Automatic installation machine for straight springs of soft sofa seat frame

A soft sofa seat and automatic installation technology, applied to sofas, couch, spring mattresses, etc., can solve the problems of low efficiency, large force required for elongation, low production efficiency, etc., and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

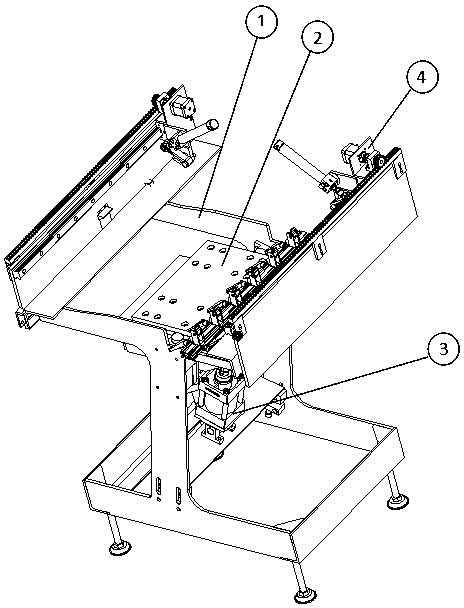

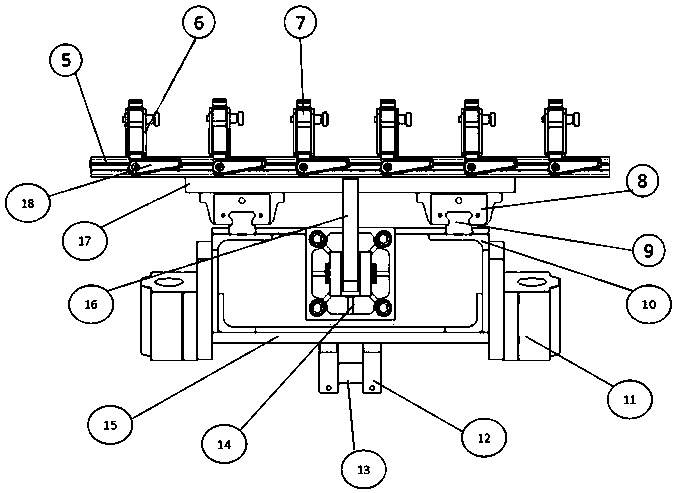

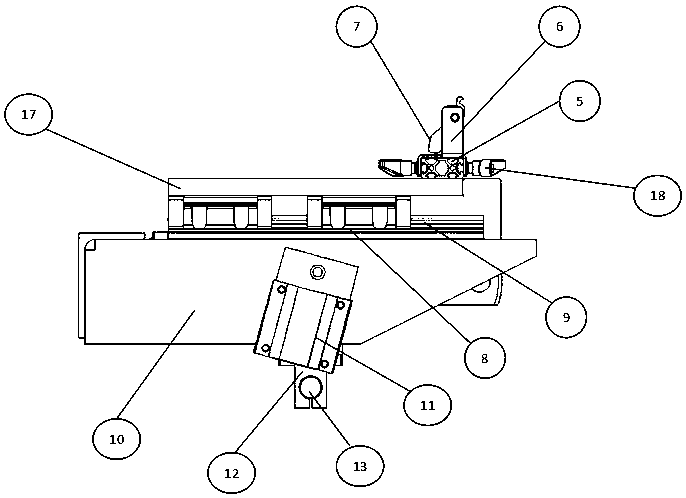

[0056] Upholstered sofa seat frame straight spring automatic installation machine, including frame 1, horizontal movement unit 2, oblique direction movement unit 3, hook pressing and nail shooting unit 4.

[0057] Realization of the spring installation function: the spring installation function is mainly completed by the cooperation of the horizontal movement unit 2 and the oblique direction movement unit 3. According to the design, the oblique direction movement unit 3 is installed on the frame 1, and its movement driving cylinder is installed on the On the frame, the piston of the cylinder drives the linear bearing 11 of the entire oblique motion unit through the pin shaft 13, and moves along a linear axis forming an angle of 75° with the horizontal direction. The moving slider 8 of the horizontal moving unit 2 cooperates with the horizontal guide rail mounting frame 10, and the cylinder 14 moves, and the moving slider 8 and the horizontal guiding rail mounting frame 10 slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com