Full-automatic carton nailing machine

A nailing machine, fully automatic technology, applied in the direction of packaging automatic control, external support, transportation and packaging, etc., can solve the problems of low degree of automation in the production line, high labor operation intensity, low nailing efficiency, etc., to improve the use of places and automation The effect of reducing the labor intensity of workers and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

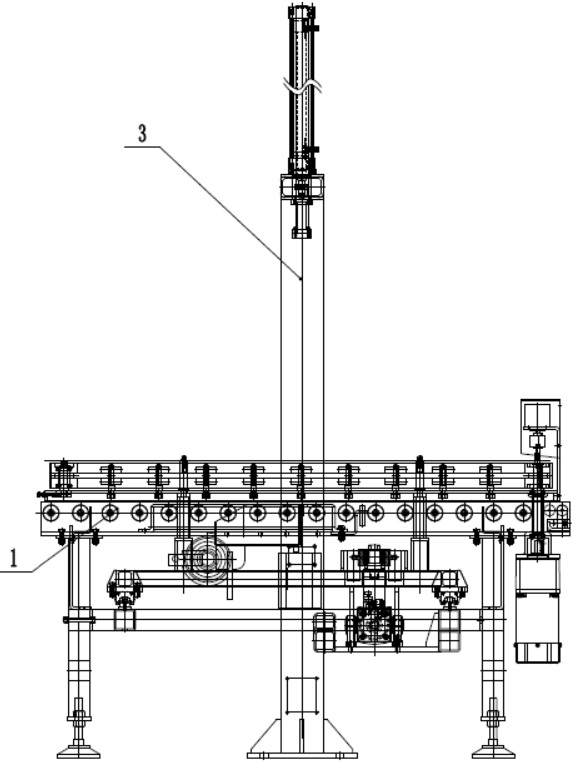

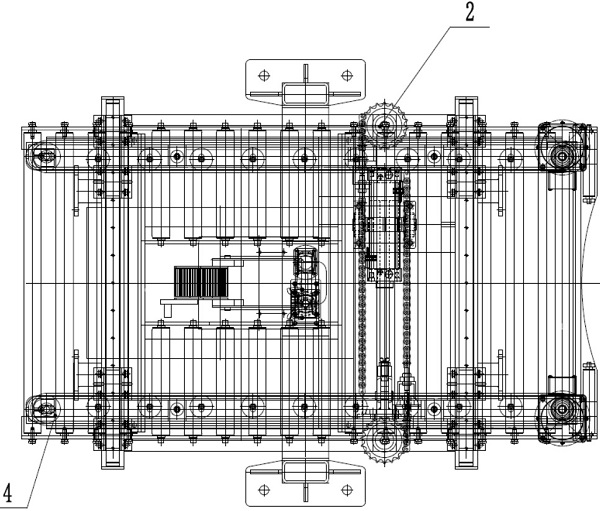

[0044] Figure 1-Figure 10 It is a specific embodiment of the present invention, which is a fully automatic carton nailing machine.

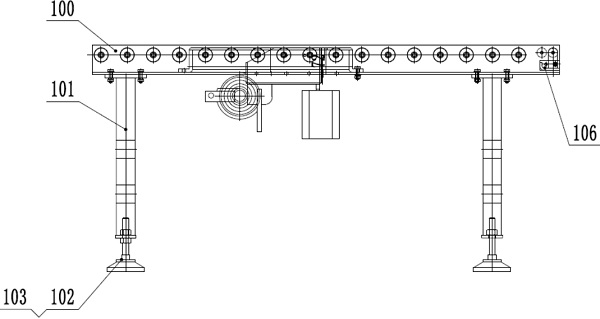

[0045] Such as image 3 , Figure 4 As shown, the adjustable feet 102 are installed on the ground for adjusting the height of the conveying part 1 from the ground to ensure the level of the conveying part 1 . One end of the support leg 101 is connected to the adjustable foot 102, and the other end is connected to the support 100, on which a non-powered roller idler 105 is installed to support the unpacked carton. In the middle part of the conveying part 1, there is a nail head relief hole. The front end of the conveying part 1 is equipped with a transition idler roller 104 through a non-powered roller mounting frame 106, and is used for conveying goods with a larger size. The LOCK nailing head 109 is installed on the nailing mounting frame 107 through the nailing mounting plate 108 . The nailing installation frame 107 is installed on the brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com