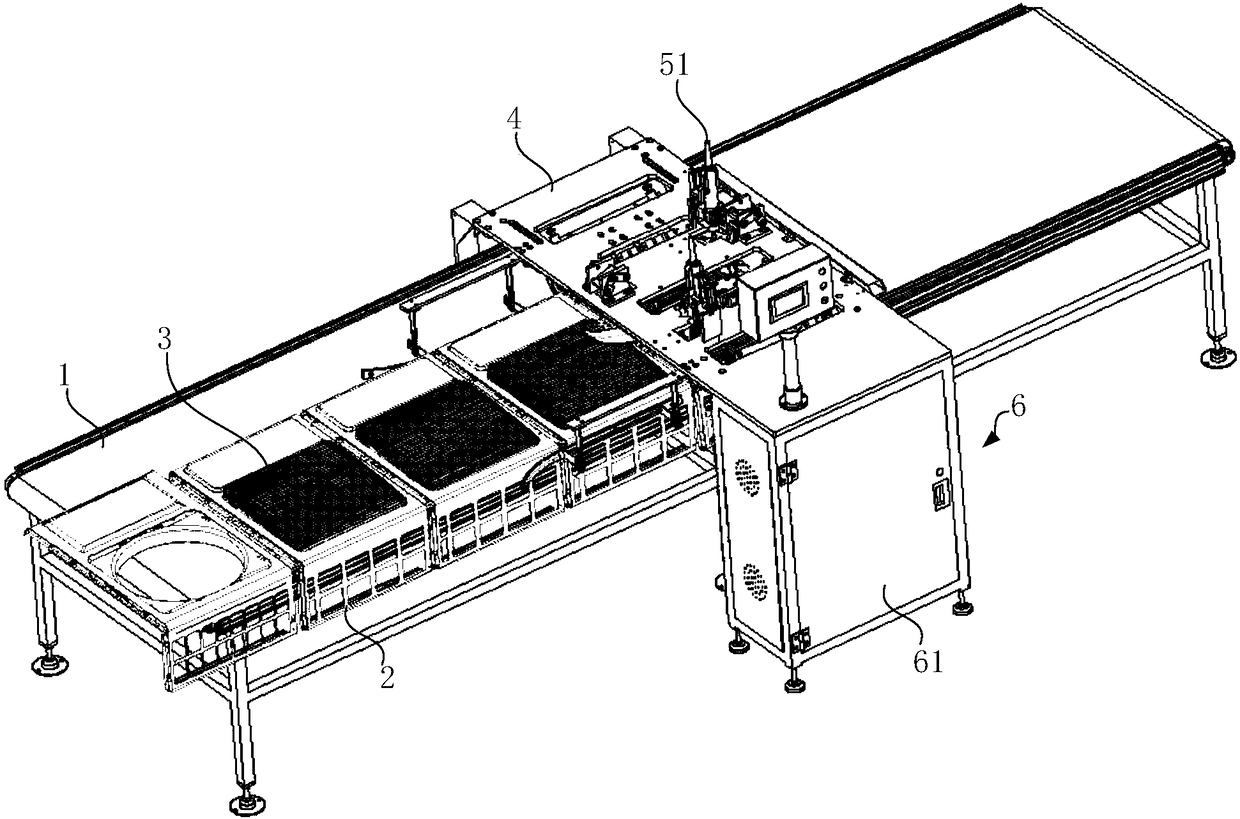

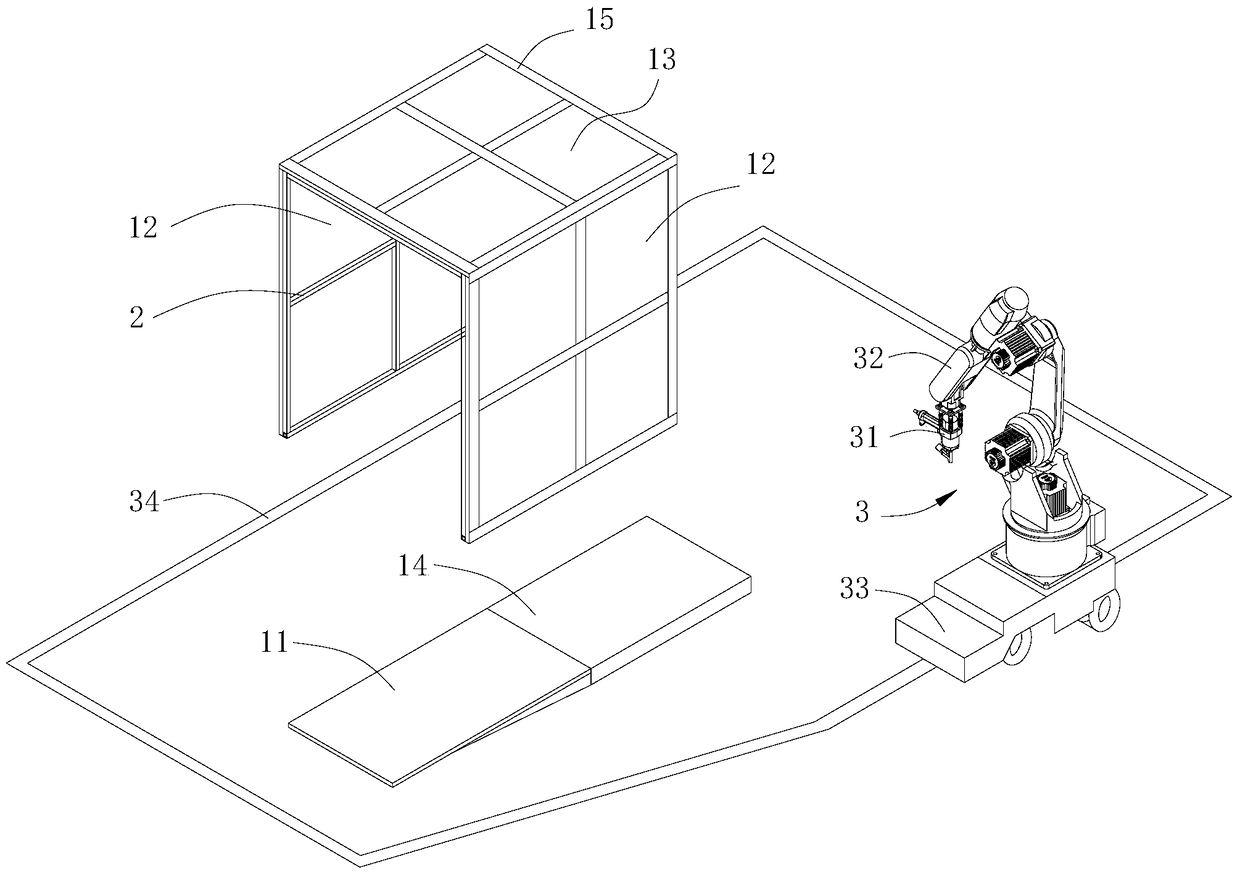

Assembly equipment of wooden box and assembly method of wooden box

ActiveCN106541484ASimple structureReduce labor intensityWood working apparatusEngineeringUltimate tensile strength

The invention discloses assembly equipment of a wooden box and an assembly method of the wooden box. The wooden box comprises a front plate, a back plate, side plates, a top plate, a bottom plate and battens, wherein the front plate is located on the front side of the wooden box, the back plate is located on the back side of the wooden box, the side plates are located on the left and right sides of the wooden box, the top plate is located on the top of the wooden box, the bottom plate is located at the bottom of the wooden box, the back plate, the side plates on both sides and the top plate are all formed in a way that a plurality of panels are spliced, and the battens are respectively arranged on the back plate, the side plates on the both sides and the top plate. The assembly equipment comprises a jig, a vacuumizing device and a nailing device, wherein the jig is supported on the ground, and the nailing device can move around the jig. When the wooden box is assembled, the back plate, the side plates on the both sides and the top plate are respectively adsorbed to corresponding positions of the jig by the vacuumizing device, and the back plate, the side plates on the both sides, the top plate and the battens are nailed by the nailing device so as to be assembled. The assembly equipment of the wooden box has the advantage of simple structure, all of nailing operations can be completed only by one person in the whole nailing process, so that manpower can be saved, the labor intensity of workers and the human cost are reduced, and additionally, the nailing efficiency and the nailing quality can be increased.

Owner:SUZHOU COV PACKAGING ENG CO LTD

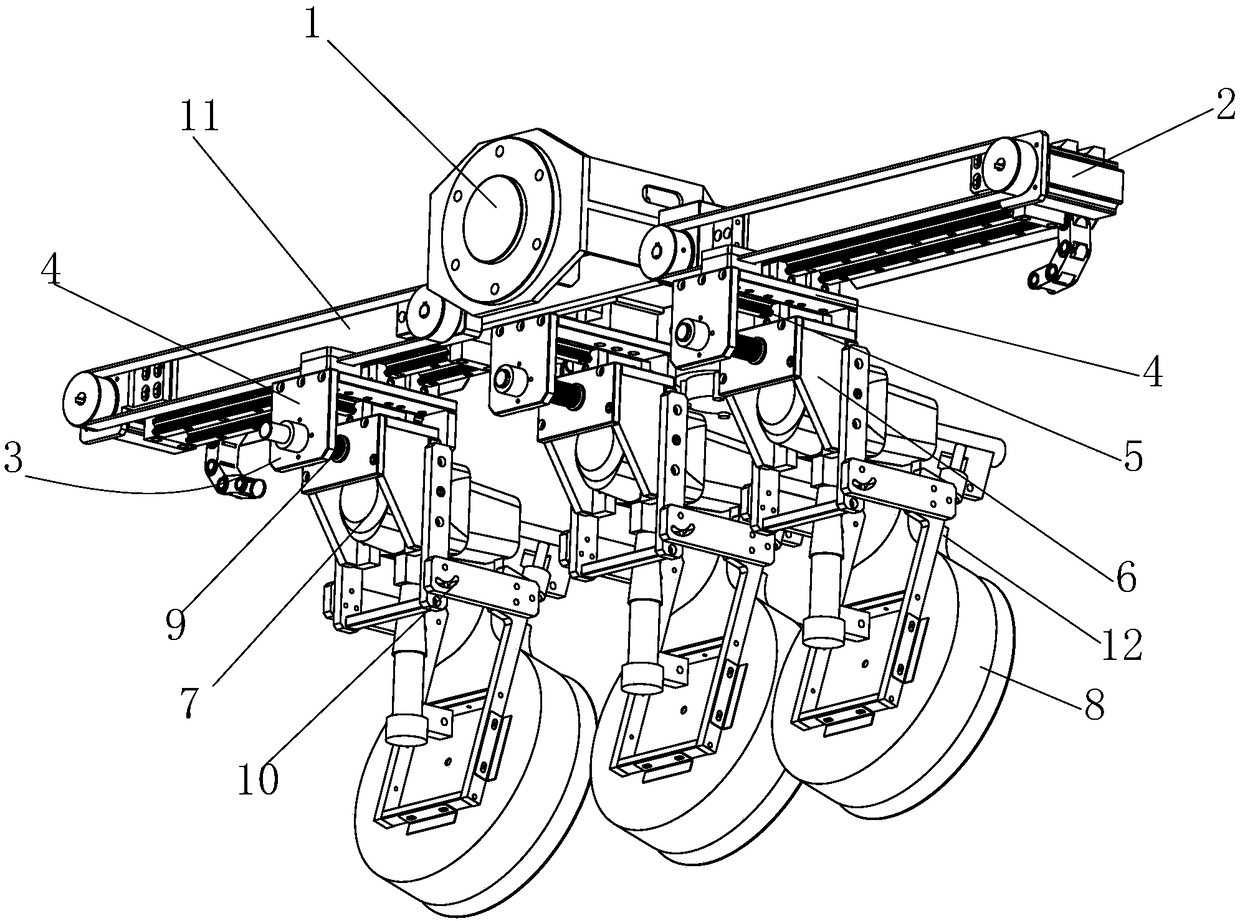

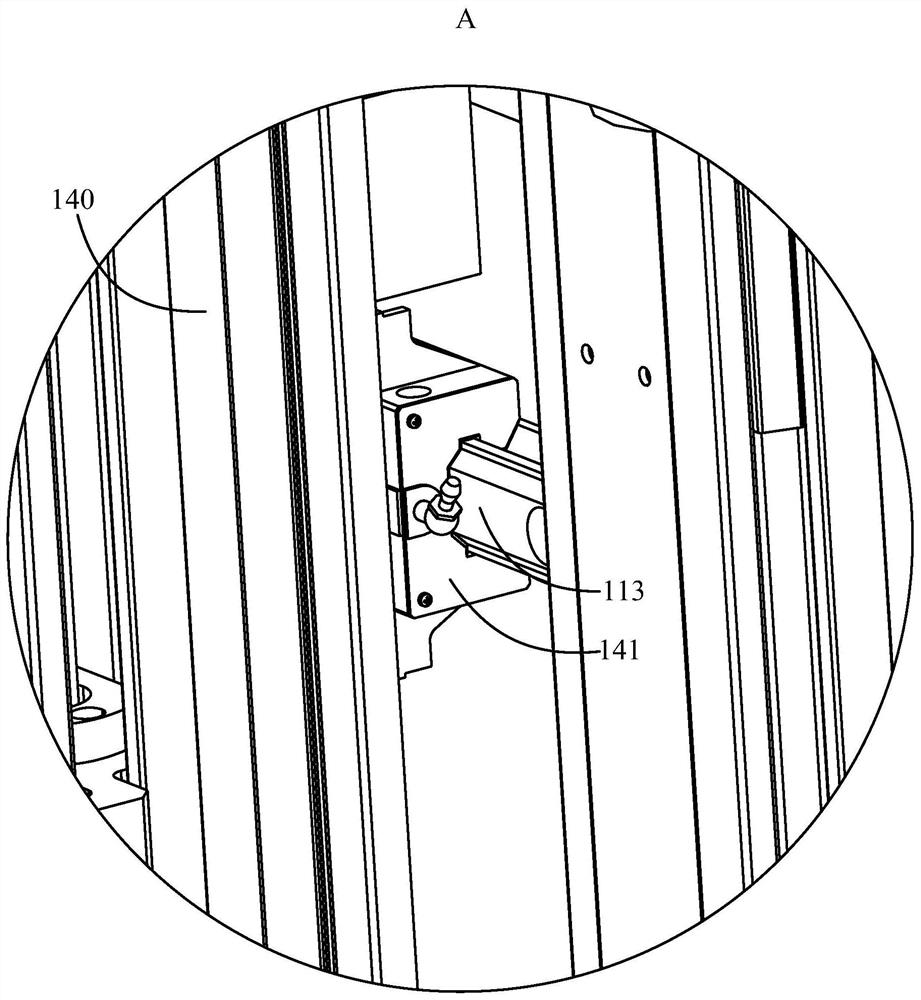

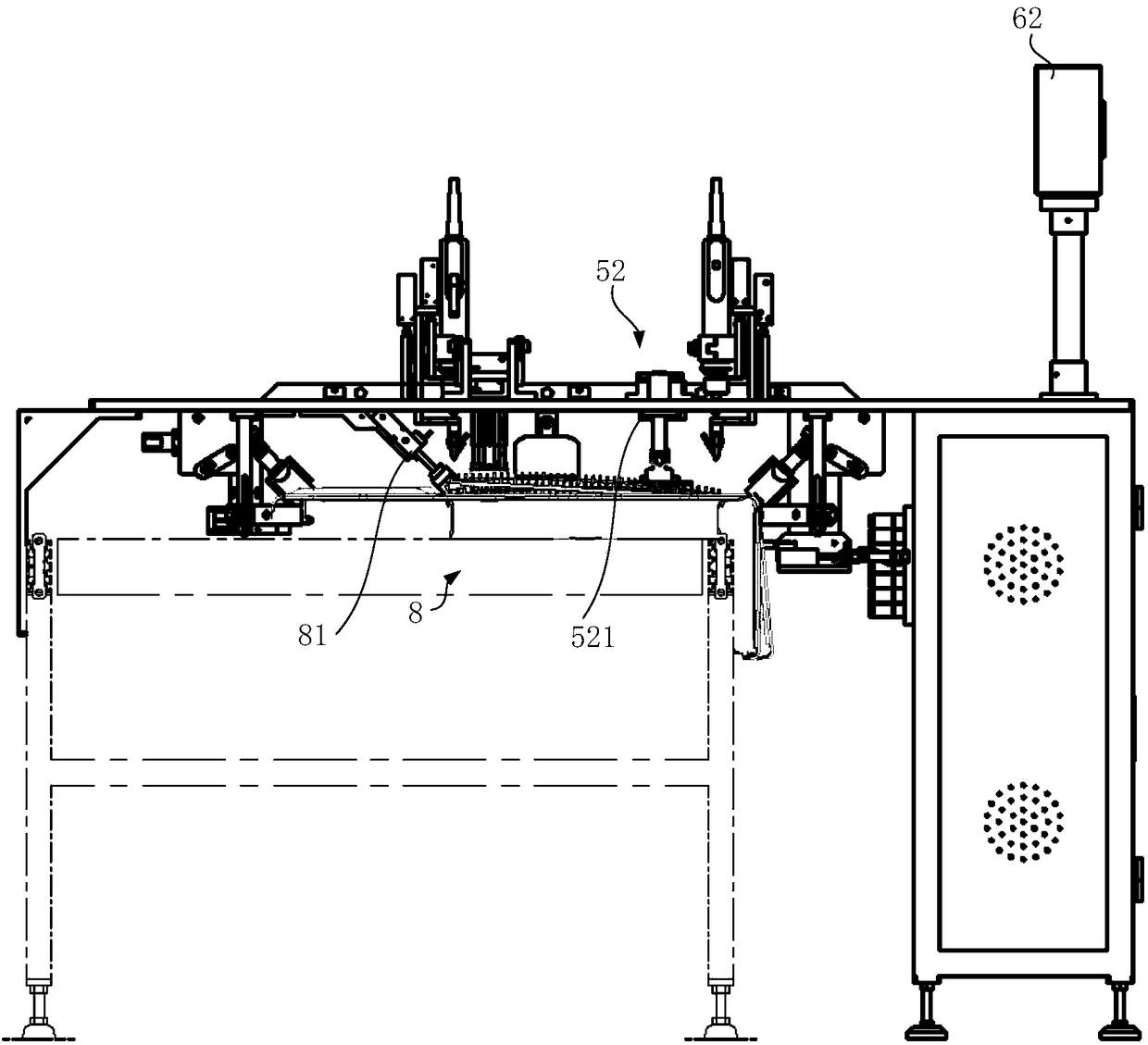

Automatic installation machine for straight springs of soft sofa seat frame

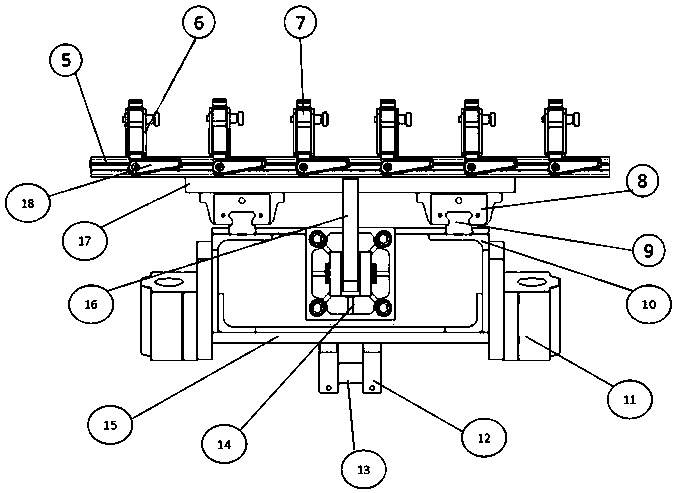

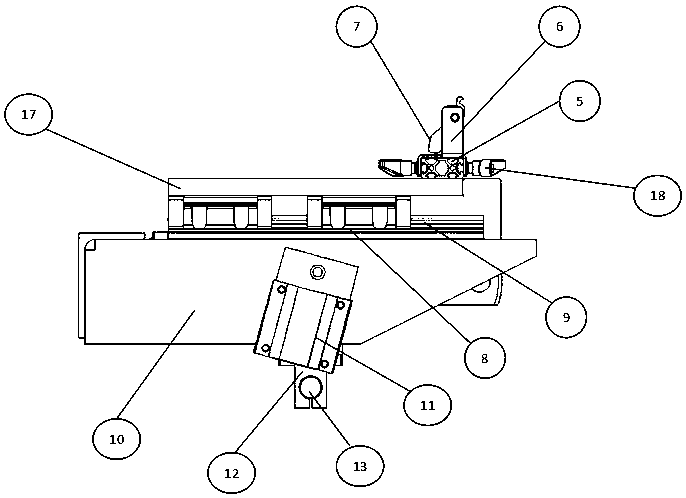

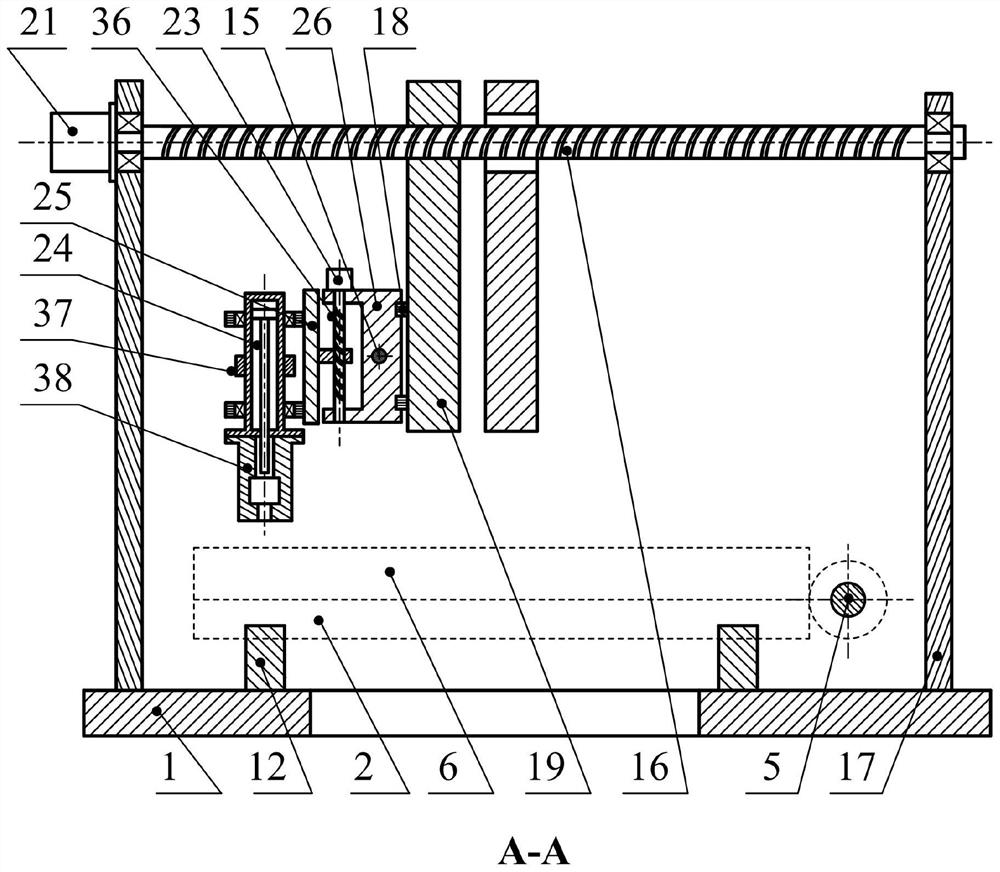

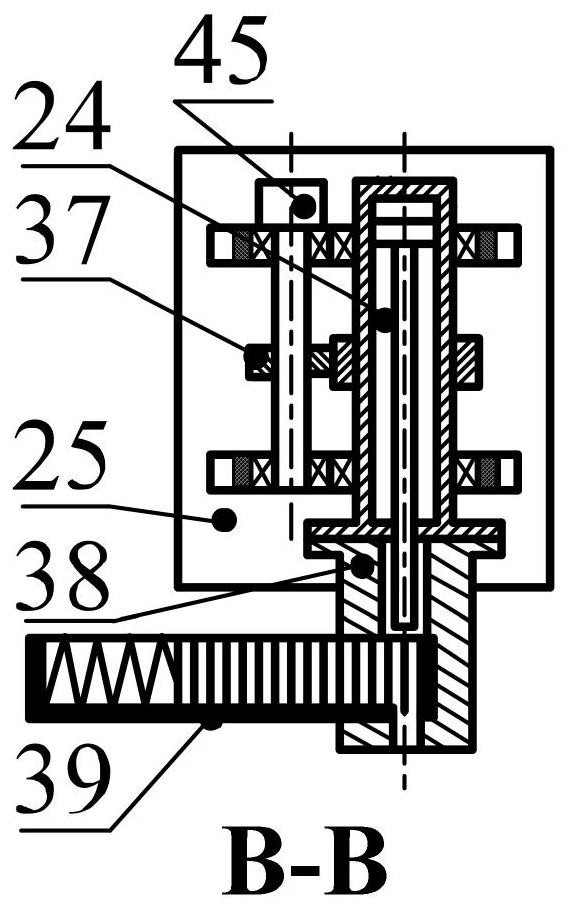

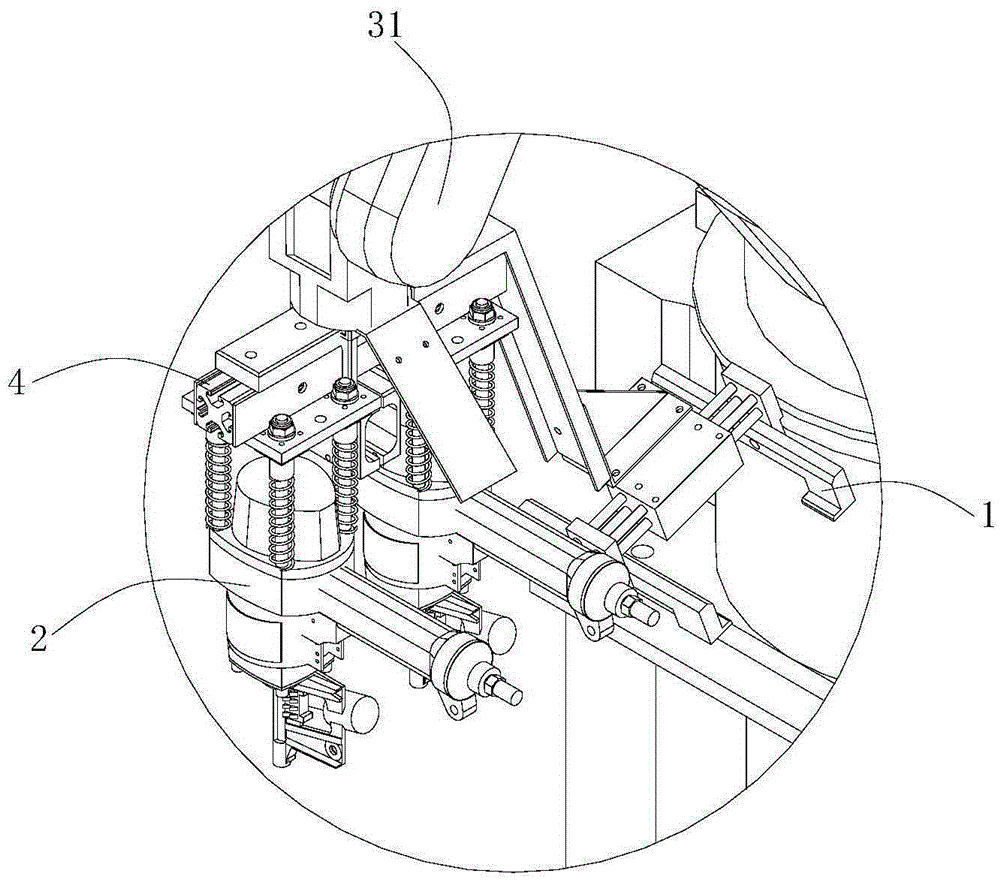

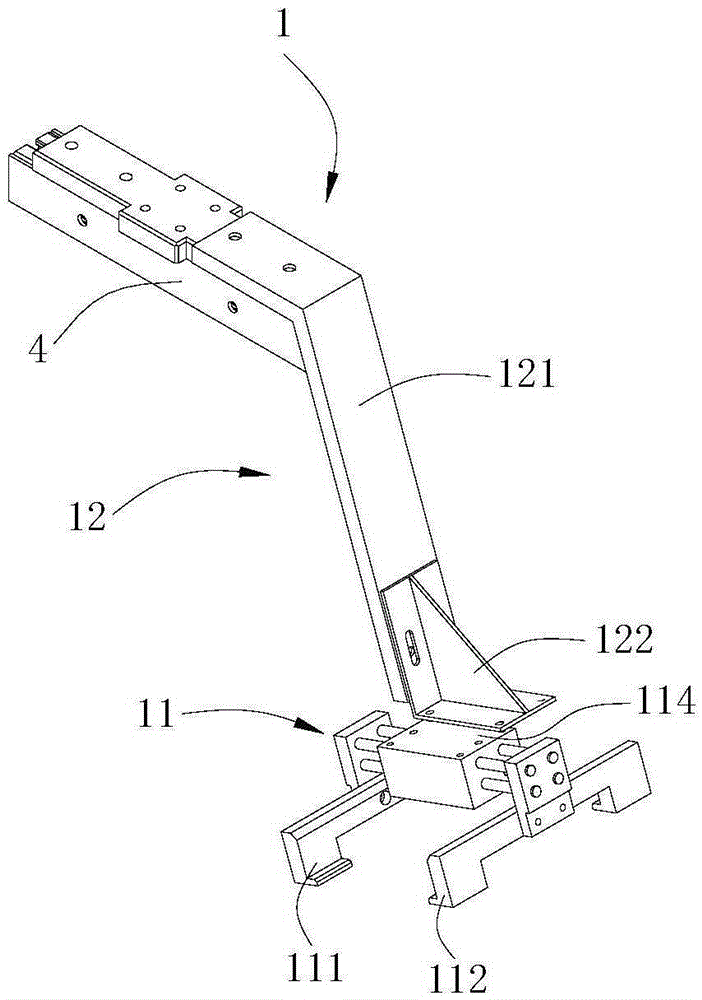

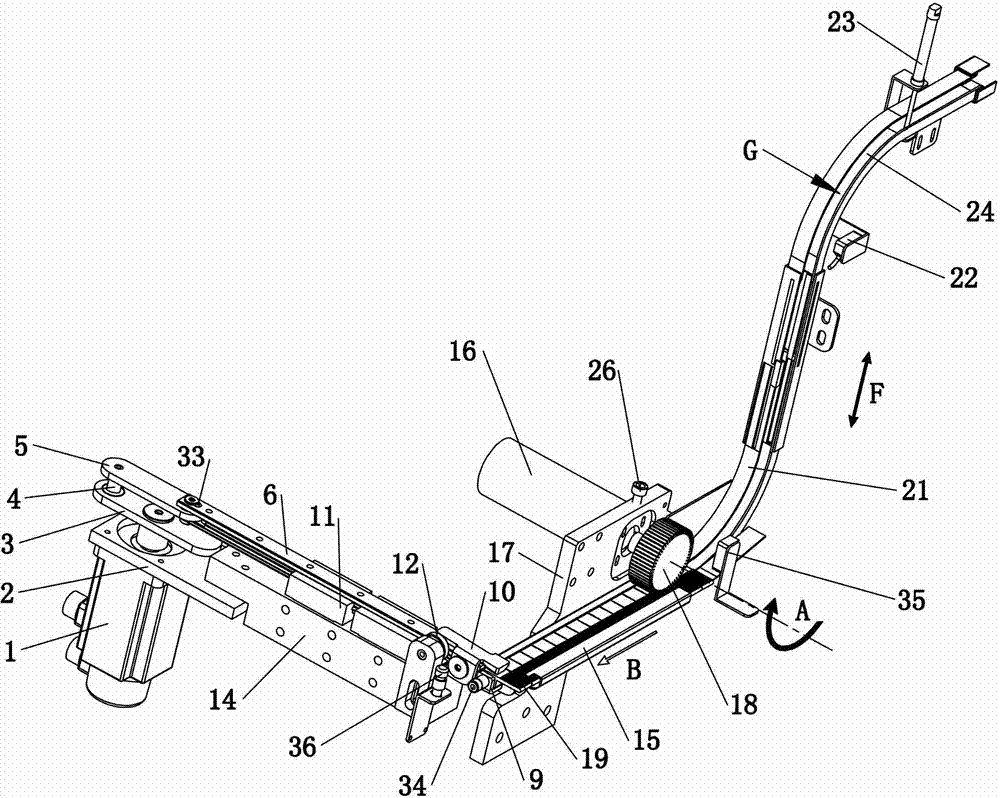

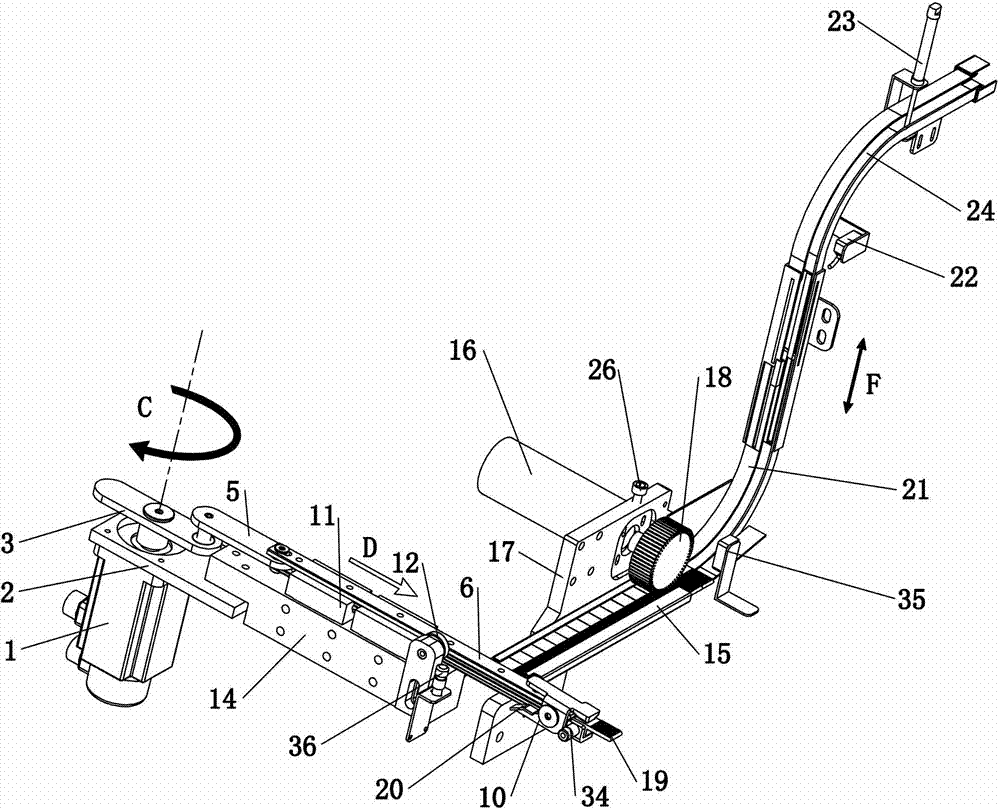

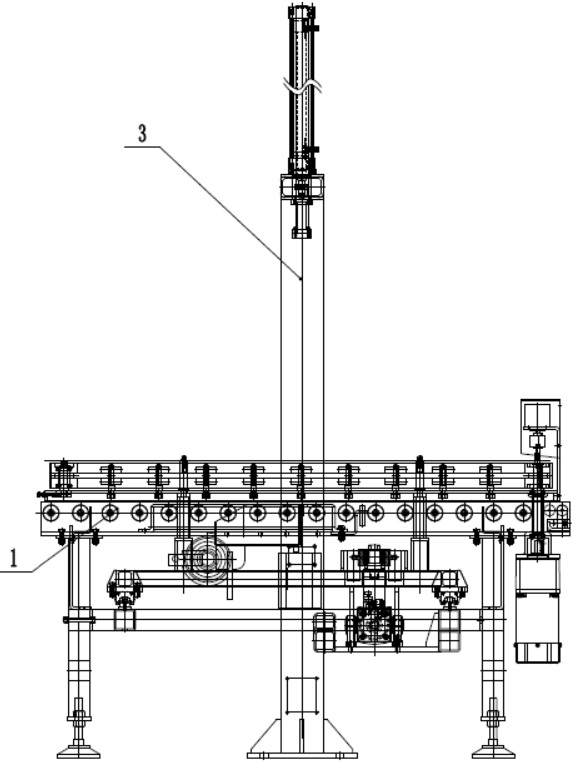

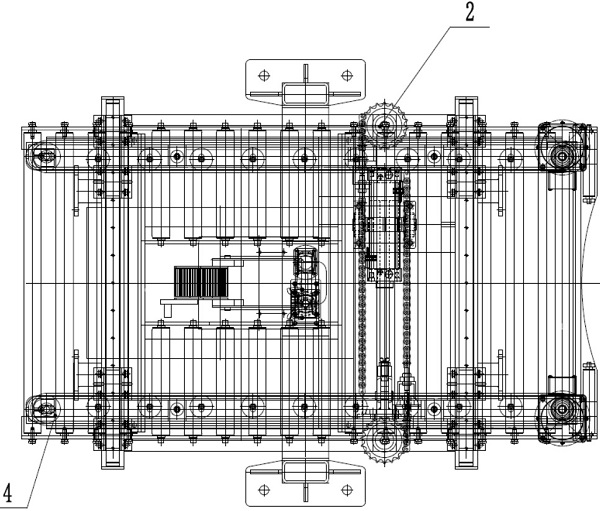

PendingCN108422177AImprove efficiencyReduce labor intensitySpring mattressesSofasEngineeringOblique angle

The invention relates to an automatic installation machine for straight springs of a soft sofa seat frame. The automatic installation machine for the straight springs of the soft sofa seat frame is characterized by comprising a rack, a horizontal movement unit, an oblique angle movement unit and two pothook compressing and nailing units. The horizontal movement unit, the oblique angle movement unit and the two pothook compressing and nailing units are arranged on the rack. An application method of the automatic installation machine for the straight springs of the soft sofa seat frame comprisesthe steps of (1) preparing; (2) lifting the springs; (3) extending the springs; (4) retracting the springs; (5) hanging pothooks; (6) compressing the pothooks and nailing; and (7) resetting. The automatic installation machine for the straight springs of the soft sofa seat frame has the advantages that (1) mechanical spring extension operation replaces manual spring extension operation, so that the labor intensity is reduced; (2) the multiple springs on the seat frame can be extended and installed for once, so that the machine is suitable for mass production; and (3) pothook compressing and nailing operation is automatically accomplished by the machine, so that the efficiency is high, and the manpower is saved.

Owner:SHANDONG YIHUA FURNITURE CO LTD

Electrical cabinet leakage troubleshooting and daily management system

InactiveCN110103184AGuaranteed to be verticalImprove management qualityNailing toolsEngineeringHigh pressure

The invention discloses an electrical cabinet leakage troubleshooting and daily management system. The electrical cabinet leakage troubleshooting and daily management system comprises an outer shell,a nail nailing pipe is arranged in the outer shell, a nail nailing device for nailing nails on an electrical cabinet is arranged in the nail nailing pipe, the nail nailing device comprises a nail nailing hammer and a positioning block, the nail nailing hammer is arranged in the nail nailing pipe in a left-right sliding mode, the positioning block is arranged in the nail nailing pipe in a left-right sliding mode and located on the left side of the nail nailing hammer, and a nail nailing high-pressure cavity is formed in the end wall of the right side of the nail nailing pipe. The positioning block is utilized to stabilize the nails, it is ensured that the nails are always kept to be perpendicular to the surface to be nailed, the nail nailing hammer is pushed through the gas pressure to slide quickly, the nails are pushed to slide quickly for nail nailing operation, the nail nailing quality is ensured, the nail nailing efficiency is improved, and the efficiency of nailing the nails on the electrical cabinet is effectively improved, and the management quality on the electrical cabinet is improved.

Owner:义乌市亿道电子科技有限公司

Nail guns for wood tray

InactiveCN108058243AImprove the level of automated productionImprove nailing efficiencyStapling toolsNailing toolsEngineeringProcedural approach

Owner:ANHUI PALLET INTELLIGENT EQUIP CO LTD

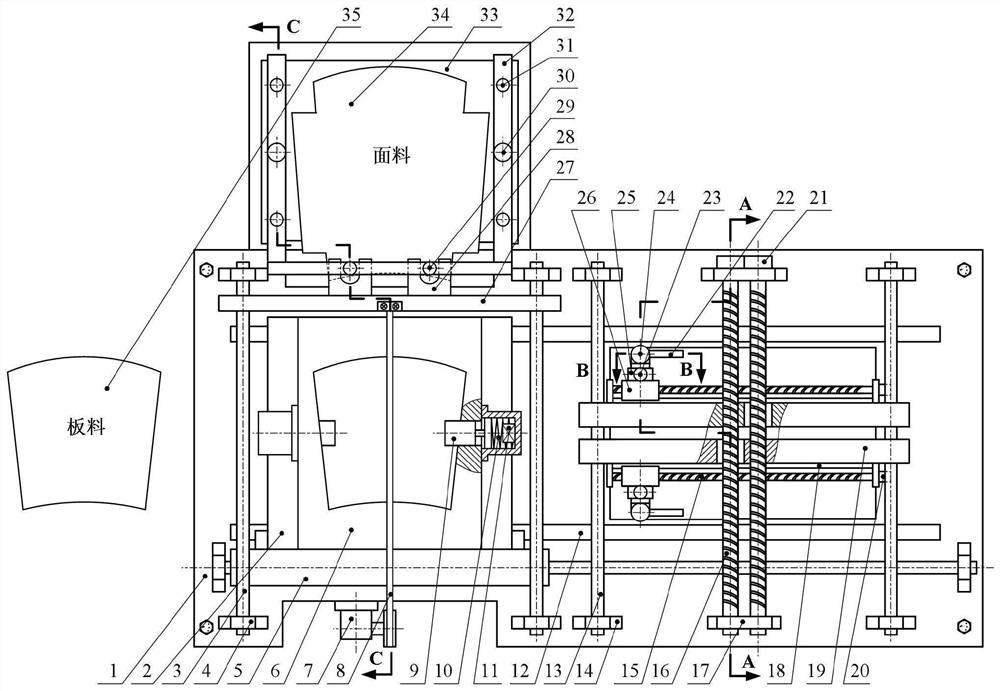

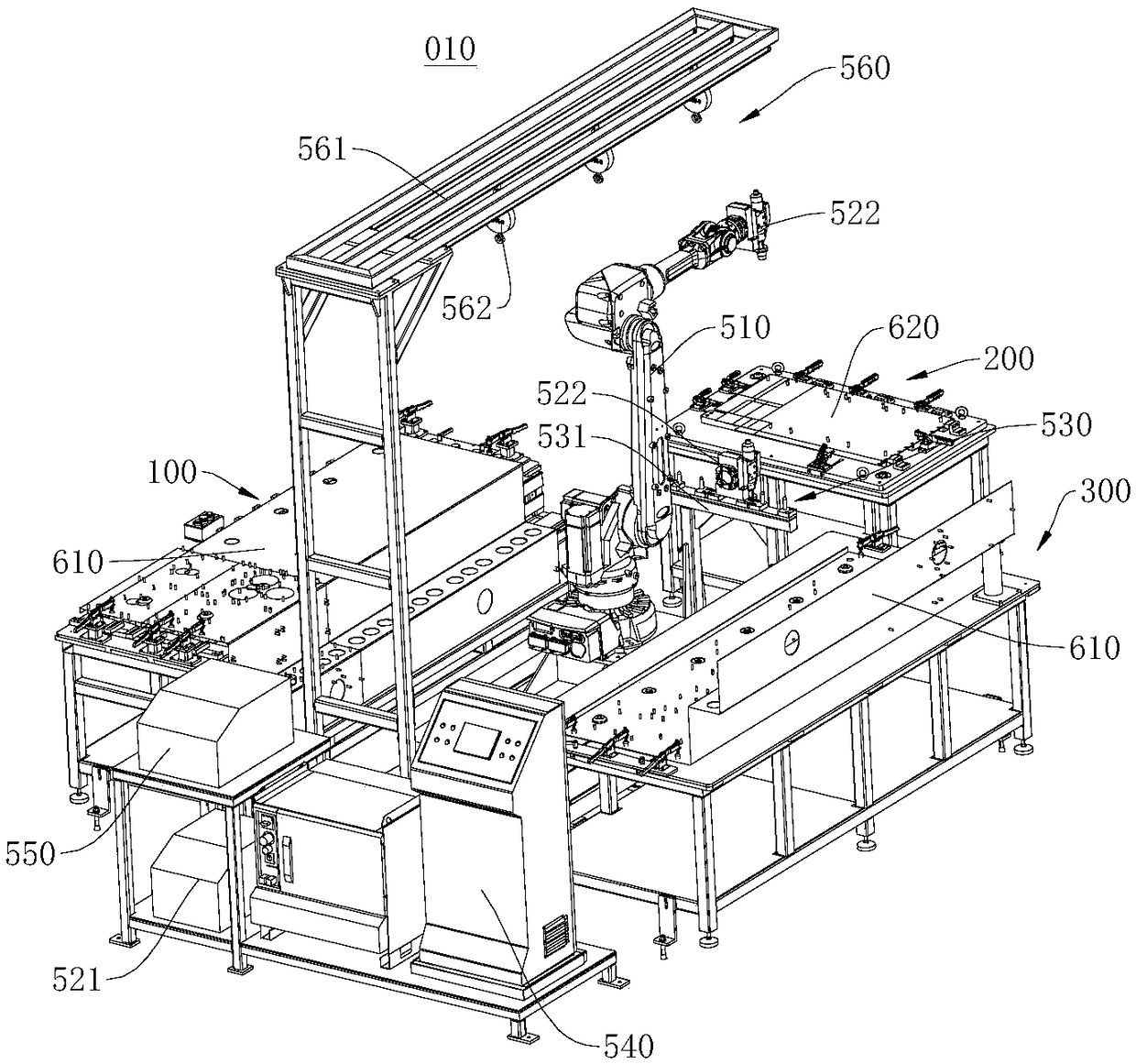

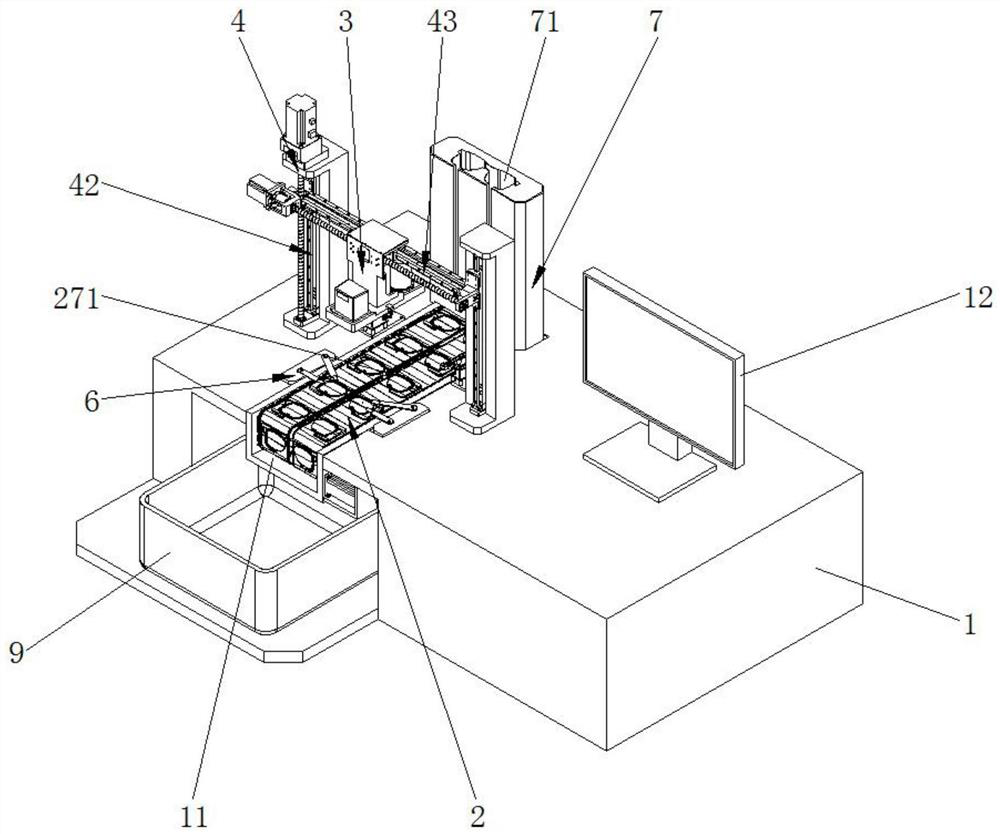

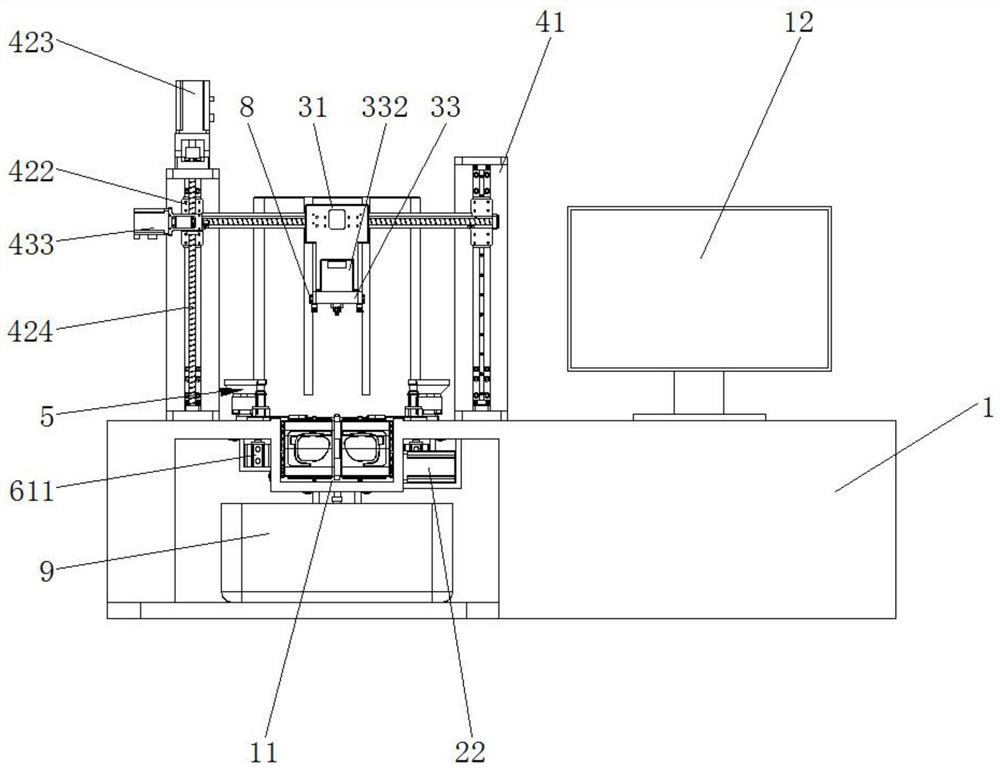

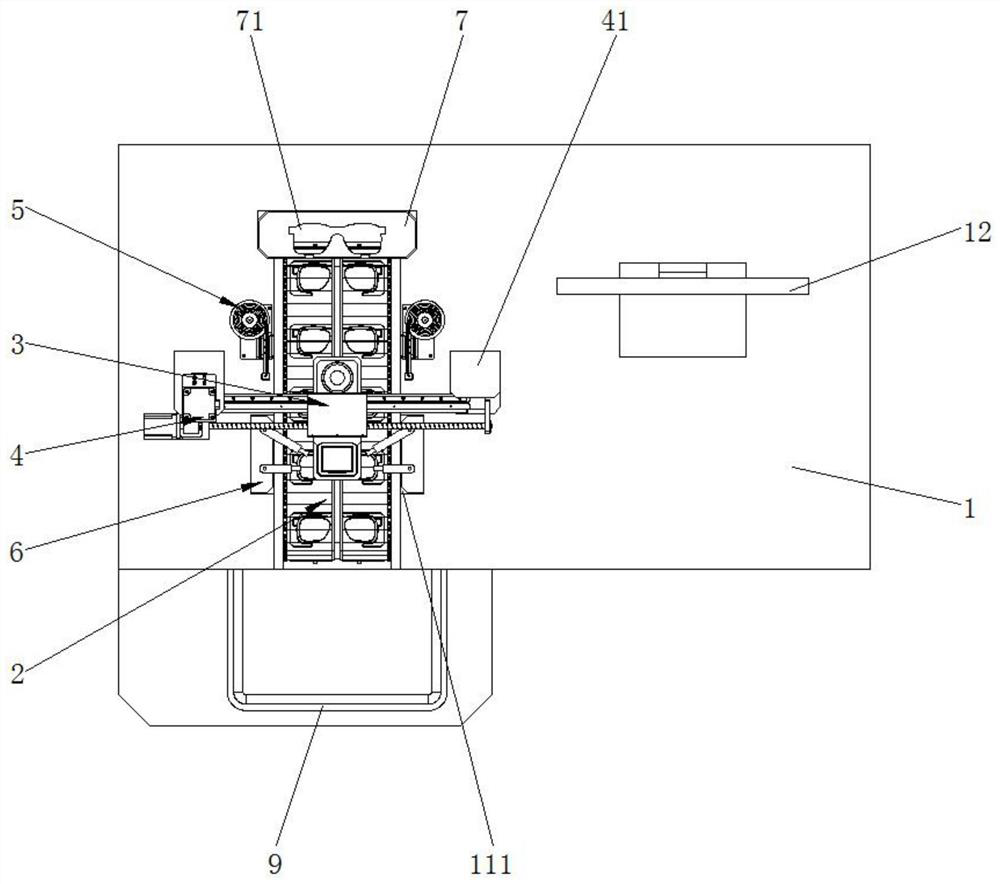

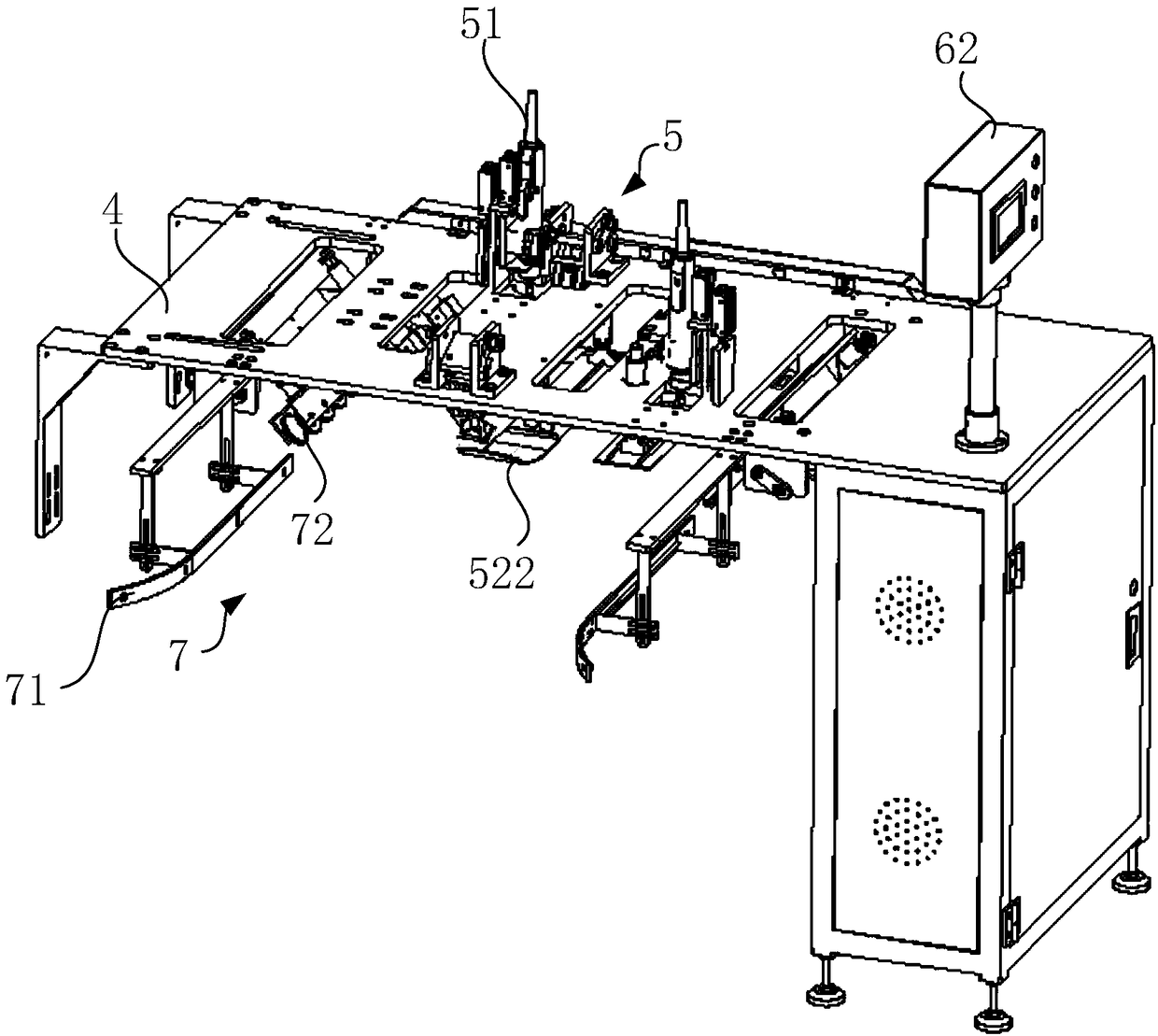

Automatic seat gunning and nailing equipment and working method thereof

ActiveCN113246242ASolve the problem that it is difficult to realize the automatic nail gun operationReduce labor intensityStapling toolsWood working apparatusManufacturing lineIndustrial engineering

The invention discloses automatic seat gunning and nailing equipment and a working method thereof. Manual gunning and nailing operation is low in production efficiency, high in labor intensity of operators and poor in gunning and nailing quality consistency. The automatic seat gunning and nailing equipment comprises a base, a station switching mechanism, an automatic fabric feeding mechanism, a gun nail head moving mechanism and an automatic gunning and nailing device. The station switching mechanism, the automatic fabric feeding mechanism and the gun nail head moving mechanism are all installed on the base. The station switching mechanism is used for installing a plate and conveying the plate to be switched between a surface material feeding station and a gunning and nailing operation station. The automatic gunning and nailing device is mounted on the gun nail head moving mechanism. The gun nail head moving mechanism drives the automatic gunning and nailing device to move along a target track. The automatic fabric feeding mechanism comprises a fabric supply assembly and clamps. The automatic gunning and nailing machine solves the problem of automatic gunning and nailing operation of plates and fabrics of seats, replaces long-term manual gunning and nailing operation with automatic equipment, and is key equipment of an automatic intelligent production line for seat manufacturing in the chair industry.

Owner:HANGZHOU DIANZI UNIV +1

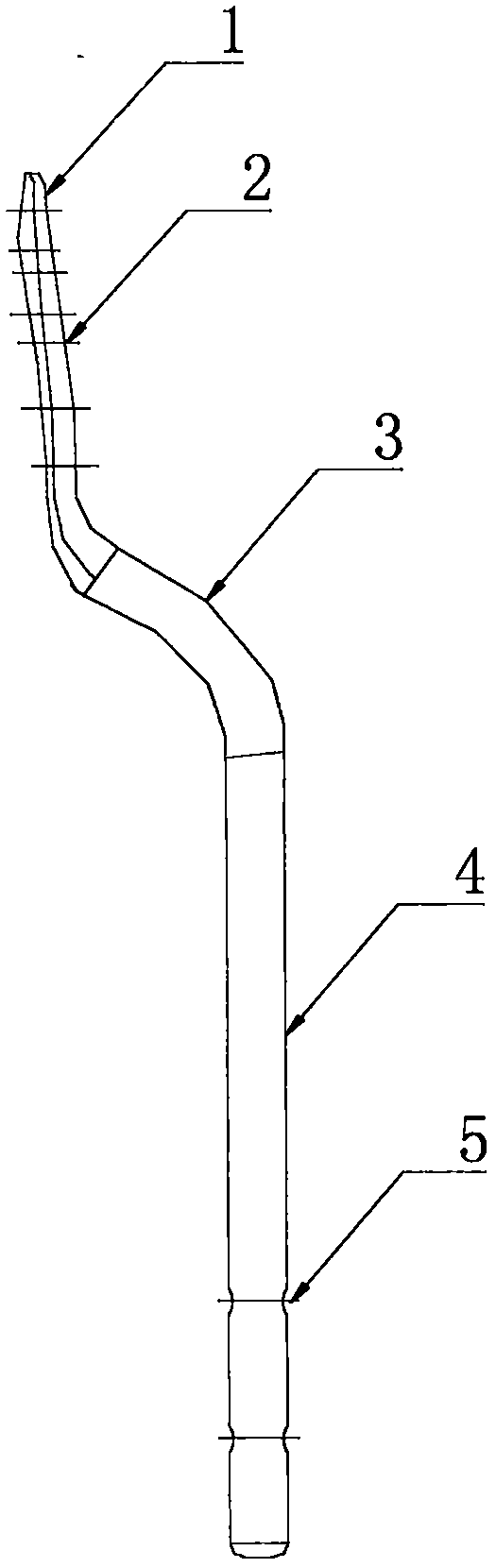

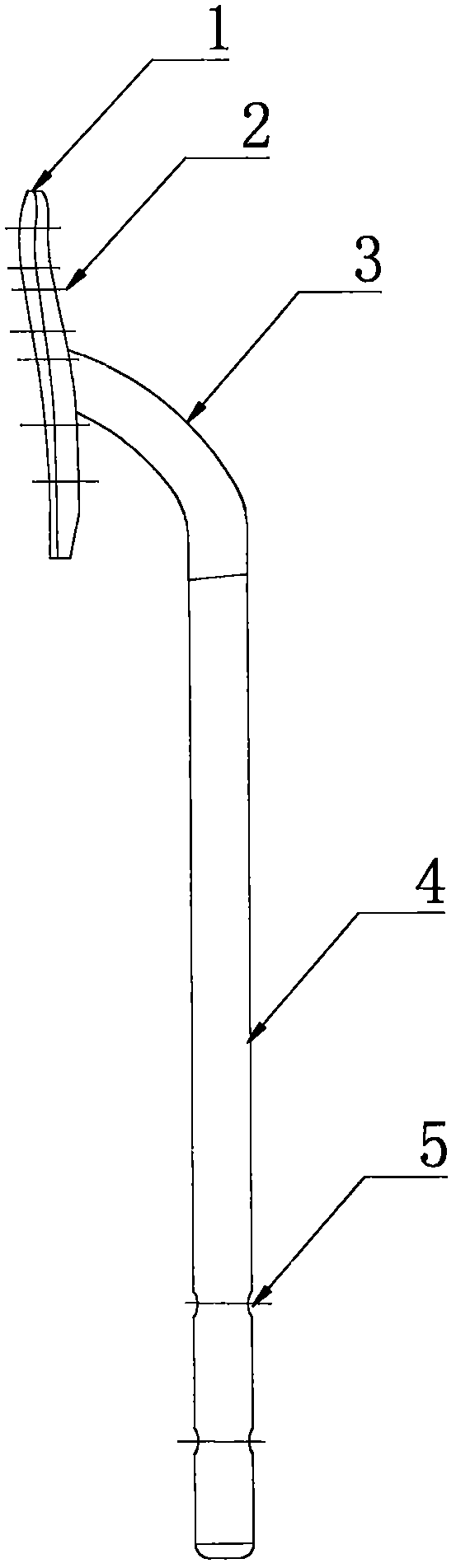

Minimally invasive intramedullary plate system

PendingCN109820585AProtect hematomaRecovery lengthInternal osteosythesisBone platesDynamic fixationFemur intramedullary nailing

The invention discloses a minimally invasive intramedullary plate system comprising an integrally formed intramedullary plate body. The intramedullary plate body is composed of an intramedullary part,an extramedullary part and a transition part connecting the two parts. The intramedullary part is in the long tube type, and the extramedullary part is attached to the epiphysis end and the articularsurface. A main body of the intramedullary part is provided with a locking nail hole, and a main body of the extramedullary part is provided with a locking threaded hole. The system combines the advantages of distal humeral plates, interlocking intramedullary nails and minimally invasive surgery techniques. The intramedullary part can provide static or dynamic fixation for the bone fracture, andsubstantially has no stress shielding effect. At the same time, the closed nailing operation mode is adopted to avoid exposure to the fracture end, protect the fractured part from hematoma, reduce damage and improve the fracture healing rate. The extramedullary part can provide a good supporting effect, and achieve the purpose of restoring the length of the fractured part, correcting the rotational displacement and correcting the force line at the same time to ensure early activities of a patient.

Owner:HEBEI RUIHE MEDICAL DEVICES CO LTD

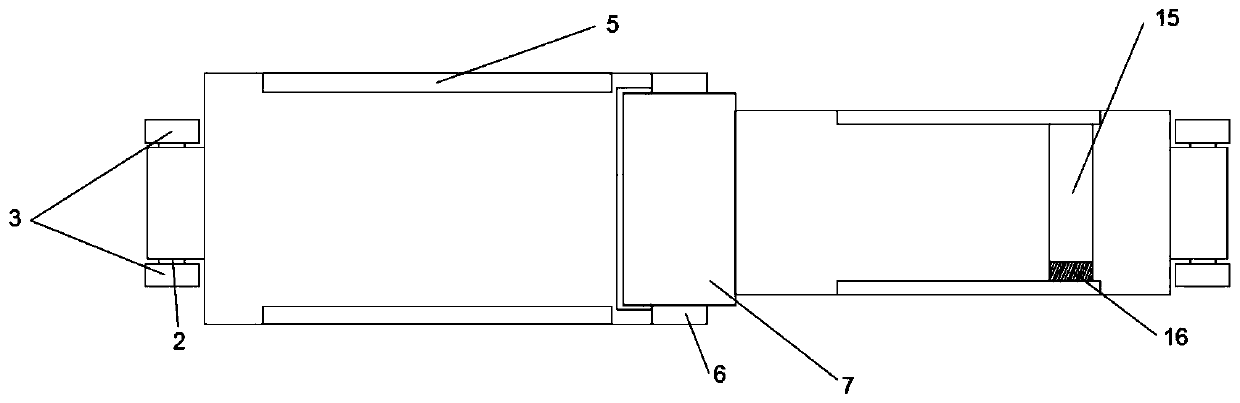

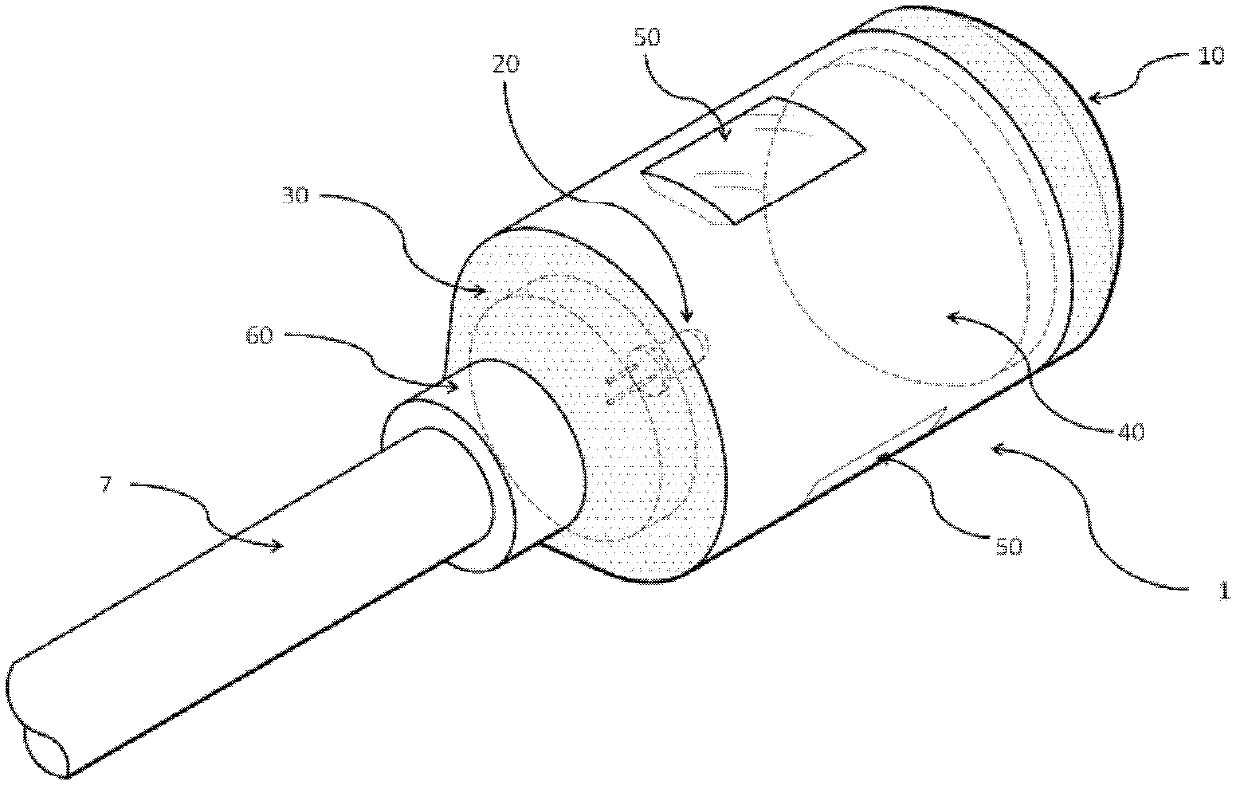

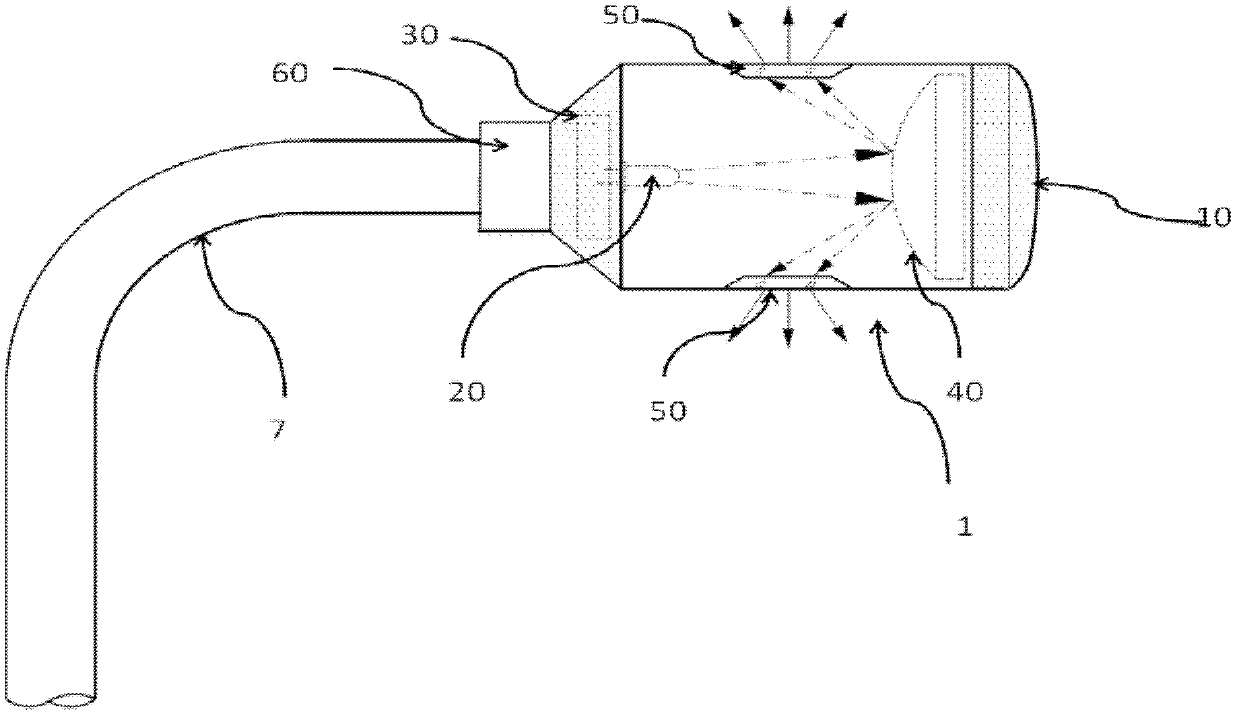

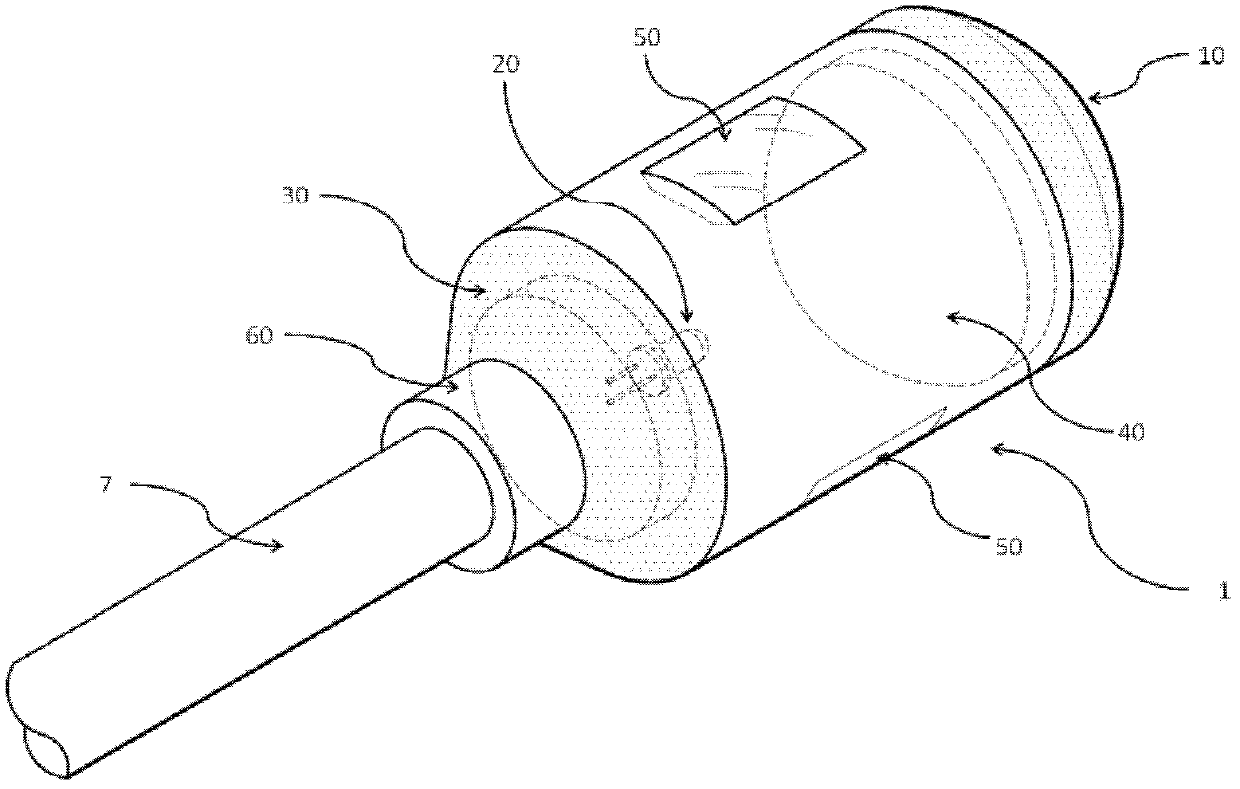

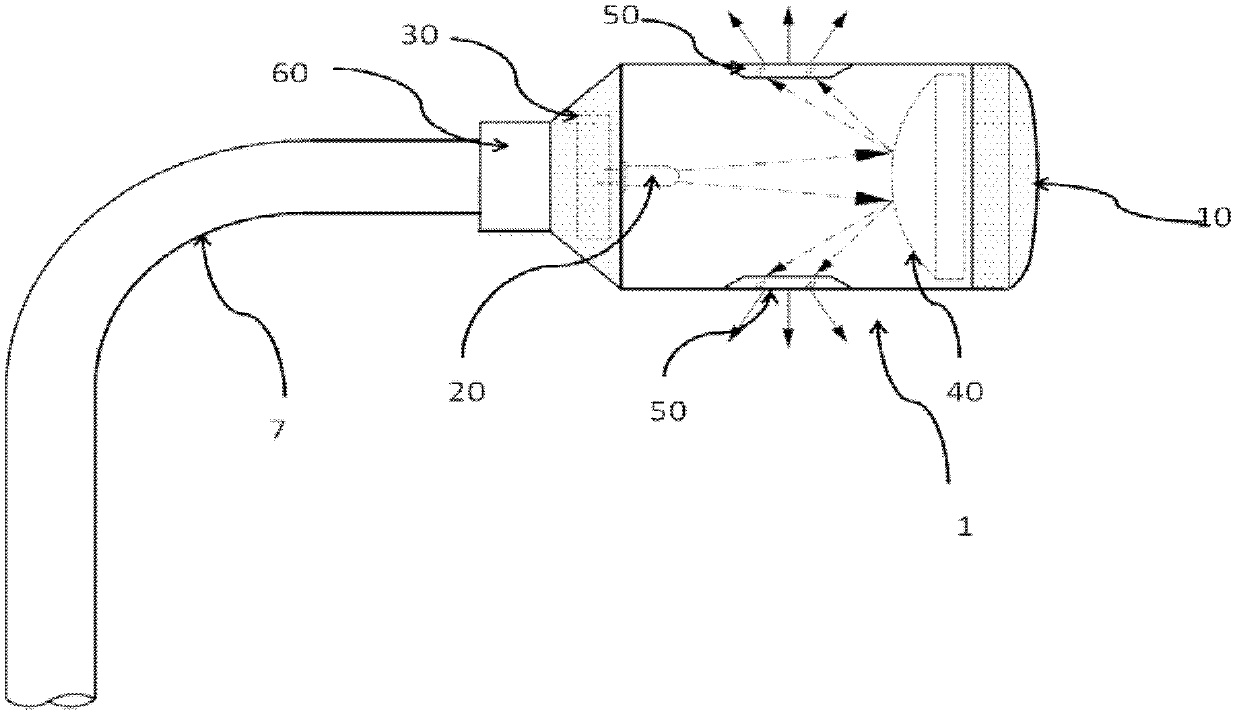

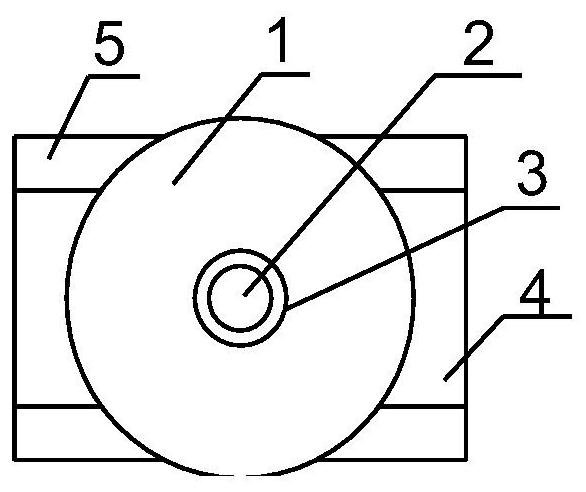

Side lighting device engaged with medullary cavity guide needle

ActiveCN102889537AAvoid pollutionAvoid damageInternal osteosythesisMedical lightingEngineeringBone marrow cavity

The invention discloses a side lighting device engaged with a medullary cavity guide needle. The device substantially comprises a sealed body, a front-end protection unit arranged at a front end of the body, and an engagement unit arranged at a rear end of the body. A lighting unit, a power supply unit, a light scattering unit, a light source intensity regulation unit and a light transmission window are arranged inside the body. According to an embodiment of the invention, the side lighting device can be movably combined with different medullary cavity guide needles and the lighting unit is powered by the power supply unit, so that the light generated by the lighting unit is subjected to scattering by the light scattering unit or further subjected to proper intensity regulation, and radiates sideways through the light transmission window; and while performing a steel nail operation in a medullary cavity, the device of the invention can be disposed inside affected parts, thereby achieving the external observation of the operation position and the accurate positioning of the steel nails.

Owner:朱唯勤

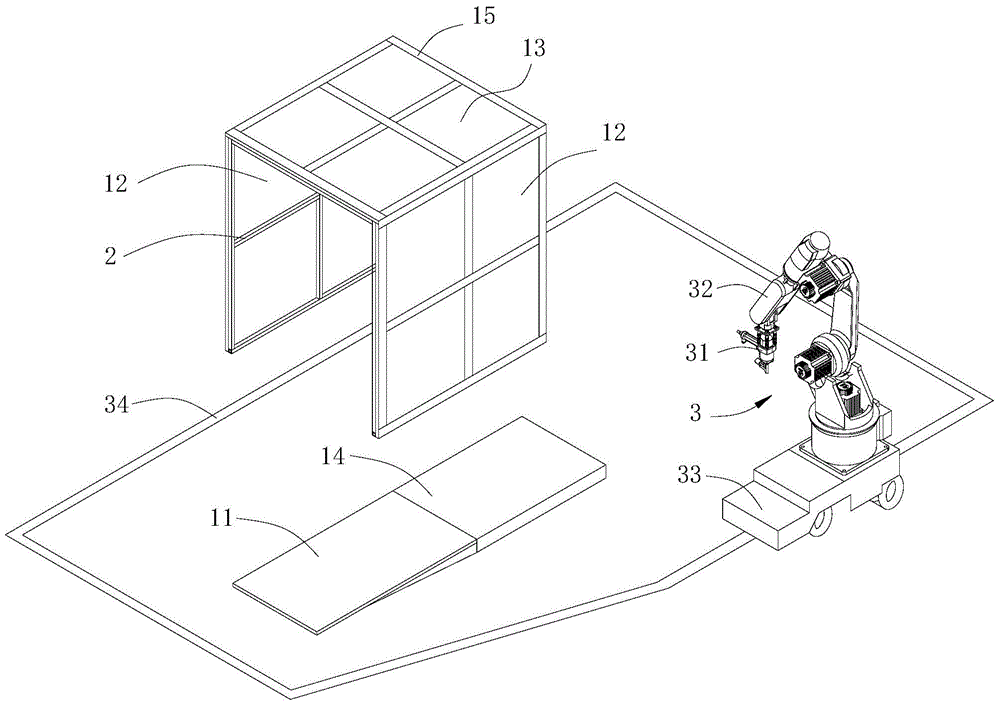

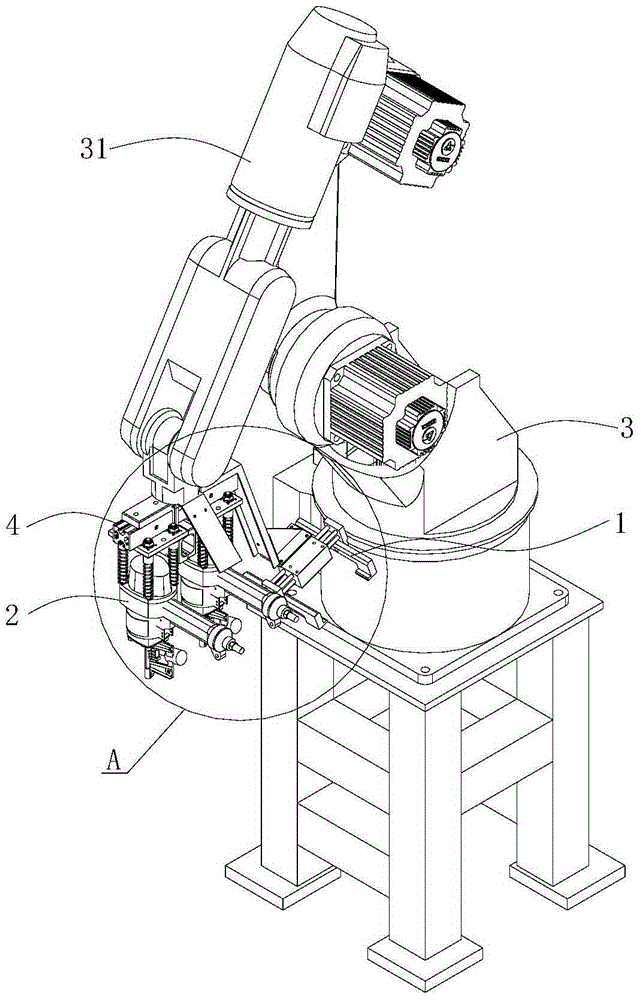

Automatic nailing device

ActiveCN109048132AReduce labor intensityImprove nailing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOperating table

The invention relates to the technical field of mechanical processing, and aims to provide an automatic nailing device. The automatic nailing device provided by the invention comprises an operating table, a nail feeding machine, a nailing robot, a first clamping mechanism, and a second clamping mechanism. The first clamping mechanism is used for fixing a first workpiece to be nailed, and the second clamping mechanism is used for fixing a second workpiece to be nailed. The nailing robot is fixedly connected with a nailing mechanism. The nail feeding machine is used for feeding screws to the nailing mechanism. The nailing mechanism moves under the driving of the nailing robot, and can perform nailing operations at different positions on the first workpiece and the second workpiece. In addition, the nail feeding machine, the nailing robot, and the nailing mechanism are all connected with the operating table, and under the control of the operating table, the nailing operations are automatically performed, the nailing efficiency is high, the labor intensity of workers is low, and the nailing quality can be guaranteed.

Owner:广州创研智能科技有限公司

Nailer with a safety device

InactiveUS20080073403A1Eliminate riskStapling toolsPortable percussive toolsEngineeringMechanical engineering

Disclosed herein is a nailer having an improved safety device. With the improved safety device, a movable plate, which is adapted to slidably move along a lower surface of a guiding unit, is formed, at a certain location thereof, with an insertion hole for the insertion of a protrusion formed at a trigger. Thereby, if the trigger is pulled in a pressed state of the movable plate, a nailing operation is accomplished. Also, in the course of pulling the trigger, the movable plate can be further inserted rearward by a predetermined distance under interaction of the insertion hole and protrusion. This has the effect of eliminating the risk of causing scratches on a nailing surface of a target structure even if the movable plate is moved while coming into close contact, at a front end thereof, with the nailing surface, resulting in several advantages, such as for example, easy nailing operation, operator's convenient working posture, and rapid and safe nailing operation.

Owner:JEIL TACKER

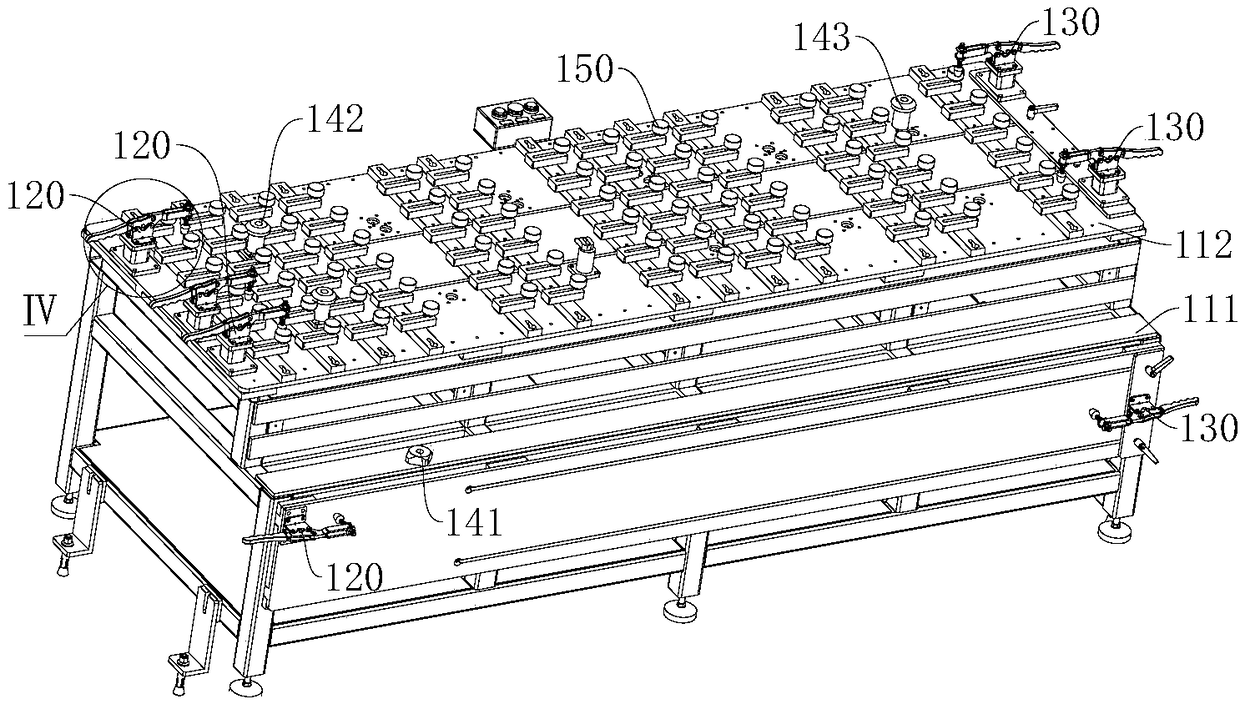

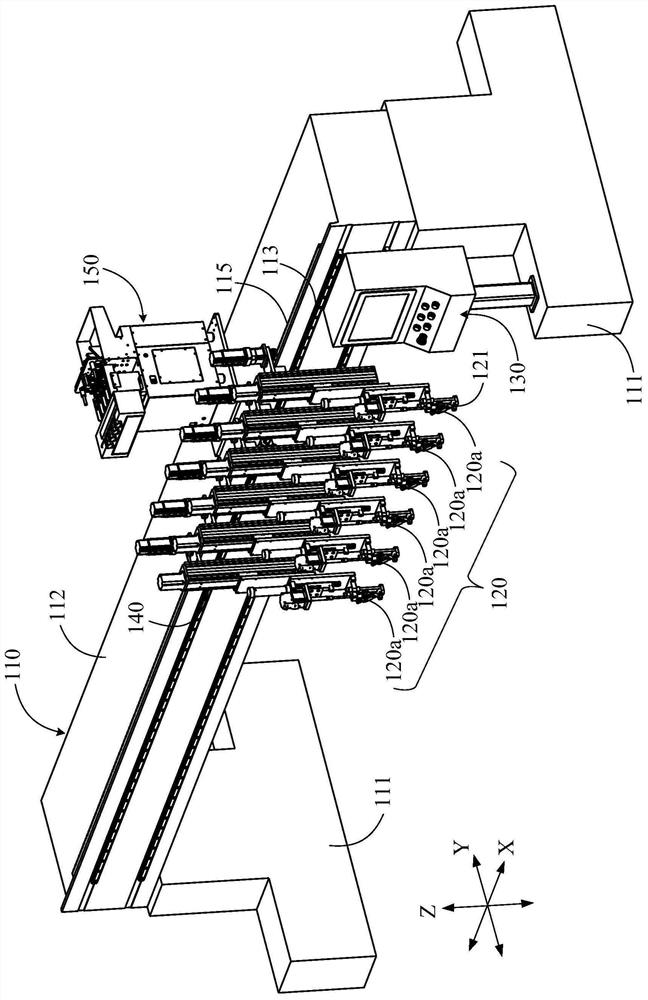

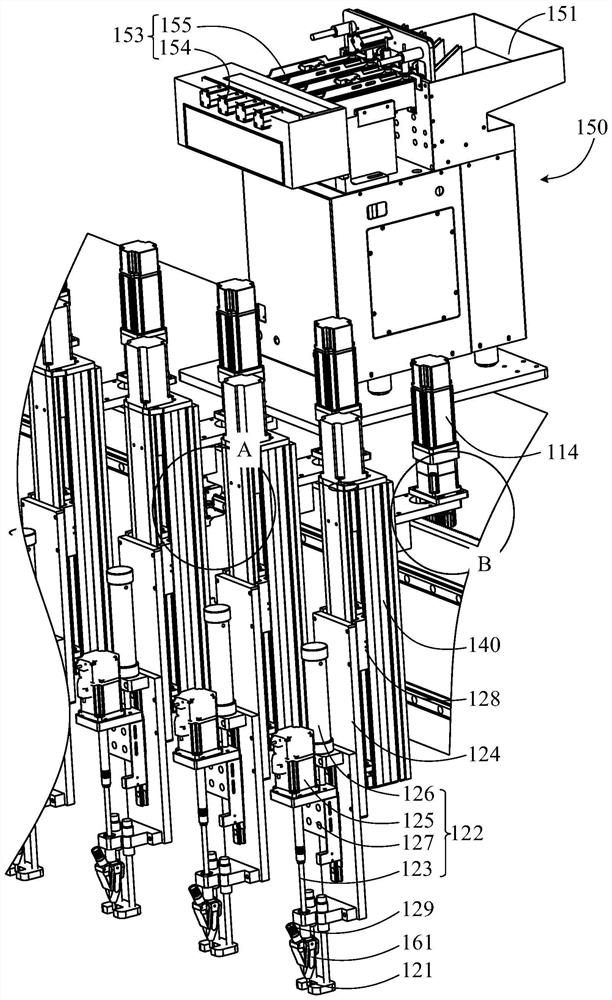

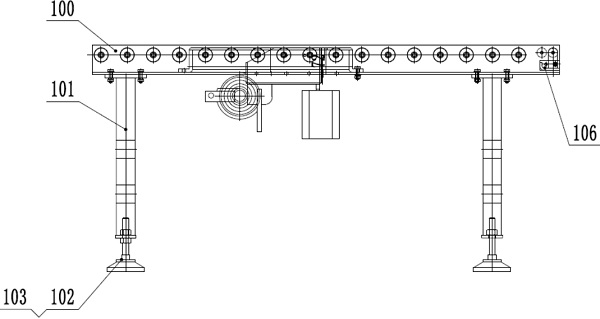

Automatic nailing system

ActiveCN112621193AImprove humanityImprove intelligenceMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic nailing system. The automatic nailing system comprises a gantry rack, a nailing mechanism and a control device, wherein the gantry rack is arranged in the X direction and can move in the Y direction perpendicular to the X direction; the nailing mechanism is arranged on the gantry rack, can move in the X direction and is provided with a nailing head; the control device comprises a graph recognition module; the graph recognition module is used for recognizing graph coordinates (x, y) of a nailing position in a workpiece graph; and the control device is configured to move the gantry rack and the nailing mechanism according to the graph coordinates (x, y) so as to automatically locate the site position of the nailing head. According to the automatic nailing system provided by the invention, the coordinates of the nailing position in the workpiece graph can be accurately recognized through the graph recognition module, the nailing head is automatically located to the site position corresponding to the coordinates in an engineering graph according to the coordinates, nailing operation is automatically completed according to the engineering graph, and humanization and intellectualization of the system are improved.

Owner:YANGZHOU TAILEE SPECIAL EQUIP +2

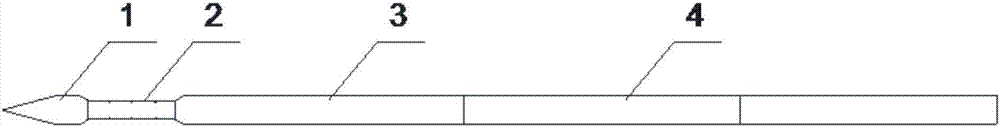

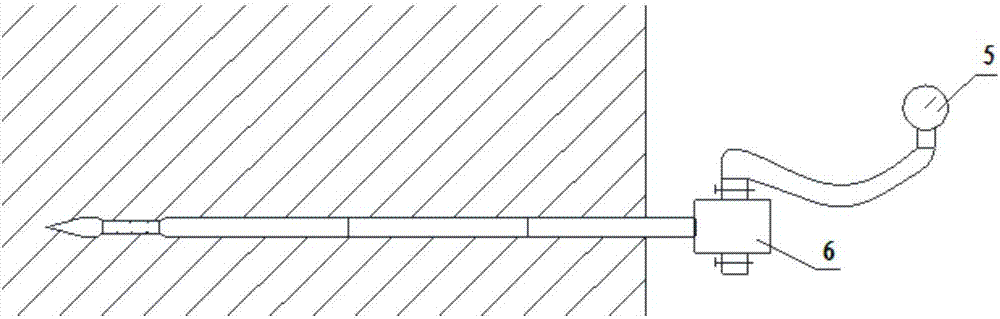

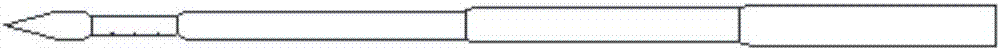

Measurement probe for measuring parameters of gas inside coal bed

InactiveCN107014554ASave the drilling rigSave the drilling processFluid pressure measurementWorkloadPressure measurement

The present invention relates to a measurement probe for measuring the parameters of gas inside a coal bed. The measurement probe comprises a conical head, a pressure measurement pipe, a first probe main pipe and a plurality of second probe main pipes, wherein the above parts are sequentially and detachably connected from left to right. During construction, the workload is small. Due to the extrusion effect of the coal mass and the probe, when the probe is nailed into the coal mass at a certain distance, the self-sealing effect is realized. Therefore, the real gas pressure at the location of the pressure measurement pipe of the measurement probe can be measured. The required test time is short. Meanwhile, not only the gas pressure measurement cycle is shortened, but also the success rate of pressure measurement is improved. Moreover, during the nailing process of the probe into the coal mass, the destroy type of the coal mass can be judged according to the difficulty degree of the nailing operation. Therefore, the measurement probe provides data for the measurement of gas-related parameters. The measurement probe is high in practicability and worthy of popularization.

Owner:NORTH CHINA INST OF SCI & TECH

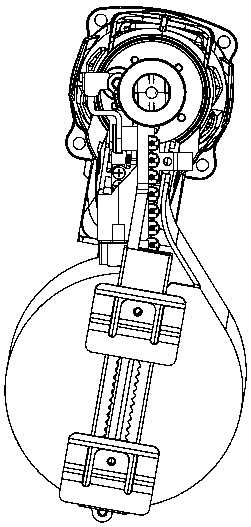

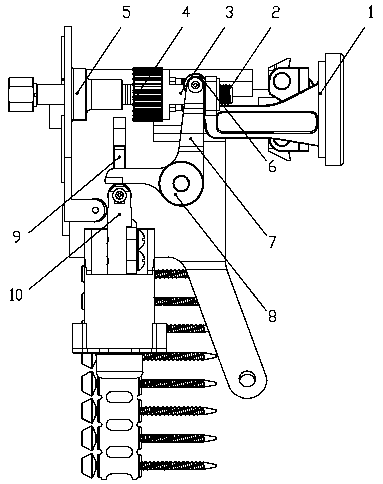

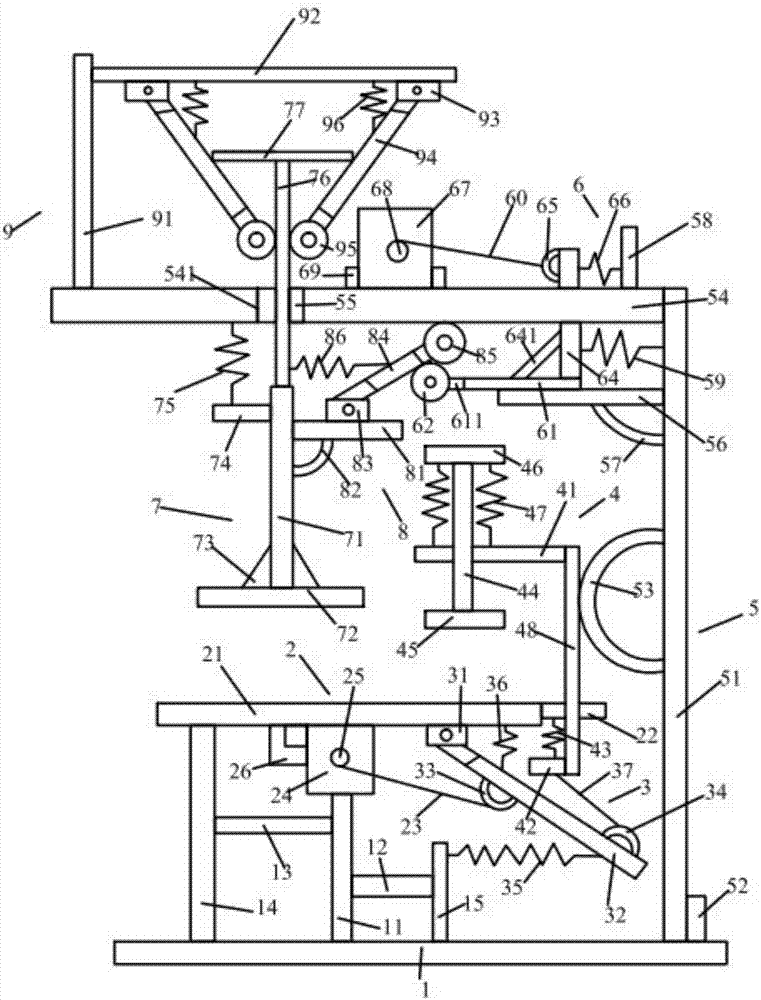

a nail gun

ActiveCN107756333BHigh degree of automationReliable mechanical actionNailing toolsClassical mechanicsPower tool

The invention relates to a coil nail gun, and belongs to the technical field of fuel gas power tools. The coil nail gun comprises a gun body with a handle, and a nail case component, wherein one end of the gun body is provided with a nailing component, the output end of the nail case component is connected to the middle portion of the nailing component, the reciprocating nail pushing rod of a power cylinder is connected to a nail pushing pulling hook, the nail pushing pulling hook is connected to a coil nail assembly, the nailing component comprises a nailing seat, the front end of the nailingseat is provided with a depth adjustment frame, the front end of the depth adjustment frame is provided with a strike head, an L-shaped nail pushing rocker is hinged and supported on the output end of the nail case component, one end of the nail pushing rocker is constrained to the depth adjustment frame, the other end bears against the extending end of the reciprocating nail pushing rod, one side of the extending end of the reciprocating nail pushing rod is provided with the nail pushing pulling hook, the external extending end of the nail pushing pulling hook extends laterally to form a hook head, and the hook head of the nail pushing pulling hook hooks the plastic sheet snapping groove of the coil nail assembly. According to the present invention, each pushing action for the nail coiling is automatically completed during the nailing operation process without any attachment operation, such that the convenience and the reliability are provided.

Owner:NANJING TENGYA PRECISE TECH DEV CO LTD

Nailing and carrying device

InactiveCN106541473ASimple structureIncrease productivityStapling toolsNailing toolsEngineeringUltimate tensile strength

The invention discloses a nailing and carrying device. The nailing and carrying device comprises a nailing device, a carrying device and a manipulator. The nailing device and the carrying device are both arranged on a movable arm of the manipulator. When the nailing device is used for nailing a workpiece, the carrying device is away from the workpiece. When the carrying device is located on the workpiece for performing carrying operation, the nailing device is away from the workpiece. The nailing and carrying device has following beneficial effects: the nailing and carrying device is simple in structure; the nailing device and the carrying device are integrated on the same manipulator; by replacing manual labor with the manipulator, nailing operation and carrying operation are achieved so that production efficiency is increased and labor intensity is reduced; and time spent on wood packaging work is shortened.

Owner:SUZHOU COV PACKAGING ENG CO LTD

Rapid sole nailing equipment for shoe production

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

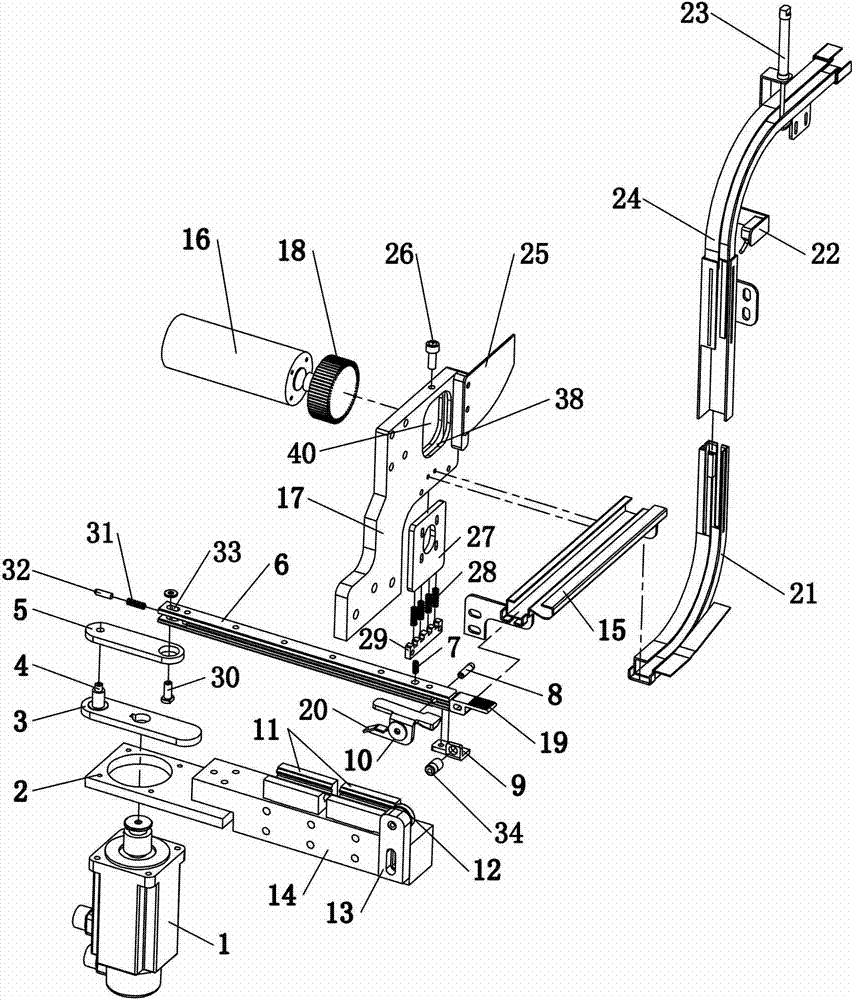

Button feeding structure of plastic button nailing machine

ActiveCN104117970AImprove work efficiencyIncrease job securityDispensing apparatusNail dispensersEngineeringNail operations

The invention relates to a button feeding structure of a plastic button nailing machine. The button feeding structure comprises a support cross beam component, a plastic button clamper, a clamper transmission mechanism, and a plastic button guide rail for limiting a plastic button transmission route, wherein the support cross beam component is provided with a touching device for touching and opening the plastic button clamper; the clamper transmission mechanism is arranged on the support cross beam component, and is in transmission connection with the plastic button clamper; one end of the plastic button guide rail is pointed to the plastic button clamper; and a plastic button transmission mechanism for pushing plastic buttons on the plastic button guide rail to the plastic button clamper is arranged beside the plastic button guide rail. The button feeding structure of the plastic button nailing machine can realize the mechanical transmission of the plastic buttons to a nail loading position for performing the nailing operation; and the plastic button transmission process is automatically controlled without needing human hands, so that the working efficiency and the safety are largely improved.

Owner:GUANGDONG MINGHUI PNEUMATIC TECH CO LTD

Full-automatic carton nailing machine

PendingCN111874371AFully automatic nailing operationEasy to useWrapper twisting/gatheringPackaging automatic controlSignal onCarton

The invention relates to a full-automatic carton nailing machine which adopts an unpowered carrier roller to support an opened carton, adopts an air cylinder to drive a conveying belt to move inwardsto clamp the carton, and adopts a driving motor to drive the conveying belt to provide power for the carton to move forwards. A nailing head is mounted at the front end of a conveying component, and when the carton triggers an optoelectronic signal on the front end, the actual walking distance is calculated by an encoder on a motor. After the distance required by a process is reached, a pressing plate of a pressing device is driven by the air cylinder to move downwards through a guide rod to press the carton. The LOCK nailing head of a linear carton sealing nail is adopted for nailing operation, the pressing plate rises after nailing is completed, and the carton is conveyed out. Microswitches for detecting goods are installed on the two sides of a centering device, automatic centering, conveying, pressing and nailing operation of opened cartons of different types and specifications can be met, and full-automatic nailing operation is achieved.

Owner:SHANDONG SINOLION MACHINERY CORP LTD

Carpet nailing strip production device

InactiveCN106272754ARealize effective guiding conveyingRealize guided deliveryStapling toolsNailing toolsPunchingBiochemical engineering

The invention relates to a carpet nailing strip production device which comprises a platform, wherein a nail punching device is arranged on the platform, a first guide groove is further formed in the platform, a nailing strip base material feeding push block is arranged in the first guide groove, a second guide groove and a third guide groove are formed in one side of the first guide groove, the second and third guide grooves are communicated with the first guide groove and are in T-shaped connection with the first guide groove, and a nailing strip base material push plate is arranged in the second guide groove; the bottom surface of the third guide groove is an inclined surface which is inclined towards the other end from the connecting end of the first guide groove, a liftable top plate is arranged in the first guide groove, and a touch switch for controlling a driving mechanism of the liftable top plate to act is arranged on the inner side end of the first guide groove. The effective guiding and conveying of nailing strip base materials can be realized, nailing operations can be realized after the nailing strip base materials are conveyed below the nail punching device, the product standardization can be realized, the quality of products can be improved, and the processing efficiency can also be increased.

Owner:TIANJIN FORWARD CARPETS

Glasses frame double-side full-automatic hinge nailing machine and using method thereof

ActiveCN113199770AImprove work efficiencyRealize automatic loading and unloading functionStructural engineeringWorkbench

The invention discloses a glasses frame double-side full-automatic hinge nailing machine which comprises a workbench, and the workbench is provided with a glasses frame conveying mechanism used for conveying glasses frames, a hinge nailing mechanism used for conducting hole milling on the glasses frames and installing hinges, a moving mechanism used for enabling the hinge nailing mechanism to move and a hinge feeding mechanism used for providing the hinges. A conveying groove is formed in the workbench, fixing assemblies are installed on the two sides of the conveying groove, a glasses frame feeding frame is arranged at the starting end of the glasses frame conveying mechanism, and a collecting basket used for collecting glasses frames is arranged at the tail end of the glasses frame conveying mechanism. The moving mechanism is arranged, the hinge nailing mechanism is installed on the moving mechanism, and meanwhile, the glasses frame is fixed to the conveying mechanism through the fixing assemblies, so that when the glasses frame is subjected to hinge nailing, the two sides of the glasses frame can be fixed through the fixing assemblies in sequence, and meanwhile the hinge nailing mechanism moves through the moving mechanism, and then the two sides of the glasses frame are automatically subjected to hinge nailing operation, and automatic production is achieved.

Owner:深圳市康视保眼镜有限公司

Double-piece color box automatic nail box machine

ActiveCN105216374BConvenient adsorption and flipAchieve precise positioningBox making operationsPaper-makingPulp and paper industryIn degree

The invention relates to a double-plate type automatic box nailing machine for a color box. The double-plate type automatic box nailing machine comprises a movable assembly which can slip on a paper feeding guide rod, wherein a fixed nailing head is further arranged below the paper feeding guide rod; the two ends of the movable assembly are respectively connected with a left suction nozzle supporting base and a right suction nozzle supporting base; a plurality of suction nozzles for adsorbing corrugated paper boards are respectively distributed on the left suction nozzle supporting base and the right suction nozzle supporting base; in a slip direction of the movable assembly, one side of the paper feeding guide rod is further provided with a plate placing table for bearing spliced corrugated paper boards; one side of the plate placing table is provided with a paper turnover swing rod capable of turning over; a swing end of the paper turnover swing rod is symmetrically provided with a plurality of suction nozzles; a pair of conveying platforms is further arranged in a turnover direction of the paper turnover swing rod; and the two ends of the conveying platform are provided with a left folding arm and a right folding arm. The double-plate type automatic box nailing machine for the color box is high in degree of automation of an integral structure, capable of releasing original labor personnel from complex double-plate type nailing operation and time-saving and labor-saving, thereby not only saving investment cost of manpower resource of enterprises, but also improving production efficiency.

Owner:泰州市华驰不锈钢制品有限公司

Side lighting device engaged with medullary cavity guide needle

ActiveCN102889537BAvoid pollutionAvoid damageInternal osteosythesisMedical lightingEngineeringBone marrow cavity

The invention discloses a side lighting device engaged with a medullary cavity guide needle. The device substantially comprises a sealed body, a front-end protection unit arranged at a front end of the body, and an engagement unit arranged at a rear end of the body. A lighting unit, a power supply unit, a light scattering unit, a light source intensity regulation unit and a light transmission window are arranged inside the body. According to an embodiment of the invention, the side lighting device can be movably combined with different medullary cavity guide needles and the lighting unit is powered by the power supply unit, so that the light generated by the lighting unit is subjected to scattering by the light scattering unit or further subjected to proper intensity regulation, and radiates sideways through the light transmission window; and while performing a steel nail operation in a medullary cavity, the device of the invention can be disposed inside affected parts, thereby achieving the external observation of the operation position and the accurate positioning of the steel nails.

Owner:朱唯勤

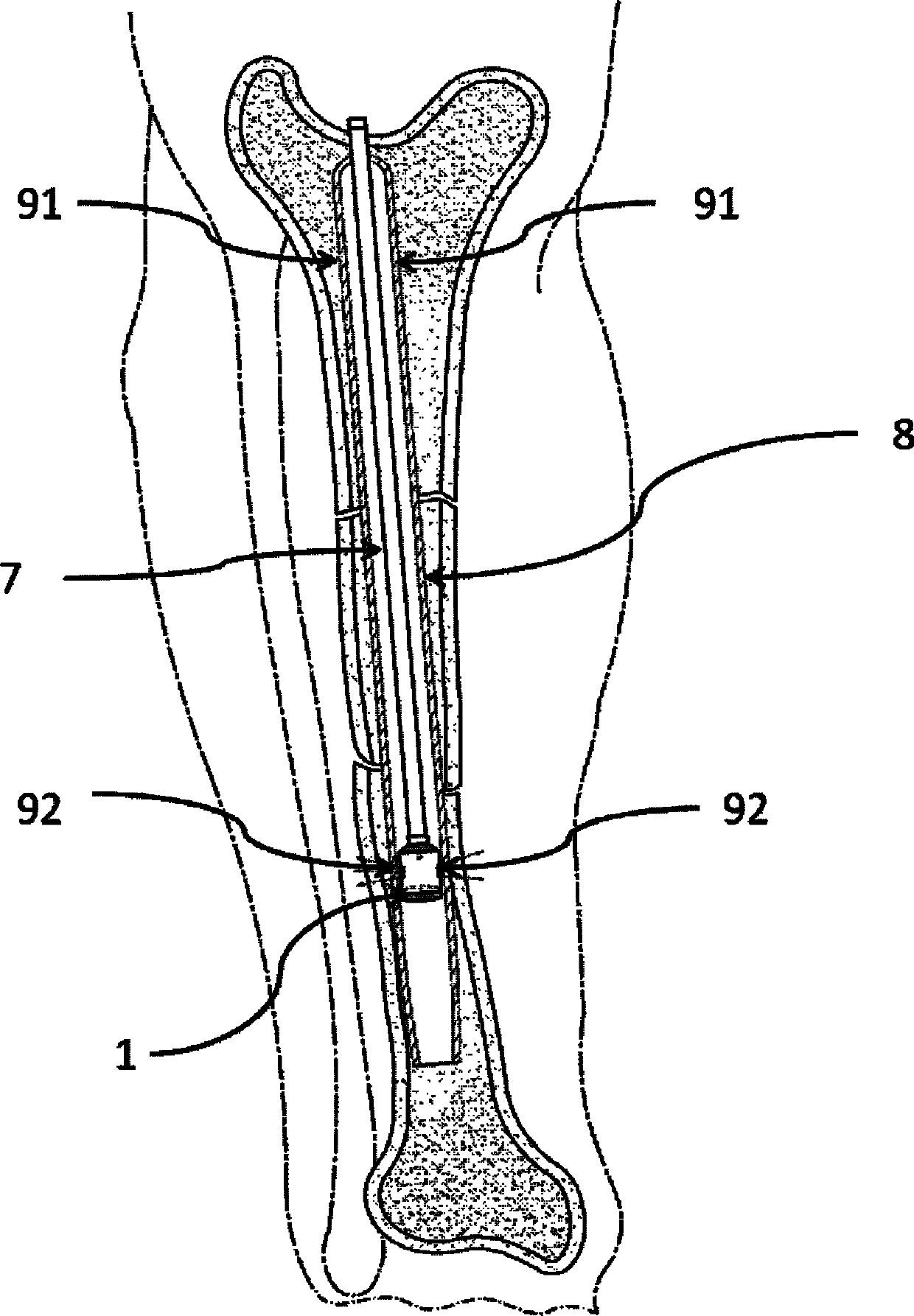

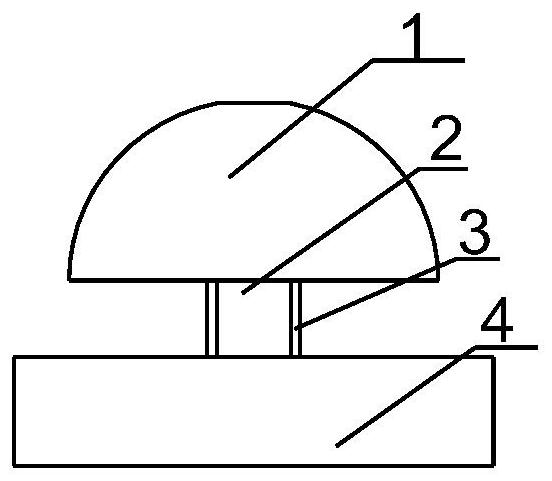

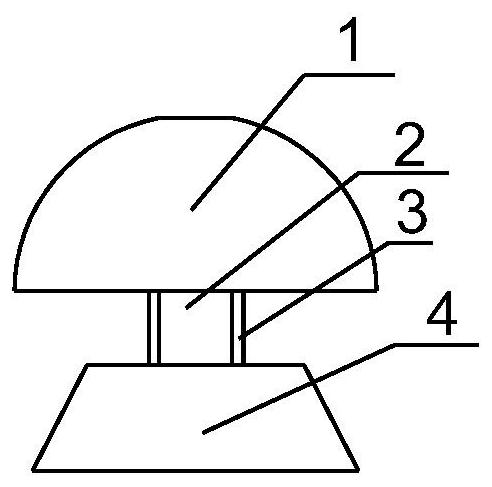

Lifting proportion template prop for bone surgery fracture operation and measuring method

ActiveCN111991099AReduce pain timeSimple structureSurgeryDiagnostic markersHuman bodyFemoral Shaft Fracture

The invention relates to the field of bone surgery medical instruments, in particular to a lifting proportion template device for bone surgery fracture operation of human body long tubular bones and ameasuring method. The proportion template device is characterized in that one end of a bolt is dynamically connected with a hemisphere through threads, and the other end is fixedly connected with a base to form a proportional template; the hemisphere can lift up and down through threads; a proximal femur anti-rotation intramedullary nail operation is carried out, a patient lies flat on a flat bed, a proportional template is placed on the flat bed to be in a horizontal state, an X-ray film is shot, an operator touches the highest point of the greater trochanter with the hand, the hemisphere ismeasured with a horizontal ruler, the hemisphere is lifted to the position at the same height as the greater trochanter, and photographing is carried out; the device has the positive effects that thediameter in the X-ray film is measured to be 1mm accurately; and the medullary cavity diameter of the bone of a treatment part required by an affected limb in the X-ray film is calculated to be 1mm accurately. The success rate of the obtained data guidance surgery is 100%. The device comprises the conditions that 1, the operation time of the proximal femur anti-rotation intramedullary needle is 15-30 minutes; 2, the femoral shaft fracture intramedullary needle operation time is less than or equal to 1 hour; 3, the tibia intramedullary needle operation time is less than or equal to 1 hour; and4, tibia steel plate operation time is less than or equal to 1 hour.

Owner:赵德来

Automatic assembly device for air conditioner panel grating

InactiveCN108080914AImplement automatic assemblyImprove assembly accuracyMetal working apparatusGratingEngineering

The invention relates to the technical field of household air conditioners, and discloses an automatic assembly device for an air conditioner panel grating. The device is arranged on a assembly line,and panels and gratings to be assembled are placed on the assembly line; the device comprises a rack, a feeding module, a positioning module, an assembling module and a control module, wherein the feeding module, the positioning module, the assembling module and the control module are arranged on the rack; the feeding module is used for transmitting the panels to be assembled and the gratings to the assembling module; the positioning module is in signal connection with the control module, and is used for positioning the to-be-assembled panels and to-be-assembled the gratings conveyed to the assembling module and sending a positioning complete signal to the control module when the positioning is completed; the control module sends an assembling signal to the assembling module according to the received positioning complete signal; the assembly module is in signal connection with the control module, and the connection is used for pressing buckle and nailing operation on the positioned to-be-assembled panel and the to-be-assembled grid when receiving the assembling signal sent by the control module, so that the automatic assembly can be realized by adopting a mechanical realization assembly line type, and the assembly efficiency and the assembly precision are relatively high.

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

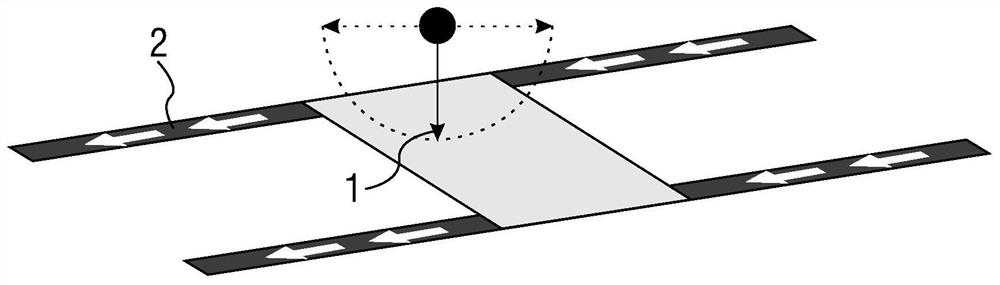

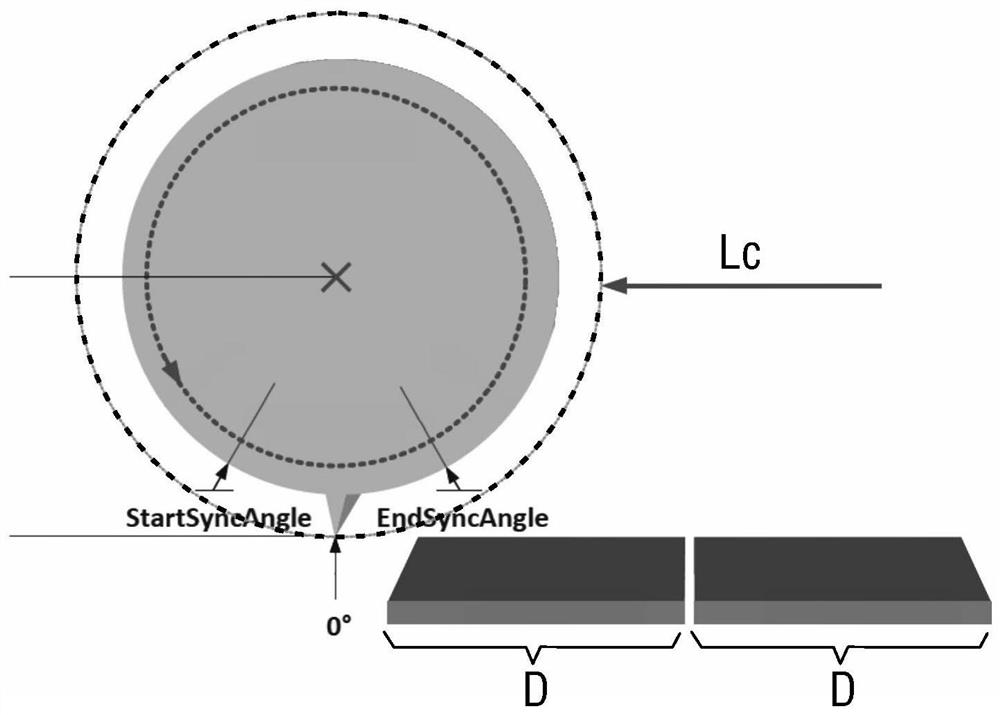

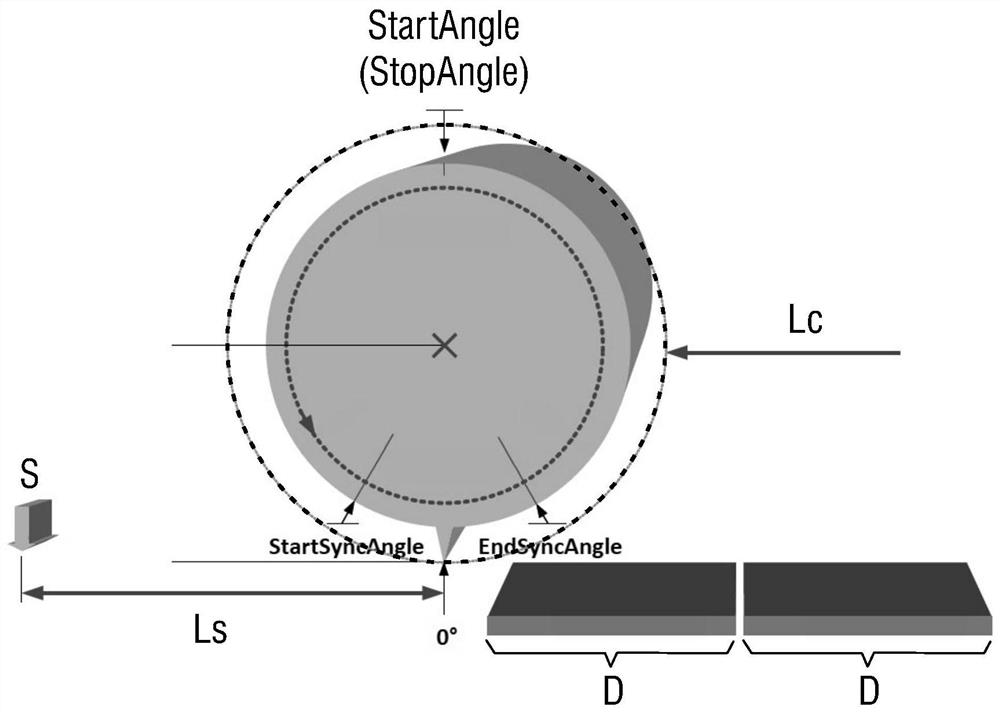

Box nailing machine control method

The invention provides a nail head control method of a box nailing machine. The nail head control method comprises the steps that box parameters and nail head parameters are received; based on the boxparameters, the nail distance is determined; a cam mode for controlling a nail head to swing is generated based on the nail distance and the nail head parameters, the cam mode comprises a synchronousarea and an adjusting area, and the adjusting area is changed according to the nail distance; and in the synchronous area, the nail head and a conveying belt of a conveying box strip synchronously swing to finish the nailing operation. According to the nail head control method, the box nailing machine can adapt to different nail distance requirements by controlling the swing speed of the nail head under the condition of not changing the swing amplitude of the nail head.

Owner:SIEMENS CHINA

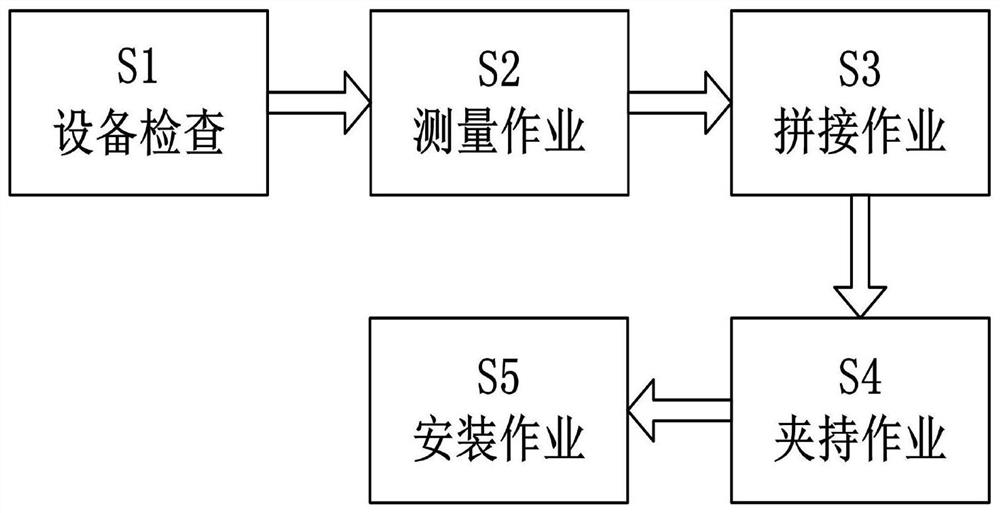

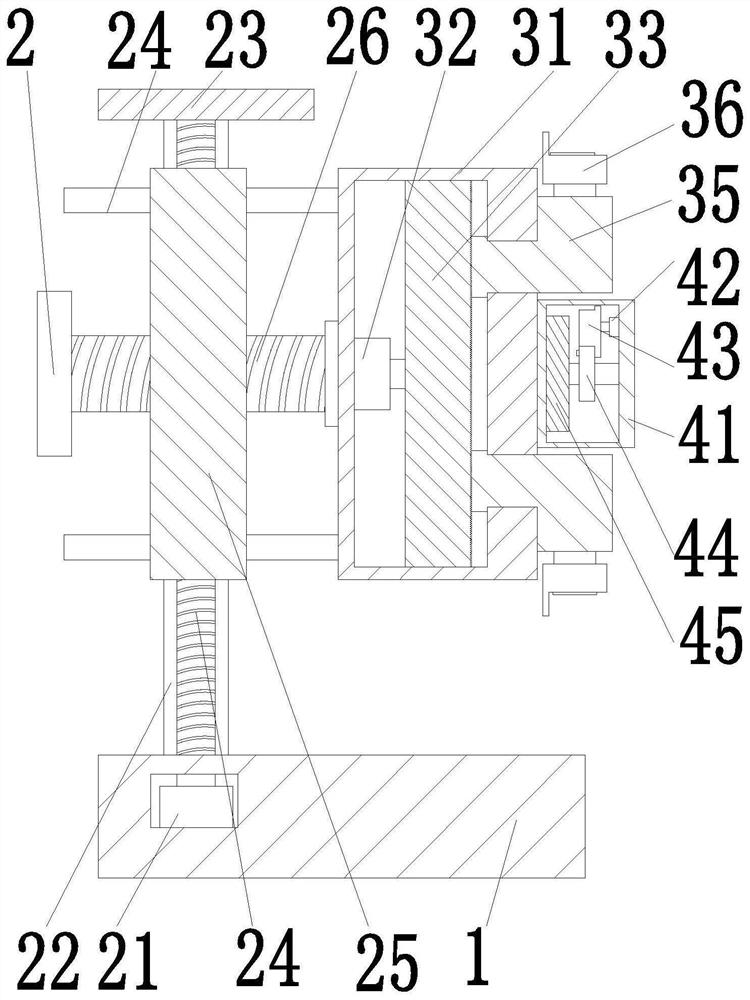

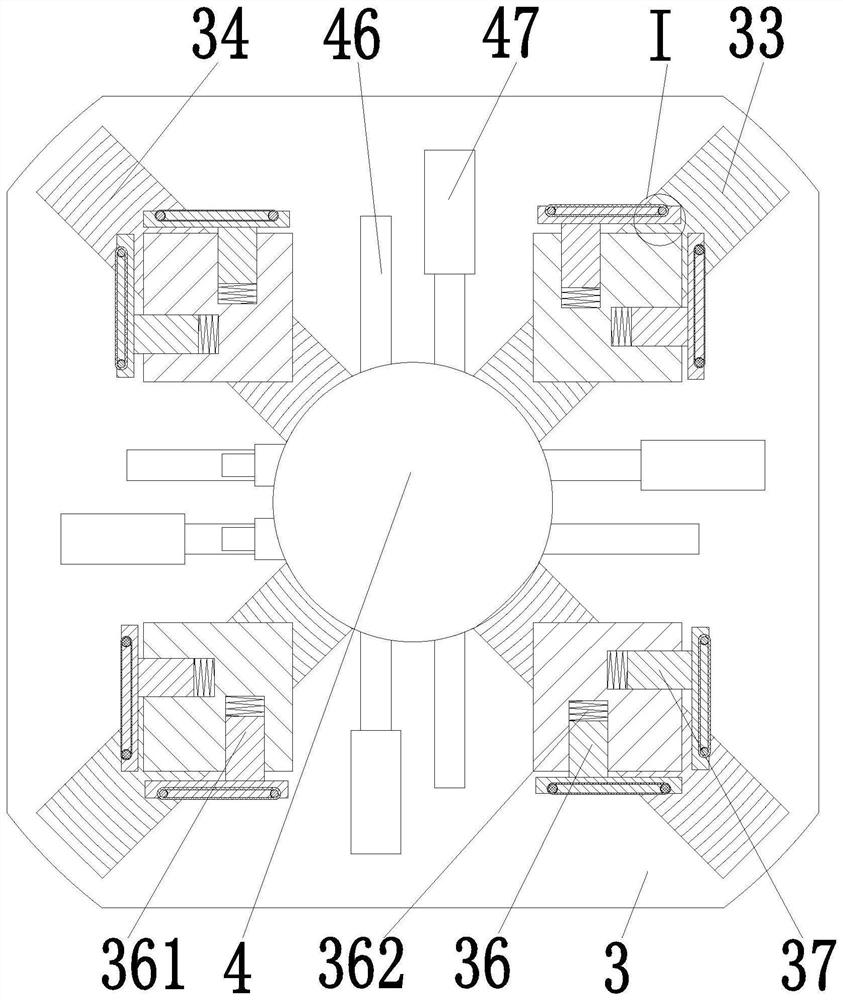

Method for installing glass doors and windows

ActiveCN111779411BAvoid the risk of fallingPrevent fallingFrame fasteningSpecial door/window arrangementsFixed frameFully automatic

The invention relates to a glass door and window installation method, which uses a glass window frame installation device, the glass window frame installation device includes a base, a lifting unit, a supporting unit and a nailing unit, the upper end of the base is provided with a lifting unit, The right end of the lifting unit is provided with a support unit; the right end of the support unit is provided with a nail unit; the invention can still move and shrink after contact with the structural design, so that when the frame length and width ratios are different, when one end of the fixed end contacts the inner wall of the frame, the other end It can still be fed to fix the other end of the frame, so that the frame can be completely fixed; the present invention completely automates the nail shooting process through the streamlined working process of nail removal, side change, and nail shooting, preventing manual failure. There are problems such as the risk of the frame falling during the nailing operation.

Owner:太仓市新业林铝制品有限公司

A kind of assembly equipment of wooden box and the assembly method of wooden box

ActiveCN106541484BSimple structureReduce labor intensityWood working apparatusEngineeringUltimate tensile strength

Owner:SUZHOU COV PACKAGING ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com