Method preparing environment-friendly corrugated board packaging box

A technology for corrugated cardboard and packaging boxes is applied in the field of preparing environmentally friendly corrugated cardboard packaging boxes, which can solve the problems of long time consumption, waste of materials, cumbersome production process, etc., and achieves the effects of reliable quality, convenient use and reduced production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

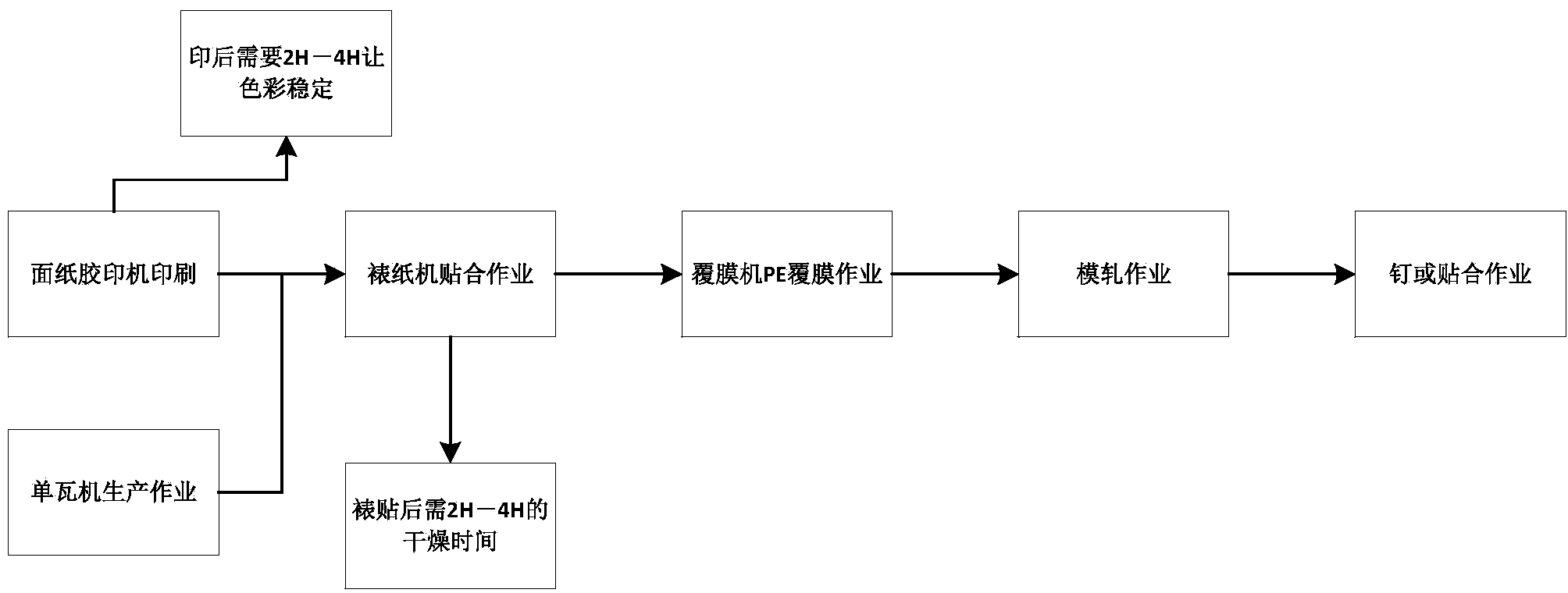

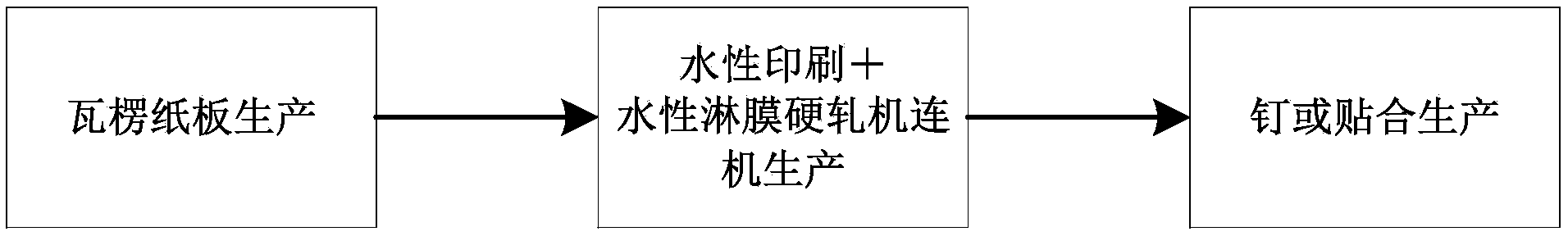

[0047] Such as figure 2 As shown, the method for preparing an environment-friendly corrugated cardboard box is carried out according to the following steps:

[0048] (1) Step of producing corrugated cardboard: produce corrugated cardboard according to the requirements of the product to be packaged;

[0049] (2) Production steps of printed pattern and hard-coated continuous rolling mill:

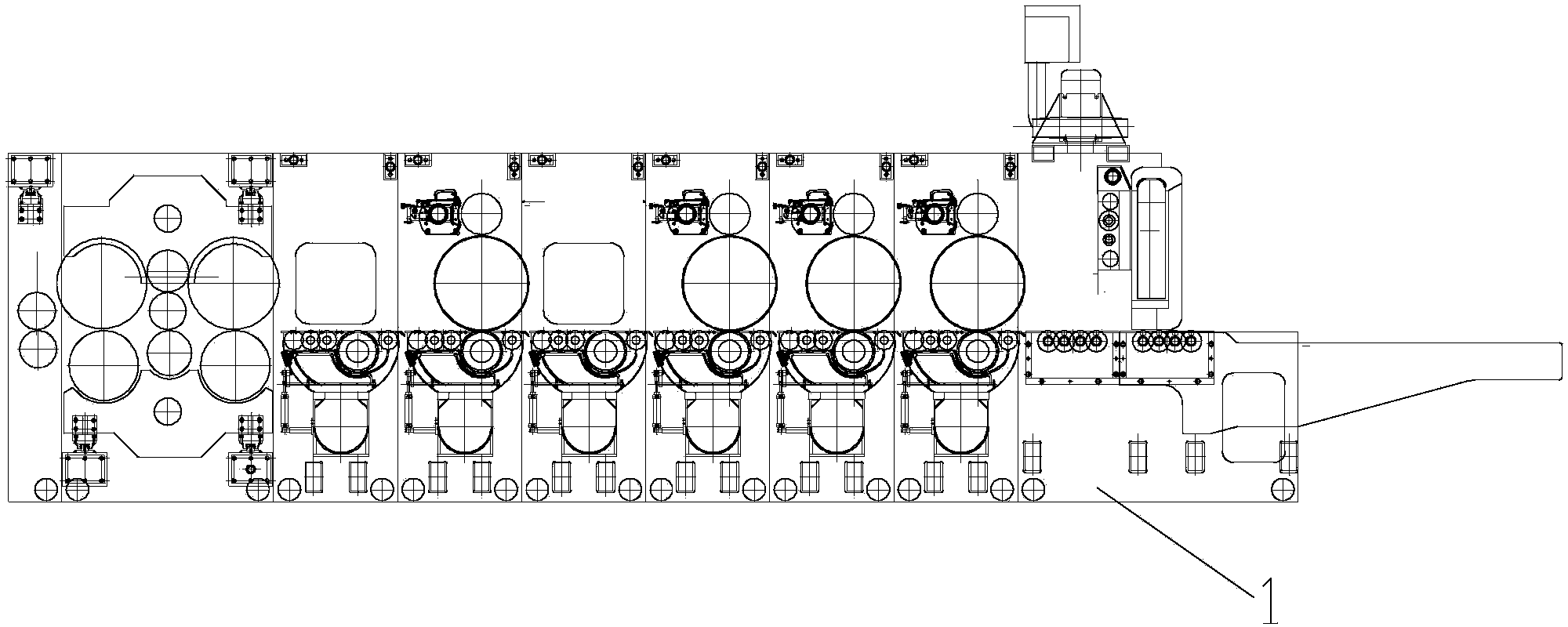

[0050] Water-based printing of the pattern required for the packaging box on the face paper of the corrugated cardboard, and then use the water-based film coating as the coating liquid to carry out the film coating operation on the printing surface of the corrugated cardboard to complete the water-based film formation on the printing surface, and finally harden rolling operation;

[0051] (3) The hard-rolled corrugated cardboard is stapled or bonded to make the corrugated cardboard packing box.

[0052] The production of printing hard rolling machine is carried out by water-based printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com