Nailing and carrying device

A technology for handling devices and nail guns, applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., can solve the problems of waste, large space occupation, etc., and achieve the goal of improving production efficiency, reducing space occupation, and reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

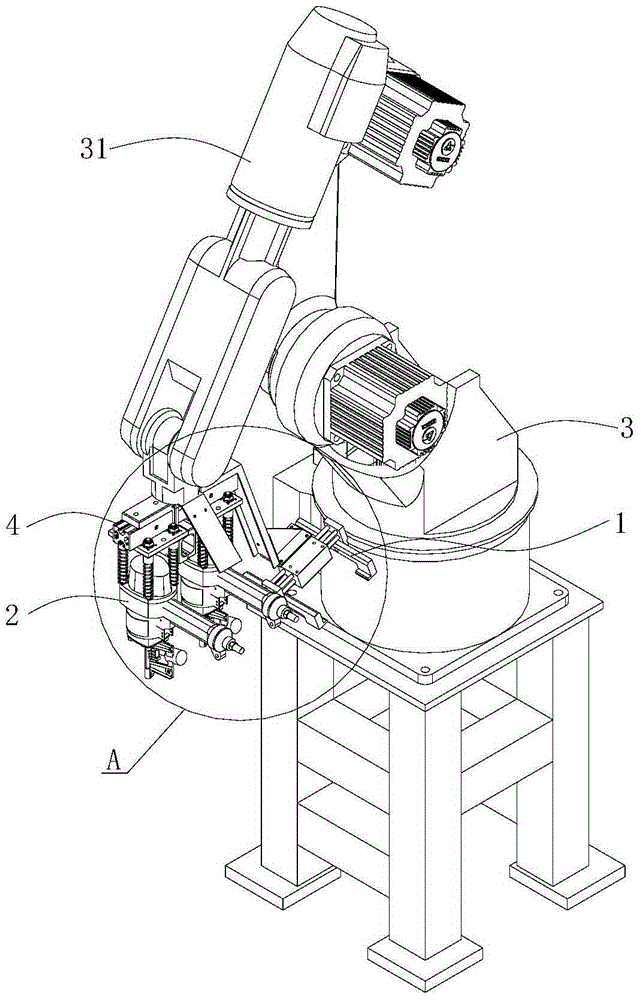

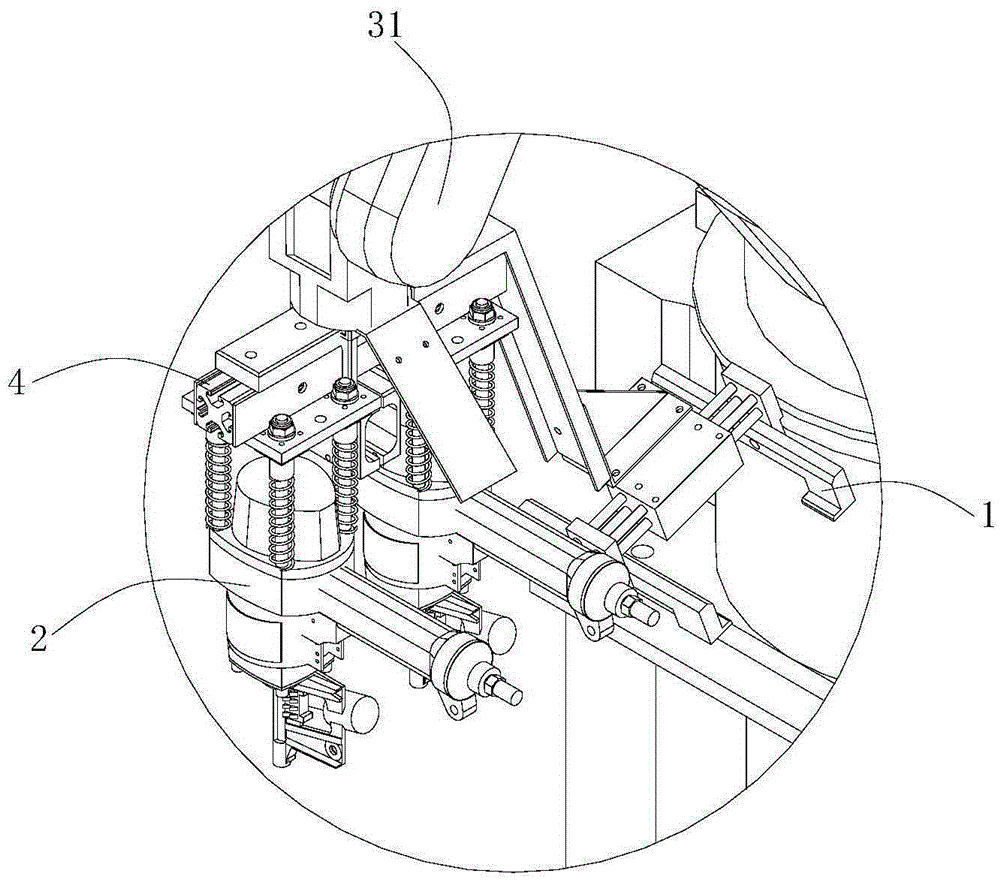

[0026] see picture 1 and diagram 2 Nailer Carrier shown, including Carrier 1 , nailing device 2 and manipulator 3 , handling device 1 and nailing device 2 are set on the same manipulator 3 movable arm 31 on, by manipulator 3 Control will handle the device 1 and nailing device 2 Move to the workpiece surface for nailing operation and handling operation respectively.

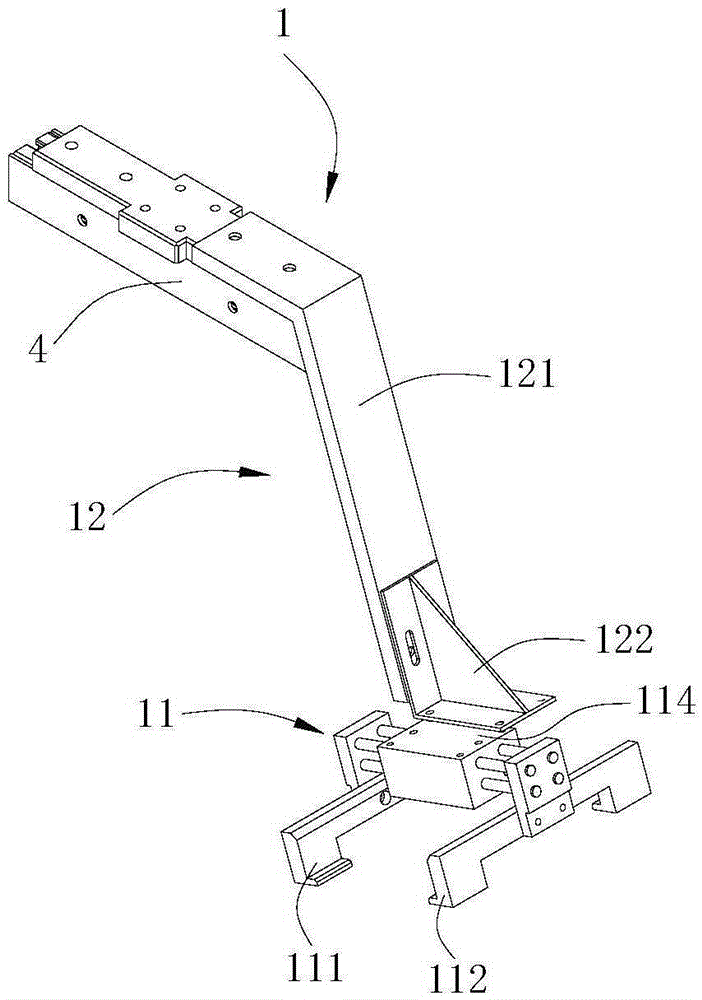

[0027] see picture 3 shown, the handling device 1 Includes clamping assembly for clamping workpieces 11 , used to connect clamping components 11 and movable arm 31 The first connected component of 12 。

[0028] Clamping components 11 including first jaws that cooperate to hold a workpiece 111 and second jaw 112 , the first jaw 111 and second jaw 112 spacing is adjustably disposed on the first connection assembly 12 top, first jaw 111 and second jaw 112 Both were inverted L shape, and set symmetrically. as a first jaw 111 and se...

Embodiment 2

[0034] In addition to realizing the non-interference mode and embodiment of nailing operation and handling operation 1 Except for the difference, the rest are the same as the examples 1 Same, no more details here.

[0035] In this embodiment, the way to realize the non-interference between the nailing operation and the handling operation is as follows: see Fig. 5~ picture 7 shown, the first connecting arm 121 The direction of extension and the second connecting arm 221 The same extension direction is perpendicular to the surface of the workpiece for nailing operation, at this time the first connecting component 12 Also includes drive clamp assembly 11 Drives that move toward or away from the workpiece 123 , driver 123 respectively with the first connecting arm 121 and clamping components 11 connected. When performing a nailing operation, the driver 123 drive clamping assembly 11 Move the clamping assembly away from the workpiece 11 The distance f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com