Nail guns for wood tray

A technology of wooden pallets and nail guns, which is applied in nailing tools, U-shaped nail tools, manufacturing tools, etc., can solve the problems that nail guns cannot adapt to automatic equipment operations, are prone to work-related accidents, and backward production methods, etc., and achieve improvement. The effect of automatic production level, improvement of nailing efficiency, and reduction of work-related safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

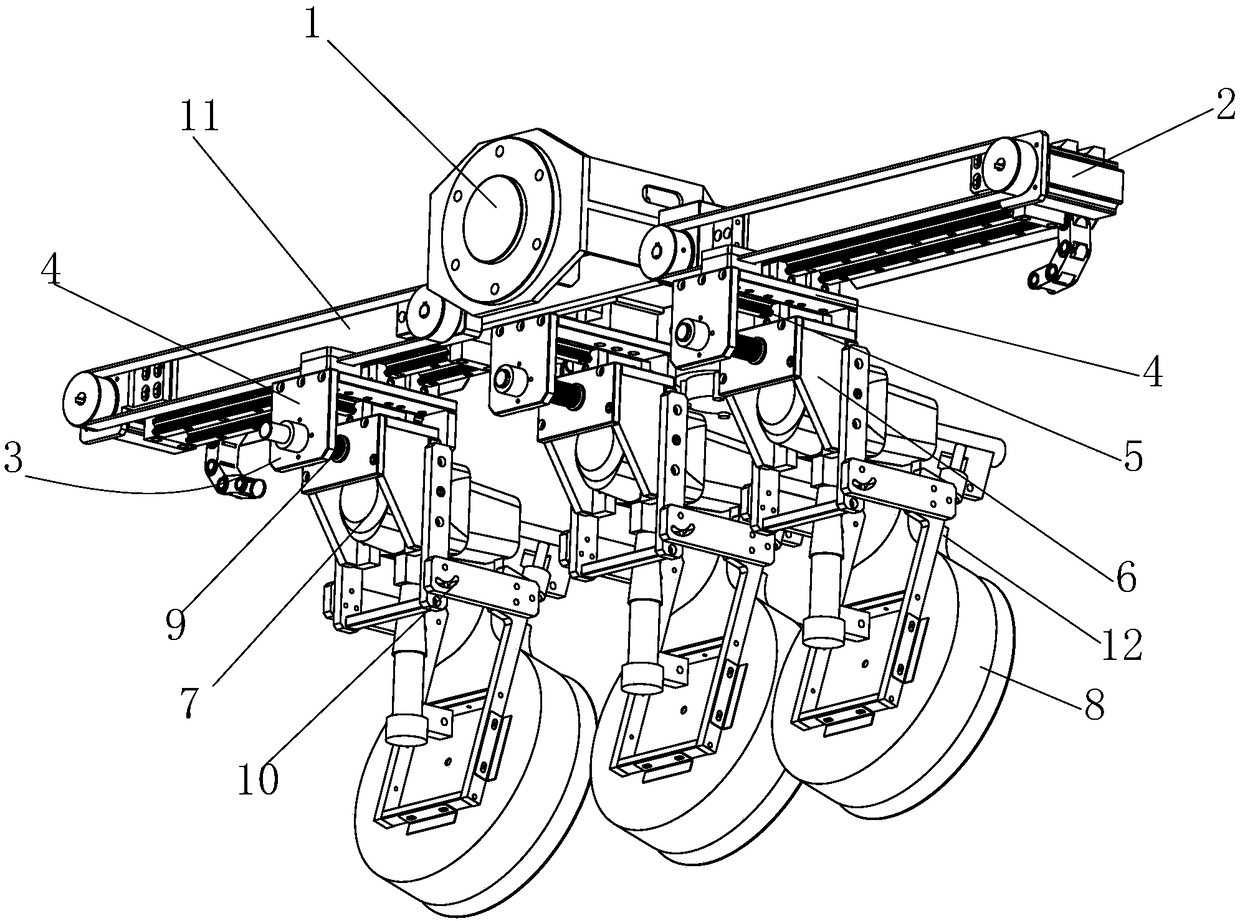

[0015] Such as figure 1 As shown, a nail gun for wooden pallets includes a main body frame 1, and a belt conveyor 11 is respectively fixed on the left and right sides of the main body frame 1, and the belt conveyors 11 are respectively driven by motors 2 installed on the corresponding sides. The belt conveyor 11 on each side is all fixed with a nail gun 3 on the conveyor belt at the bottom, and a nail gun 3 is also installed at the bottom of the main body frame 1 .

[0016] Described nail gun 3 all comprises the moving frame 4 that is installed on the corresponding side conveyer belt, and the bottom of described moving frame 4 is all fixed with the slideway 5 that vertically arranges, and slideway 5 is all slidably fitted with sliding frame 6, so A stage clip 9 extending longitudinally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com