Measurement probe for measuring parameters of gas inside coal bed

A parameter measurement and probe technology, applied in measurement devices, fluid pressure measurement, instruments, etc., can solve the problems of easy gas leakage, long measurement period, large workload, etc., and achieve a small space for gas pressure balance and shorten the measurement period. , the effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

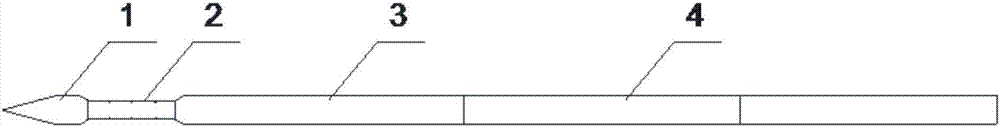

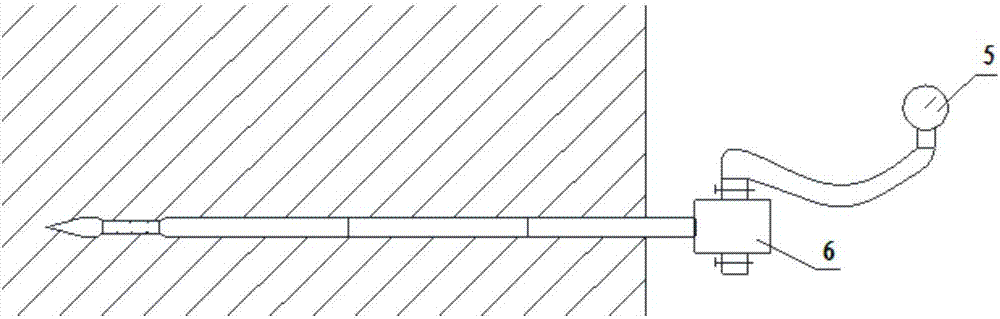

[0021] The invention provides a gas parameter measurement probe in a coal seam, which is combined below figure 1 The structure schematic diagram of the present invention is described.

[0022] Such as figure 1 As shown, a probe for measuring gas parameters in coal seams provided by the present invention includes a conical head 1, a piezometric tube 2, a first probe main pipe 3 and a plurality of second probe main pipes which are detachably connected in sequence from left to right 4.

[0023] Further, the detachable connection is threaded, and all threads are coarse threads, and the pitch and thread height of all threads are the same.

[0024] Further, the conical head 1 includes a conical end, a cylindrical section and a connecting section that are fixed in sequence, the conical angle of the conical end is <45°, the outer diameter of the cylindrical section is 10-15mm, and the length is 3-10mm. The connecting section is provided with an internal thread for connection, the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com