a nail gun

A nail rolling gun and nail rolling technology, which is applied in nailing tools, manufacturing tools, etc., can solve the problems of insufficient automation and insufficient stability and reliability of the pushing nail mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

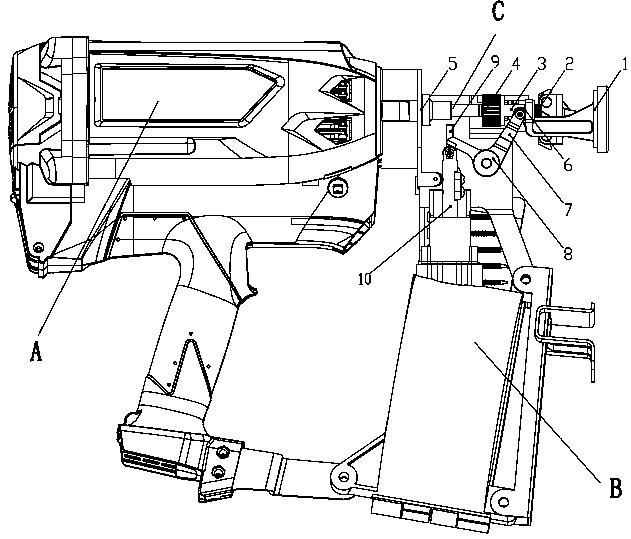

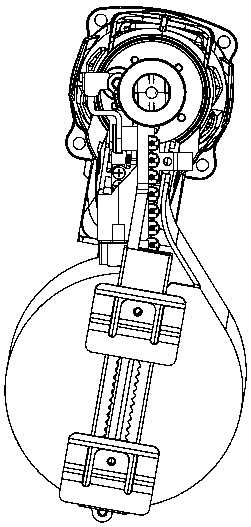

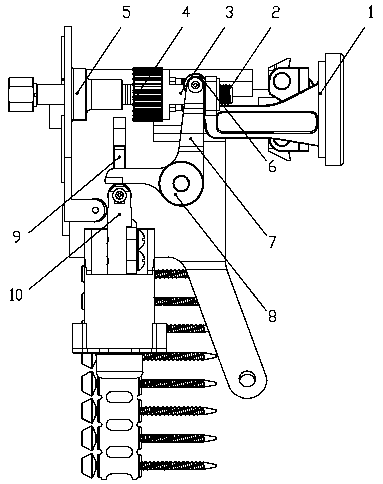

[0019] The volume nail gun of the present embodiment is as Figure 1 to Figure 2 As shown, its basic main structure is: a gas power cylinder is installed in the gun body A with a handle, a nail coil assembly is placed in the nail box part B, a nailing part C is installed at one end of the gun body A, and the output end of the nail box part B passes through The nail feeding channel is connected with the middle part of the nailing part C. The push nail reciprocating rod 10 of the power cylinder is connected with the push nail pull hook 9 , and the push nail pull hook 9 is connected with the roll nail assembly 12 . The nailing part C includes a nailing base 5 which is fixedly connected to the gun body. The front end of the nailing base 5 is equipped with a depth adjustment frame 3 which forms a moving pair through a sliding groove. Mechanism-linked striker head 1. The screw depth adjustment mechanism can adjust the extension length of the depth adjustment rod 2 by means of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com